A Note on Terminology: In the bulk water industry, the large bottles for water coolers are universally known as "5-gallon" bottles, which have a standard metric volume of 18.9L. While sometimes colloquially referred to as "20L," all technical discussions in this article are based on the industry-standard 5-gallon (18.9L) bottle.

Thinking about entering the 5-gallon bottled water market? It's a major step with unique challenges. The process is far more complex than just scaling up your small bottle production line.

A 5-gallon (18.9L) bottle blow molding machine is specifically engineered for these large containers. It features a robust clamping unit, a larger mold area, and a specialized, powerful heating oven to properly process thick-walled preforms, ensuring bottle quality and consistent production.

This guide will walk you through everything. I want to share my years of experience to help you make the right choices for your business. We will cover the machines, materials, processes, molds, and the investment. Let's get started on your journey to producing high-quality 5-gallon water bottles.

More Than Just a Bigger Size: Why Do 5-Gallon (18.9L) Bottles Need a Specialized Blow Molding Machine?

You might think making a big bottle just needs a big machine. But this thinking can lead to costly mistakes and production failures. The reality is much more complex.

A 5-gallon (18.9L) bottle requires a machine built for its unique demands. The massive preform weight, thick walls, and large surface area need a stronger clamping force, a bigger mold space, and a much more powerful, penetrating heating system than any standard machine can provide.

Dive Deeper: The Engineering Behind Large Bottle Production

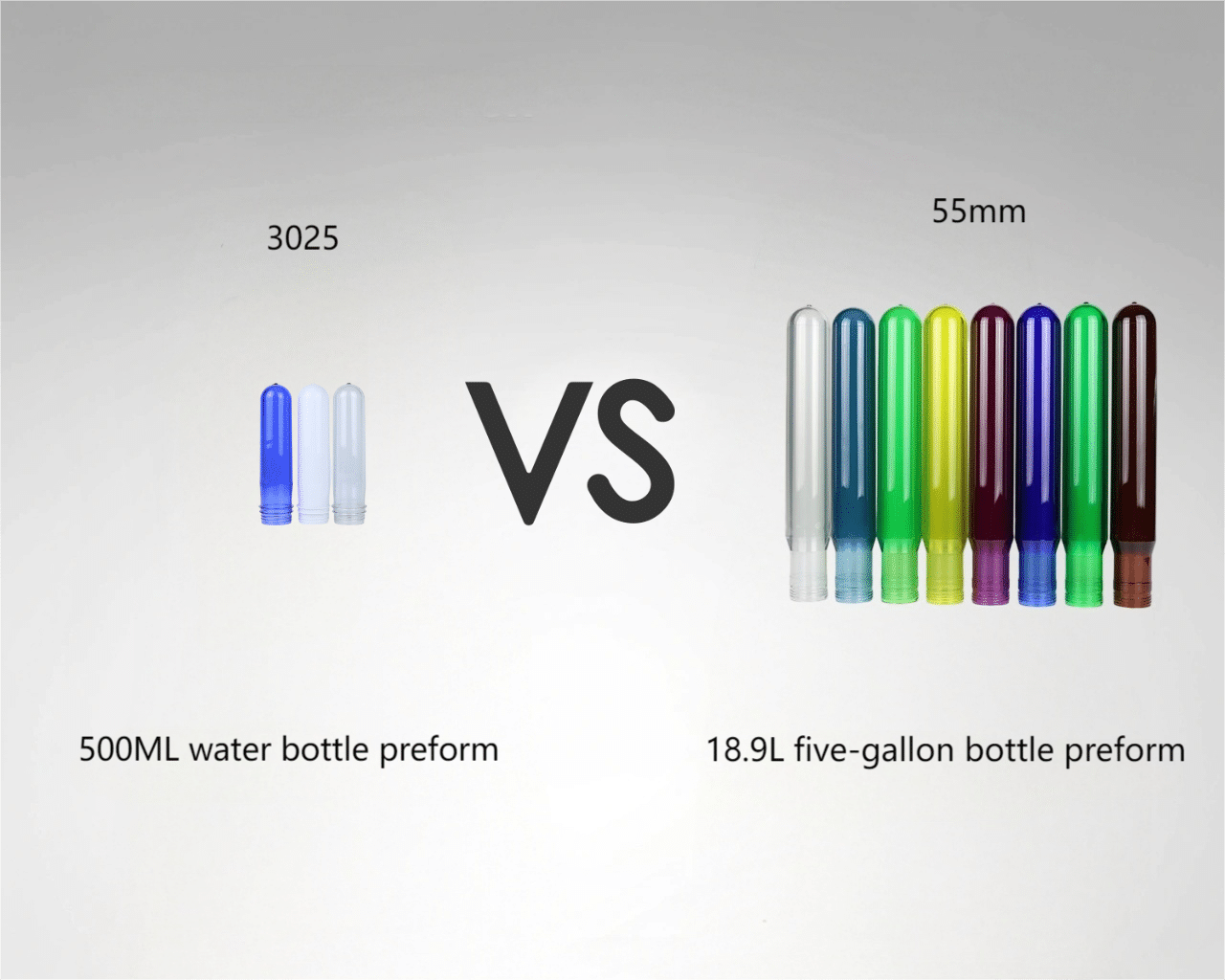

When I talk to clients new to the large-format bottle market, the first thing I do is show them a 5-gallon preform next to a standard 500ml bottle preform. The difference is always a shock. You’re not just scaling up; you are entering a different world of polymer processing. Understanding these core differences is the first step in appreciating why a specialized large capacity bottle machine is not a luxury, but a necessity.

The Massive Difference in Preforms

The heart of the problem starts with the raw material—the preform. A typical 500ml water bottle preform might weigh around 13 to 20 grams. A 5-gallon (18.9L) PET preform starts at around 680 grams and can go up to 730 grams. This isn't a linear increase; it's an exponential leap in mass. This mass has to be heated, stretched, and blown into a perfect container.

| Feature | Standard 500ml Preform | 5-Gallon (18.9L) Preform |

|---|---|---|

| Typical Weight | 13g - 20g | 680g - 730g |

| Wall Thickness | ~2.5 mm | ~10 mm or more |

| Length | ~80 mm | ~150 mm |

| Heating Time | Short | Significantly Longer |

| Material Mass | Low | Extremely High |

This massive weight and thickness mean you need a machine that can handle the sheer physics of the process. I once had a client in South America who tried to modify a smaller machine to fit a 5-gallon mold. They bypassed safety features and pushed the machine to its limits. The result was a disaster. They couldn't get the preform heated evenly, the clamping force was insufficient leading to massive material waste, and they eventually damaged the machine. Their attempt to save money cost them more in the long run. I often tell this story, not to scare, but to educate. The right tool for the right job is paramount in this industry. Check out our range of specialized bottle blowing machines to see what a purpose-built machine looks like.

Structural Demands: Force and Space

A specialized 5-gallon bottle blow molding machine has three main structural differences from a standard one:

- Massive Clamping Force: When you blow high-pressure air into a mold with a surface area as large as a 5-gallon bottle, the separating force trying to push the two mold halves apart is enormous. To counteract this, you need a very high clamping force, often in the range of 30 to 60 tons or more. A standard machine simply doesn't have the hydraulic power or structural integrity to provide this.

- Generous Mold Platen Size: The mold for a 5-gallon bottle is a huge, heavy piece of steel. A specialized machine has large platens and a significant distance between the tie bars to ensure the mold actually fits. It’s a basic but critical point. It's always a good idea to confirm your blow mold fit and machine mounting dimensions before any purchase.

- Longer Mold Opening Stroke: To get a tall bottle (nearly 400mm) out of the mold, the machine needs to open wide enough for the bottle to be ejected without getting stuck or scratched. 5-gallon machines are designed with a much longer opening stroke for this exact reason.

The Heating System Challenge

Perhaps the most critical, and most underestimated, component is the heating oven. As I mentioned, a ~700g preform has incredibly thick walls. Getting heat to penetrate from the outside surface to the very core of that plastic evenly is a major engineering challenge.

Specialized 5-gallon machines solve this with longer heating tunnels, more heating lamps, and advanced ventilation systems. Without this specialized heating, you'll face a host of problems, from uneven wall thickness to weak bases. Many common bottle issues can be traced back to improper heating, a topic we cover extensively in our guide to fixing common PET blow molding defects. In short, the machine isn't just bigger; it's smarter and stronger in all the right places.

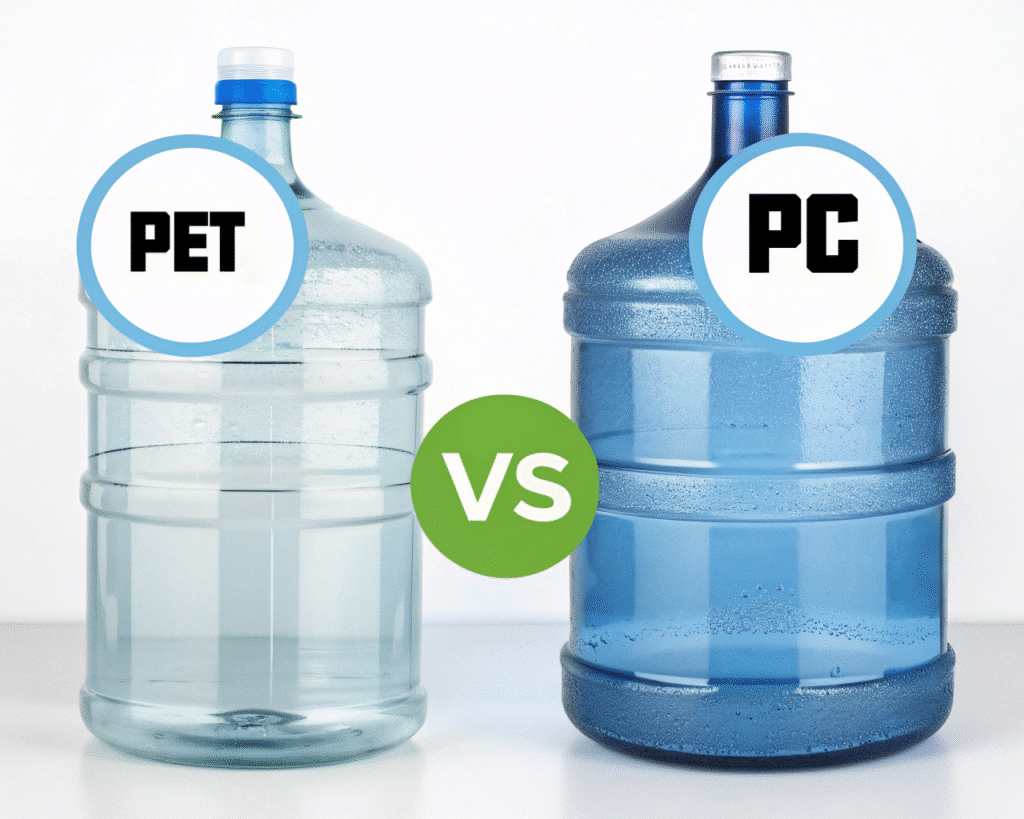

The Critical Material Choice: PET vs. PC for Your 5-Gallon (18.9L) Water Bottle Business?

Choosing between PET and PC is more than a material choice; it's a fundamental choice of production technology and business model. The processes to make bottles from these two materials are completely different.

PET bottles are made using a "Two-Step" process, reheating a pre-made preform. This is ideal for the single-use market. Traditional PC bottles are made via a "One-Step" extrusion blow molding process, designed for the high-durability, returnable-and-reusable market.

Dive Deeper: Aligning Material with Process and Business Model

When discussing the 5-gallon market with new clients, I must first clarify that we are talking about two entirely different manufacturing technologies. Getting this wrong means investing in a completely incorrect production line.

PET Process: Two-Step Reheat Stretch Blow Molding

This process is divided into two stages. First, standardized, test-tube-like "preforms" are manufactured using an injection molding machine. Second, in the blow molding machine, these preforms are reheated to the proper temperature, vertically stretched by a stretch rod, and horizontally inflated by high-pressure air to take the shape of the final mold. A semi-automatic blow molding machine performs this second step.PC Process: One-Step Extrusion Blow Molding

This process is typically done in a single step. PC plastic pellets are melted in an extruder and forced through a die head to form a hollow, tube-like "parison." When the parison hangs to a predetermined length, the two halves of a mold close around it, and air is blown in, inflating the parison into the shape of the mold. This uses a completely different machine, known as an extrusion blow molding machine.

Let me tell you about a client I worked with in Indonesia. They wanted to start a water delivery business and were caught in this exact dilemma. They saw traditional water stations using sturdy, returnable PC jugs. But as we researched, they realized that a PC extrusion blow molding machine was not only expensive but also required highly skilled operators to control the parison thickness and stability.

I advised them to consider a PET Two-Step semi-automatic blow molding machine. This offered a much lower investment barrier. More importantly, the operator's job—placing preforms into the heater and then into the blowing station—was far simpler than controlling a hot, continuously extruded PC parison. They adopted this advice, invested in a PET semi-automatic line, and achieved great success. They were able to get their product to market quickly and affordably, proving that choosing a process that matches your current technical and financial capability is critical.

PET vs. PC: A Full Comparison of Process, Investment, and Market

To help you decide, let's break down these two technology paths in a more accurate table.

| Feature | PET (Two-Step Reheat Blow Molding) | PC (One-Step Extrusion Blow Molding) |

|---|---|---|

| Process Technology | Injection molded preform is reheated and blown. | Resin is melted, extruded into a parison, and blown. |

| Core Equipment | PET Blow Molding Machine (Semi or Full Auto). | PC Extrusion Blow Molding Machine. |

| Raw Material Form | PET Preforms (purchased from a supplier). | PC Resin Pellets (fed directly to the machine). |

| Initial Investment | Lower. A semi-automatic PET machine is the lowest-cost entry point. | Higher. Extrusion machines are complex and expensive. |

| Operational Complexity | Simpler. Especially semi-auto machines, operators are easy to train. | More Complex. Requires skilled technicians to control the parison and process. |

| Primary Business Model | Single-use, one-way sales (e.g., supermarket retail). | Multi-use, return-and-refill loop (e.g., water station delivery). |

| Product Durability | Good (sufficient for one-way transport and use). | Excellent (can withstand dozens of returns, washes, and impacts). |

| Recycling | PET is a widely recycled material globally (Code #1). | PC recycling is less common; focus is on the product's reusability. |

Ultimately, your choice is a strategic one. It's about which technology you want to adopt and the investment and technical barriers you are willing to handle. If you want to enter the retail market quickly with lower risk, the PET two-step process is the clear answer. If you have significant capital and plan to build a traditional delivery network based on a reusable asset, then the PC one-step extrusion process is the proven path. A great bottle starts with a great concept, which is why a solid PET bottle mold design guide can be an invaluable resource.

Understanding the Specs: What Are the Three Core Metrics for a 5-Gallon (18.9L) Blow Molding Machine?

Looking at a machine's technical sheet can be overwhelming. But for a PET two-step machine, you only need to focus on three core metrics to start. Get these right, and you're on the right track.

The three most critical specifications are Clamping Force, Mold Platen Size, and Theoretical Output. These numbers determine if the machine can physically make your bottle, if your mold will fit, and how many bottles you can produce per hour.

Dive Deeper: Decoding the Data Sheet for Success

When a client receives a quote, they often get a technical data sheet filled with numbers. I always tell them to start with the "Big Three." These are the fundamental blow molding machine specifications that determine if a machine is even a candidate.

Metric 1: Clamping Force (Unit: kN or Tons)

This is arguably the most important number for large bottle production. It's the maximum force the machine can apply to keep the two halves of the 5-gallon blow mold tightly shut during the blowing process. If the force is too low, plastic will seep out, creating a defective bottle ("flash"). For a typical 5-gallon PET bottle, you should be looking for a machine with a clamping force of at least 300 kN (around 30 tons).

Metric 2: Mold Installation Space (Units: mm)

This is about simple geometry: will your mold physically fit inside the machine? You need to check three dimensions:

- Distance Between Tie Bars (H x V): Your mold must be smaller than this space.

- Max/Min Mold Thickness: Your mold's depth must fall within this range.

- Mold Platen Size (H x V): Your mold's base must fit on these plates to be secured.

Before you even think about buying a machine, you should have the basic dimensions of your intended blow bottle mold. A reliable supplier should make this easy. We, for example, have a database of mounting dimensions for over 80% of blow molding machines worldwide, which helps eliminate this problem for our clients.

Metric 3: Theoretical Output (Unit: BPH - Bottles Per Hour)

This number tells you about the machine's productivity. For 5-gallon bottles, the numbers are much lower than for small bottles. A semi-automatic machine might produce 60-90 BPH. A fully automatic single-cavity machine might produce 250-500 BPH. Remember that "real-world" output is typically 80-90% of the "theoretical" number due to breaks and changeovers.

The Large Preform Heating Challenge: Why Is the Oven the Heart of a 5-Gallon (18.9L) Machine?

Many people focus on the blowing station, but for the PET two-step process, the real magic happens in the oven. If the preform isn't heated perfectly, you can't make a good bottle.

The heating oven is the heart of a 5-gallon machine because a ~700g preform's thick walls require a long, powerful, and precise heating process. It must deliver deep, even heat penetration to ensure the plastic flows correctly, forming a strong, uniform bottle.

Dive Deeper: The Science of Heating Thick-Walled Preforms

In all my years in this business, I can say with certainty that a majority of bottle quality issues originate in the heating oven. For a thick-walled 5-gallon preform, heating is an unforgiving science. The oven isn’t just a hot box; it’s a sophisticated thermal conditioning unit that is the single most important factor in producing a quality bottle.

The Problem of Heat Penetration

Imagine trying to cook a very thick steak. If the heat is too high, the outside is burnt while the inside is still raw. This is the exact challenge we face with a 5-gallon preform. We need that heat energy from the infrared lamps to travel all the way to the inner wall of the preform, creating a uniform temperature throughout. Improper heating leads to defects like uneven wall distribution, haziness, and weak bases. For a deep dive into these issues, our guide on how to fix common PET blow molding defects is a must-read.

Special Design Features of a 5-Gallon Heating Oven

A purpose-built oven for a 5-gallon bottle blow molding machine is engineered to overcome the heat penetration challenge.

| Feature | Standard Oven | 5-Gallon Specialized Oven | Purpose |

|---|---|---|---|

| Heating Tunnel Length | Short (e.g., 1-2 meters) | Long (e.g., 3-5 meters) | Allows for a longer, more gradual heating time for deep penetration. |

| Lamp Configuration | Fewer rows of lamps | More rows, higher density | Provides the raw power needed to heat the massive preform. |

| Zonal Control | Basic (3-5 zones) | Advanced (8-12+ zones) | Enables creation of a precise vertical temperature profile. |

| Ventilation & Cooling | Basic fan | Targeted air jets and cooling shields | Protects the sensitive neck threads from heat. |

The Art of the Temperature Curve

The ultimate goal is to create the perfect "temperature curve" along the preform's length just before it enters the mold. Different zones (neck, shoulder, body, base) need to be at different temperatures. This process is part art, part science, and it is absolutely essential for making a strong, functional 5-gallon bottle. This is also why understanding how to choose the right preform neck size is critical, as the neck design dictates how it is handled in the oven.

Special Design of 5-Gallon (18.9L) Blow Molds: The Importance of Cooling and Venting?

A 5-gallon bottle mold is not just a scaled-up version of a smaller one. Its massive size and the thick plastic wall introduce huge challenges in cooling and air removal.

The special design of a 5-gallon blow mold must include highly efficient cooling channels to solidify the thick plastic quickly and extensive venting to evacuate the large volume of air instantly. These features are critical for achieving a reasonable cycle time and a defect-free bottle.

Dive Deeper: The Engineering Within the Steel

When customers invest in water bottle factory equipment, I always draw their attention to the mold. A poorly designed mold can cripple the output of even the best machine. The two most critical aspects are cooling and venting.

The Critical Role of High-Efficiency Cooling

A 5-gallon bottle is formed from nearly 700 grams of molten plastic. This heat must be removed as quickly as possible. Cooling time is often the largest single portion of the entire blow molding cycle. High-quality 5-gallon molds feature a complex network of contour cooling channels designed for high-flow, turbulent water circulation, which is far more effective at transferring heat. This is why a well-designed mold needs a powerful chiller, a topic we explore in our article about why PET blow molds need to be connected to a chiller.

The Necessity of Abundant and Strategic Venting

When the preform is blown, the air inside the mold cavity needs to get out instantly. If it can't, it gets trapped and compressed, causing defects like incomplete forming or burn marks. Venting is the art of creating tiny escape routes for this air—at the parting line, with special vent plugs, and around logos. It's a highly detailed and experience-driven process.

Special Structural Features

- Handle Design: The handle area is complex and often requires moving inserts in the mold to form properly. Our PET bottle mold design guide covers these design stages in detail.

- Base Structure: The base needs reinforcing ribs (a "petaloid" base is common) for stability. The design of these ribs is critical for the bottle's strength.

Investing in a well-designed, well-built blow bottle mold from an experienced manufacturer is one of the smartest decisions you can make.

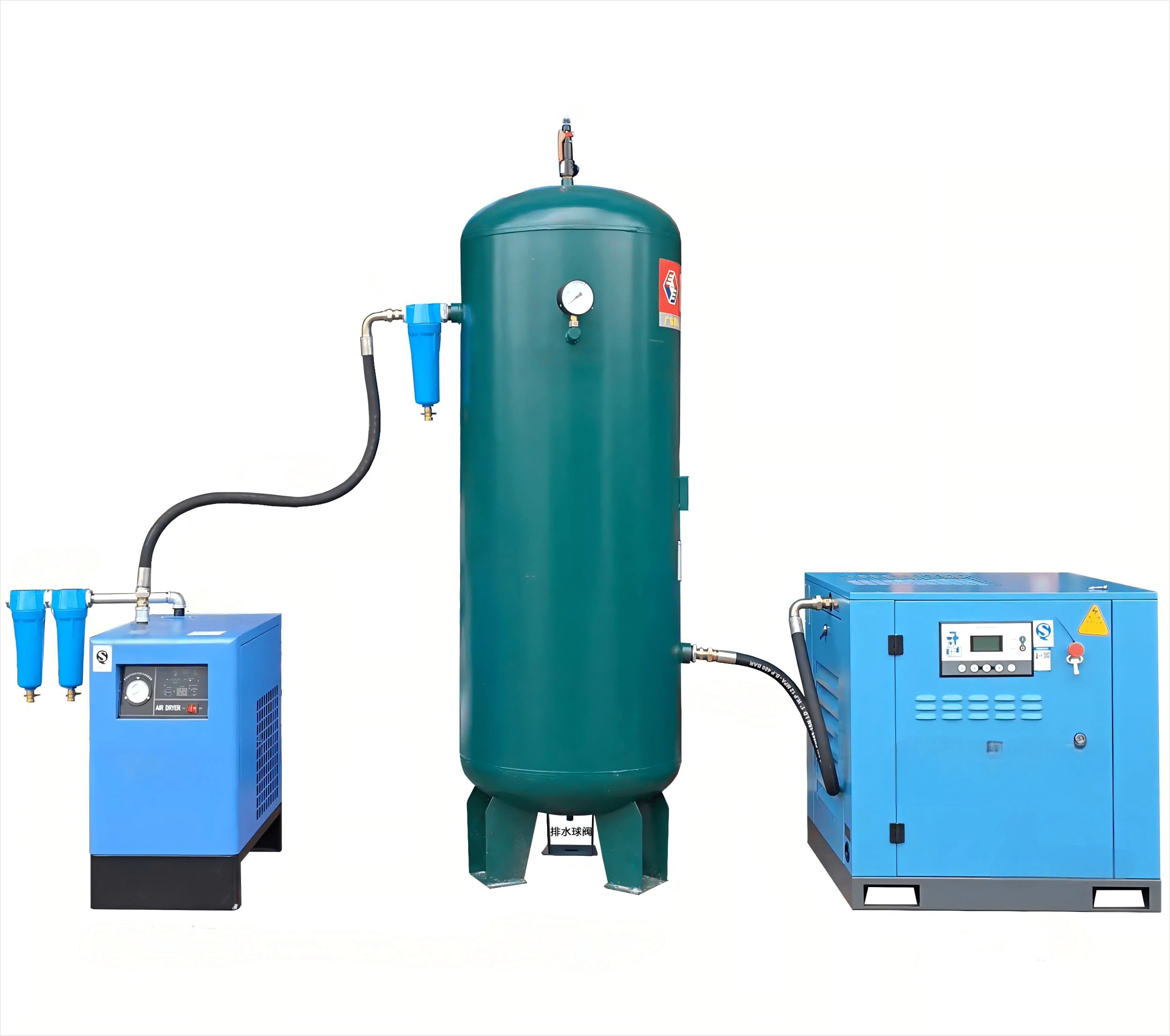

The Supporting Cast is Crucial: Necessary Auxiliary Equipment for 5-Gallon (18.9L) Production?

Focusing only on the blowing machine is a common mistake. For a semi-automatic line, the auxiliary equipment—the air compressor and the water chiller—is just as important. They are necessities, not optional extras.

For 5-gallon production, you must have the correct auxiliary systems. You need a high-volume, high-pressure air compressor to supply the massive burst of air and a high-capacity chiller to cool the large mold efficiently.

Dive Deeper: Building a Complete and Balanced Production Line

I often use the analogy of a race car. You can have the most powerful engine (the blow molding machine), but if you have the wrong tires and brakes (the auxiliary equipment), you will never perform well. A 5-gallon bottle blow molding machine is a high-demand engine. It needs a support system that can keep up.

1. The High-Pressure Air Compressor System

This is the lungs of your operation. Blowing a 5-gallon bottle requires a massive volume of air to be delivered in a fraction of a second. A standard compressor will lack the required flow rate (measured in CFM or m³/min). It won't be able to recover pressure before the next cycle, leading to inconsistent bottles and forcing you to slow down the entire line. You need a complete high-pressure system sized for the job. Investing in a properly sized, cost-efficient air system is not an option, it's a requirement.

2. The Industrial Water Chiller

This is the circulatory system that removes heat from the mold. A 5-gallon mold has a huge amount of thermal energy to dissipate. A small chiller lacks the cooling capacity (measured in kW or Tons of refrigeration). The mold's temperature will slowly rise, leading to longer cooling times and softer bottles. You need an industrial chiller with a cooling capacity matched to the thermal load of your process.

| Auxiliary Equipment | For Standard Small Bottles | For 5-Gallon Large Bottles | Key Consideration |

|---|---|---|---|

| High-Pressure Compressor | Lower Flow Rate (e.g., 1-2 m³/min) | High Flow Rate (e.g., 4-6 m³/min or more) | Air Volume (Flow Rate) |

| Water Chiller | Lower Capacity (e.g., 5-10 kW) | High Capacity (e.g., 20-40 kW or more) | Heat Removal Capacity |

When you budget for your water bottle factory equipment, you must budget for the entire system. A balanced line where every component is correctly sized is the only way to run a stable, profitable operation.

Investment and ROI Analysis: Evaluating the Profitability of 5-Gallon (18.9L) Bottle Production?

Investing in a 5-gallon production line is a major financial decision. You're worried about the high costs and whether you can actually make money. This uncertainty can be paralyzing.

By carefully breaking down the initial investment and calculating the per-bottle production cost, you can accurately forecast your potential profit margins and investment payback period. This analysis transforms a risky guess into a solid business plan.

Dive Deeper: From Capital Outlay to Profitable Output

Every serious conversation about a 5-gallon bottle blow molding machine eventually comes down to money. Let's build a basic framework for this analysis.

Part 1: Deconstructing the Initial Investment (CAPEX)

Your total upfront cost is more than just the price tag of the main machine. You need to account for the entire ecosystem.

| Investment Component | Description | Estimated % of Total (Example) |

|---|---|---|

| Blow Molding Machine | The core semi-automatic machine. | 40% - 50% |

| Bottle Mold(s) | A high-quality, single-cavity 5-gallon mold. | 15% - 20% |

| Auxiliary Equipment | Compressor system, Chiller, Piping. | 20% - 25% |

| Shipping & Logistics | Freight, transport, insurance. | 5% - 7% |

| Installation & Training | Technician service fees. | 3% - 5% |

| Contingency Fund | For unexpected costs (site prep, etc.). | 5% |

When you ask a blow molding machine manufacturer for a quote, ask them for a full line proposal.

Part 2: Calculating Your Per-Bottle Production Cost (OPEX)

You need to know exactly how much it costs to produce a single 5-gallon bottle.

Single Bottle Cost = Preform Cost + Electricity Cost + Labor Cost + Maintenance/Spares Cost

Here's a sample calculation for a semi-automatic line:

| Cost Component | Example Value | Calculation Notes | Cost per Bottle (USD) |

|---|---|---|---|

| PET Preform | $0.50 per ~700g preform | This is your largest variable cost. | $0.500 |

| Electricity | $0.12 per kWh | (Total kW of line) / (Actual BPH). | ~$0.040 |

| Direct Labor | $15/hour for 1 operator | (Hourly Wage) / (Actual BPH). Assume realistic 80 BPH. | $0.187 ($15 / 80 BPH) |

| Maintenance & Spares | 2% of machine cost per year | A general rule of thumb. | ~$0.010 |

| Total Estimated Cost Per Bottle | ~$0.737 |

Part 3: Analyzing Profitability and Return on Investment (ROI)

- Market Price: Research the wholesale price of a 5-gallon bottle in your market.

- Gross Profit per Bottle: Market Price - Your Production Cost.

- Annual Gross Profit: Gross Profit per Bottle * Annual Production Volume.

- Payback Period: Total Initial Investment / Annual Gross Profit.

This final number, the payback period, is what every investor wants to see. It tells you how long it will take for the project to pay for itself.

Choosing a Reliable Partner: How to Evaluate a Supplier for Your 5-Gallon (18.9L) Machine?

Buying a large machine is a long-term commitment. You are not just buying steel; you are buying a relationship. A bad supplier can lead to endless problems.

To choose a reliable partner, you must verify their specific experience with 5-gallon machines. Ask for case studies, videos of machines in operation, and customer references. Prioritize their technical support and after-sales service capabilities over just a low price.

Dive Deeper: Vetting Your Long-Term Manufacturing Partner

Purchasing a 5-gallon bottle blow molding machine is one of the most significant capital investments your company will make. The supplier you choose becomes an integral part of your success.

1. Verify Specific, Provable Experience

The market for large-capacity machines is a niche. Many manufacturers claim they can build a 5-gallon machine, but that is very different from having a proven track record of successfully delivering them.

- Ask for Specific Case Studies: Don't accept a general company brochure.

- Request Videos of Machines in Operation: A raw video from a customer's factory floor is proof.

- Talk to Their Existing Customers: This is the ultimate test.

2. Evaluate Their Technical and Service Capabilities

For a complex piece of water bottle factory equipment, the service after the sale is just as important as the machine itself.

- Installation and Commissioning: Does the supplier send their own experienced engineers?

- Operator Training: A machine is only as good as the person running it. Does the supplier offer comprehensive on-site training?

- After-Sales Support: What happens when you have a problem six months down the line? How responsive is their support team?

3. iBottler's Commitment: A Partnership Approach

I've built my career and our company, iBottler, on the principle of being a long-term partner, not just a one-time vendor. We know that if you succeed, we succeed.

- We Showcase Our Experience: We are proud of our work in the large bottle sector and readily share videos, case studies, and technical details of our successful 5-gallon bottle machine installations.

- We Provide Comprehensive Support: Our service commitment includes sending our own expert engineers for installation and training. From helping with your initial PET bottle mold design to providing rapid prototyping with 3D printed samples, our goal is to be your technical resource.

- We Are Here for the Long Haul: Our after-sales support is structured to provide quick and effective solutions, minimizing your downtime. Our relationship with clients doesn't end when the final payment is made; it's just the beginning.

Conclusion

Choosing the right 5-gallon blow molding machine requires a deep look at technology, materials, and your business plan. Your success depends on a specialized machine and a reliable partner.

Frequently Asked Questions (FAQ)

1. What is the real, day-to-day output I can expect from a 5-gallon semi-automatic machine?

The "real-world" output is typically 80-90% of the theoretical BPH. For a single-cavity semi-automatic machine with a theoretical output of ~90 BPH, a realistic, sustainable daily average is between 60 to 80 bottles per hour. This accounts for operator fatigue and handling time. Always use this more conservative number for your business plan.

2. Are the machines for making PET and PC 5-gallon bottles the same?

No, and this is a critical distinction. They are completely different technologies. PET bottles use a PET Stretch Blow Molding Machine (a "two-step" process) that reheats a pre-made preform. Traditional PC bottles use a PC Extrusion Blow Molding Machine (a "one-step" process) that starts from plastic pellets.

3. For a new water business with limited capital, what should I choose?

If you have limited startup capital, the PET semi-automatic two-step blow molding line is the clear, most cost-effective choice. The equipment investment is significantly lower than for PC extrusion blow molding, and the operation is simpler, allowing you to enter the market quickly with the lowest possible barrier.

4. How much factory space do I need for a complete 5-gallon semi-automatic line?

A complete line is more than just the blow molder. You must account for the air compressor system (compressor, tank, dryer), the chiller, a large area for preform storage, and space to stack the bulky finished bottles. A safe estimate for a complete line is a minimum of 70-100 square meters (approx. 750-1000 sq ft) to allow for smooth workflow and safe maintenance access.

5. Besides the machine itself, what's the biggest challenge when starting 5-gallon production?

For a semi-automatic line, the biggest challenge is creating a stable and efficient operational workflow. This means training your operator well to master the optimal preform heating time, the rhythm of loading and unloading, and how to quickly identify common blowing defects. The skill and consistency of your operator will directly determine your final daily output and product quality rate.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

📞 Contact: Vivian

🏭 Zhongshan Jindong Machinery Co., Ltd.

🌍 www.ibottler.com

📧 Vivian@ibottler.com | 💬 WhatsApp: +86-13106288777

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr