Are you buying a PET mould? You are not just buying metal. You are buying your product's future, and a bad choice costs thousands.

This guide ranks China's Top 10 PET blow mould factories. We focus on what matters: custom bottle design, lightweighting ability, and machine integration. This helps you find a partner, not just a supplier.

| Key Takeaway | Why It Matters for Buyers |

|---|---|

| Value is in Grams, Not Dollars | A factory that masters bottle lightweighting saves you more on materials than a "cheap" mold. |

| Integration is Risk Management | Buying a mold and machine from one expert (like iBottler) means one company is responsible for performance. |

| Giants vs. Specialists | Giants (XL, Tech-Long) are for massive, standard orders. Specialists (iBottler) are for custom design and flexibility. |

| Design > Materials | A smart structural design (for pressure) is more valuable than just using expensive 7075 aluminum. |

I have been in this business for 20 years. I have seen too many buyers make the same mistakes. You must understand what you are really buying. Let's break down the real value.

What Is the True Value of a "Top" PET Blow Mould?

You ask for the price of a mould. But this price means nothing. The real cost shows up later, in material waste and low production speed.

The true value is your bottle's future competitiveness. It is measured by four things: bottle design and lightweighting ability, structural strength, mold-to-machine matching, and finally, the materials and precision used.

I'm Vivian. I work at iBottler, which is also called Jindong Machinery. I must be very honest with you. Stop asking your supplier, "How much does the mould cost?" This is the wrong question. You must start asking, "How many grams will my finished bottle weigh?"

A "cheap" mould that produces a heavy, weak bottle is the most expensive thing you can buy. A successful "lightweighting" design from a true expert can save you tens of thousands of dollars in PET material costs every year. That is the mould's real value. You need a "process expert" who understands bottles, materials, and machines. You do not want just a "mould craftsman."

1. Bottle Design and Lightweighting Ability

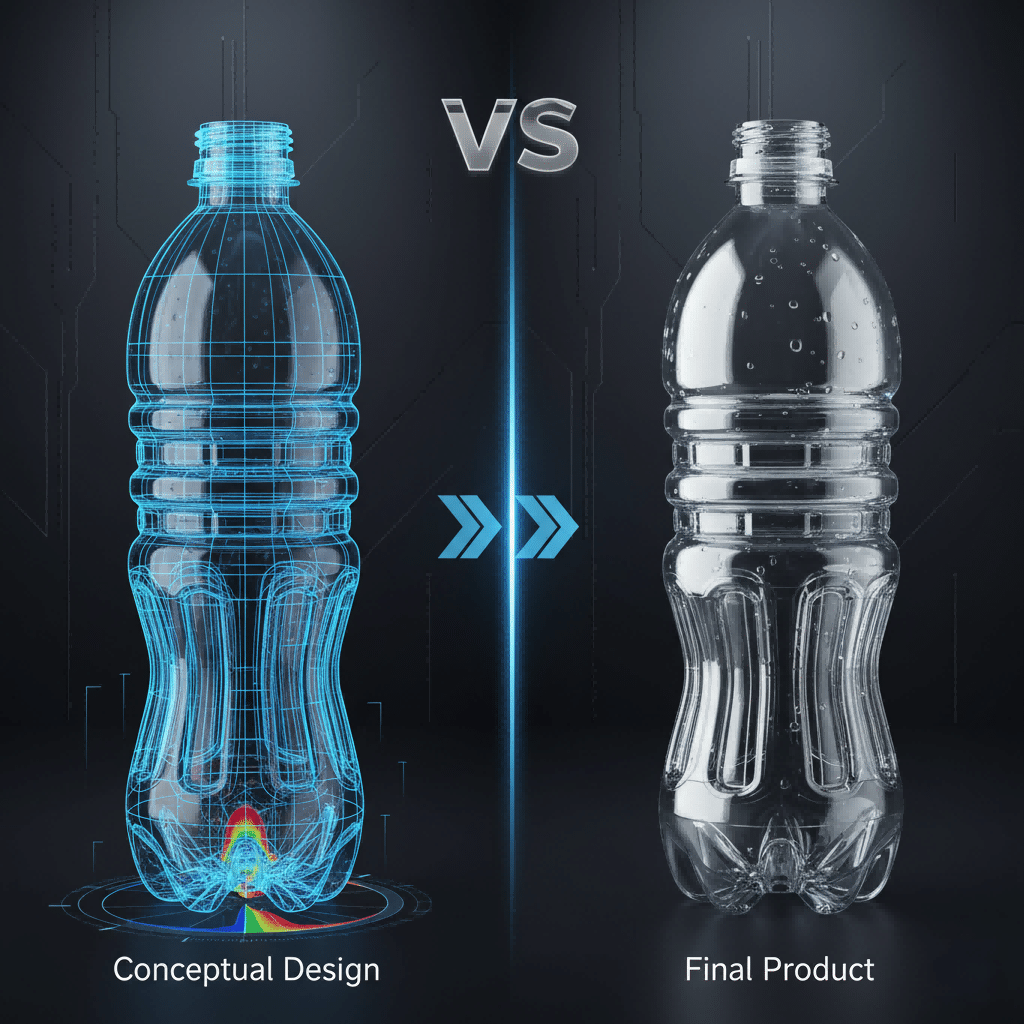

This is the most important factor. A mould is not just a cavity. It is an engineering tool. The factory you choose must be a PET bottle design expert.

What does this mean? It means they do not just copy your sample or 3D file. They analyze it. They ask hard questions. "Can we make this 1 gram lighter?" "Is this rib structure the most efficient for stacking?" "Can we change the base to save 0.5 grams and increase strength?"

I had a client from Africa last year. He wanted a 500ml water bottle. He brought me a sample from his competitor. It was 15 grams. It was a very old, heavy design. My engineering team and I studied it. We kept the brand look that he loved, but we redesigned the ribs and the base structure. We ran simulations. We presented him with a new design: 12.5 grams.

He was nervous. 2.5 grams seemed like a lot. But we guaranteed the performance. He produces 10 million bottles a year. That 2.5-gram saving equals 25,000 kilograms of PET resin saved. At today's market price, that is over $30,000 saved. Every. Single. Year.

The cost of my mould was forgotten in the first six months. He is now one of my best customers. This is what I mean by value. You are not buying metal; you are buying a lighter bottle.

2. Structural and Pressure Resistance

This is especially true for carbonated soft drinks (CSD). This is not just about looks. It is about physics. Your bottle must survive shipping. It must be stacked high in a hot warehouse. And if it holds a carbonated drink, it must withstand high internal pressure 24/7.

A cheap mould factory does not understand this. They will copy a "petaloid" base (the five-footed base) but not understand why it is shaped that way. The exact curves are designed to distribute stress. If the design is wrong, or if the mold cooling is bad, you get weak spots. This leads to bottles bursting.

What is the "craftsman's" solution? They just add more plastic. They make the base 2 grams heavier to fix the weakness. This is a terrible solution. It costs you a fortune.

The "expert's" solution is to fix the design. We analyze the stress points. We design a base that is both strong and light. We see so many common bottle defects, and most of them begin with a bad design, not bad material. A "process expert" knows how to design a CSD bottle that is lightweight but will not fail.

3. The 100% Mold-to-Machine Match

This is the secret almost everyone forgets. A mould is not a standalone product. It is one half of a system. The bottle blowing machine is the other half. They must work together perfectly.

A mould designed for a high-speed Sidel rotary machine has different heating and stretching needs than a mould for a linear machine. The stretching ratio, the heating parameters, the blowing pressure, the cooling time... everything is connected.

This is iBottler's biggest advantage. We manufacture both the mould and the machine. When my team designs your blow bottle mold, we already know exactly which machine it will run on. We know the heating box layout, the stretch speed, the air volume. The mould is optimized for that specific process.

When you buy a mould from Factory A and a machine from Factory B, they blame each other when there is a problem. The mould guy says, "Your machine heating is bad." The machine guy says, "Your mould cooling is bad." You are stuck in the middle.

When you buy from me, there is no one to blame. There is only one person responsible: me, Vivian. I guarantee it works. That is our "100% Match" promise.

4. Materials and Precision (The Final 10%)

Finally, we talk about the metal. Yes, materials matter. Good factories use high-quality 7075 aircraft-grade aluminum for the mold body. It has excellent heat transfer, which means faster cooling and a faster production cycle. They use S136 stainless steel for the mold base and neck inserts, because those areas get more wear.

Precision matters too. A high-quality CNC machine will create a "seamless" parting line, so your bottle looks clean.

But this is the last thing to check, not the first. A mould made from the best aluminum in the world, but with a heavy, weak bottle design, is still a bad mould. Good materials and precision are the minimum standard. They are not the main value.

| Feature | "Mould Craftsman" (Just a Factory) | "Process Expert" (A Partner) |

|---|---|---|

| Main Focus | Sells you a block of metal (the mold). | Sells you a profitable bottle (the result). |

| Key Question | "How much does the mold cost?" | "How many grams can we save?" |

| Service | Copies your drawing. | Designs, analyzes, and optimizes your bottle. |

| Risk | You are responsible for matching it to your machine. | Guarantees the mold and machine work together. |

| Value | Low upfront price. | Long-term savings on materials and efficiency. |

The 2025 China PET Blow Mould Factory Top 10 List: An Expert's View?

You see many "Top 10" lists online. They are often just advertisements. They do not tell you the real story or who is right for you.

This Top 10 list is based on my 20 years of industry experience. It is not an absolute ranking. It is a professional review focused on "bottle design" and "process integration" to help you find the right partner.

I want to be very clear. This list is my professional opinion as Vivian. I have competed with, worked with, and respected many of these companies for decades.

The "best" factory does not exist. The factory that is "best for you" does exist.

Before you read the names, you must define your own needs. I meet buyers every day. They are often in one of these three categories:

Category 1: The Global Giant

- Who you are: Coca-Cola, Pepsi, Danone, Nestle.

- What you need: Your needs are scale, reliability, and global standards. You need a supplier with massive capacity. They must have top-level ISO certification, strict QC, and the ability to make ten identical 96-cavity molds. Your bottle design is already fixed by your global headquarters. You just need perfect, high-speed execution.

- Recommendation: For you, giants like XL or Huayan are the correct choice.

Category 2: The Regional Champion

- Who you are: A large, established national water brand or beverage company.

- What you need: You are already big in your country. You need to expand. You need a complete, high-speed production line. You want a "turnkey" solution from one main supplier. You have a good budget (often over $1 million). You value speed and output (e.g., 20,000 to 40,000 bottles per hour).

- Recommendation: For you, a complete line provider like Tech-Long or Demark is a very strong choice.

Category 3: The Startup or Growing Brand (The Innovator)

- Who you are: This is who I love to work with. You have a new idea. A new juice, a craft soda, a new mineral water, a new "look."

- What you need: You need more than a mould. You need an engineering partner. You need someone to help you take a sketch and turn it into a real, functional, and beautiful bottle. You need 3D prototyping and validation. You need flexibility. You need a low barrier to entry. But you still demand high quality. Your biggest concern is risk. What if the bottle leaks? What if the mould does not fit your machine?

- Recommendation: For you, a specialist partner like iBottler is the best choice.

My list is not based on company size. It is not based on who sells the most molds. It is based on who they serve best and their core strength. My perspective is that of a "process expert." I value design, lightweighting, and machine integration above all else.

| Your Company Profile | Your Main Need | Recommended Factory Type | Example(s) |

|---|---|---|---|

| Global Mega-Brand | Extreme Scale, Standardization | Preform & Mold Giants | #1 XL, #2 Huayan |

| Large Regional Company | High-Speed Turnkey Lines | Complete Line Giants | #3 Tech-Long, #4 Leshan |

| Startup / Innovator | Custom Design, Flexibility, Low Risk | Process Integration Specialist | #7 iBottler (Jindong) |

| Experienced Factory (DIY) | Price-Competitive Mold Only | Taizhou Craftsmen | #9 Mega, #10 Topworks |

I remember a customer from South America. He went to one of the "giant" factories first with his new bottle idea. They told him the minimum order was four molds, and they would not change his design. He was discouraged.

He then came to me. He said, "Vivian, I just have this one idea." We spent a week doing 3D models. We printed samples. We found a way to save him 2 grams. We built him one blow bottle mold and one bottle blowing machine that were perfectly matched. Today, he has four of my lines. He became a regional champion. But he started as an innovator. He needed a partner who would grow with him.

This is why "best" is relative. This list respects the giants. But it is written to help the innovator. It is written to help you find the partner who will listen.

Why Do Giants Like Coca-Cola Choose #1 XL and #2 Huayan?

You want the best. You hear Coca-Cola uses XL and Huayan. So you think they must be the best for you. This can be a very costly mistake.

XL (Xinglian) and Huayan are China's industry benchmarks. They serve top global brands like Coca-Cola and Pepsi. Their core strength is high-cavity, high-stability preform molds and large-scale blow molds for massive, standardized production.

When we talk about the "top" of the Chinese mold industry, XL and Huayan are always the first names. They are giants. Their scale is enormous. Their client lists are a "who's who" of global food and beverage.

The Core Strength: Preform Molds

You must understand this clearly. The primary, core-competence of both XL and Huayan is not blow molds. It is PET preform molds.

A preform mold is an injection mold. It is a highly complex piece of engineering. It can have 72, 96, or even 128 cavities. It must inject molten PET perfectly into every cavity to create the "test-tube" shaped preforms. The neck finish (the threads) is formed here. This requires incredible precision, advanced hot-runner technology, and materials like S136 steel.

XL and Huayan are masters of this. They supply preforms (and the molds to make them) to the entire world.

Their Blow Mold Business

Because they serve giants like Coca-Cola, they also supply the blow molds that match the preform molds. These are for massive, high-speed rotary machines from companies like Sidel and Krones.

Their strength is standardization. Coca-Cola needs their 500ml bottle to be identical in Shanghai, Nairobi, and Mexico City. XL and Huayan deliver this reliability at a massive scale. Their focus is on 0.01mm tolerance, 24/7 reliability, and molds that can run for 10 million cycles without stopping. They are not in the "custom design" business. They are in the "mass-scale precision" business.

My Insight: Are They for You?

Here is my honest advice as Vivian. If you are a startup, XL and Huayan are probably not the right fit. I say this with respect. They are built for "giants."

Think of it this way: they build cannons to win wars. If you need a single, custom-made rifle, they are not the right workshop.

A client once told me he sent an inquiry to one of these giants for two blow molds. He had a great new bottle design. He was very proud of it. The sales team replied six weeks later. They said the design was "non-standard" and the minimum order was 8 molds. He was crushed.

He came to iBottler. We had his 3D printed samples in his hand in one week. We built his two molds. This is the difference. They are a "supertanker." We are a "speedboat." You need to know what kind of partner you are looking for. If you just need a standard 48-cavity PCO preform mold, they are an excellent choice. If you are designing a new bottle from scratch, you need a design expert.

| Feature | XL & Huayan (The Giants) | The Startup Buyer |

|---|---|---|

| Primary Product | High-cavity Preform Molds | Custom-designed bottles |

| Ideal Customer | Coca-Cola, Pepsi, Danone | New water/juice brand |

| Core Value | Standardization, massive scale | Flexibility, unique design |

| Service Model | Serves purchasing departments | Partners with entrepreneurs |

| Cost | Very high, high minimum order | Competitive, low barrier to entry |

Are Complete "Turnkey" Lines from #3 Tech-Long and #4 Leshan Your Best Bet?

You need a full production line. It seems easy to buy everything from one giant supplier. But this convenience comes at a very high price, in both money and flexibility.

Tech-Long (Dalong) and Leshan are China's top-tier "complete line" manufacturers. They provide entire bottling plants, from blowing to filling to packing. They are excellent for mature companies needing high-speed, high-budget, integrated solutions.

Now we move from "mold specialists" to "line specialists." Tech-Long and Leshan are famous names in China. When a large water factory wants to build a new 30,000 bottle-per-hour plant, they call Tech-Long. These companies sell systems.

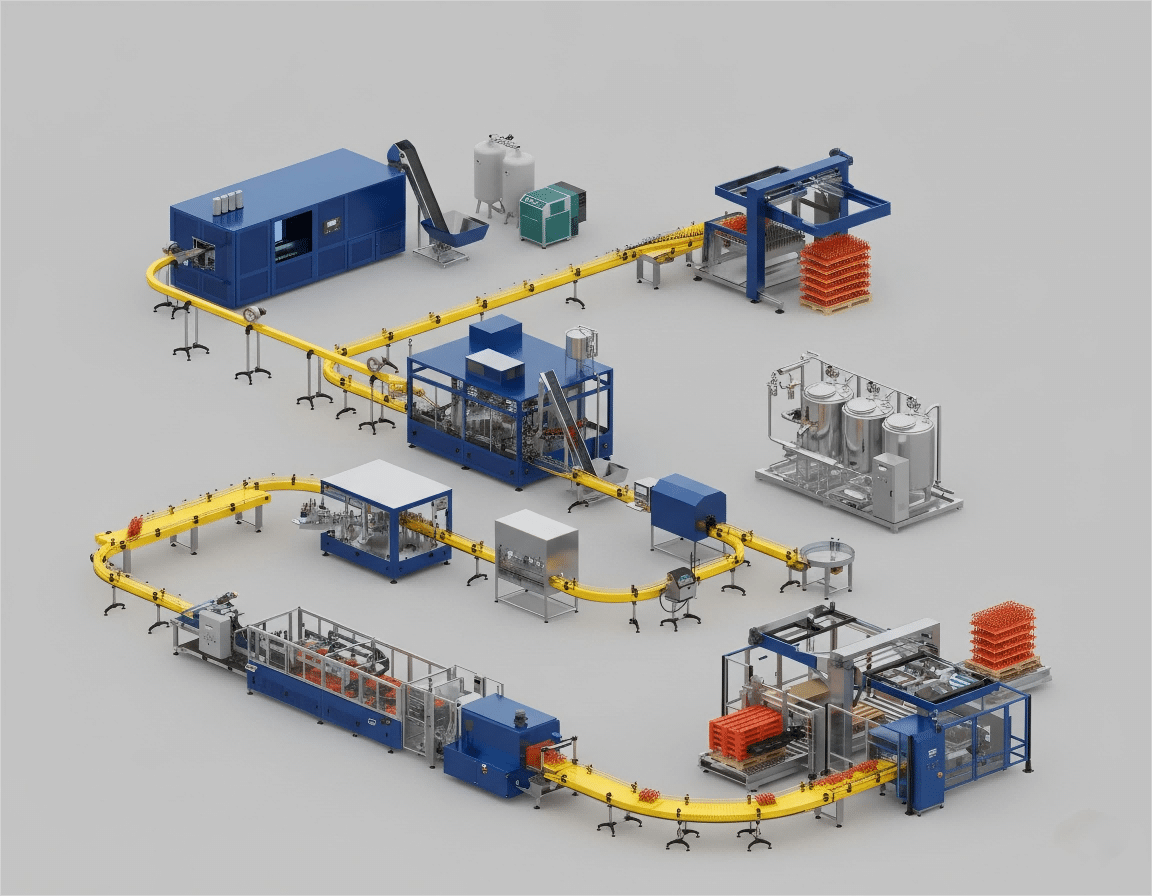

What is a "Complete Line" (Turnkey Solution)?

A turnkey solution means one supplier provides everything. This includes:

- The high-speed rotary bottle blowing machine.

- The blow bottle molds (which they often make in-house).

- Air conveyors to move the empty bottles.

- The high-speed filling and capping machine (the "filler").

- Labeling machines.

- Packing and palletizing machines.

This is a massive, multi-million dollar project. Tech-Long is famous for its high-end, high-speed lines. They compete directly with European brands. Leshan is also a major player, especially for large water plants. Leshan also has a strong specialty in PC (polycarbonate) molds for large 5-gallon water jugs.

The main advantage is integration. The blower is perfectly connected to the filler. This is often called a "Combibloc." The bottle is blown, moves directly to the filler, is filled, and then capped. It is very efficient. It is the standard for high-speed beverage production.

My Insight: The "Startup" Problem

Like the first group, Tech-Long and Leshan are respected. I admire their engineering. But they have the same "problem" for new businesses. Their "entry price" is very high. Their entire business model is built for large, established companies. They do not want to sell you one machine. They want to sell you a floor of machines.

I (Vivian) had a customer who got a quote from one of these large line providers for a new project. The price was over $1.5 million. He only needed a 4,000 bottle-per-hour line for his new energy drink. The solution was too big and too expensive.

He came to iBottler. We provided him with a complete, matched system that was right for him. This included:

- One iBottler 4-cavity blowing machine.

- Three sets of custom-designed, lightweighted molds.

- An efficient air compressor system.

- The matching water chiller.

The total cost was a small fraction of the giant's quote. And, we spent two weeks designing his unique bottle with him. The giant company just gave him their 'standard' bottle shape.

So, if you are a mature business with a $2 million budget, Tech-Long is a fantastic choice. If you are a startup with a $200,000 budget and a new idea, you need a specialist. You need a partner who sees your vision, not just your purchase order. These giants sell you what they have. A partner like me helps you build what you need.

| Factor | #3 Tech-Long / #4 Leshan | #7 iBottler (Jindong) |

|---|---|---|

| Solution | Complete, high-speed (20k+ BPH) factory lines. | Custom, flexible (2k-10k BPH) lines. |

| Core Focus | High-speed machine integration. | Custom bottle design & process matching. |

| Flexibility | Low. Built for standard, large-scale runs. | High. Built for custom shapes and startups. |

| Budget | $$$$$(Millions) | $$$ (Affordable entry point) |

| Relationship | Vendor to a large corporation. | Partner to an entrepreneur. |

Sino's "Mould Supermarket" & Demark's "Taizhou Speed": A Good Deal?

You need many different things: injection molds, blow molds, and machines. A "one-stop-shop" like Sino or a fast "turnkey" provider like Demark seems easy. But is "easy" the same as "best"?

Sino Mould is a "supermarket" for all types of molds. Demark is a key Taizhou player known for high-speed turnkey solutions with a good price. They offer convenience, but you must ask if custom bottle design is their core strength.

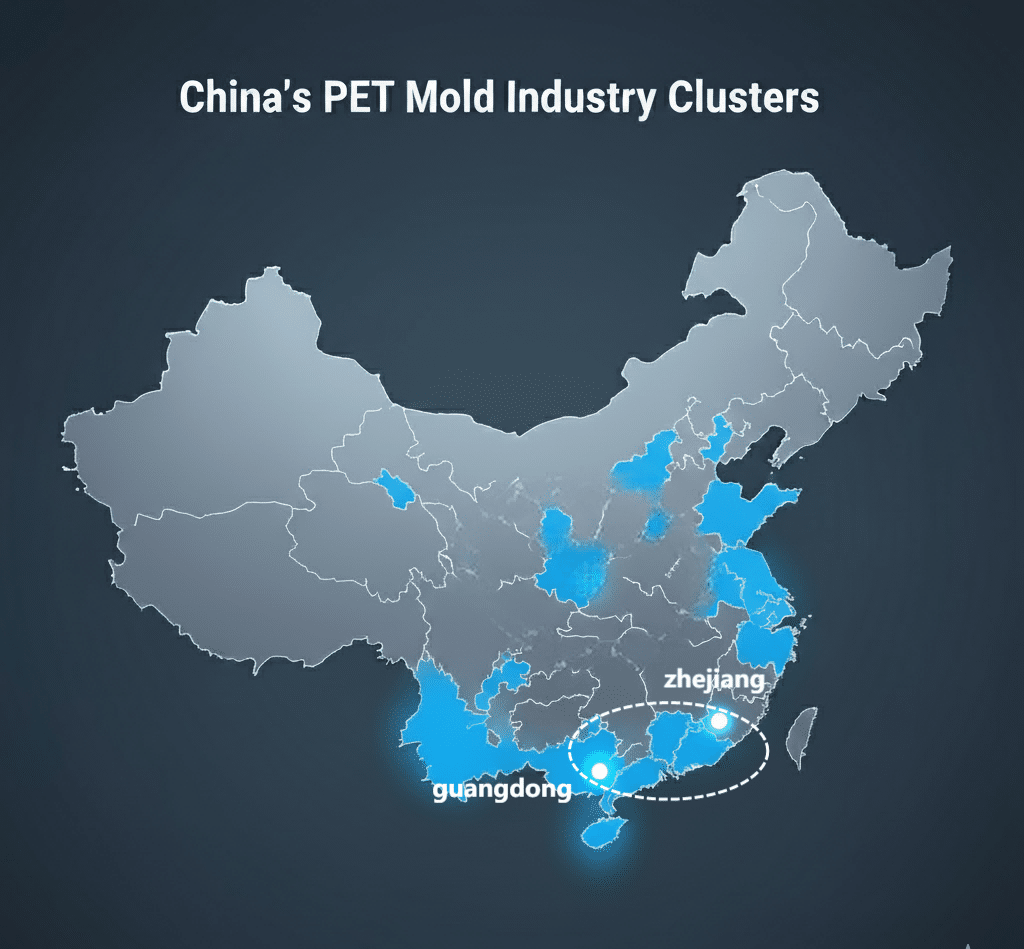

This group is interesting. They are both based in the "mould town" of China, Taizhou (Huangyan). They represent the "all-in-one" convenience model. But they do it in different ways.

5 Sino Mould: The "Mould Supermarket"

Sino is a very large, very broad company. Their catalog is huge. They make:

- PET Preform Molds

- PET Blow Molds

- Injection Molds (for caps, crates, chairs, car parts, everything)

- Injection Machines

Their advantage is convenience. If you are setting up a whole new factory, you can theoretically buy everything from them. They are a "jack of all trades." This can be good. But it can also be a warning.

My philosophy, as Vivian, is that "expert" is better than "generalist." This is especially true in blow molding. Making a car bumper mold is very different from making a pressure-resistant CSD blow bottle mold. The physics are different. The process is different. The cooling is different.

When a factory's focus is split 10 ways, is your PET bottle project getting their best engineers? Or is it just one small department?

6 Demark: The "Taizhou Speed" Representative

Demark is a very strong Taizhou-based company. They focus on PET packaging. They provide high-speed, fully automatic linear and rotary blowing machines and the molds to match.

They are a direct, price-competitive alternative to the "giant line" providers like Tech-Long. They are very good at "turnkey" solutions. You give them a factory space, they install a complete line. They have a good reputation for "Taizhou Speed," meaning fast production and good value.

My Insight: The Core Strength Question

Both Sino and Demark offer good turnkey solutions. But as a buyer, you must ask this critical question: Is "bottle design" and "lightweighting" their core competence, or is it just a supporting service?

Here is what I mean. At iBottler, our work starts with your bottle design. My engineers live and breathe PET structural analysis. We are a design and process company that also happens to make machines and molds.

For some "all-in-one" factories, the mold is just an accessory to their machine. They have a "mould department" to help sell the machine. Will they spend two weeks with you, fighting to save 0.5 grams from your bottle? Or will they give you their standard '15-gram' mold design because it is faster and runs easily on their machine?

This is the key difference. I always tell clients: "Do not buy a 'supermarket' solution for an 'expert' problem." Designing a high-performance, lightweight PET bottle is an expert problem.

| Company Type | Sino Mould (The "Supermarket") | Demark (The "Turnkey Provider") | iBottler (The "Specialist") |

|---|---|---|---|

| Breadth | Very Wide (All molds, all machines) | Focused (PET lines) | Hyper-Focused (Custom PET Design & Process) |

| Strength | One-stop-shop convenience. | Good price-to-speed ratio. | Expert design, lightweighting, 100% match. |

| Risk | Is PET blow molding their real focus? | Is the bottle design optimized, or just standard? | We are smaller than the giants. |

| Best For | Buyers who need many different types of molds. | Buyers who want a good value, high-speed line. | Buyers who want a unique, optimized bottle. |

Why is #7 iBottler (Jindong) the Expert for Custom Bottle Design & Process?

You have a great bottle idea. But giants will not talk to you, and small factories cannot get it right. Your project is stuck, and you are losing money.

We are iBottler (Jindong Machinery). We are not the biggest. We are the process experts. We specialize in what giants (like XL) will not do, and what small factories (in Taizhou) cannot do: custom bottle design and lightweighting.

Yes, I am putting my own company, iBottler, on this list. I am placing us at #7. Why not #1? Because, as I said, there is no single "best." XL is #1 for scale. Tech-Long is #1 for high-speed lines.

We are #1 for startups and innovators.

Our Core Philosophy: We Are Process Experts

We are a 20-year-old family company based in Zhongshan. My father started this company. Our philosophy is simple: We do not just sell machines or molds. We sell a result. We sell a perfect, lightweight, and profitable bottle.

What does this mean? It means we are one of the only companies in China that designs and manufactures both the custom blow mold and the bottle blowing machine in the same factory, under one roof.

This is not the same as a "turnkey" provider. A turnkey provider assembles many parts from other suppliers. We engineer the two most critical parts (mould and machine) to work as one perfect system.

What We Do (That Others Don't)

- We Start with Design: You bring me an idea. A sketch on a napkin. A sample bottle you like. My team and I will start with 3D modeling. We run Finite Element Analysis (FEA) to see where the stress points are. We will show you, "If we add this micro-rib, we can remove 1 gram from the body." We are bottle design experts first.

- We Master Lightweighting: This is my passion. This is where we save you real money. I have helped clients redesign 18-gram bottles into 15-gram bottles. I have taken 30-gram bottles and made them 25-grams. This is our real value.

- We Guarantee the 100% Match: Because my engineers are designing the mold, they are sitting 10 meters away from the machine engineers. They talk all day. They know the exact stretching speed, the exact pre-blow time, the exact cooling channel layout of the iBottler machine. The mold is built for the machine. The machine is programmed for the mold. This eliminates all risk for you.

A Case Study: The Startup's Dilemma

I had a client from the Middle East. He wanted to launch a new vitamin water. The bottle shape was

very complex, with sharp square corners. It was a beautiful design.

He went to a "mold-only" factory in Taizhou first. They made the mold. He put it on his existing machine in his factory. The bottles were terrible. The corners were not formed properly. The base was too thin. He had many blowing defects.

The mold factory blamed his machine. The machine factory blamed his preforms. He was stuck.

He called me (Vivian). He was very frustrated. I looked at his design. I told him the problem. "Your machine's stretching speed is too slow for this sharp-corner design. And your mold's cooling is not focused on the sharp corners."

He was worried. I said, "Let us handle it." My team redesigned the mold with special cooling inserts. We built him one of our iBottler-4S machines, which has a high-speed servo-stretching system. Three months later, he was producing 6,000 bottles per hour. Perfect bottles. Every single one.

He sent me a video. He said, "Vivian, I should have called you first." He learned the hard way: the match is everything.

| Feature | The iBottler (Jindong) Way | The "Normal" Way |

|---|---|---|

| The Process | One expert partner designs bottle, mold, & machine. | Buyer must find and manage 3-4 different suppliers. |

| Responsibility | 100% iBottler's responsibility. One phone call to me. | Suppliers blame each other for problems (mold, machine, preform). |

| Core Skill | Lightweighting and custom structural design. | Metal cutting (mold) or assembly (machine). |

| Our Standard | The 100% Match is our minimum standard. | "Mold fit" is your problem. (We also help with mold fit on other machines). |

We place ourselves at #7. We are not a giant. We are a dedicated team of experts. We are for the entrepreneur who believes their bottle design is part of their brand. We are for the factory manager who is tired of "blame games." We are the specialist.

The Taizhou Cluster (#8 Waton, #9 Mega, #10 Topworks): Good Price or Big Risk?

You need a mold fast. You need a good price. The factories in Taizhou/Huangyan are famous for this. But a low price today can mean big risks tomorrow.

Waton, Mega Mould, and Topworks are strong players in the Taizhou/Huangyan cluster. Waton provides machines and molds. Mega and Topworks are professional "mold-only" craftsmen. They offer flexibility and great prices, but the risk is on you.

We end our list back in Taizhou, the heart of China's mold-making industry. This cluster is famous for its speed, flexibility, and highly competitive pricing. These three companies represent the "Taizhou spirit" very well.

The "Taizhou Model"

Huangyan (a district in Taizhou) has thousands of mold factories. It is an incredible ecosystem. This creates intense competition. The results are:

- Speed: They can often make a mold faster than anyone else.

- Price: The competition keeps prices very low.

- Flexibility: They are often happy to take small, one-mold orders.

The Players

- #8 Waton Machinery: Waton is similar to Demark but often focuses on small-to-medium-sized machines. They make good semi-automatic machines and smaller fully-automatic lines. They provide the blow molds to match their machines. They are a good entry-level "turnkey" option for those on a tight budget.

- #9 Mega Mould & #10 Topworks Mould: These two are different. They are pure mould craftsmen. They focus 100% on making molds. They do not make machines. They are very skilled at cutting metal. They can make bottle molds, cap molds, and preform molds. They are true "mold-only" specialists.

My Insight: The "Buyer Beware" Risk

I (Vivian) have great respect for these Taizhou factories. They are the "craftsmen" of the industry. But I must be honest about the risk. This model is for experienced buyers only.

When you buy from a "mold-only" factory like Mega or Topworks, you are the systems integrator. You are the process expert.

- Design Risk: You must give them a perfect 3D bottle design. They will cut exactly what you give them. If your design has a structural flaw (like it's too thin in one area), that is your problem. They are not bottle design experts; they are mold makers.

- Matching Risk: You must give them the exact technical drawings for your blowing machine. This includes the mounting plate, the stretch rod positions, the cooling water inputs. If the mold arrives and does not fit your machine, that is your problem. This is a huge issue in the industry. We created a guide for mold fit just to help people avoid this.

- Process Risk: This is the big one. If the mold is on your machine, but the bottles have defects (e.g., white spots, uneven walls), who do you call? The mold factory will say, "Our mold is perfect. Your heating is wrong." The machine company will say, "Our machine is perfect. Your mold cooling is bad." You are stuck in the middle.

So, if you are an engineer, you have 10 years of experience, and you just need a simple mold built from your own perfect drawing, these Taizhou factories are a great, low-cost choice.

If you are an entrepreneur with a new idea, this is a very high-risk path.

| Factor | Taizhou "Craftsman" (Mega, Topworks) | iBottler "Expert" (Jindong) |

|---|---|---|

| Role | A supplier who cuts metal for you. | A partner who designs a solution with you. |

| Strength | Low price, fast delivery. | Optimized design, guaranteed performance. |

| Who takes the risk? | YOU. (For design, matching, and process). | ME (Vivian). (For everything). |

| Best For | Experienced factory managers who already have a perfect bottle design and full technical team. | Startups, innovators, and anyone who wants a guaranteed result. |

Why is an "Integrated Process Expert" the Best Choice for a Startup?

You need to buy a mold and a machine. The "Mix and Match" method seems cheaper. But when problems happen, suppliers blame each other. You are left with a broken line.

An integrated process expert (like iBottler) is the best choice for startups. They take 100% responsibility. You get one partner. This eliminates the "blame game" between mold and machine suppliers, saving you time, money, and risk.

We have reviewed the Top 10. We have seen the Giants, the Line Providers, the Supermarkets, the Craftsmen, and the Specialists (like iBottler).

Now, I want to give you my final, most important advice as a buyer. This is for you, the startup or the growing business.

The #1 Mistake: The "Blame Game"

This is the most common and most expensive mistake I see.

- A buyer purchases a blow mold from Factory A (a Taizhou "craftsman").

- He purchases a blowing machine from Factory B.

- He purchases preforms from Factory C.

The mold arrives. It doesn't fit the machine perfectly. Factory A says, "You gave us the wrong drawings." Factory B says, "Our machine is standard." You pay a local welder to fix it.

Finally, it runs. But the bottles are bad. You see common defects.

- Factory A (Mold) says: "Our mold cooling is fine. Your machine's heating is uneven."

- Factory B (Machine) says: "Our machine is perfect. Your preforms are bad."

- Factory C (Preform) says: "Our preforms are fine. Your preform neck size is wrong for your bottle design."

You are trapped. You have three suppliers, and zero solutions. This "blame game" can shut down your production for months. You lose your contract with the supermarket. Your new product launch fails.

This is why the "cheapest" option is often the most expensive.

The Solution: One Supplier, One Responsibility

The choice is simple. You must find a partner who takes total responsibility.

A "giant line" provider like Tech-Long does this. They are responsible for the whole line. But, as we saw, they are too big and expensive for most startups.

An "integrated process expert" like iBottler (Jindong) is the perfect solution for a startup.

When you work with me, I (Vivian) am your only contact.

- I am responsible for the bottle design.

- I am responsible for the lightweighting.

- I am responsible for the preform mold (if you need it).

- I am responsible for the blow mold.

- I am responsible for the blowing machine.

- I am responsible for the chiller and compressor settings.

- I am responsible for the final, perfect bottle.

If there is a problem, you do not need to be an engineer. You just need to make one phone call. To me. I will not blame anyone. My team will fix it. This is our promise. This is the 20-year reputation of my family's company.

| Buying Model | Who is the "Process Expert"? | Who Takes the Risk? | Final Result |

|---|---|---|---|

| "Mix & Match" (Mold from A, Machine from B) | YOU. You must be the expert. | YOU. 100% of the risk is yours. | High stress, high risk of failure. (The "Blame Game") |

| "Giant Line" (e.g., Tech-Long) | The Supplier. | The Supplier. | Low risk, but very high cost. Not flexible for startups. |

| "Integrated Specialist" (e.g., iBottler) | WE ARE. (Vivian's Team) | WE ARE. (iBottler takes 100% responsibility). | Low risk, affordable cost. A true partnership. |

My Final Advice

I respect all the companies on this list. They are all good at what they do. But I am an expert in helping entrepreneurs succeed. Do not risk your new business to save 10% on a mold. Do not become the middle-man in a "blame game."

Find a partner, not a supplier. Find someone who cares as much about your bottle as you do.

I am Vivian. At iBottler, we are that partner. When your bottle has a problem, you call me. I will be responsible for you. That is the promise of a 20-year-old factory.

Conclusion

Choosing a mold factory is not about price. It is about finding the right partner. Choose a process expert who guarantees design, lightweighting, and a 100% match.

2025 Top 10 Factory Summary

| Factory Rank & Name | Core Strength | Best For |

|---|---|---|

| #1 XL / #2 Huayan | Preform Molds, Massive Scale | Global Giants (Coca-Cola) |

| #3 Tech-Long / #4 Leshan | High-Speed Complete Lines | Large, Mature Companies |

| #5 Sino / #6 Demark | "All-in-One" / Turnkey | Buyers needing convenience / good price-speed |

| #7 iBottler (Jindong) | Custom Design, Lightweighting, 100% Mold+Machine Match | Startups & Innovators |

| #8 Waton / #9 Mega / #10 Topworks | "Mold Craftsmen", Low Price | Experienced DIY Buyers |

Frequently Asked Questions (FAQ)

1. Q: What is "Lightweighting" in bottle design, and why is it so important?

A: Lightweighting is the art of re-designing a PET bottle's structure (especially the base and walls) to use the minimum amount of PET material while maintaining (or even increasing) its strength. This is your #1 cost-saving factor. A 1-gram reduction in a bottle that you produce millions of, translates to tens of thousands of dollars saved in raw material costs per year.

2. Q: My bottle is for carbonated drinks (CSD). What's important for the mold?

A: For CSD, the bottle base design is critical. You need a specialized "petaloid" base structure to withstand high internal pressure. This requires a highly precise bottom mold insert, optimized cooling for that thick area, and a machine with a stable process. We at iBottler have extensive experience designing CSD molds that are both strong and lightweight.

3. Q: What is the real difference between a blow mold and a preform mold?

A: They do two totally different jobs. A Preform Mold (like what XL and Huayan are masters of) is an injection mold (high pressure, S136 steel) that creates the "preform" with the finished neck threads. A Blow Mold (which we are discussing) takes that preform, heats it, and blows it into the final bottle shape. Your bottle's neck is made by the preform mold; the body and base are made by the blow mold.

4. Q: Why should my startup choose iBottler (Ranked #7) over a giant like Tech-Long (Ranked #3)?

A: Because Tech-Long (达意隆) sells massive lines; iBottler (缙东机械) delivers custom solutions. A giant like Tech-Long is built for high-speed, 50,000 bottle-per-hour lines. iBottler is built for you. We offer: 1. Flexibility: We love custom, small-batch projects. 2. Custom Design: We will help you design your unique, lightweight bottle from scratch. 3. 100% Match: We manufacture both the mold and the machine, guaranteeing they work perfectly together. You talk directly to me (Vivian), your expert partner.

5. Q: What is the process if I have a new bottle idea?

A: It's simple with us. 1. You send me (Vivian) your idea, drawing, or sample. 2. My engineering team provides 3D modeling, structural analysis, and lightweighting suggestions. 3. Once you approve the design, we manufacture the mold and build the matching machine. 4. We test the entire system in our Zhongshan factory and send you perfect bottle samples before shipping. We handle everything from idea to finished bottle.

🔗 Related Pages on Our Website

PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr