Are you constantly battling with bottles that exhibit milky white bottoms, erratic wall thickness distribution, or a hazy, pearlescent appearance that destroys your product's shelf appeal? These are not random "ghosts" in the machine; they are the direct, calculable consequences of an improper heating profile. In the competitive world of beverage packaging, a deviation of just 2°C in your preform temperature can mean the difference between a profitable run and a scrap pile of 50,000 rejected bottles.

Optimizing the temperature settings of a PET blowing machine requires a mastery of thermodynamics, balancing the "Glass Transition" state of the material against its crystallization limit. By establishing a strategic heating profile—low energy at the neck, stabilized heat soak in the body, and high-intensity penetration at the base—you can eliminate stress whitening, ensure uniform material distribution, and achieve cycle times under 2 seconds per cavity.

For many operators, the infrared heating oven is a "black box." They blindly set percentages on the HMI, hope for the best, and struggle when the ambient temperature shifts from morning to afternoon. At iBottler, we believe that temperature control is 80% science and 20% art. It is not just about making the plastic hot; it is about conditioning the molecular structure of the PET so it flows exactly where the mold dictates. In this comprehensive guide, we will dissect the thermodynamics of the blowing process, turning your heating oven from a mystery into a precision instrument of profitability.

Understanding the "Glass Transition": Why Temperature Matters?

Why does a seemingly insignificant difference of just 2°C in preform surface temperature result in a bottle that shatters during the drop test or fails top-load requirements?

The answer lies in the molecular physics of Polyethylene Terephthalate (PET). The Glass Transition Temperature (Tg) of PET is the critical thermodynamic threshold (approximately 76°C - 80°C) where the polymer chains transition from a rigid, glassy, frozen state to a rubbery, stretchable, amorphous state. Successful blow molding occurs within a specifically narrow "Blowing Window"—typically between 90°C and 115°C—where the material is pliable enough to stretch but strong enough to hold its shape.

The Physics of Molecular Mobility and Viscosity

To master temperature settings, you must first deeply understand the material you are processing. PET is a semi-crystalline polymer. When it arrives as a preform, it is (ideally) in an amorphous state. The function of the heating oven is to inject enough thermal energy (Kinetic Energy) into the polymer chains to overcome their intermolecular forces (Van der Waals forces).

If the temperature is too low (e.g., nearing 85°C), the molecular chains remain entangled and stiff. Stretching them requires immense force from the high-pressure air (35-40 bar). This is known as "Cold Stretching" or "Strain Hardening." While the bottle might appear visually acceptable immediately after ejection, it possesses high levels of residual internal stress. When filled with warm liquid or exposed to summer heat, these stresses release, causing the bottle to shrink, warp, or distort.

Conversely, if the temperature is too high (approaching 120°C or more), the molecular chains move so freely that they begin to align and reorganize into spherulites—a process known as Thermal Crystallization. The material loses its structural integrity (Melt Strength) and becomes essentially a liquid that cannot support itself against gravity. This leads to "runner drool" inside the oven or a bottle that has no mechanical strength. The "Sweet Spot" is a delicate balance where the material has enough elasticity to stretch 10 to 12 times its surface area (biaxial orientation) but retains enough tensile strength to resist rupturing.

Vivian’s Insight: The "Hand Pinch" Test vs. Infrared Sensors

I often observe new technicians staring obsessively at the voltage percentages on the PLC screen or the readings from the infrared pyrometer, completely ignoring the physical reality of the preform in front of them. I always tell my team at iBottler: "The HMI screen is just a reference; the preform itself is the truth."

In my years of training production teams, I teach the "Hand Pinch" Test. Before you even lock the mold to start blowing, take a heated preform out of the oven manually (wearing thermal safety gloves, of course). Squeeze the body of the preform.

- Too Cold: If it feels like a hard plastic tube or requires significant force to dent, it is under 90°C.

- Too Hot: If it feels like sticky gum, leaves a permanent fingerprint impression, or sags under its own weight, it is over 120°C.

- Perfect: It should feel like a "firm rubber" or a "soft gummy candy." It should yield to your pinch pressure but possess enough memory to bounce back slightly when released. This tactile feedback is often more reliable than a dusty, miscalibrated infrared sensor.

The Heating Profile Strategy: Neck, Body, and Base?

Why does setting all your heating lamps to a flat 80% guarantee a failed production run and inconsistent wall thickness?

A successful heating profile is never linear or flat; it must be contoured to match the mass distribution of the preform. The neck finish requires aggressive protection (low heat), the body requires uniform soaking, and the base (gate) requires high-intensity penetration to heat the thickest section of the plastic without burning the surface.

The "U" Curve and Step-Down Approach

When we set up a high-performance bottle blowing machine, we divide the oven into specific functional zones. A standard linear or rotary oven might have 8 to 10 layers of infrared lamps.

- The Neck (Zone 1): The threaded neck of the preform must never be heated. If the neck gets hot (above 60°C), it becomes oval, and the cap will not seal, leading to leaking bottles. We typically set the top lamp to 0% or a very low percentage and rely on the chilled water protection plates to shield the threads.

- The Shoulder (Zone 2-3): The shoulder of the preform is often the thinnest part of the transition. If you overheat this area, the material stretches too early (pre-blow), resulting in a "paper-thin" shoulder that dents during labeling or handling. We keep heat moderate here.

- The Body (Zone 4-6): This is the main reservoir of material. We need a steady, soaking heat. The goal is to heat the preform wall all the way through, from the outer skin to the inner skin (Thermal Conduction).

- The Base/Gate (Zone 7-8): This is the most critical area. The injection gate is the thickest part of the preform. It acts as a heat sink. You must blast this area with higher energy to ensure the heat penetrates the core. If the gate is cold, it will not stretch, leaving a heavy lump of plastic in the bottle bottom.

Detailed Heating Profile Parameter Table

Example Profile for a 28g PCO 1881 Preform (500ml Bottle) on an 8-Zone Oven:

| Heating Zone | Target Area | Typical Voltage % | Physical Objective | Consequence of Error |

|---|---|---|---|---|

| Zone 1 (Top) | Neck Support Ring | 0% - 10% | Protect the finish geometry. | Oval neck, cap leakage. |

| Zone 2 | Shoulder / Transition | 35% - 45% | Initiate gentle softening. | Thin shoulder, folded neck. |

| Zone 3 | Upper Body | 45% - 55% | Soaking heat. | Uneven upper wall. |

| Zone 4 | Middle Body | 50% - 60% | Main wall heating. | Mid-section rupture. |

| Zone 5 | Lower Body | 60% - 70% | Prepare material for base stretch. | Uneven material distribution. |

| Zone 6 | Heel / Chime | 70% - 80% | Stretch into mold corners. | Webbing / Folded feet. |

| Zone 7 | Base | 80% - 90% | Penetrate thick base material. | Stress whitening (Pearlescence). |

| Zone 8 (Bottom) | Gate / Sprue | 85% - 95% | Heat the Sprue Point. | Cracks, thick amorphous bottom. |

Vivian’s Insight: The Trap of the "Flat Profile"

I recently visited a client producing edible oil bottles who was complaining about bottles bursting during the filling process. I inspected their HMI settings, and every single lamp from Zone 1 to Zone 8 was set to 75%. They assumed this would ensure "even" heating.

In reality, because the preform thickness varies (thin body, thick gate), "even" power resulted in a melted, sagging shoulder and a frozen, brittle bottom. The bottom wasn't stretching, so all the material stayed there as a lump, while the shoulder was dangerously thin. We adjusted to a graduated profile—40% at the top, increasing to 85% at the bottom—and the burst issues disappeared immediately. You must map the heat to the mass of the plastic, not the geometry of the oven.

Semi-Auto vs. Fully Auto: Adjusting for Speed and Ventilation?

Why does copying the voltage settings from a semi-automatic machine cause disaster on a high-speed automatic line?

The primary difference between semi-auto and fully auto settings lies in the "heat soak" time and ventilation efficiency. Fully automatic machines have high-speed transport chains and aggressive airflow (Chimney Effect), requiring higher voltage settings to achieve heat penetration in a fraction of the time compared to the slower, manual transfer of semi-auto systems.

The Factor of Residence Time and Thermal Inertia

In a Semi-Automatic process, an operator takes the preform out of the oven manually, places it on a transfer arm or directly into the mold. This transfer might take 3 to 5 seconds. During this time, the preform is losing heat rapidly to the environment (convection). To compensate, semi-auto settings often aim for a slightly higher overall temperature (e.g., exiting oven at 115°C) so that the preform is still at the correct 105°C when the mold closes. The heating is "Slow and Low"—lower voltage over a longer time to allow deep soaking.

In a Fully Automatic bottle blowing machine, the transfer time is measured in milliseconds (e.g., 1.2 to 1.5 seconds). The preform moves from the oven to the mold instantly via a servo-driven star wheel. There is almost no time for heat loss. However, the preform also spends less time inside the oven because the machine runs faster (high output). Therefore, you need "Flash Heating"—higher intensity infrared energy to drive heat into the plastic quickly before it exits the tunnel.

Ventilation and the Chimney Effect

Fully automatic machines utilize powerful exhaust fans to create air circulation (the Chimney Effect) around the preforms. This airflow cools the surface of the preform while allowing the Short-Wave Infrared rays to penetrate deep into the core.

In contrast, semi-auto machines often have weaker fans. If you use high voltage on a semi-auto machine, the ambient air inside the oven gets too hot (saturation). The preform starts heating via convection (hot air) rather than radiation. This leads to the surface turning white (haze) before the inside is soft.

Operational Comparison Table: Semi-Auto vs. Fully Auto

| Feature | Semi-Automatic Machine | Fully Automatic Machine |

|---|---|---|

| Lamp Voltage Strategy | Lower Voltage (40-60%) | Higher Voltage (70-90%) |

| Heating Time (Residence) | Long (45 - 90 seconds) | Short (15 - 30 seconds) |

| Ventilation (Airflow) | Low / Passive | Aggressive / Forced Air |

| Transfer Time | 3 - 8 Seconds (Heat Loss) | < 2 Seconds (Adiabatic) |

| Primary Risk | Inconsistent soak due to manual timing. | Surface overheating due to high intensity. |

| Optimal IV | Can handle lower IV (easier heating). | Requires stable IV (0.80+) for consistency. |

Vivian’s Insight: The "Under-cooked" Preform

I had a customer upgrade from a semi-auto line to our high-speed rotary machine (12,000 BPH). He was terrified of burning the preforms, so he inputted his old voltage settings (around 40-50%).

The result? The machine ran, but the bottles were practically "raw." The preforms were cold. The high-speed airflow of the new machine was cooling them down faster than his low voltage could heat them. I had to explain that with the strong ventilation of a modern machine, you must be brave with the voltage. We cranked the zones up to 70-80%, and the airflow kept the surface perfect while the core reached the optimal 105°C. Do not use "slow thinking" for a fast machine.

Troubleshooting Haze (Opalescence): When It’s Too Hot?

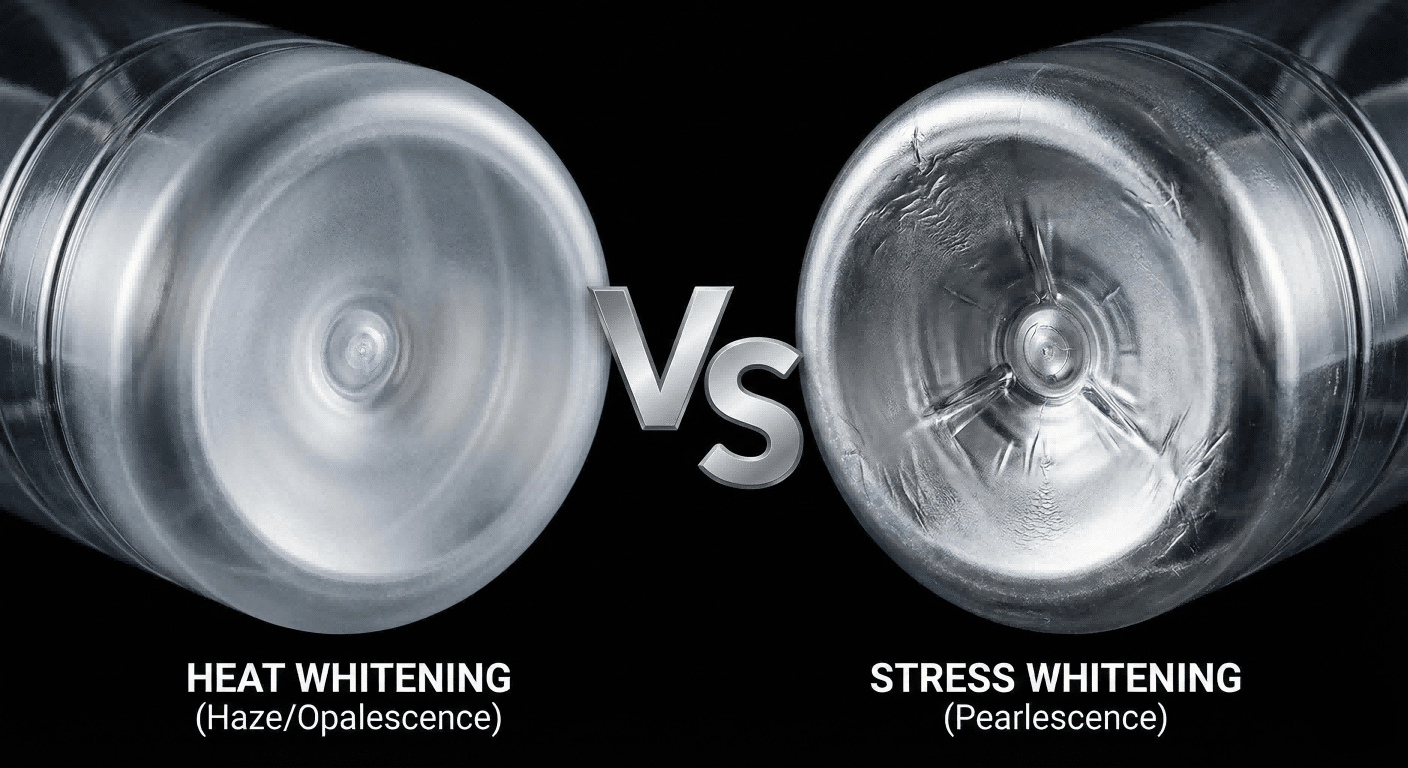

How do you distinguish between a "hot" defect and a "cold" defect when both turn the bottle white?

Haze, or thermal opalescence, occurs when the PET temperature exceeds its crystallization limit (approx. 115°C - 120°C), causing the material to turn a milky, cloudy white. This defect requires lowering the lamp voltage or, counter-intuitively, increasing the oven ventilation to cool the preform surface while maintaining core heat.

Identifying Thermal Crystallization

Haze is physically distinct. It looks like fog. It is usually uniform around the circumference of the bottle. If you cut the bottle, the cross-section is usually consistent. This whiteness is caused by Spherulites—microscopic crystals that form because the molecular chains have so much thermal energy they start to organize into ordered structures. Once PET crystallizes, it becomes brittle and loses its transparency.

This usually happens in two scenarios:

- General Overheating: The overall voltage is simply too high, raising the entire preform above 120°C.

- Surface Overheating: The voltage is appropriate for the core, but the ventilation is poor. The surface of the preform reaches 130°C while the core is only 90°C. This is common in thick-walled preforms used in preform molds for 5-gallon containers or jars.

The Role of Acetaldehyde (AA)

Heat does not just affect visuals; it affects chemistry. Overheating PET causes thermal degradation, which releases Acetaldehyde (AA). AA is a volatile organic compound that smells like green apples. If your preforms are slightly hazy, it is highly likely your AA levels have spiked. For water bottlers, this is a disaster, as it gives the water a "plastic" or "fruity" off-taste.

The Solution: Airflow Management

When operators see haze, their instinct is to drop the voltage. While this works, it might make the inside of the preform too cold.

A better approach is often to check the Oven Ventilation. Are the intake filters clogged with dust? Are the exhaust fans running at 100% frequency? By increasing the airflow, you strip the heat off the "skin" of the preform. This allows you to keep the lamp power high (to heat the inside) without burning the outside.

Vivian’s Insight: The "Roasted" Bottle

If your bottle looks like it is covered in a white veil, it is "roasted." I often see this when a machine stops for an emergency and then restarts. The preforms sitting in the oven during the stop soaked up too much residual heat.

Modern iBottler machines have an "Auto-Eject" function for overheated preforms after a stop. Ensure this is enabled. Also, if you are producing sensitive products like mineral water, smell the bottle. If it smells sweet, you are running too hot. Lower the temperature until the bottle just starts to show cold stress signs, then bump it up slightly. That is the safe operational window.

Troubleshooting Pearlescence (Stress Whitening): When It’s Too Cold?

Why does the bottom of your bottle look like it has fractured white cracks inside the plastic?

Pearlescence, or stress whitening, is a mechanical defect caused by stretching the PET when it is below its glass transition window (too cold). The molecular chains are forced to stretch beyond their elastic limit, causing microscopic voids or tears (Crazing) that diffract light and appear as opaque white patches.

The Micro-Cracking Phenomenon (Crazing)

Unlike haze, which is cloudy and smooth, stress whitening looks solid, metallic, or pearly. It usually happens in the areas of greatest stretch—typically the corners of the base or the feet of a petaloid bottom.

When PET is cold (e.g., 85°C), the entanglement of the polymer chains is strong. When the high-pressure air (40 bar) forces the material to expand, the chains don't uncoil gracefully; they snap. These micro-voids scatter light, creating the white appearance. This is actually structural damage. A bottle with pearlescence has compromised drop-impact resistance.

Solving the "Cold Feet" Problem

This is the most common issue with common pet blow molding defects. The bottom of the preform (the gate) is thick and hard to heat. If you see pearlescence in the bottle feet:

- Increase Zone 8/Last Zone: Boost the voltage significantly (by 5-10%) in the lowest heating zone.

- Move the Lamps: Physically lower the last bank of lamps to focus energy on the gate tip.

- Check Preform Design: Sometimes, the preform mold design leaves the gate too thick. A thick gate takes too long to heat.

Defect Diagnostic Table: Haze vs. Stress Whitening

| Characteristic | Thermal Haze (Overheating) | Stress Whitening (Underheating) |

|---|---|---|

| Appearance | Milky, foggy, translucent white. | Solid, metallic, pearl-like white. |

| Texture | Smooth surface. | Often rough or internal crazing. |

| Location | General body or uniform surface. | Localized at high-stretch areas (feet, corners). |

| Sound | Bottle sounds dull when tapped. | Bottle sounds sharp/brittle. |

| Solution | Decrease Voltage / Increase Ventilation. | Increase Voltage / Increase Soak Time. |

Vivian’s Insight: The Sound of Cold

You can often hear a cold bottle being blown. It makes a sharp "cracking" or "popping" sound inside the mold. A properly heated bottle blows quietly. Distinguishing between Overheat Whitening and Stress Whitening is the most important skill for a technician. If you confuse them, you will fix a cold bottle by making it colder, which leads to explosions in the mold.

Thickness Variation: Using Differential Heating for Square/Flat Bottles?

How do you ensure uniform wall thickness when blowing a rectangular detergent bottle or a flat flask?

For non-round (square, oval, or flat) bottles, uniform heating results in uneven wall thickness because the corners travel further than the flat faces. "Differential heating" (or Preferential Heating) involves adjusting the lamp output so that the sides of the preform that will stretch into the corners are hotter (more elastic) than the sides that will form the flat faces.

The "Dog Bone" Effect

If you blow a flat bottle with a uniformly heated preform, the material will hit the flat front/back walls of the mold first and freeze upon contact. The remaining hot material will then stretch into the corners. This usually results in thick centers on the flat panels and paper-thin corners that rupture easily. This distribution profile is often called "Dog Boning."

To fix this, we need to manipulate the material distribution. We want the material that goes to the corners to be hotter (so it stretches thinner) or cooler (so it stays thicker), depending on the specific geometry and stretch ratio.

Implementing Preferential Heating

This requires a machine capable of stopping the preform rotation or selectively shielding parts of the preform.

- Selective Cooling: Some machines use cooling pads to touch two sides of the preform, creating "cool stripes." These cool stripes resist stretching and become the heavy corners of a square bottle.

- Lamp Shielding: You can place physical shields on the lamps to shadow parts of the preform.

- Differential Voltage: Advanced ovens allow you to set different voltages for different angles of rotation, though this is rare in standard linear machines.

Vivian’s Insight: The Art of the Flat Bottle

Blowing round bottles is largely luck and basic science. Blowing flat bottles is pure craftsmanship.

If you are producing a flat flask for hand sanitizer or detergent, you simply cannot allow the preform to rotate freely and heat evenly. You must create a "Thermal Memory" in the plastic. You have to intentionally make the preform "two sides hot, two sides cold." This ensures that when the stretch rod pushes down, the material flows intelligently. It takes patience to dial this in, but it prevents the dreaded "dog bone" thickness profile where the middle is thick and the edges shatter.

Why iBottler's Machines Make Temperature Control Easier?

Why do some machines produce perfect bottles in the morning and scrap in the afternoon?

iBottler’s blowing machines integrate advanced voltage stabilization modules and independent PLC temperature control loops. This ensures that fluctuations in your factory’s main power grid do not affect the infrared output of the lamps, guaranteeing consistent thermal energy delivery regardless of external conditions.

The Enemy: Voltage Fluctuation

In many industrial zones, the grid voltage fluctuates. It might be 380V in the morning but drop to 360V in the afternoon when everyone turns on their heavy machinery.

If your IR lamps are directly coupled to the grid, a 5% voltage drop results in a significant drop in heat output (Heat Power $P$ is proportional to Voltage squared, $V^2/R$). Suddenly, your perfect settings from the morning are producing cold, stress-whitened bottles in the afternoon.

The iBottler Solution: Closed-Loop Stability

We treat temperature consistency as the foundation of quality. Our machines feature:

- SCR Power Controllers: We use Silicon Controlled Rectifiers to regulate voltage precisely.

- Closed-Loop Sensors: We use infrared sensors to read the actual preform temperature exiting the oven, not just the air temperature. The machine automatically micro-adjusts voltage to maintain the target surface temperature (e.g., 105°C).

- Recipe Storage: Once you find the perfect profile, you save it. Next time you run that blow bottle mold, you load the recipe, and the machine replicates the exact energy profile.

Vivian’s Service Promise

Even the best master technician cannot fight unstable physics. We sell not just a machine, but "repeatable process stability." When you buy from iBottler, we help you establish these base curves. We provide the initial "Golden Settings" for your specific bottle design, so you aren't starting from zero.

iBottler's "Crash Kit" Commitment:

While we are discussing maintenance and stability, I must mention our spare parts philosophy. At iBottler, we recommend and provide a comprehensive "Crash Kit" with every machine and mold. This kit is not for regular maintenance; it is for emergency recovery. It includes extra heating lamps, solid-state relays, valve pins, and insulation caps. The cost of this kit is roughly 2% of your investment, but the cost of not having a heating lamp when one blows at 3 AM is massive—potentially stalling your air compressor system and blowing line. If you use parts from this kit, please contact us immediately to restock.

Conclusion

Optimizing the temperature settings of a PET blowing machine is about finding the delicate thermodynamic balance between the Glass Transition and Crystallization. By employing a strategic Heating Profile—protecting the neck, soaking the body with stabilized heat, and penetrating the base with high intensity—you can eliminate defects like haze and stress whitening. Remember, the machine is only as good as its operator. Use your eyes to spot the haze, use your ears to hear the cracking, and use your hands to feel the material.

FAQ: Common Temperature & Heating Questions

Here are the top questions I receive from clients struggling with their heating profiles.

| Question | Answer |

|---|---|

| Q1: What is the ideal temperature for PET preforms before blowing? | Generally, the PET preform surface temperature should be between 90°C and 115°C just before entering the mold. However, this varies based on the preform's Intrinsic Viscosity (IV) and wall thickness. Higher IV materials require slightly higher heat to stretch properly. |

| Q2: Why is my bottle bottom turning white? | This is usually stress whitening (too cold). The bottom of the preform is the thickest part and hardest to heat. Increase the power of the bottom lamps (Zone 8) and ensure the preform gate area is fully soaked with heat. |

| Q3: How do I adjust settings for a semi-automatic machine? | Since semi-auto machines rely on manual transfer, the preform cools down (heat loss) while moving from the oven to the mold. You typically need to heat the preform slightly higher (about 5-10°C higher) than in a fully automatic machine to compensate for this ambient loss. |

| Q4: Can ambient temperature affect my blowing quality? | Yes, drastically. If your factory is 35°C in summer and 5°C in winter, the initial temperature of the cold preforms is different. You must adjust your voltage settings seasonally. iBottler machines with chiller systems help stabilize the mold, but the oven settings need manual tweaking. |

| Q5: Why is the bottle wall thickness uneven (Eccentricity)? | Aside from a bent stretch rod, this is often an eccentric heating issue. Check if the preform is rotating smoothly in the oven. If the rotation is jerky, one side gets hot and the other stays cold, causing the hot side to stretch thinner. |

Summary of Heating Defects and Solutions

| Defect Appearance | Technical Name | Root Cause | Immediate Action |

|---|---|---|---|

| Cloudy / Foggy White | Thermal Haze (Opalescence) | Too Hot / Poor Ventilation | Reduce Lamp Voltage OR Increase Oven Exhaust Fan Speed. |

| Solid / Metallic White | Stress Whitening (Pearlescence) | Too Cold / Cold Stretching | Increase Lamp Voltage in affected zone (usually base). |

| Bottle bursts (Loud) | Rupture | Too Cold (Material brittle) | Increase overall heating soak time. |

| Thin Shoulder | Material Distribution Error | Shoulder Zone Too Hot | Reduce Zone 2-3 voltage to keep material thick at top. |

| Thick Bottom (Off-center) | Gate Offset | Uneven Heating / Bad Rotation | Check preform rotation chain and spindles. |

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr