Have you ever wondered how a plastic bottle is made? You know you need a machine, but the actual process seems complex and technical. You're not alone, and it's frustrating when you can't find a simple explanation.

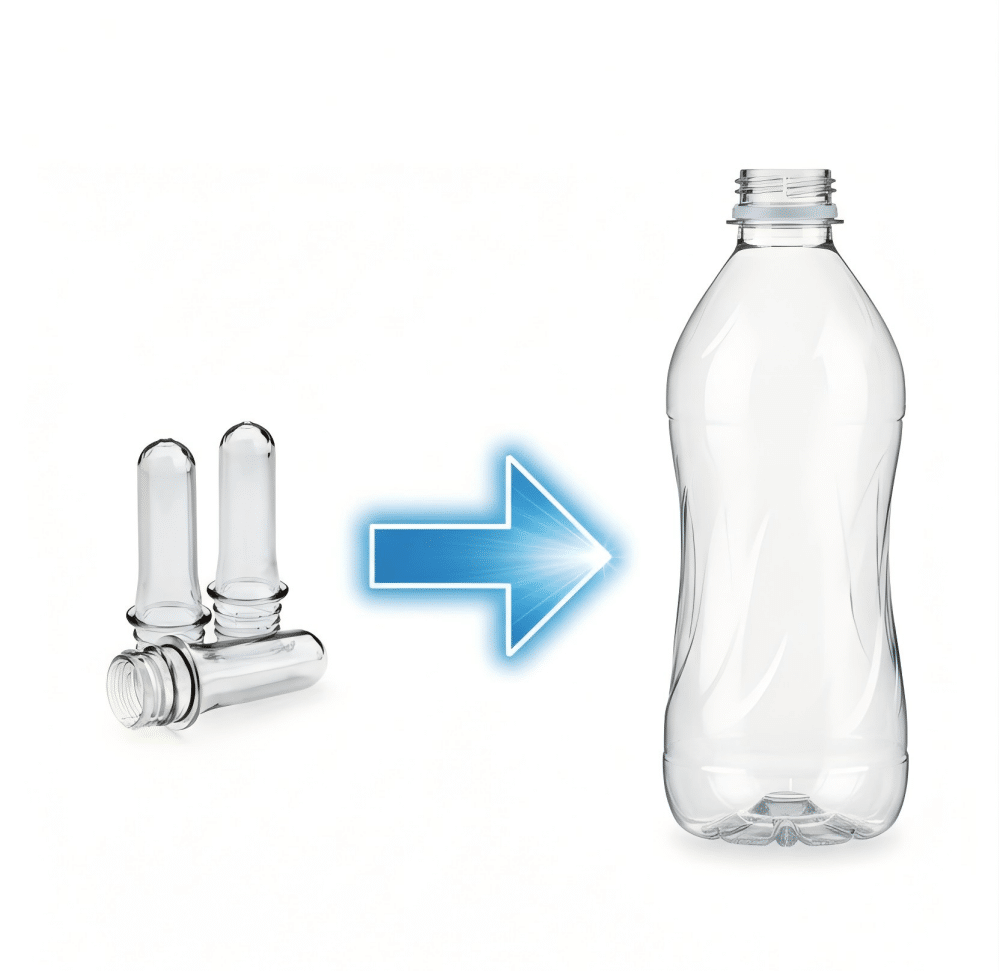

The PET bottle blowing process transforms a small, test-tube-shaped plastic piece called a "preform" into a full-sized bottle using heat and compressed air inside a mold. It is a straightforward and fascinating manufacturing method that, once understood, makes perfect sense.

Over my 16 years in the PET packaging industry, I've partnered with over 200 businesses, and I can tell you that most of them started exactly where you are now. Many of my clients, especially entrepreneurs from Southeast Asia, are brilliant at marketing their products but are complete beginners when it comes to the manufacturing process. I remember a client from Angola who was determined to start his own water bottling plant. He had done a lot of research on Google but was completely overwhelmed. He called me, and we spent hours on the phone as I walked him through each step, one by one. I have immense respect for buyers like him who take the time to learn the fundamentals before investing. This article is for them, and for you. I want to demystify the plastic bottle manufacturing process and explain it simply, so you can move forward with confidence.

First, What is PET and Why Is It Perfect for Bottles?

You see "PET" on the bottom of almost every water and soda bottle, but what is it? Is it just random plastic, or is there a reason it's the number one choice for beverages?

PET, which stands for Polyethylene Terephthalate, is a type of plastic that is strong, transparent, and safe for contact with food and drinks. Its unique combination of properties makes it the ideal material for manufacturing bottles worldwide.

When you're a beginner, all plastics might seem the same. But in reality, every type of plastic has a different personality. Some are cloudy, some are flexible, and some are brittle. PET's "personality" is what makes it a superstar for bottling. Think about the last bottle of water you drank. You could see the liquid clearly. The bottle was so light you could carry it anywhere. If you dropped it, it didn't shatter like glass. And when you were done, you could toss it in a recycling bin to be made into something new. All of these conveniences are thanks to the specific chemical makeup of PET. It was engineered to be the perfect container, especially for liquids. Understanding these basic advantages is the first step in understanding the entire plastic bottle manufacturing process. It's not just about the machine; it starts with choosing the right, high-performing material.

Key Advantages of PET for Bottles

To truly appreciate why PET is the industry standard, let's break down its main benefits in a simple table. Each feature directly contributes to a better, safer, and more cost-effective product for both manufacturers and consumers.

| Property | Simple Explanation | Why It's a Huge Advantage for Bottles |

|---|---|---|

| Transparency | It's crystal clear, like glass. | Consumers can see the product inside, which builds trust. It makes beverages look fresh and appealing on the shelf. |

| Lightweight | It weighs very little compared to glass or metal. | Drastically reduces shipping costs, saving money on logistics. It's also easier for consumers to carry and handle. |

| Shatterproof | It is very tough and doesn't break easily if dropped. | A major safety advantage over glass in production, shipping, and homes. It significantly reduces product loss due to breakage. |

| Excellent Barrier | It's great at keeping CO2 in (for sodas) and oxygen out. | Carbonated drinks stay fizzy for longer, and other beverages are protected from oxidation, extending their shelf life. |

| Recyclability | It is one of the most recycled plastics in the world (look for the #1 symbol). | It can be cleaned, melted down, and reformed into new bottles (rPET) or other products, making it a key part of the circular economy. |

| Design Flexibility | It can be molded into a huge variety of shapes and sizes. | Brands can create unique and recognizable bottle designs, which is a powerful marketing tool. Check out our PET bottle design guide to see the possibilities. |

These properties work together to make PET the dominant choice. It delivers on safety, performance, cost, and sustainability, which is a winning combination for any beverage business.

What is Blow Molding? (Think of it Like a High-Tech Balloon)?

The term "blow molding" sounds very industrial and complicated. Are there complex chemicals or reactions involved? How does a solid piece of plastic become a hollow bottle?

Blow molding is a manufacturing process that forms hollow plastic parts. The simplest way to understand it is to imagine inflating a small, warm, and stretchy balloon inside of a bottle-shaped container.

Let's stick with this balloon analogy because it's the most helpful one I've used with beginners for years. Forget about the big, noisy machines for a moment and just focus on the core concept.

Imagine you have a tiny, thick-walled balloon. You warm it up slightly to make it soft and pliable. Then, you place this warm little balloon inside a metal box that has been carved out on the inside in the exact shape of a bottle. You seal the box shut, and then, through a small opening, you blow a strong puff of air into the balloon. What happens? The balloon instantly expands, pressing up against the cold, bottle-shaped walls of the box. After a second, it cools down and holds that new shape. When you open the box, you no longer have a small balloon; you have a perfectly formed, hollow bottle.

That's it. That is the fundamental principle of the PET bottle blowing process. Everything else—the machines, the controls, the temperatures—is just technology built around this simple, clever idea. The small "balloon" is called a PET preform, the metal box is the blow mold, and the puff of air is delivered by a blowing machine. By thinking of it this way, you remove the mystery and can see it for what it is: a fast, efficient way to turn a small solid shape into a large hollow one.

The Two Key Players: The PET Preform and the Blowing Machine?

You now understand the concept of blow molding, but what do the actual parts look like? What are the "ingredients" that go into this process?

In the PET blowing process, there are two essential components you must know: the PET preform, which is the starting material, and the bottle blowing machine, which performs the transformation.

Let's formally introduce our two main characters. On one side, we have the PET preform. It looks like a plastic test tube with the final bottle's threads already formed at the top. This is the "seed" or the "embryo" of the bottle. It contains all the plastic that the final bottle will have, just compressed into a small, dense, and easy-to-handle shape. Preforms are made in a separate process called injection molding, using a preform mold. They come in different weights and neck sizes depending on the desired final bottle.

On the other side, we have the star of the show: the bottle blowing machine. If the preform is the seed, the blowing machine is the high-tech greenhouse that makes it grow. This machine is responsible for the three critical steps we're about to cover: heating the preform, blowing it into shape, and cooling the final bottle. These machines range from small, semi-automatic units that can make a few hundred bottles an hour to massive, fully automatic rotary machines that can produce tens of thousands of bottles in the same amount of time. But regardless of their size or speed, their core function remains exactly the same: to turn that little preform into a finished bottle.

Step 1: The Heating Stage – Getting the Preform Ready?

If you tried to blow up a PET preform at room temperature, it wouldn't work. It's hard and rigid. So, how do you make it soft enough to be inflated like a balloon?

The first crucial step in the bottle making process is heating. The body of the PET preform is passed through a specialized oven with infrared lamps to raise its temperature to the perfect point for stretching.

Before you can shape plastic, you must make it pliable. The heating stage is all about preparing the PET material for the transformation ahead. The preforms are loaded into the blowing machine, where they travel along a track through a heating oven. Inside this oven, powerful infrared lamps heat the preforms as they rotate. This rotation is critical because it ensures every side of the preform is heated evenly.

One of the most important details for a beginner to understand is that not all parts of the preform are heated equally. The main body needs to be heated to around 100-110°C (212-230°F) to become soft and rubbery. However, the neck area—the part with the threads where the cap will go—is shielded from the heat. It needs to remain cool and rigid to maintain its precise dimensions. If the neck were to soften and deform, the cap wouldn't seal properly, leading to leaks.

This precise temperature control is a hallmark of a good bottle blowing machine. If the preform is too hot, the material will be too runny and might result in weak spots in the bottle. If it's too cold, it won't stretch properly, potentially causing cloudiness or an incomplete shape. Many common PET blow molding defects can be traced back to improper heating. So, this first step isn't just about warming up the plastic; it's a carefully controlled scientific process that sets the stage for a perfect bottle.

Step 2: The Blowing Stage – From Preform to Bottle in an Instant?

The preform is now perfectly heated and has a soft, rubbery consistency. How does it magically transform from a small tube into a full-sized bottle in the blink of an eye?

The blowing stage is a near-instantaneous, two-part action. A steel rod stretches the preform vertically while high-pressure air simultaneously inflates it horizontally to fill the mold cavity.

This is the magic moment. The warm, pliable preform is quickly placed inside the two halves of a metal blow bottle mold, which clamps shut around it. Then, two things happen almost at the same time:

- Stretching (Axial Stretching): A long, thin steel rod, called a stretch rod, shoots down from the top and pushes on the inside base of the preform. It stretches the preform vertically, all the way to the bottom of the mold. This action is crucial because it stretches the PET molecules in one direction, which gives the bottle its vertical strength and clarity.

- Blowing (Radial Stretching): Immediately as the stretching happens, high-pressure air (pre-blow and then high-blow) is blasted into the preform. This powerful gust of air acts like the puff of air in our balloon analogy. It forces the stretched plastic outwards, expanding it horizontally until it presses tightly against the cold inner walls of the mold. This second action stretches the PET molecules in the other direction, giving the bottle its hoop strength (resistance to being squeezed).

This combined process is technically known as Stretch Blow Molding, and it's what gives PET bottles their incredible strength despite being so thin and light. The entire event, from the mold closing to the bottle being fully formed, happens in a fraction of a second. It's a beautifully coordinated dance of mechanics and physics, repeated thousands of times per hour, turning each little preform into a perfect bottle.

Step 3: The Cooling Stage – Locking in the Perfect Shape?

The bottle is now fully formed and pressed against the inside of the mold. What happens if you open the mold and take it out right away? It would shrink and deform because the plastic is still hot.

The final step inside the mold is cooling. The bottle remains pressed against the cold mold walls for a moment, which rapidly cools the plastic and permanently "locks" it into its final, stable shape.

This last step is just as important as heating and blowing. The blow mold is not just a shaping tool; it's also a heat exchanger. It is kept cold by chilled water circulating through channels inside the mold walls. This is why a reliable industrial chiller is a critical piece of auxiliary equipment for any bottling line.

When the hot, stretched plastic makes contact with the cold surface of the mold, the heat is rapidly drawn out of the bottle. This process, called quenching, freezes the PET molecules in their stretched and aligned state. This molecular alignment is what gives the final bottle its strength and clarity. If the cooling is too slow, the molecules have time to relax and shrink back, which would ruin the bottle's shape, dimensions, and structural integrity.

The efficiency of the cooling stage directly impacts the overall production speed. The faster you can cool the bottle to a stable temperature, the sooner you can open the mold and eject it, making way for the next preform. In a high-speed production environment, even fractions of a second saved in the cooling phase can add up to thousands of extra bottles per day. Once cooled, the mold opens, the finished bottle is ejected, and the cycle begins all over again.

The Entire PET Blowing Process at a Glance [Infographic]?

We've covered the steps individually, but how do they all fit together in the bigger picture? Can we see the entire journey from raw material to finished product?

Absolutely. A visual flowchart is the best way for a beginner to connect all the dots. It shows the complete lifecycle, from plastic pellets to the bottle you hold in your hand.

While I can't place a full infographic here, let's outline the simple, linear flow that you would see. This is the complete journey of a PET bottle, which is very helpful to visualize.

The Journey of a Plastic Bottle

| Stage | What Happens | The Simple Analogy |

|---|---|---|

| 1. Raw Material | The process starts with small, clear pellets of PET resin. | These are like the flour or raw ingredients for our product. |

| 2. Injection Molding | The PET pellets are melted and injected into a preform mold to create the PET preforms. | This is like baking the "seed" or "dough" for our balloon. |

| 3. Heating | The preform is loaded into the blowing machine and heated by infrared lamps until it is soft and pliable. | Warming up the balloon to make it stretchy. |

| 4. Stretch Blowing | The preform is placed in the bottle mold, stretched by a rod, and inflated with high-pressure air from an air compressor system. | Putting the balloon in the box and blowing it up. |

| 5. Cooling | The newly formed bottle is held against the cold mold walls to lock its shape. | Letting the inflated balloon cool down so it doesn't shrink. |

| 6. Ejection | The mold opens and the finished, perfectly formed bottle is ejected from the machine. | Opening the box and taking out your finished bottle-shaped balloon. |

This six-stage process is the heart of plastic bottle manufacturing. Every bottle of water, juice, or soda made from PET has gone through this exact journey. Understanding this flow gives you a complete picture and a solid foundation of knowledge.

Congratulations, You Understand the Basics! What's Next?

You've made it! You now understand the core concepts of PET, the magic of blow molding, and the step-by-step process that turns a small preform into a finished bottle.

By grasping these fundamentals, you are no longer a complete beginner. You have a solid framework to build upon as you explore the world of beverage packaging and production more deeply.

First, give yourself a pat on the back. You've learned the language of an entire industry in just a few minutes. You now know more about this process than 99% of the population. My client from Angola was thrilled when these concepts finally "clicked" for him, and it gave him the confidence to ask smarter questions and make better decisions for his business.

So, what's the next step on your learning journey? Now that you understand the "how," you can start exploring the "what" and the "which." For example:

- Types of Machines: You could explore the difference between semi-automatic and fully automatic bottle blowing machines to understand which scale is right for different business sizes.

- Customization: How are different bottle shapes created? This will lead you to the fascinating world of custom blow bottle mold design, where engineering meets branding. You can even explore how we use 3D printed samples to rapidly test new designs.

- The Finer Details: You might wonder how to choose the right cap size, which is a great question that leads to understanding preform neck size standards.

The journey into the world of PET packaging is vast and exciting. You've taken the most important step by learning the basics. Keep that curiosity going, and you'll be an expert in no time.

Summary of the PET Bottle Blowing Process

| Stage | Key Action | Purpose | Simple Analogy |

|---|---|---|---|

| Heating | Preform is heated by infrared lamps. | To make the PET plastic soft and stretchable. | Warming up a small balloon. |

| Blowing | A rod stretches and air inflates the preform inside a mold. | To shape the soft plastic into a bottle. | Inflating the balloon inside a box. |

| Cooling | Bottle is held against the cold mold walls. | To harden the plastic and lock in the final shape. | Letting the balloon cool to hold its new shape. |

Frequently Asked Questions (FAQ)

Q: Why do some PET bottles have a small dot on the bottom?

A: That small dot, or gate, is a remnant from when the PET preform was made. In the injection molding process used to create the preform, melted PET plastic is injected through a tiny opening into the preform mold. That dot is where the plastic entered, and it remains on the preform and, subsequently, on the bottom of the final bottle.

Q: What's the main difference between a preform and the final bottle?

A: The main differences are size, wall thickness, and molecular structure. A preform is small, compact, and has very thick walls. The final bottle is much larger, has very thin walls, and is hollow. Critically, the molecules in the preform are randomly arranged, while in the bottle, they have been stretched and aligned (biaxial orientation), which is what gives the bottle its strength and clarity.

Q: Can any type of plastic be used for blow molding?

A: No, not all plastics are suitable for blow molding, especially stretch blow molding. While other plastics like HDPE (for milk jugs) and PP (for yogurt containers) are commonly blow-molded, PET is uniquely suited for creating clear, strong, and lightweight containers for carbonated beverages and water due to its excellent stretching properties and barrier characteristics.

Q: Is it possible to make bottles from recycled PET plastic?

A: Absolutely! This is a very common and growing practice. Recycled PET is often called rPET. Used bottles are collected, sorted, cleaned, and broken down into clean flakes, which are then melted and purified to create new rPET resin. This resin can then be used to make new preforms and bottles, helping to create a closed-loop system and reduce waste.

Q: How many bottles can a machine make in one hour?

A: This varies dramatically depending on the machine and the mold. A small, semi-automatic machine with a single-cavity mold might produce 500-800 bottles per hour. A large, industrial, fully automatic rotary blowing machine with a multi-cavity mold (e.g., 12 or more cavities) can produce anywhere from 10,000 to over 20,000 bottles per hour.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr