Your production line is down, alarms are flashing, and every second costs you money. The cause is a tiny, inexpensive part. The solution is having the right spare parts on hand.

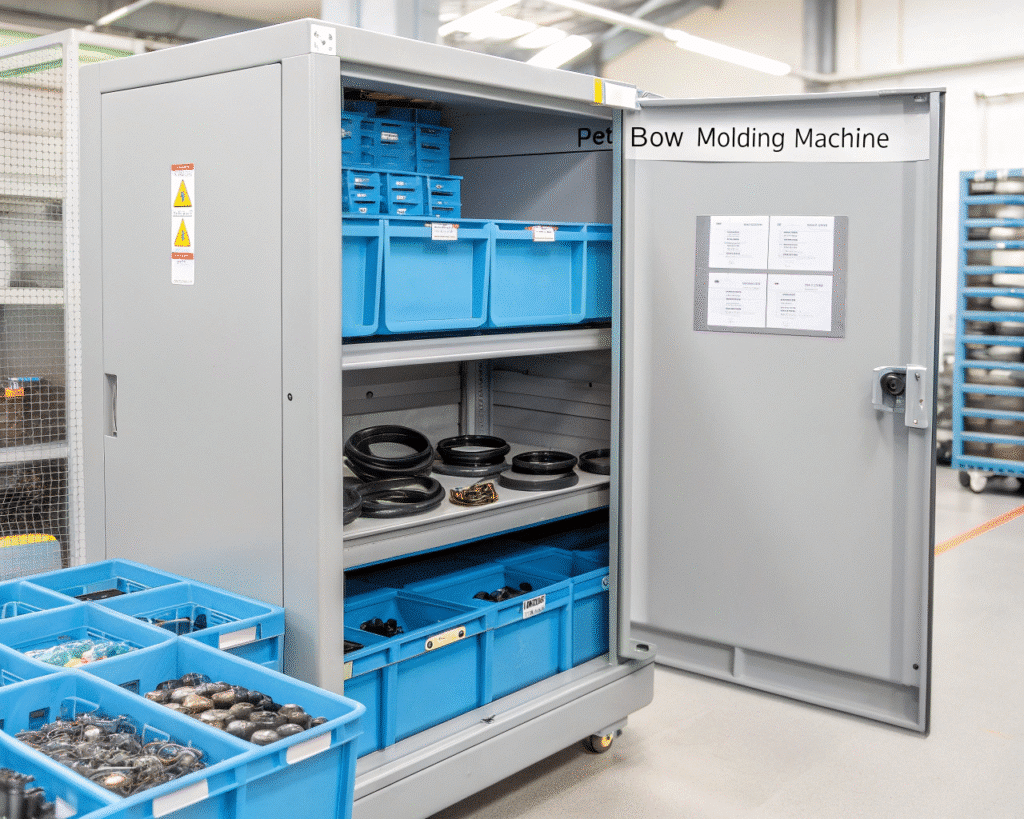

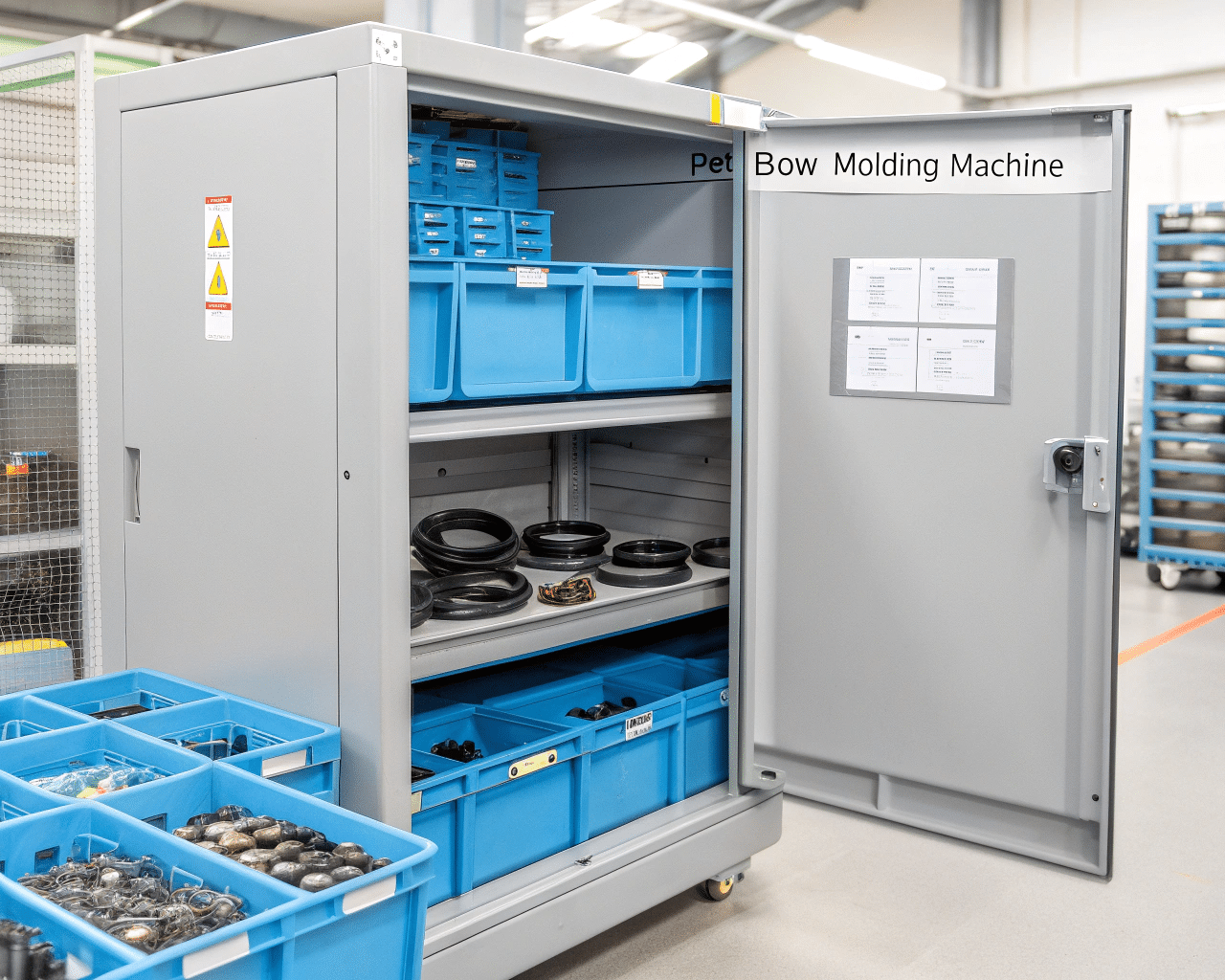

Having a well-organized stock of critical PET blow molding machine spare parts is the single most effective strategy to prevent catastrophic downtime. This includes heating lamps, power supplies, sensors, high-pressure valves, seals, stretch rods, and essential air compressor service items.

I've been in this business for over 16 years, and I've seen it all. A simple phone call can turn a company's profitable day into a nightmare of lost revenue. But I've also seen how a little preparation can turn a potential disaster into a minor, 15-minute fix. This isn't just about parts; it's about a mindset that values uptime above all else. Let’s dive deep into what you need on your shelf and, more importantly, why you need it there. This is the knowledge that separates the pros from the people who are always fighting fires.

The True Cost of a Shutdown: Why a $5 Part Can Cost You Thousands?

The machine stops. Your operator is confused. Orders are waiting. The real cost of that shutdown isn't the part; it's the time you lose while you wait for it.

A single $5 seal failing can halt your entire production line for hours, or even days. This downtime can easily cost you thousands of dollars in lost output, idle labor wages, express shipping fees, and potential penalties for late orders. Stocking spares is an investment with a massive return.

I want to tell you a story that perfectly illustrates this. I got a frantic call a while back from a client in Australia. He was in the middle of a huge production run, and his machine just stopped making good bottles. Every bottle was malformed, and he could hear the distinct, money-draining hiss of an air leak somewhere. He was losing his mind, thinking his brand-new bottle blowing machine was a lemon.

Over the phone, I walked him through a diagnostic process. "Listen closely," I said. "Where is the sound coming from? Is it near the blow block? Is it near the clamping unit?" We narrowed it down to one of the main action valves that controlled the mold clamping. I then asked him to go to the spare parts kit I had insisted he purchase with the machine—the very kit he thought was an unnecessary expense. I told him, "Open the box, find the bag labeled 'Action Valve Seal Kit,' and replace the main seal on that valve."

He was skeptical, but he followed the instructions. Thirty minutes later, he called me back. The hissing was gone, the machine was running perfectly, and he was back in production. That seal kit cost him maybe $50. But how much did it save him? Let's do the math. His line was down for a total of about three hours from the time the problem started to when he called me and fixed it.

Let's break down the real cost of a situation like that in a more structured way.

The Anatomy of Downtime Costs

| Cost Category | Description | Example Calculation (4-Hour Shutdown) |

|---|---|---|

| Lost Production Value | The profit you didn't make because you weren't producing bottles. | 5,000 bottles/hr @ $0.10 profit/bottle = $500/hr. Total: $2,000 |

| Idle Labor Costs | Paying your operator and other staff while the machine is not running. | 2 employees @ $25/hr each = $50/hr. Total: $200 |

| Emergency Part Shipping | The premium you pay for overnight or international express shipping. | A 2kg package from overseas can easily cost $150 - $300. |

| Delayed Order Penalties | Contractual fees or lost goodwill from failing to meet a delivery deadline. | This can range from hundreds to thousands of dollars. |

| Wasted Energy | The factory lights, air conditioning, and other auxiliary equipment are still running. | An often-overlooked but constant drain on resources. |

| Management & Maintenance Time | The time spent by managers and maintenance staff diagnosing the problem. | This diverts skilled labor from value-adding tasks. |

In my Australian client's case, that $50 kit saved him at least $1,500 in lost profit for those three hours, not to mention the cost of flying in a part, which would have kept him down for days, potentially costing him over $10,000. He went from being a skeptic to a true believer in preventative maintenance. He understood that the small box of critical spare parts sitting on his shelf wasn't a cost; it was the cheapest insurance policy he had ever purchased. This is the mindset shift I try to instill in all my clients. Don't think about the cost of the parts. Think about the cost of not having the parts.

The Critical 10 (Part 1): Core Electrical & Control Components?

Your machine suddenly goes dark. Or maybe it's stuck in a loop, throwing the same frustrating alarm over and over. You have a mechanical problem that isn't mechanical at all.

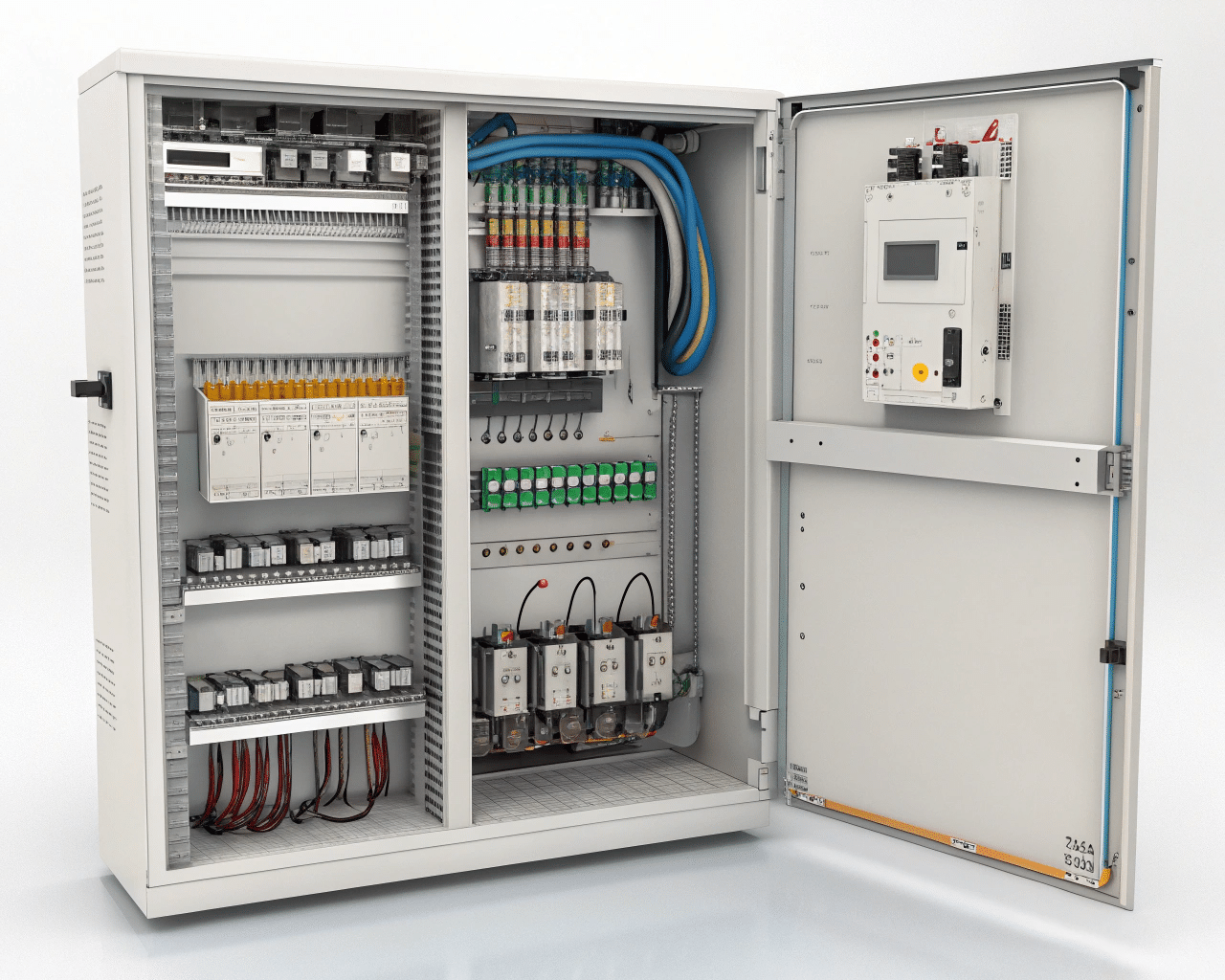

These issues often trace back to the machine's nervous system: its electrical and control parts. Components like heating lamps, the main power supply, sensors, and control valves are the absolute foundation of its operation. When one of them fails, the machine stops instantly, with no warning.

Think of your blow molder like a human body. The PLC is the brain, the wires are the nerves, and the sensors are the eyes and ears. If the power supply fails, it's like the heart stopping—everything goes dark. If a sensor fails, the machine is blind and refuses to move, fearing it will damage itself. These aren't parts that degrade slowly; they usually fail completely and suddenly. That’s why having them on hand is non-negotiable for serious production environments. Let's break down the most critical components in this category.

1.Heating Lamps: The Most Replaced Part

The heating lamps are perhaps the most essential consumable part in the entire machine. Their job is to heat the PET preforms to the precise temperature needed for stretching and blowing. If the heating is inconsistent, your bottle quality will be terrible.

- Function: To emit infrared radiation that penetrates the preform wall, bringing it to the ideal malleable temperature, usually around 100-110°C.

- Why They Fail: Like any lightbulb, they have a finite lifespan, typically a few thousand hours. They are also sensitive to voltage fluctuations and can be damaged by physical shock.

- Symptoms of Failure: You'll see defects in your bottles that are classic signs of uneven heating. One side might be thin and weak, while the other is thick and hazy. This is one of the first things to check when troubleshooting common PET blow molding defects. A visual inspection will often show a lamp that is simply not glowing.

- My Recommendation: Based on my experience, you should always have at least 10% of your machine's total lamp count as spares on the shelf. If your oven has 50 lamps, have a minimum of 5 ready to go at all times. They are relatively inexpensive and are the most common reason for a service call.

2. Switching Power Supply: The Unsung Hero

This is one of the most overlooked PET blow molding machine spare parts. The switching power supply is a small box, usually tucked away in the electrical cabinet, that converts your factory's high AC voltage into the low-voltage (typically 24V DC) power that runs the entire control system.

- Function: Powers the PLC (the brain), the HMI (the touch screen), all the sensors, and the solenoids for the action valves.

- Why It Fails: Heat is its enemy. Poor ventilation in the electrical cabinet or power surges can cause it to fail prematurely.

- Symptoms of Failure: The machine will appear completely dead. The touch screen will be black, no lights will be on, and nothing will respond. I have personally seen clients waste an entire day trying to troubleshoot sensors and wiring, only to discover the issue was a failed $100 power supply that could have been replaced in 10 minutes.

- My Recommendation: Have one exact replacement on hand. Always. There is no workaround for a failed power supply. The machine is a paperweight without it.

3.Sensors (Photoelectric/Proximity): The Machine's Eyes and Ears

Modern blow molders are covered in sensors. They detect if a preform is loaded, if a bottle has ejected correctly, if the safety doors are closed, and if mechanical parts are in their home position.

- Function: To provide feedback to the PLC, ensuring every step of the process happens in the correct sequence.

- Why They Fail: They operate in a harsh environment. Dust can block them, vibration can knock them out of alignment, and they can be accidentally hit by operators or tools.

- Symptoms of Failure: A single faulty sensor can cause constant, maddening alarms that halt production. The machine might refuse to start a cycle, claiming a bottle is jammed when there isn't one. This is because a sensor is giving a "false positive" signal.

- My Recommendation: Your machine's manual will list the different types of sensors it uses. Identify the 2-3 most common types (e.g., preform detection, bottle-out detection) and have at least one of each in your kit.

4.High-Pressure & 5.Action Valves: The Muscle Controllers

These valves direct the flow of air that makes everything happen. They are the link between the electrical signals from the PLC and the powerful mechanical movements of the machine.

- Function:

- High-Pressure Valves: Control the final, powerful blast of air (up to 40 bar / 580 PSI) that forms the bottle.

- Action Valves (Solenoid Valves): Control the low-pressure air for all other movements: clamping the mold, moving the stretch rods, transferring preforms, etc.

- Why They Fail: The internal seals and moving parts wear out over millions of cycles. Contaminated air can also cause them to stick or leak.

- Symptoms of Failure: A leaking

high-pressure valvewill result in bottles that are not fully formed. A sluggish action valve will slow down your cycle time or cause jerky movements. A complete failure will stop a specific machine function entirely. This was the exact issue my Australian client faced. - My Recommendation: For the main high-pressure blow valves, have a complete spare unit if your budget allows, or at a minimum, a full seal rebuild kit. For the smaller action valves, identify the 2-3 most used types on your machine and have one of each.

Here’s a quick reference table for these critical electrical parts.

| Component | Primary Function | Common Failure Symptom | Recommended Stock |

|---|---|---|---|

| Heating Lamps | Heats preforms to a malleable state. | Uneven bottle wall thickness, visual burnout. | 10% of total machine count. |

| Switching Power Supply | Powers the PLC, HMI, and sensors (24V DC). | The machine is completely dead, screen is black. | 1 unit. |

| Sensors | Detects position of preforms, bottles, parts. | Persistent, "ghost" alarms; machine won't cycle. | 1 of each major type. |

| High-Pressure Valve | Releases high-pressure air to form the bottle. | Bottles not fully formed, slow cycle time. | 1 full rebuild kit or 1 complete unit. |

| Action Valves | Controls all pneumatic movements. | Air leaks, sluggish movement, function failure. | 1 of each major type. |

The Critical 10 (Part 2): Essential Mechanical Wear & Sealing Parts?

You hear a constant, faint hissing of escaping air. A mechanical arm seems sluggish. Your production efficiency is slowly dropping, and you can't figure out why.

These are the tell-tale signs of mechanical wear. Unlike the sudden failure of electrical parts, mechanical components often degrade over time. These are the parts that are in constant motion, under high stress, and are designed to be replaced. Ignoring them is a recipe for disaster.

This second group of five critical parts focuses on the components that are subject to friction, physical impact, and pressure. From the rod that stretches the bottle to the tiny O-ring that holds back immense pressure, these parts are the workhorses. Having replacements on your shelf prevents a slow degradation of performance from turning into a sudden, catastrophic failure that brings your line to a grinding halt.

6. Stretch Rods: The Heart of the Stretching Process

The stretch rod is a deceptively simple but incredibly vital component. It is the part that plunges into the heated preform, stretching it vertically just before the high-pressure air blows it into the mold's shape. The precision of this action directly impacts the final bottle's material distribution and strength.

- Function: To perform the axial stretching of the preform, which is critical for the biaxial orientation of the PET molecules, giving the bottle its strength and clarity.

- Why They Fail: They are long, thin rods that move at high speed. They can bend from misalignment or a machine jam. The tip, which makes contact with the preform, can wear down over time, changing its shape. In rare cases of severe malfunction, they can break.

- Symptoms of Failure: A bent stretch rod is an immediate production killer. It will likely damage the mold or other components. A worn tip will create defects in the center of the bottle's base, often looking like a small, hard spot. This can be a major quality issue, especially for carbonated beverage bottles. A proper PET bottle mold design considers the stretch rod tip's interaction with the mold base.

- My Recommendation: You must have at least one full set of

stretch rodsin your spare parts inventory. If one rod is damaged, it is often best practice to replace the entire set to ensure even stretching across all cavities.

7. Seals & O-rings: The Smallest Giants

If there's one thing I've learned, it's to respect the humble O-ring. These small, inexpensive rubber rings are everywhere in a blow molding machine. They are in every valve, every pneumatic cylinder, and every air connection. They are the single most common wear item in the entire system.

- Function: To create a pressure-tight seal between two joining parts, preventing air from leaking out.

- Why They Fail: They are made of materials that degrade over time due to friction, heat, and contact with compressor oil. With millions of cycles, they simply wear out, flatten, and lose their ability to seal.

- Symptoms of Failure: The most common symptom is a hissing sound, indicating a leak. This leak wastes expensive compressed air, which directly increases your energy costs. A significant leak can cause a drop in operating pressure, leading to sluggish machine movements and poor bottle quality.

- My Recommendation: I tell all my clients that a comprehensive seal and O-ring kit is non-negotiable. It should be one of the first things you buy. The kit should be well-organized and labeled, so you can quickly find the exact size you need. My Australian client's story is a perfect testament to the power of having the right seal on hand.

8. Cylinder Seal Kits: A Full Rebuild in a Bag

While a single O-ring might fix a small leak on a fitting, the main pneumatic cylinders that perform heavy tasks (like clamping the mold or moving the transfer arms) require a more comprehensive solution when they start to fail.

- Function: These kits contain all the necessary seals, gaskets, and wear bands to completely rebuild the internals of a pneumatic cylinder.

- Why They're Needed: The internal piston seal of a cylinder travels back and forth thousands of times a day. Eventually, it will wear down, causing air to leak past the piston. This is called "blow-by."

- Symptoms of Failure: The cylinder will become weak and slow. It may not be able to fully clamp the mold with enough force, or it may struggle to move its load. This is a more serious issue than a simple fitting leak and requires immediate attention.

- My Recommendation: Rebuilding a cylinder with a seal kit is far more cost-effective than replacing the entire cylinder unit, which can be very expensive. For the most critical cylinders on your machine (clamping, stretching), you should have one full seal kit for each.

9. Grippers: The Hands of the Machine

The grippers are the mechanical "fingers" that handle the preforms and the finished bottles, moving them from one station to the next. They are subject to immense repetitive stress.

- Function: To securely hold and transfer preforms and bottles throughout the machine cycle.

- Why They Fail: They are subject to constant mechanical wear from opening and closing millions of times. They can also be damaged during a machine jam. The materials they are made from can wear down, causing them to lose their grip.

- Symptoms of Failure: Dropped preforms or bottles are the most obvious sign. This will cause a machine jam and halt production. Worn grippers can also scuff or scratch the neck of the preform, leading to quality rejects.

- My Recommendation: Have a few spare gripper assemblies on hand. They are often quick to change, allowing you to get the machine running again while you repair the damaged one offline.

10. Air Filters: The Protective Shield

This is a purely preventative part, but it's one of the most important on this entire list. The air filter element is what protects all the expensive and sensitive pneumatic components downstream.

- Function: To remove dust, moisture, and oil particles from the compressed air before it enters the machine's pneumatic system.

- Why They're Needed: Dirty air is the #1 killer of pneumatic valves and cylinder seals. Small particles act like sandpaper, scoring surfaces and destroying seals. Moisture can cause corrosion and wash away lubrication.

- Symptoms of Failure: A clogged filter will cause a significant pressure drop, starving the machine of air. A failed or bypassed filter won't show any immediate symptoms, but you will find yourself replacing expensive valves and seals far more often than you should.

- My Recommendation: Air filter elements are cheap. Follow the manufacturer's recommended replacement schedule religiously. I recommend having at least 2-3 replacement elements in your stock at all times. This is a key part of any good

blow molding machine maintenanceplan.

| Component | Primary Function | Common Failure Symptom | Recommended Stock |

|---|---|---|---|

| Stretch Rods | Stretches preform vertically. | Bent rod causes jams; worn tip causes base defects. | 1 full set. |

| Seals & O-rings | Creates airtight seals in pneumatic system. | Hissing air leaks, pressure loss, slow movement. | 1 comprehensive kit. |

| Cylinder Seal Kits | Rebuilds internal seals of major cylinders. | Weak or slow cylinder action, internal leaks. | 1 kit for each critical cylinder. |

| Grippers | Transfers preforms and bottles. | Dropped preforms, machine jams, scratches. | 2-3 spare assemblies. |

| Air Filters | Cleans compressed air for the machine. | Pressure drop (if clogged), premature failure of other parts. | 2-3 replacement elements. |

Beyond the Machine: Key Wear Parts for Your Blow Mold?

Your machine is running perfectly, but your bottles are coming out with a thin line of plastic on the side. The quality is dropping, and you're getting complaints.

The problem isn't always the machine itself. Your blow bottle mold is a high-precision tool that is also subject to wear and tear. While these parts may not need replacement as often as the "Critical 10," ignoring them can lead to serious quality issues and even permanent mold damage.

I always remind my clients that the machine and the mold are a system. They have to work together perfectly. Spending a little attention on your mold's key wear parts is a crucial step in maintaining top-tier production quality. A high-quality mold from a reputable supplier will be designed for longevity, but no material can withstand millions of cycles of pressure and friction without some wear. Let’s look at the areas you need to watch.

Mold Lips (Parting Line): The Critical Sealing Edge

The parting line, or mold lip, is the surface where the two halves of the mold come together and seal. This edge must withstand the full force of the mold clamp and contain the high-pressure blowing air.

- Function: To create a perfect seal that prevents molten plastic from escaping the mold cavity during the blowing process.

- Why They Wear: Over millions of cycles, the repeated clamping force can cause the steel on this fine edge to wear down or "hob." A small piece of debris or a misaligned clamp can also cause a dent or a nick.

- Symptoms of Wear: The classic symptom is "flashing." This is a thin, razor-sharp web of plastic that squeezes out at the parting line of the bottle. It's a major quality defect and can be a safety hazard. As the wear gets worse, you may not be able to build enough clamping tonnage to seal the mold properly.

- My Recommendation: Regular inspection is critical. I advise operators to run their fingernail along the parting line of the mold (when the machine is safely locked out, of course) at the beginning of each shift. You can feel a nick or a dent long before you can see it. Minor damage can sometimes be stoned or polished out by a skilled toolmaker, but significant wear may require the mold to be sent out for professional repair and welding. Knowing the condition of your mold lips is part of a proactive

preventative maintenance checklist.

Guide Pillars & Bushings: Ensuring Perfect Alignment

The guide pillars (or leader pins) and their corresponding bushings are what ensure the two halves of the blow mold align with absolute precision every single time they close.

- Function: To guarantee that the cavity half and the core half of the mold line up perfectly, ensuring consistent wall thickness in the final product.

- Why They Wear: They are constantly sliding against each other under high force. Inadequate or improper lubrication is the primary cause of premature wear.

- Symptoms of Wear: When the pillars and bushings wear, they develop "play" or looseness. This allows the mold halves to shift slightly upon closing. The result is inconsistent bottle wall thickness. You might find one side of your bottle is significantly thinner than the other. In severe cases, it can cause the mold lips to misalign and damage each other. The importance of alignment is something we emphasize when discussing how to ensure blow mold fit with our customers' machines.

- My Recommendation: Lubrication is key. Use the type and amount of grease recommended by the mold maker. At regular intervals, you should check for any play in the mold when it is closed. Having a spare set of bushings is a good idea, as they are typically designed to be the sacrificial wear component, protecting the more expensive pillars.

Cooling Connectors & Seals: The Key to Temperature Control

Efficient cooling is vital for a fast cycle time and a stable PET bottle. This is achieved by circulating chilled water through channels within the mold. The connectors and seals that manage this water flow are common failure points.

- Function: To provide a leak-proof connection for the chiller lines to the mold body.

- Why They Fail: These connectors are often "quick-disconnect" types that get plugged and unplugged frequently during mold changes. The O-rings inside them wear out. They can also be damaged by being dropped or hit.

- Symptoms of Failure: A water leak is the most obvious sign. A coolant leak is not only messy but can also be a safety hazard (slip hazard). If the leak is significant, it will reduce the cooling efficiency of the mold, which can force you to extend your cycle time or result in hazy, poorly formed bottles. The connection between proper cooling and bottle quality cannot be overstated, which is why a reliable chiller connection is so important.

- My Recommendation: Leaky connectors are incredibly disruptive. I strongly advise every client to keep a small box with spare quick-disconnect fittings and a good assortment of the O-rings that go inside them. It’s a very small investment that can prevent a lot of headaches during a mold change.

Don't Forget the Powerhouse: Your Air Compressor's Service Kit?

Your entire production line is running slow. Bottles aren't forming correctly, and you're getting quality defects. The problem isn't your blow molder. It's the powerhouse that feeds it.

Your high-pressure air compressor is the heart and lungs of your PET blowing operation. Neglecting its basic maintenance is one of the fastest ways to cause system-wide problems and risk a catastrophic, expensive failure. Having a service kit on hand is essential.

I've seen beautiful, state-of-the-art production lines crippled by a poorly maintained compressor. The blow molder can only perform as well as the quality and consistency of the air it receives. Thinking you can save money by skipping a service is a classic example of being "penny wise and pound foolish." Let's talk about the simple rules that will keep your powerhouse running strong.

The 4000-Hour Service Rule

In the world of high-pressure piston compressors used for PET bottling, the "4000-hour service" is the industry standard for a reason. It is the critical preventative maintenance interval that addresses the most common wear items.

- What is it? A 4000-hour service is a scheduled maintenance event where key consumables are replaced. This typically includes changing the lubricating oil, replacing the oil filter, replacing the air intake filters, and sometimes replacing key seals or valve components.

- Why is it Critical?

- Oil Breakdown: The oil in a high-pressure compressor works incredibly hard. Over time, it breaks down, losing its ability to lubricate effectively. It also becomes contaminated with microscopic wear particles. Running on old oil is like running your car's engine without an oil change—it leads to rapid wear and overheating.

- Filter Clogging: Air and oil filters collect contaminants. Once they become clogged, they restrict flow. A clogged air filter makes the compressor work harder to draw in air. A clogged oil filter can starve the bearings of lubrication.

- Preventing Catastrophe: Sticking to this schedule allows a technician to spot small problems (like a minor leak or an unusual noise) before they turn into a major failure, like a seized crankshaft or a broken connecting rod, which can cost tens of thousands of dollars to repair.

- What are the Risks of Delaying? I've seen the consequences firsthand. Delaying service can lead to:

- Contaminated Air: Degraded oil can get past the piston rings and enter the high-pressure air stream. This "oil carry-over" will then travel down the lines and contaminate your entire pneumatic system, fouling your expensive

high-pressure valvesand causing them to fail prematurely. - Reduced Efficiency: A poorly maintained compressor has to work harder to produce the same pressure, consuming more electricity and increasing your operating costs.

- Complete Failure: The worst-case scenario. A catastrophic failure not only costs a fortune to repair but will shut down your entire production line for days or even weeks while you wait for major components. I've seen some operations be tempted to run their whole line with just one compressor, and while it's possible, it leaves absolutely no room for error or downtime. Having a robust and well-maintained air system is paramount.

- Contaminated Air: Degraded oil can get past the piston rings and enter the high-pressure air stream. This "oil carry-over" will then travel down the lines and contaminate your entire pneumatic system, fouling your expensive

Essential Compressor Spares to Have on Hand

You don't need to be a compressor expert, but you do need to have the basic service items ready for your maintenance team or service technician. This is the air compressor maintenance equivalent of the "Critical 10" for your blower.

Here is a basic preventative maintenance checklist and the parts you should have on your shelf.

| Maintenance Task | Frequency | Spares Needed On-Hand | Purpose |

|---|---|---|---|

| Check Oil Level | Daily | 1 full oil change worth of OEM Lubricating Oil. | Ensures proper lubrication of all moving parts. |

| Inspect/Replace Air Filters | Weekly / Monthly | 2-3 sets of Air Filter Elements. | Prevents dirt and dust from entering the compressor. |

| Drain Water Separators | Daily | N/A | Removes condensed water from the compressed air. |

| Perform 4000-Hour Service | Every 4000 hours of operation | One complete "4000-Hour Service Kit" from the manufacturer. | Includes oil, oil filter, air filters, and often key seals or valve plates needed for the service. |

Having a complete 4000-hour kit on the shelf is the smartest thing you can do. When your machine's hour meter approaches the service interval, you can schedule the maintenance without having to worry about ordering parts and waiting for them to arrive. It turns maintenance from a reactive headache into a proactive, scheduled event.

From List to Strategy: Building Your Custom "Shutdown Prevention" Kit?

This list of 10 parts is a great starting point, but I know what you're thinking. My machine is older. My production volume is unique. How do I know exactly what I need without overspending?

The answer is to turn this list into a living strategy. You must create a custom "Shutdown Prevention Kit" tailored specifically to your operation. This is about being smart and strategic with your inventory, ensuring you have the highest return on investment for every dollar you spend on bottle machine parts list management.

Over my 16 years of working with over 300 clients, I've developed a simple framework to help them build this custom kit. It's not about just buying one of everything. It's about understanding risk and prioritizing the parts that will save you the most money and stress when they fail. This process empowers you to take control of your maintenance budget and your production uptime.

Step 1: Analyze Your Machine and Operation

The first step is to look at the specific context of your equipment and how you use it.

- Machine Age and Model:

- Newer Machines: Tend to have more complex electronics and proprietary sensors. For these machines, having an extra power supply and the exact OEM sensors is crucial, as generic replacements often don't work.

- Older Machines: These have likely had their electronic quirks worked out, but their mechanical components have seen millions of cycles. For older workhorses, I'd place a heavier emphasis on stocking cylinder seal kits, extra stretch rods, and key bearings.

- Production Volume and Schedule:

- 24/7 Operation: If you are running three shifts, seven days a week, your wear rate for all components will be three times higher than a single-shift operation. Your on-hand inventory needs to be deeper. You will wear out a set of seals much faster, and a heating lamp's lifespan in months will be much shorter.

- Single-Shift Operation: You have more downtime available for maintenance, but a shutdown during your single production shift is just as costly. Your focus should be on having the "machine down" parts from the Critical 10 to ensure you can recover from a failure within the same day.

- Number of Identical Machines: If you have multiple identical bottle blowing machine models, you can create a shared pool of more expensive spares, like a complete high-pressure valve unit or a spare PLC. This is a very cost-effective way to manage inventory.

Step 2: Review Your Maintenance History

Your own data is your most powerful tool. If you are not already doing it, start today: keep a simple log of every repair and part replacement.

- What to Track: Log the date, the machine number, the part that failed, the symptoms of the failure, and the hours on the machine.

- Look for Patterns: After six months, you will start to see patterns. Is the same sensor on cavity #3 failing every two months? Perhaps there's an alignment issue. Are you replacing seals on a specific valve more than others? Maybe the valve body itself has a scratch. This data is invaluable. It tells you exactly where your weaknesses are and allows you to stock parts based on evidence, not just a generic list. This historical data is the foundation of a true

preventative maintenance checklist.

Step 3: Categorize Your Spares (The A-B-C Method)

Now, take the master list of potential spares and categorize them. This transforms your list into an actionable inventory strategy.

| Category | Description | Examples | Inventory Strategy |

|---|---|---|---|

| Category A: "On-Site" | Critical, machine-down parts. A failure of one of these parts will stop production immediately, and you cannot operate without it. | Heating Lamps, Power Supply, Key Sensors, Seals & O-rings, Air Filters, High-Pressure Valve Seal Kit. | Must have on your shelf at all times. The cost of the part is insignificant compared to the cost of the downtime. |

| Category B: "Supplier Stock" | Important parts that cause a shutdown but may fail less frequently. Or parts that you can temporarily work around. | A complete Action Valve, a spare Stretch Rod set, Cylinder Seal Kits, Grippers. | Confirm your supplier has these in stock for quick (1-2 day) delivery. You might keep one on hand if your supplier is far away or if your data shows frequent failures. |

| Category C: "Order on Demand" | Major, expensive components that rarely fail. | The main PLC unit, a servo motor, the HMI touch screen, a major casting for the clamp unit. | Do not stock these. The carrying cost is too high. Rely on your supplier's ability to source these when needed. |

This A-B-C method allows you to focus your budget on Category A, which gives you the highest possible protection against downtime for the lowest investment. It's the core of smart blow molding machine maintenance. It also gives you a clear set of questions to ask your machine supplier about their parts availability for Category B items.

Your Supplier as a Partner: Predicting Needs and Ensuring Availability?

You've identified a broken part, but finding the exact part number is a nightmare. You finally find it and call your supplier, only to hear the dreaded words: "It's on backorder from the factory."

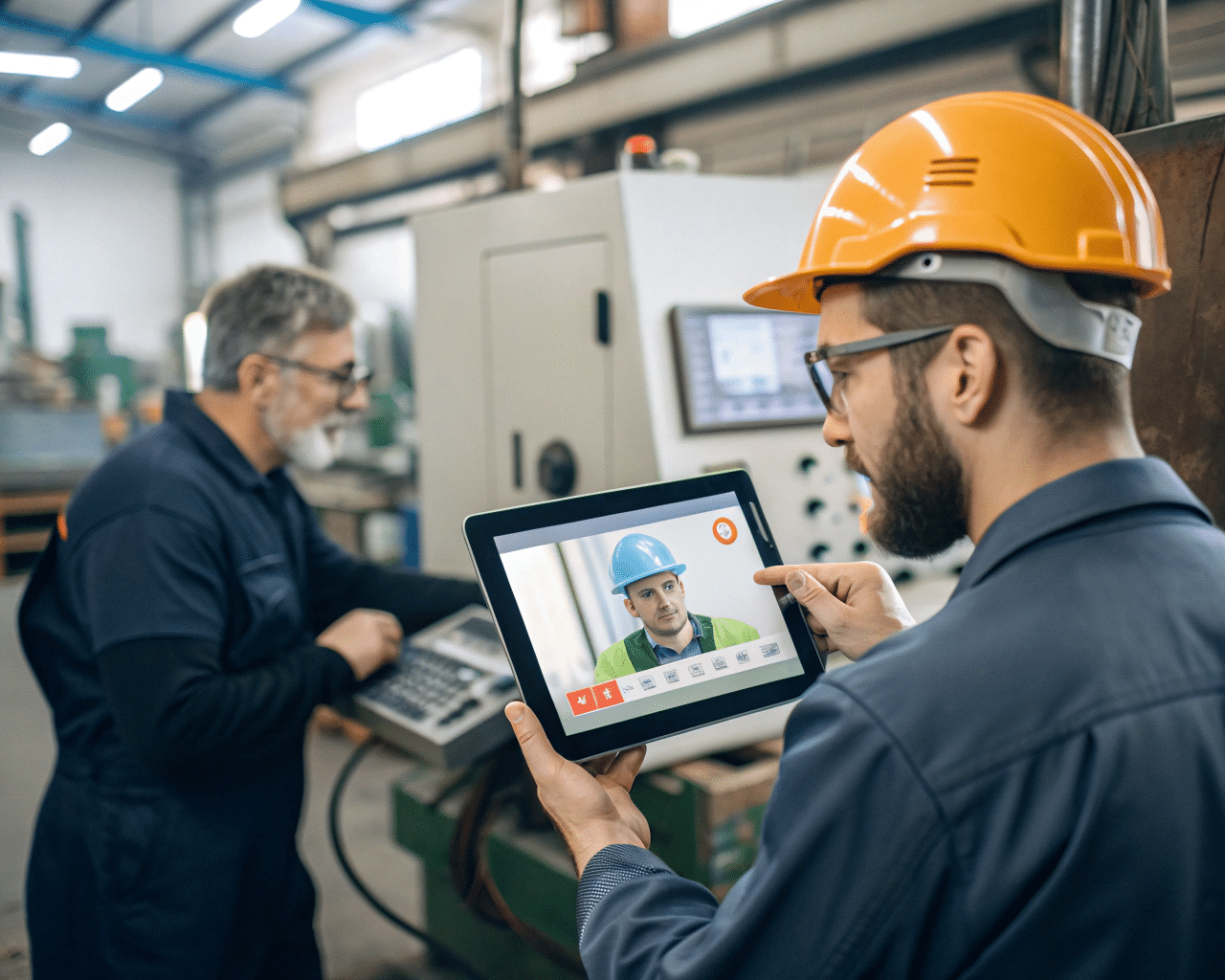

This is a scenario that plays out far too often. A great equipment supplier should be more than just a company that sells you a machine; they must be a long-term partner in your success. A crucial part of this partnership is their approach to spare parts and support. They should help you predict your needs and guarantee the availability of components to minimize downtime.

In my 16 years of delivering bottling solutions, I've always seen my role as extending far beyond the initial sale. The free spare parts list I provide with every machine isn't just a sales gimmick; it's the start of a critical conversation about uptime. A supplier who doesn't talk to you about critical spare parts from day one is not fully invested in your operational success.

What You Should Expect from a True Partner

When you are evaluating a supplier for a new bottle blowing machine, you should look for these key indicators of a strong partnership:

- Proactive Recommendations: A good supplier won't wait for you to have a problem. From the very beginning, they should provide you with a recommended spare parts list tailored to your specific machine configuration and your expected production volume. At iBottler, this list is based on data aggregated from hundreds of machines in the field. We know what parts fail most often and under what conditions. We use this experience to give you a scientifically-backed starting point for your inventory.

- Clear and Comprehensive Documentation: The machine's technical manual should be your bible. It must include:

- Exploded-view Diagrams: Detailed drawings that show how everything fits together.

- Bill of Materials (BOM): A complete list of every single component, right down to the last nut and bolt.

- Clear Part Numbers: Every component should have a unique, easy-to-read part number.

This level of detail is crucial. It eliminates ambiguity and ensures that when you call for a "preform loading sensor," you get the exact right one for your machine.

- Guaranteed Stock of Critical Parts: This is a question you must ask any potential supplier: "Do you keep the Category A (On-Site) parts for my machine in stock at your local facility?" The answer must be "yes." Waiting for a heating lamp or a power supply to be shipped from a factory overseas is unacceptable in a modern manufacturing environment. A supplier committed to your uptime will invest in their own inventory to support the machines they sell.

- Expert Technical Support: Sometimes, the hardest part isn't changing the part; it's figuring out which part is broken. This is where expert support becomes invaluable. Your supplier should have technicians who can help you diagnose problems over the phone or via video call. My experience with the Australian client is a perfect example. We solved a "machine down" situation in 30 minutes from opposite sides of the world because my team has the hands-on experience to understand the symptoms and guide the client to the solution. This is the kind of partnership that truly saves you money.

For example, when a client is designing a new bottle, we don't just think about the blow bottle mold; we think about the entire production process. We might provide guidance on preform neck size selection to ensure compatibility and efficiency. This holistic, partnership-based approach is what prevents problems before they start.

Conclusion: From Reactive Repairs to Proactive Uptime?

Are you tired of the stress that comes with unexpected shutdowns? Are you constantly in "fire-fighting" mode, reacting to problems as they happen? There is a much better, more profitable way to run your operation.

The key is to shift your entire mindset. A well-stocked spare parts shelf isn't an expense; it's a strategic investment. It transforms your maintenance from a reactive scramble into a proactive plan, ensuring consistent, predictable, and highly profitable production uptime.

For over 16 years, I have seen the stark difference between companies that embrace this proactive philosophy and those that don't. The ones who plan ahead are the ones who grow, innovate, and lead their markets. They are not held hostage by the fear of a breakdown. The ones who are constantly reacting are always struggling, falling behind on orders, and dealing with frustrated staff and customers.

The journey from reactive to proactive begins with a single step: taking the lists and strategies we've discussed and putting them into action.

The Transformation to Proactive Uptime

When you move from being a reactive "firefighter" to a proactive "planner," your entire business benefits:

- Increased Profitability: This is the ultimate goal. Every hour of uptime you gain is an hour of pure profit added back to your bottom line. Reducing downtime is the single most impactful thing you can do to improve your factory's financial performance.

- Reduced Stress: For plant managers, maintenance staff, and operators, a predictable production schedule is a godsend. It eliminates the chaos and frantic pressure of unexpected breakdowns. It creates a calmer, safer, and more professional work environment.

- Improved Product Quality: A well-maintained machine is a consistent machine. When parts are replaced before they fail catastrophically, the machine operates within its ideal parameters, producing higher quality bottles with fewer defects.

- Predictable Scheduling: With proactive maintenance, you are in control. You can schedule repairs and part replacements during planned downtime, rather than having your schedule dictated by random failures. This allows you to meet customer deadlines with confidence.

Your First Step

Don't let this be just another article you read. Take action today. Go to your spare parts shelf. Use the "Critical 10" list as a checklist. What do you have? What are you missing? Start the conversation with your team and your supplier.

Creating your "Shutdown Prevention Kit" is not a cost. It is you buying back your future production time. It's the best insurance policy you can have for your factory's health and your own peace of mind. It's the definitive step in taking control of your production and moving from reactive repairs to proactive, profitable uptime.

Conclusion

Stocking the right spare parts is not an expense; it is the most valuable insurance you can buy for your production line. It's the simple key to maximizing your uptime and profitability.

Frequently Asked Questions (FAQs)

1. I just bought a new machine. Which 3-5 parts from this list are the absolute most critical to buy on day one?

For a brand new machine, I would focus on the parts that fail most frequently and are easiest to replace. My "Day One Starter Kit" would be:

- Heating Lamps: At least 5-10 spare lamps. They are the #1 consumable.

- A Full Seal & O-ring Kit: A small leak can stop you just as easily as a major failure. This kit is invaluable.

- Key Sensors: Specifically, the preform detection and bottle-out detection sensors. A failure here is common and will stop the machine immediately.

- Air Filter Elements: Start with good habits. Having these on hand ensures you will perform the first critical filter change on time.

- Switching Power Supply (24V DC): This is your "get out of jail free" card for the most confusing "dead machine" scenarios.

2. Is it safe to use non-OEM (third-party) spare parts for components like seals or filters?

This is a great question about balancing cost and risk. For simple, standardized components, high-quality third-party parts can be a good option.

- Safe to try (with caution): Standard-size O-rings (ensure the material - Viton, NBR, etc. - is correct for the application), air filter elements from reputable filter manufacturers.

- Risky / Avoid: Critical, precision components. I strongly recommend using only OEM parts for

high-pressure valves, complex electronic sensors, the switching power supply, and stretch rods. The risk of incompatibility, poor performance, or premature failure with a non-OEM part in these areas is too high and could cause even more damage.

3. What are the risks if I delay the 4000-hour service for my air compressor?

Delaying the 4000-hour service is one of the most dangerous financial gambles you can make. The immediate risks are:

- Oil Carry-over: Old, broken-down oil will get into your air lines, contaminating every valve and cylinder in your blow molder. This can cause thousands of dollars in damage.

- Overheating: Clogged filters and old oil reduce cooling and lubrication efficiency, which can lead to the compressor overheating and shutting down, or worse, seizing completely.

- Catastrophic Failure: The ultimate risk is a major mechanical failure like a broken crankshaft. This is an extremely expensive repair and will shut down your entire plant for an extended period. The cost of a single 4000-hour service kit is microscopic compared to the cost of a compressor rebuild.

4. How often should I inspect the wear parts on my blow mold, like the mold lips?

Mold inspection should be a routine part of your operation. I recommend a two-level approach:

- Daily (Pre-shift): A quick visual and tactile inspection by the operator. Before starting production, with the machine safely locked out, they should visually inspect the cooling connections for any drips and run a finger over the mold parting line (lips) to feel for any new dings or nicks. This takes 60 seconds.

- Weekly/Monthly (Deeper Inspection): As part of your scheduled preventative maintenance, you should do a more thorough check. Clean the mold surfaces, check the guide pillars for any excessive play or looseness, and inspect the vent tracks to ensure they are clear. The exact frequency depends on your production volume (e.g., weekly for a 24/7 operation, monthly for a single-shift).

5. How can I find the exact part number for a component on my machine to ensure I order the correct one from my supplier?

Finding the correct part number is essential to avoid costly mistakes. Here is the process I teach my clients:

- Start with the Manual: Your first and best resource is the technical manual supplied with your machine. Look for the "Spare Parts" section, which should have exploded-view diagrams and a corresponding parts list (Bill of Materials).

- Look on the Part Itself: Many components, especially electrical ones like sensors or power supplies, will have the part number and manufacturer's name printed directly on them.

- Take Clear Photographs: If you can't find the number, take several clear, well-lit photos of the part from multiple angles. Be sure to include photos of any labels, tags, or engravings.

- Contact Your Supplier: Send the photos, along with your machine's model and serial number, to your supplier's technical support team. A good supplier with experienced staff can often identify the part for you and ensure you get the exact correct replacement.

Your Free "Shutdown Prevention" Checklist

To help you put this knowledge into action immediately, I've created a simple, one-page PDF checklist of the 10 critical spare parts, plus the key mold and compressor items.

You can download it, print it, and take it right to your stockroom. Use it to audit your current inventory and create a shopping list. Pin it to the wall in your maintenance area as a constant reminder of the parts that form the foundation of a proactive uptime strategy.

Printable Checklist: The 10 Critical Blower Spare Parts

Company:

Machine Model:

Date: ___

Part 1: Core Electrical & Control Components

| Priority | Component | Status (✔) | On-Hand Quantity | Notes (Part #, etc.) |

|---|---|---|---|---|

| 1 | Heating Lamps | ☐ | Recommend 10% of total | |

| 2 | Switching Power Supply (24V DC) | ☐ | Must be exact model | |

| 3 | Sensors (Key Positions) | ☐ | Preform detect, bottle out | |

| 4 | High-Pressure Valve(s) (or Seal Kit) | ☐ | ||

| 5 | Action Valves (Common Types) | ☐ | Identify most used models |

Part 2: Essential Mechanical Wear & Sealing Parts

| Priority | Component | Status (✔) | On-Hand Quantity | Notes (Part #, etc.) |

|---|---|---|---|---|

| 6 | Stretch Rods | ☐ | Full set recommended | |

| 7 | Seals & O-rings | ☐ | Comprehensive kit is best | |

| 8 | Cylinder Seal Kits | ☐ | For critical cylinders (clamp, etc.) | |

| 9 | Grippers | ☐ | Preform/bottle transfer | |

| 10 | Air Filter Elements | ☐ | Main machine air inlet |

Bonus: System Essentials

| Priority | Component | Status (✔) | On-Hand Quantity | Notes (Part #, etc.) |

|---|---|---|---|---|

| — | Blow Mold Wear Parts | ☐ | Cooling connectors & seals | |

| — | Air Compressor Service Kit | ☐ | 4000-hour service kit |

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

📞 Contact: Vivian

🏭 Zhongshan Jindong Machinery Co., Ltd.

🌍 www.ibottler.com

📧 Vivian@ibottler.com | 💬 WhatsApp: +86-13106288777

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr