Sourcing on Alibaba is complex. You need a custom blow mold but might only connect with a sales rep who doesn't understand technical details. This can put your project at risk from the start.

You can spot a real factory by checking their product list for "red flags" and asking 3 key technical questions that only an engineer can answer. This guide shows you how to do this objectively.

I have been in this industry for 20 years. My purpose in writing this article is to share my experience as an insider. I want to show you how to analyze information and find a partner who is truly responsible for your project. This guide will provide the exact steps I use.

Why is the "Factory vs. Trader" Distinction So Critical?

You might find a mold supplier with a great price. You place the order. The mold arrives, but it doesn't fit your machine. It becomes a 200kg, unusable piece of steel.

The biggest risk is "factory-gate accuracy." A blow mold is 100% custom. This is the real risk of traders. Many of them don't understand the technology; they just use low prices on Alibaba to attract customers, then find cheaper, often unprofessional factories to produce the mold. This model usually results in a one-time business because if the mold's installation data (like shut height) is wrong by even 1mm, the machine at the customer's factory cannot install it. The shipping costs and time loss to send the mold back to China for modification are severe.

The Factory's "Certainty" Commitment

How does a real, professional blow mold factory ensure a match? This is divided into two scenarios:

- In-House Trial Run (for small/medium machines): For blow molding machine molds, we will install the mold on our own in-house test machine for a "live trial run" before shipment. This ensures the mold's installation, operation, and cooling channels are 100% correct.

- Data Verification (for large rotary machines): For large rotary blowing machines, it is true that factories (including us) cannot conduct an in-house trial. However, we possess the mold installation data for over 80% of the world's mainstream blowing machine brands. More importantly, before mold manufacturing, we provide the customer with detailed installation drawings for their final verification.

This process of "data verification" and "archived data" is the key to guaranteeing a 100% accurate fit. This is something traders cannot do, as they lack this historical data and may not understand the critical dimensions on the drawings.

Step 1: Analyze the "Company Profile" & "Product List" for Red Flags?

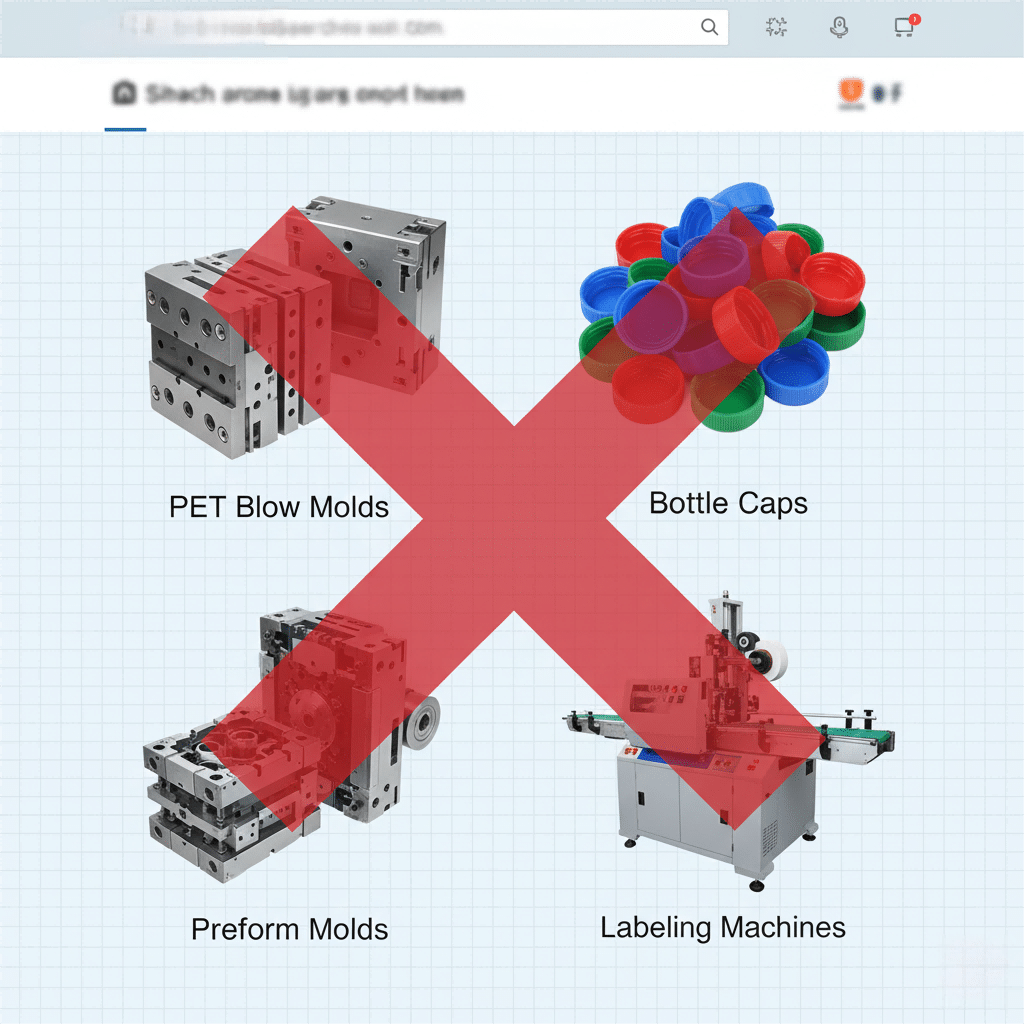

You open a supplier's page. They sell a wide variety of products. Molds, caps, machines, even preforms. It looks like they have a rich product line. But this is a risk.

A supplier selling blow molds, injection preforms, caps, and labeling machines is a 99% trader. These are four completely different factory types. A real factory is specialized. A "generalist" mold factory also has potential issues.

This is your first filter. You can do this in 60 seconds on their Alibaba page. Go straight to their "Products" tab and look for "red flags" or "yellow flags."

Red Flag 1: The "Keyword Collector" Trader

You see a product list that looks like this:

- PET Blow Molds (30%)

- Bottle Preform Molds (30%)

- Bottle Caps (20%)

- Labeling Machines (20%)

This is a 99% certain trader. I call them a "keyword collector." Their goal is to capture every search term related to "bottle."

Let me be very clear. As a 20-year factory insider, I can tell you:

- Blow Molds are made in a blow mold factory. This factory uses CNC milling and high-speed drilling.

- Preforms & Caps are made in an injection mold factory. This factory uses different CNCs, EDM, and high-precision grinding.

- Labeling Machines are made in an automation/assembly factory. This factory uses electrical engineers and PLC programming.

No single factory does all of this. They are completely different technologies, supply chains, and engineering skills. This supplier is just a sales office. They find your keyword, get your order, and then they go find the cheapest factory to make it. You have no control over the quality.

Yellow Flag 2: The "Generalist" Mold Factory

This one is harder to spot. You find a supplier, and their list looks better.

- Product List:

- Automotive Bumper Molds (40%)

- Home Appliance Molds (e.g., TV shell) (40%)

- PET Blow Molds (20%)

This is good news and bad news. The good news: This is a real factory. They make molds. They are not a trader.

The bad news: They are not a blow mold specialist.

This is a "general" mold factory. Their main business is large auto parts. This means their best engineers, their best CNC machines, and their research are all focused on auto parts. "Blow Molds" are just a side business for them.

This creates a new potential issue. Do they really understand PET bottle design? Do they know why 7075 aluminum is critical for cooling, or will they just use P20 steel because it's what they use for car bumpers? They might just copy their auto-part experience. This is something to be aware of for your cycle time and bottle quality.

Supplier Type Comparison

| Supplier Type | Product List Example | Risk Level | Why? |

|---|---|---|---|

| Trader (Red Flag) | Molds, Caps, Labelers | Very High | They make nothing. They are a "keyword collector" who will find the cheapest, lowest-quality factory. |

| General Factory (Yellow Flag) | Car Molds, Appliance Molds, Blow Molds | Medium | They are a real factory, but not specialists. They may not understand blow mold physics, materials, or cooling. |

| Specialist Factory (Green Flag) | PET Blow Molds, Water Bottle Molds, 5-Gallon Molds | Low | This is their core business. Their engineers and equipment are all optimized for blow molds. |

You must ask more questions to find out if a "Yellow Flag" factory is good enough.

Step 2: Decode "Factory Photos" & "Equipment Videos" (How to Spot Fakes)?

The supplier's page has beautiful photos. A huge, clean factory. Brand new CNC machines. But are these photos even theirs?

Look for consistency. Are the floor tiles, wall colors, and machine brands the same in all photos? Is the logo physically painted on the equipment or wall, or is it just a digital watermark? These details reveal a supplier using composite materials.

How to Spot Faked Factory Photos

I look for two things: consistency and logos.

1. Consistency:

- Floors and Walls: Look at the factory floor in all their photos and videos. Is it green epoxy paint in one photo, grey concrete in another, and yellow tiles in a third? This means they are likely showing you three different factories. A real factory has one consistent workshop.

- Machines: Look at the CNC machines. Are they all "HAAS" brand in one video, but "Mazak" in another, and a generic Chinese brand in a photo? A real factory usually buys similar brands of equipment. This makes maintenance and training easier.

- Lighting: Does the lighting look different? Bright white LEDs in one shot, old yellow fluorescent lights in another? This is a clear red flag.

2. Logos:

- Digital Watermarks: Look at their company logo. Is it just a transparent "watermark" placed over the video or photo? This is very easy to fake.

- Real Logos: A real, proud factory will physically paint their logo on the wall of their workshop. They will put a sticker on their CNC machines. They will have it on their toolboxes. Look for the logo in the physical world, not on the image. A logo that is physically present is much harder to fake.

The Ultimate "Right Now" Test

This one test works almost every time. It cuts through all the excuses.

When you are in the Alibaba chat (TradeManager) with a salesperson, you ask them this:

"This looks great. Can you please do one thing for me? Please go to your workshop right now. Stand next to one of your CNC machines. Take a piece of paper, write my name (e.g., 'Hello John') and today's date on it. Hold that paper and take a photo for me. Send it to me right now."

A real factory salesperson (who is at the factory) will say: "No problem, give me 5 minutes." They will be proud to show you. They will walk 30 seconds from their desk to the workshop.

A trader (who is in a 10th-floor city office, 100km from any factory) will start making excuses.

You will get these replies:

- "I am not in the factory right down." (This is the most common one).

- "Our workshop does not allow photos." (This is usually not true. Factories need photos for their own quality control).

- "I need to make an appointment to go to the workshop."

- "Our boss is not here, I cannot go."

This simple, 30-second test will filter out 90% of the traders immediately.

Step 3: Ask These 3 "Key" Technical Questions in the Alibaba Chat?

The salesperson is very friendly. They promise good prices and fast delivery. But do they know anything about molds?

Ask these three questions: 1. What material for the mold body? 2. How is your cooling designed? 3. Can you provide the Material Certificate of Origin? A trader will give vague or wrong answers. An engineer will give precise, technical details.

This is a key step. This is where you separate the real engineers from the sales script-readers. A trader can only talk about price and delivery time. An engineer talks about performance and cycle time.

Question 1: Material (P20 vs. 7075 vs. S136)

You ask: "What material do you recommend for my mold body? P20, 7075 aluminum, or S136 stainless steel?"

- Trader Answer: "S136 stainless steel! It's the best. Very hard, lasts forever."

- Why this might be wrong: This answer sounds good, but it's technically bad for many applications. I had a client who insisted on S136 for an 8-cavity water bottle mold. The mold was over 200kg! It was very cumbersome for his workers to change. Worse, the heavy mold put huge stress on his machine's clamping frame, which cracked after a year.

- Professional Answer: "That depends on your bottle. For a PET water bottle, we strongly recommend 7075 aircraft aluminum for the main body. Its heat transfer is excellent, which shortens the cooling time and gives you a faster cycle. We only use S136 stainless steel for the small inserts at the neck and bottom, because those areas need high wear resistance. Of course, if your bottle is for 'hot-fill' or corrosive 'daily chemicals,' then using S136 stainless steel for the mold body is more appropriate, as it has excellent corrosion resistance and hardness."

This professional answer shows they care about your production speed and machine life, not just selling you the "most expensive" material.

Question 2: Cooling Channel Design

You ask: "How do you design your cooling channels?"

- Trader Answer: "We use the best design. It has very fast cooling." (This is 100% vague and means nothing).

- Professional Answer: "Our cooling channels are CNC-drilled to follow the contour of the bottle. We use a cross-drilled pattern to get water everywhere. Most importantly, our bottle base insert has its own independent cooling loop. This is critical, because the PET base is thick and needs to cool fast to be stable. This design is what reduces your cycle time."

Question 3: Material Certificate of Origin

You ask: "Can you provide the 'Material Certificate of Origin' for the 7075 aluminum?"

- Trader Answer: "Yes, of course." (Then they will hesitate, or send you a fake PDF).

- Professional Answer: "Yes, of course. We will provide the original certificate from our supplier. You can check the documents."

A real factory has these documents on file for every project. It is a standard part of their quality control. A trader has to go ask their supplier, and they might just fake it to get the sale.

Trader vs. Expert: Quick-Check Table

| Question | Vague Trader Answer | Expert Factory Answer |

|---|---|---|

| 1. Material? | "S136 is best. Very hard." | "Depends. For PET, 7075 Aluminum (fast cooling). For hot-fill or daily chemical, S136 (corrosion resistant)." |

| 2. Cooling? | "We have the best cooling." | "Contour-drilled channels with an independent cooling loop for the base to reduce cycle time." |

| 3. Certificate? | "Yes, I will ask for it." (Hesitates) | "Yes, this is standard. We can provide the 'Material Certificate of Origin' (Material Certificate) for the 7075 aluminum." |

Step 4: Demand a "Surprise" Live Video Audit via Alibaba's Platform?

You might be almost convinced. The photos look good, and the salesperson (maybe) answered well. But faking is possible. How can you be more certain?

Do not schedule a factory tour. During your chat, suddenly click the "Video Call" button. Ask them to switch to their rear camera and give you a live tour of their CNC shop, design office, and test machines.

This is an effective verification step. Photos can be faked. Documents can be faked. Even a salesperson can be coached to memorize technical answers.

But a live, surprise video call is almost impossible to fake.

The Direct Video Call Request

Do not email them and ask, "Can we have a video tour next Tuesday?" This gives a trader one week to find a factory, pay them, and go there to pretend it's theirs.

Here is what you do. You are in the middle of a good chat on the Alibaba platform. You have asked your technical questions.

Then, you click the "Video Call" button.

When they answer (if they answer), you say: "Hi! It's great to finally see you. I would love to see your factory. Can you please switch to your rear camera and just give me a 2-minute walk around?"

What You Must See (Your Checklist)

A real, proud factory will be happy to show you these things.

- 1. The CNC Workshop: Ask them to walk into the workshop. Are machines running? Are there metal chips on the ground? Can you see mold blocks being cut? Ask them to walk up to a specific CNC machine.

- 2. The Design Office: Ask them to show you their engineers. Are there people sitting at computers running design software (like CAD or SolidWorks)? A real factory has an engineering team, often right next to the workshop.

- 3. The Test Machines: This is important. Ask them: "Where are your blow molding machines for mold testing?" A professional blow mold factory must have these (at least for small/medium tests).

- 4. The General Environment: Is it a real, noisy, busy workshop? Or is it a silent, empty building?

How a Trader Will Fail This Test

A trader will fail this test in seconds.

- Scenario 1: The "Connection Drop." This is the most common. As soon as you ask for the tour, the video will freeze. "Oh, the connection is very bad. Let's type."

- Scenario 2: The "Office" Problem. They will answer the call, but you will see they are in a fancy city office building. The background is all glass and desks. You will ask for the factory tour, and they will say, "The factory is in another district, I am in the sales office." This confirms they are a trader. A real factory's sales team is at the factory.

- Scenario 3: The "No, I can't" Excuse. They will just say "I am sorry, that is not allowed."

A real factory, like mine, is open to this. We are proud of our machines. I can walk out of my office and be at our 15 CNC machines in 30 seconds. We have nothing to hide. This live tour is the best way to build trust.

[Case Study] The High Price Clients Pay for "Factory" Imposters?

Choosing a cheaper quote might look like cost savings. But if the mold arrives and is unusable, that "savings" quickly turns into high costs for delays and repairs.

I've seen clients lose months of production. A Kenyan client's mold didn't fit (wrong shut height). A UAE client's "7075 aluminum" mold was just regular aluminum and started pitting in weeks. The trader disappeared.

These stories are real. I have changed the names, but these are from clients who came to us after having a bad procurement experience.

Case Study 1: The Kenya Installation Failure

This client was launching a new water bottle brand in Nairobi. He was new to sourcing. He used Alibaba and found a "Gold Supplier" with "Trade Assurance." The price was 15% lower than other quotes.

He ordered 4 sets of molds. They arrived by air freight (very expensive).

His team tried to install the first mold. It would not fit. They tried the second. Same problem.

They called us. We did a video call. I asked them to measure the mold shut height. It was 195mm. Their machine's minimum shut height was 200mm. The mold was 5mm too thin. It was impossible to install.

This is a basic, technical error. The "supplier" (a trader) likely had no idea what "shut height" even meant. They just passed the order to a cheap factory that made a mistake.

The client's result:

- He had to pay to air freight all four heavy molds back to China.

- He lost his original payment.

- He lost 2 full months of production, missing his launch window.

- He finally paid us (a real factory) to fix the other factory's mistake.

This is why we are so focused on mold and machine matching. A 5mm error is a severe incident.

Case Study 2: The UAE Material Fraud

This client was in Dubai. He was an experienced producer. He specifically ordered 6 sets of blow molds made from 7075 aircraft aluminum. He knew this was the best material for cooling.

He found a supplier who promised 7075 aluminum and gave him a good price. They even sent him a "Material Certificate."

The molds arrived and worked... for a few weeks.

Then, his operators started seeing small "pits" or black spots on the inside surface of the bottles. He stopped production and looked at the mold cavities. The surface was pitting. It was corroding.

Real 7075 aluminum is very hard and corrosion-resistant. This was not 7075. It was probably a cheap, common 6061 aluminum, or worse. The "Material Certificate" was a fake.

The trader just sold him a lie. When the client went back to complain, the supplier's Alibaba account was already closed. He had to throw away all 6 molds. This is the danger of a partner you cannot trust.

Is This Audit Process Worth Your Time?

You are a busy project manager. You have a deadline. Do you really have time to perform this complex series of audit steps just to buy one mold?

You now have the skills to filter out 90% of unreliable suppliers. But this process takes time, energy, and expertise. You are still taking a risk. This audit itself is a "time cost."

Let's review what you have to do to find a real supplier on Alibaba.

First, you have to search Alibaba and screen dozens of suppliers.

Second, you have to carefully analyze their product lists and photos for "red flags" and "yellow flags."

Third, you have to prepare key technical questions to judge their professionalism.

Fourth, you have to demand "right now" photos and "surprise" video calls for verification.

This is a lot of work.

The "Cost of Auditing"

As a business owner, I think about "time cost." Your time is valuable. Every hour you spend "vetting" a supplier is an hour you are not spending on marketing, R&D, or managing your team.

You are not looking for a complex process. You are looking for a reliable, long-term partner. You need someone who can build a high-performance mold, ship it on time, and support you if there is a problem.

The Alibaba platform model requires you, the buyer, to take on most of the risk and all of the auditing work.

The Final 10% Risk

Even if you do all this, a very clever trader might still mislead you. They might have a "partner" factory they use for video calls. They might send you a real material certificate, but use fake material in the real mold.

You are still carrying that final 10% risk.

My question to you is: Is this worth it? Is the potential for a slightly lower price worth this huge investment of your time and this significant risk?

For a simple product, like a phone case, maybe.

For a high-precision, 100% custom piece of industrial tooling like a blow mold, the risk is just too high. You are not just buying a product. You are buying a performance guarantee.

A More Direct Option: Why We Chose the Transparency of an Independent Site?

You might want to skip the complex "audit" and "verification" process. You just want to talk to a real engineering team and get your project done right.

You won't find iBottler (ibottler.com) on Alibaba. We invest in technology and service, not platform ad fees. Alibaba is an information platform you must "audit." Our independent site is a 100% transparent communication channel.

As I said at the beginning, you will not find my company, iBottler (ibottler.com), on Alibaba.

This is a business choice we made years ago.

We (iBottler) are a 20-year-old manufacturing factory. We own our own plant and our 15 high-precision CNC machines. We are engineers.

We found that competing on Alibaba often means we must compete on price against traders who have no technical background and just attract orders with low prices.

We choose to invest our time and money in "better cooling channel design," "more durable steel," and "faster after-sales service," rather than platform ad fees.

Alibaba is a platform with vast information that requires you to spend significant energy to "audit" it. Our independent site, www.ibottler.com, is a 100% transparent and direct communication channel to you.

If you want to speak directly with a 100% real, transparent factory engineering team from the very beginning, you are welcome to visit our website. We offer free, live video factory tours. You can speak directly to me (Vivian) or our engineers and ask any technical questions.

Conclusion: How to Find a Quality Supplier on Alibaba?

Finding a quality blow mold factory on Alibaba is entirely possible. It requires you to use professional knowledge to filter them. As we've discussed, you need to check their product specialization (Step 1), verify their actual workshop (Step 2), and ask key technical questions (Step 3).

Alibaba is a platform with a massive amount of information, and supplier quality varies. Encountering a low-quality factory is not a problem with the platform itself. It just means that as professional buyers, we must have more specialized knowledge to lead the screening process. Mastering these professional audit methods is the key to finding a truly high-quality factory partner you can cooperate with long-term.

Audit Steps Summary

| Step | Action | What It Finds |

|---|---|---|

| 1 | Analyze Product List | Spots "Keyword Collector" Traders vs. "Generalist" Factories. |

| 2 | Decode Photos & Videos | Spots faked materials by checking consistency and logos. |

| 3 | Ask 3 Key Questions | Separates real engineers from sales-script readers. |

| 4.0 | Demand Surprise Video Tour | The final verification. Impossible for an office-based trader to fake. |

Frequently Asked Questions (FAQ)

1. Is a "Gold Supplier" on Alibaba a real factory?

Not always. "Gold Supplier" is a paid membership. It means they paid Alibaba a fee. It does not mean they are a factory. Many "Gold Suppliers" are traders. You must still use the audit steps in this guide.

2. What about "Verified Supplier"? Is that better?

"Verified Supplier" is a step up. It means a third-party company (like SGS or TÜV) visited their office. However, they may only verify the trader's office, not the factory they use. Some traders will "rent" a factory for a day for the verification. It is better, but you must still be careful and do your own video audit.

3. Why is 7075 aluminum better than steel for PET water bottle molds?

Because of heat transfer. Aluminum conducts heat much faster than steel. In blow molding, "cooling time" is the biggest part of your cycle. A 7075 aluminum mold pulls heat out of the PET bottle faster, letting you shorten your cooling time. This means you can make more bottles per hour. We only use S136 steel for the small neck and base inserts, which need high wear resistance.

4. What is the single most important question to ask a supplier?

"Can you take me on a live video tour of your CNC workshop right now?" This one question, and their immediate reaction, will tell you everything you need to know. A real factory will say "Yes!" A trader will make an excuse.

5. Why don't you just sell on Alibaba?

We want to build long-term partnerships. On Alibaba, we are forced to compete on price against traders who lie about materials and quality. We choose to invest our money in better engineering and better materials instead of ad fees. We find that the best clients, who value quality and reliability, are happy to find us on our own independent website.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr