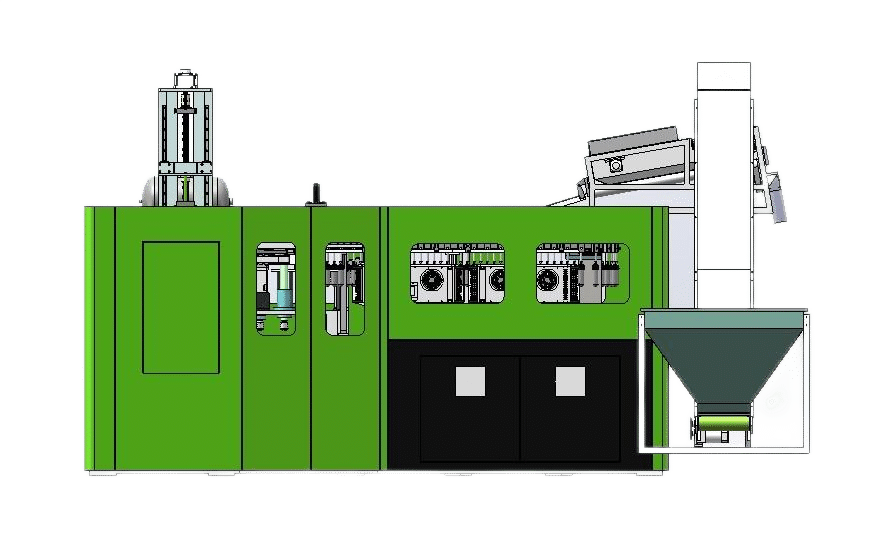

Fully Automatic, Maximum Efficiency

High-speed, energy-saving blow molding machine designed for seamless production and unmatched performance!

In-house R&D, Serving Global Clients

Fast Blowing

We have been focusing on the research and development and manufacturing of PET bottle blowing machines for 20 years. We have independent programming systems, high-speed energy-saving solutions, adaptability to a variety of bottle types and filling lines, support remote services and global installation, and have cooperated with more than 200 customer projects in food and beverage, daily chemicals, etc.

Smart · Efficient · Easy ,All-in-One Blow System

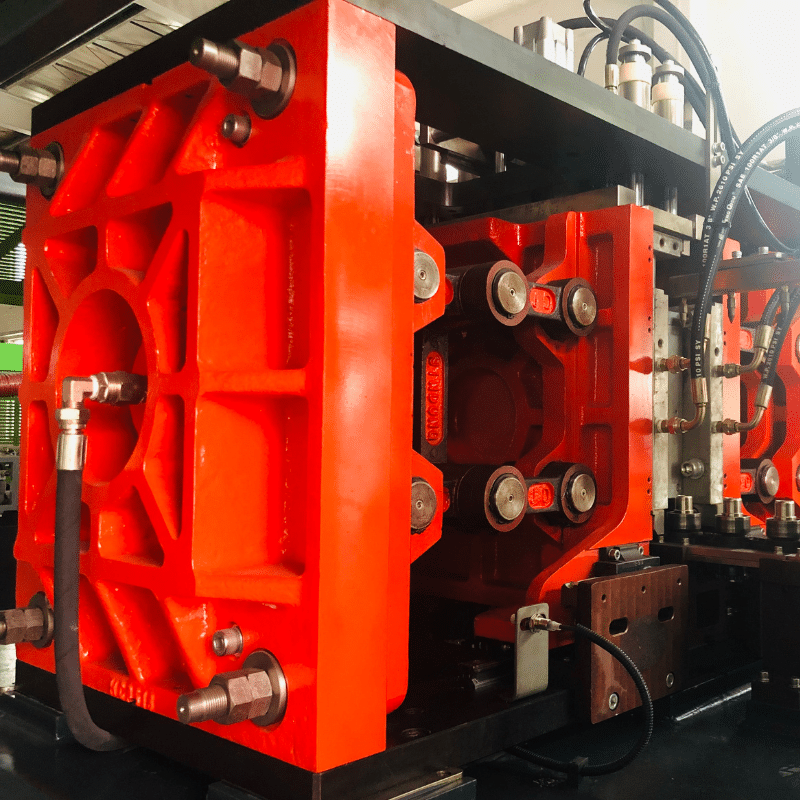

Better structure

Smart Servo Control

High-performance servo motors drive key actions like stretching, transfer, and clamping for rapid, precise operation. Combined with a large, intuitive touchscreen interface, parameter setup is clear and easy, enabling efficient and stable production effortlessly.

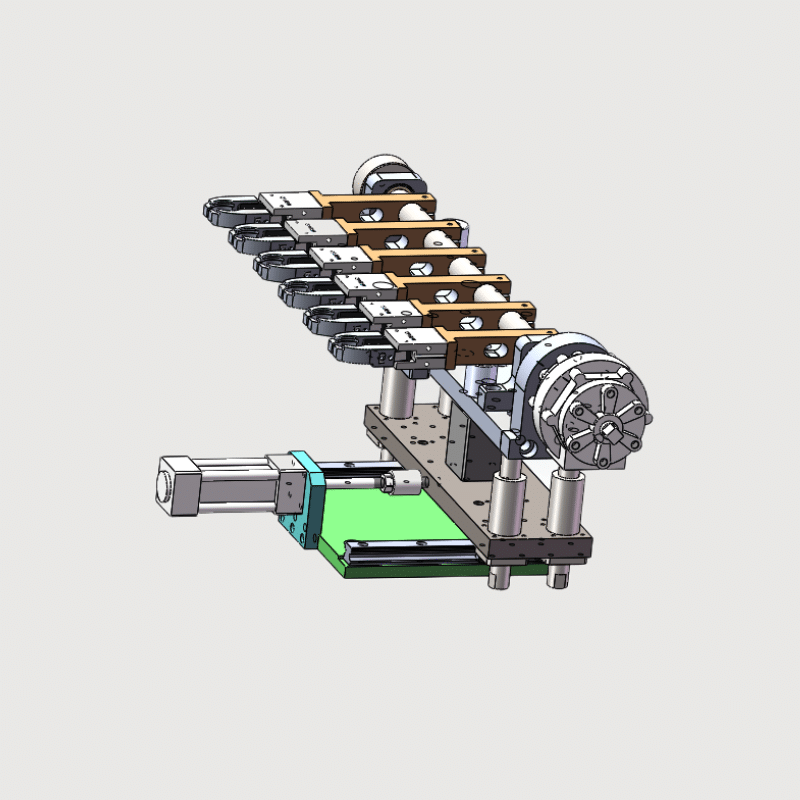

Automated Handling

Features intelligent robotic arms for fully automated preform loading and finished bottle removal. This enables continuous, unmanned production, reducing labor costs, minimizing manual contact, and ensuring efficient, stable line operation.

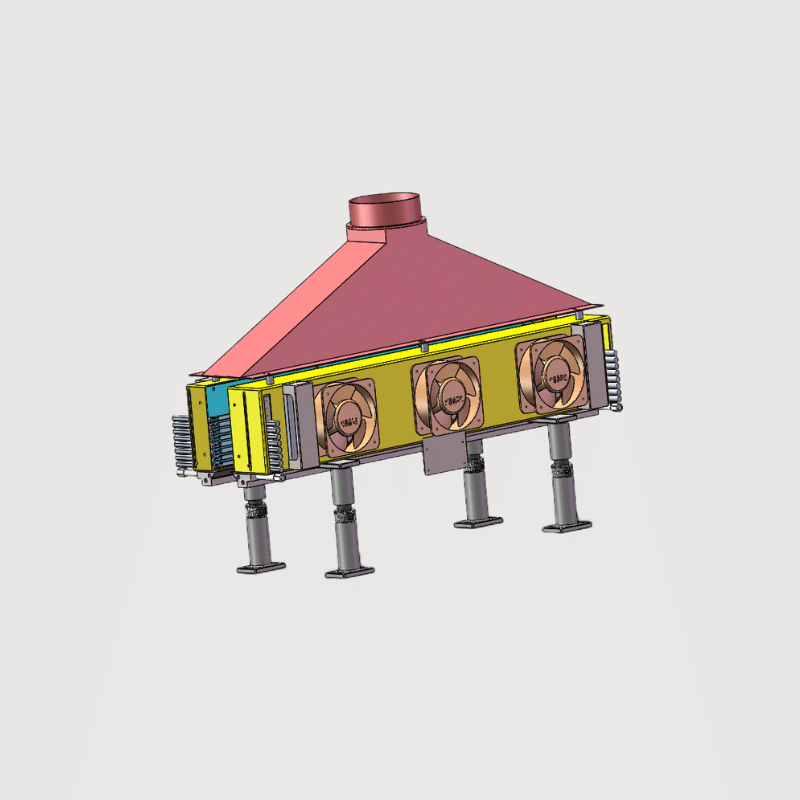

Precision Heating Control

An innovative heating system allows independent, precise temperature control for each lamp zone. Store and recall optimized heating profiles for different molds, ensuring uniform preform heating, adaptability, and consistent product quality.

Full Servo Precision

Description: Full servo drive, stretch & clamp ensures high speed, precision, and stability.

Energy Valve

Equipped with Parker high-pressure valve and air recycling to reduce energy consumption significantly

Smart Panel

Over 90% of electrical parts are from top global brands, ensuring stable performance and longer machine life

Smart Touch Control

HD touch screen interface offers intuitive control for easy settings & monitoring.

From Design to Delivery, Start Your Bottling Line with Ease

one-stop solution

| NO. | Name | Parameters |

|---|---|---|

| 1 | Automatic bottle blowing machine(Variable pitch heating) | 1/2 cavities |

| 2 | Output | 600/1200PCS/H |

| 3 | Maximum caliber/capacity | 55mm/20L |

| NO. | Name | Parameters |

|---|---|---|

| 1 | Automatic bottle blowing machine(Isometric heating) | 4-cavities |

| 2 | Output | 7000-8000 PCS/H |

| 3 | Maximum caliber/capacity | 38mm/2L |

| NO. | Name | Parameters |

|---|---|---|

| 1 | Automatic bottle blowing machine(Isometric heating) | 6- cavities |

| 2 | Output | 8000-9000 PCS/H |

| 3 | Maximum caliber/capacity | 38mm/0.8L |

| NO. | Name | Parameters |

|---|---|---|

| 1 | Automatic bottle blowing machine(Isometric heating) | 2 cavities |

| 2 | Output | 1800-2400PCS/H |

| 3 | Maximum caliber/capacity | 38mm/2L |

| NO. | Name | Parameters |

|---|---|---|

| 1 | Automatic bottle blowing machine(Isometric heating) | 2 cavities |

| 2 | Output | 10000-2000 PCS/H |

| 3 | Maximum caliber/capacity | 120mm/2L |

We offer a diverse range of blow molding machines to meet various production and bottle design needs, with full customization available. Our optimized bottle designs help reduce material costs and enhance molding efficiency and product yield—empowering your production line with higher performance and lower costs.

| NO. | Name | Brand | Name | Brand |

|---|---|---|---|---|

| 1 | Programmable Controller PLC | Omron | Mould closing servo motor | Yaskawa |

| 2 | High pressure air blowing combination valve | Parker | Robot Rotary Cylinder | CKD |

| 3 | Action valve | SMC | Action valve | Schneider |

| 4 | Frequency converter | Bosch Rexroth | Stepper servo motor | Yaskawa |

| 5 | Operation panel | Kunlun Tongtai | Bottom mold cylinder | MetalWork |

Why did we choose this bottle blowing machine?

Their real feedback

This blow molding machine is very stable, almost no downtime, output is satisfying. Their service team responds quickly with professional technical support. Reliable partner.

Smooth process from initial contact to installation. Machine performance meets our requirements, truly boosting production efficiency. A solid supplier choice

Bottles from this machine are excellent quality: uniform thickness, high clarity. Operation is simpler than expected; easy worker training and quick to master.