Blow mold manufacturing

Our Manufacturing Process

01

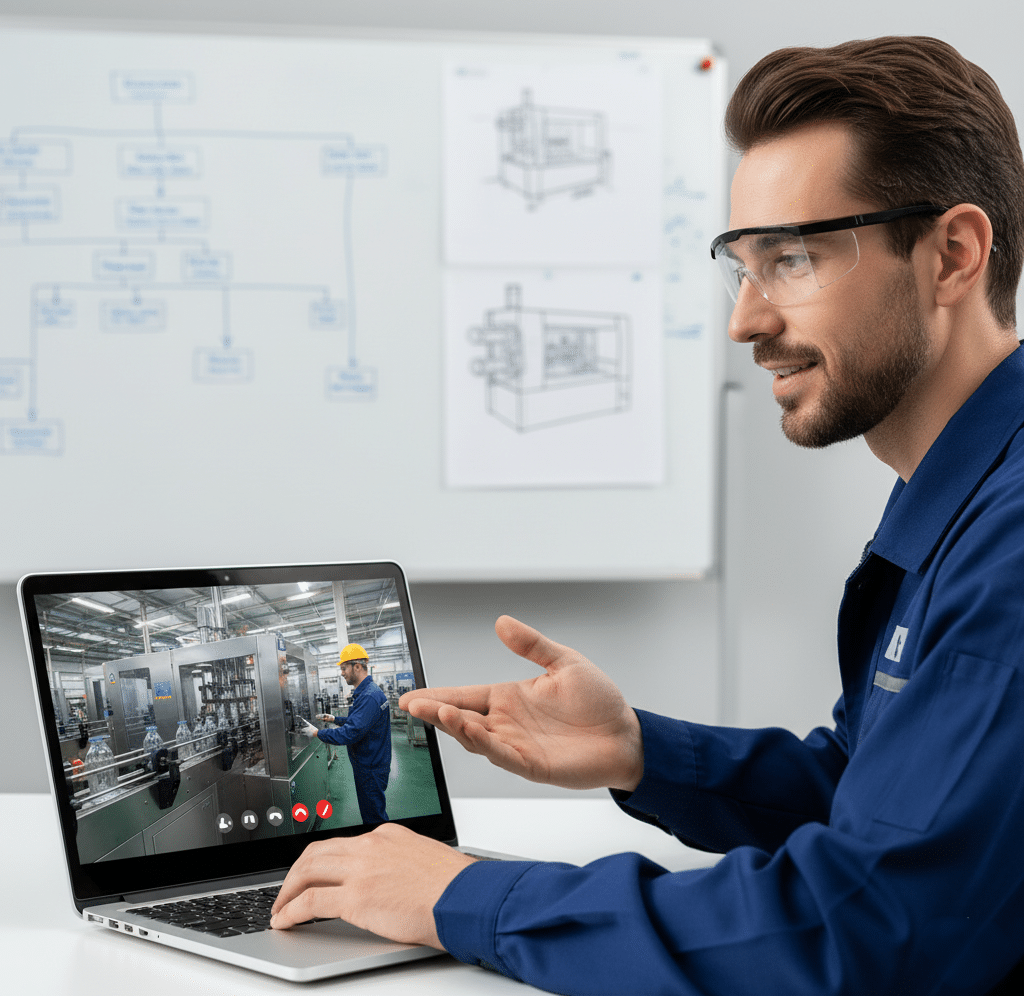

Project Consultation & Bottle Design

.png)

02

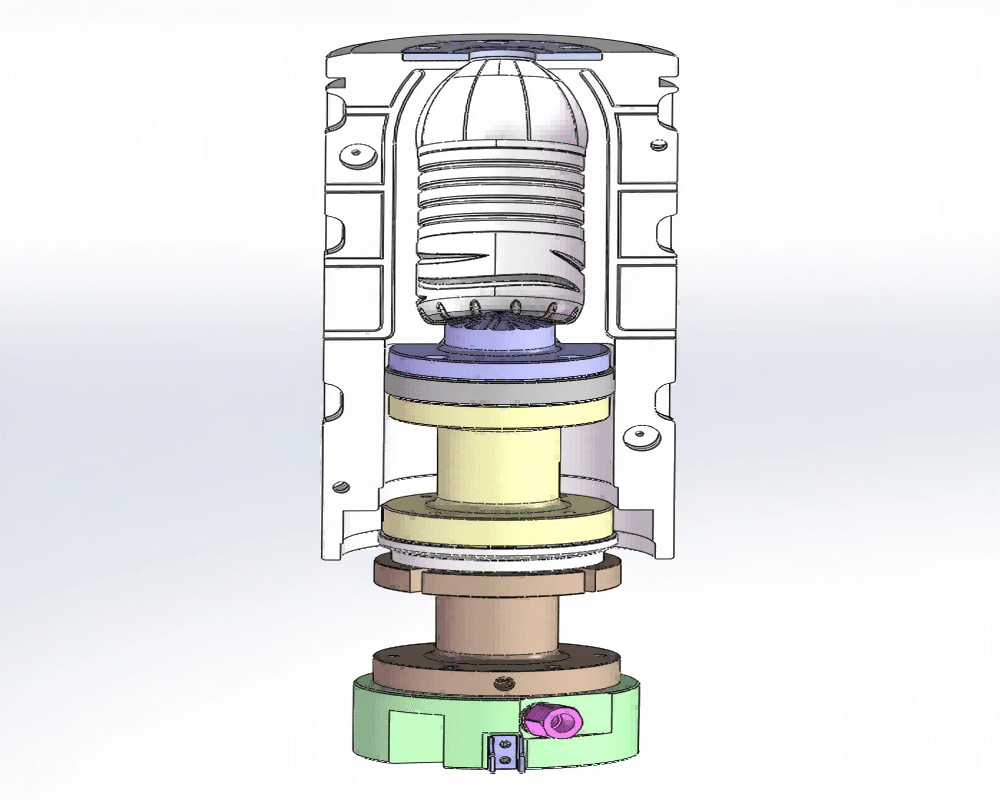

3D Modeling & Structural Validation

03

High-Precision CNC Machining

04

Fine Polishing & Mold Assembly

05

Quality Inspection & Mold Trial

06

Final Approval & Shipment

Helping You Launch Bottle Projects Faster

Value-added Services

Free Bottle Design

Free Sample Trial

Bottle Performance Test

In-house R&D, Serving Global Clients

Fast Blowing

Custom Mold Process

STEP.1

Requirement Confirmation

STEP.2

Mold Design

STEP.3

Mold Manufacturing

STEP.4

Testing & Delivery

.png)

Solve your problems effectively

FAQ

A: Yes, we have a professional installation team with rich installation experience and can provide on-site installation service to ensure that your equipment is put into production quickly. Our engineers will provide you with detailed operation training during the installation process to help your team get started as soon as possible.

A: We value after-sales service and have a professional team on standby to provide timely remote technical support and maintenance services. In addition, we provide spare parts services to ensure the normal operation of the equipment, minimize downtime, and protect your production.

A: Of course, we have a database of more than 80% brands of blow molding machine molds, which can be well matched with your blow molding machine. Of course, we will also assist you in measuring the installation data of the mold to ensure that the installation size is correct and can be 100% produced.

A: Our blow molding machines are made with high-precision processing equipment after 20 years of factory experience. The core parts of the machine are made of high-quality materials to ensure stability and durability even under long-term production. We also provide long-term after-sales support so that you don’t have to worry about it. docking, according to your factory to provide the whole line design and planning, to product customization, installation and commissioning to produce bottled mineral water.

Why did we choose this bottle blowing machine?

Their real feedback