Are you struggling to figure out if producing your own bottles is cheaper than buying them? The initial numbers look good, but a nagging feeling says you're missing something important.

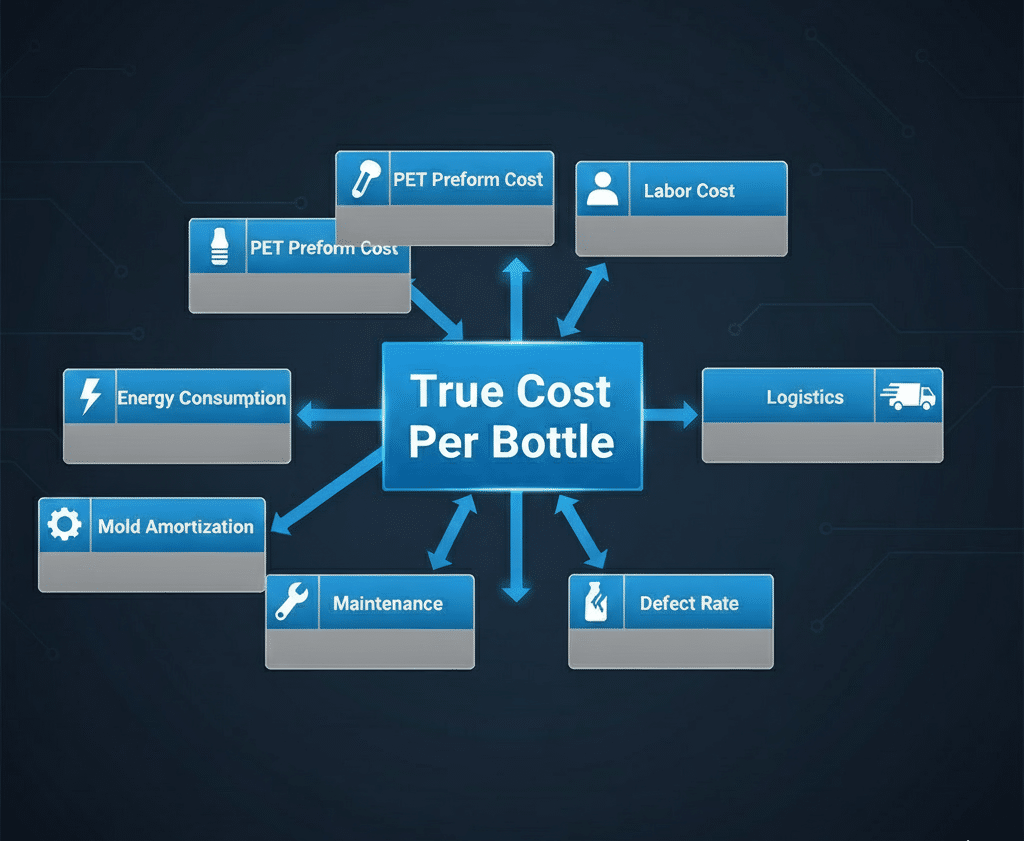

The true cost of a 500ml PET bottle goes far beyond the price of the plastic preform. It must include equipment depreciation, auxiliary power consumption, production scrap, maintenance, and downtime. Ignoring these hidden costs will give you a dangerously inaccurate and overly optimistic cost per bottle.

I see this all the time. An entrepreneur is excited to take control of their supply chain. They get a quote for a blow molding machine and a price for preforms. They do some quick math and think they've found a goldmine. But this simple calculation is the first step toward a major financial mistake. I want to walk you through the real costs, the ones that hide in the details, so you can build your business on a solid foundation of accurate numbers. This is the conversation I have with every serious investor.

Beyond the Preform: Why Your First Cost-Per-Bottle Calculation is Probably Wrong?

Are you basing your entire business plan on the preform price plus a little electricity? This common oversight can lead to serious budget overruns and threaten your profitability before you even start.

Your initial calculation is likely wrong because it only accounts for direct material costs. It ignores crucial indirect operational expenses like machine depreciation, auxiliary equipment power, scrap rates, maintenance, and downtime, which significantly inflate the final cost.

I remember a client from Singapore who was facing this exact problem. They were using about 100,000 bottles a month. Buying them meant dealing with inconsistent quality and unstable delivery times. Plus, they had to rent extra warehouse space just to store inventory. It was a headache. They came to me asking for the cost to produce a single 500ml bottle. They wanted to compare my number to what they were paying their supplier.

I explained that I couldn't just give them a single number. The cost depends on the price of the bottle blowing machine, the weight of the preform, and local labor and electricity rates. So, I walked him through the real calculation, using Chinese market rates as an example. I showed him how to factor in not just the obvious costs, but the five major hidden costs we're about to discuss.

After running the numbers for his situation in Singapore, he had his answer. Even with all the hidden costs included, producing his own bottles was more economical than buying them. He saw the full picture, not just the tip of the iceberg. This comprehensive understanding gave him the confidence to invest in his own production line. This is the journey I want to take you on now. We will break down each of these hidden costs so you can make an informed decision, just like he did.

The Anatomy of Bottle Cost: Apparent vs. True

Most people new to the industry only see the "Apparent Cost." This is a dangerous simplification. The "True Cost" includes all the factors that actually impact your bottom line. To plan for long-term success, you must focus on the True Cost.

| Cost Category | Apparent Cost Calculation (The Mistake) | True Cost Calculation (The Reality) |

|---|---|---|

| Material | Price of one PET preform. | Price of preforms consumed, including those wasted during production (scrap rate). |

| Machinery | Not included, or seen as a one-time capital expense. | The purchase price of all equipment, depreciated over its lifespan and allocated to each bottle produced. |

| Energy | Electricity for the main blow molder only. | Electricity for the main machine PLUS high-pressure air compressor, chiller, and dryer. |

| Maintenance | Ignored. Assumed to be a distant, minor expense. | Regular budget for spare parts, lubricants, and potential service calls, distributed as a micro-cost on every bottle. |

| Labor & Overhead | Sometimes includes operator salary during uptime. | Includes operator salary, rent, and other fixed overheads during BOTH uptime and downtime. |

Understanding this difference is the first step toward building a realistic business model. The apparent cost makes the venture look easy and cheap. The true cost prepares you for the realities of manufacturing and empowers you to build a profitable, sustainable business. Don't let a simple calculation lead to a complex failure.

Hidden Cost #1: The True Cost of Your Machinery (Equipment Depreciation)?

Did you buy a shiny new machine and think of it as a one-time expense? That massive investment needs to be accounted for in every single bottle you produce, or you're not tracking your true profit.

Equipment depreciation is an accounting method that spreads the cost of your machine over its useful lifespan. You must add a small fraction of the machine's cost to each bottle to accurately reflect its manufacturing expense.

Think of it like this: if you buy a $50,000 machine that will last for 10 years, it's not free to use after you've paid for it. In reality, it costs you $5,000 every year to own it. If you produce one million bottles that year, then each bottle carries $0.005 of the machine's cost. This seems small, but it's a real cost that affects your profit margin. Ignoring it means you are overstating your profits and might be selling your product for less than it actually costs to make.

This concept is crucial for long-term financial health. It ensures you are setting aside funds (at least on paper) for the eventual replacement of your equipment. It also gives you a much more accurate picture of your production costs, which is essential for setting correct pricing and making smart business decisions. A responsible business owner knows the cost of their tools, not just their materials.

Calculating and Allocating Depreciation

The most common and straightforward method to calculate this is "straight-line depreciation." It's simple and effective for production planning.

The formula is:

Annual Depreciation = (Purchase Price of Equipment - Salvage Value) / Useful Lifpan in Years

- Purchase Price: This is the total cost to acquire and install the equipment. It should include the bottle blowing machine, air compressor, chiller, molds, and any other necessary gear.

- Salvage Value: This is the estimated resale value of the equipment at the end of its useful life. For simplicity in planning, this is often set to $0.

- Useful Lifespan: This is the number of years you expect the machine to be in productive service. For PET blow molding machinery, a lifespan of 8 to 10 years is a standard industry benchmark.

Let's run through a practical example:

Scenario:

- Total Equipment Investment (Machine, Compressor, Chiller, Mold): $85,000

- Salvage Value: $0

- Useful Lifespan: 10 years

- Working Days per Year: 300

- Working Hours per Day: 8

- Bottles Produced per Hour: 2,000

Step-by-Step Calculation:

| Calculation Step | Formula / Logic | Example Value |

|---|---|---|

| 1. Annual Depreciation | ($85,000 - $0) / 10 years | $8,500 per year |

| 2. Daily Depreciation | $8,500 / 300 days | $28.33 per day |

| 3. Hourly Depreciation | $28.33 / 8 hours | $3.54 per hour |

| 4. Depreciation per Bottle | $3.54 / 2,000 bottles | $0.00177 per bottle |

This $0.00177 is your first hidden cost. It might look insignificant, but over millions of bottles, it adds up to a substantial amount. When you add this to your cost formula, you are one step closer to understanding the true cost of production and building a resilient business. Ignoring it is like building a house without accounting for the cost of the foundation.

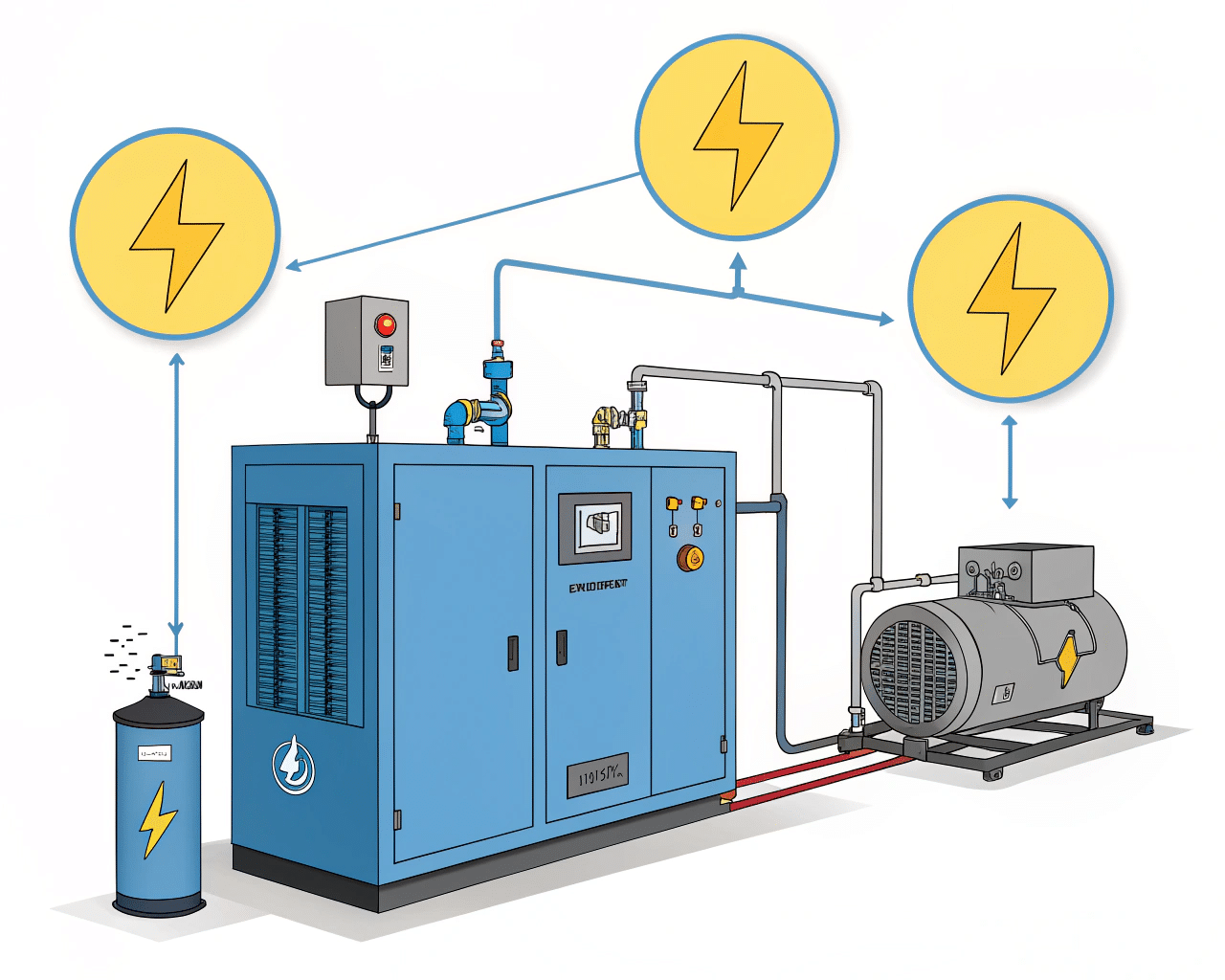

Hidden Cost #2: The Power Bill You Didn't Expect (Auxiliary Equipment)?

Are you calculating your energy costs based only on the main blow molding machine's specs? If so, you're about to be shocked by your first electricity bill, as the biggest power consumers are hiding in plain sight.

The main blow molder is often not the biggest energy user. The high-pressure air compressor, industrial chiller, and preform dryer are auxiliary machines that can collectively consume more electricity than the molder itself, drastically increasing your energy cost per bottle.

When I talk to new investors, this is the cost that surprises them the most. They see the kilowatt (kW) rating on the bottle blowing machine and use that for their projections. But the process of turning a small, hard preform into a thin, clear bottle requires two critical support systems: immense air pressure and intense cooling. These systems are managed by separate, power-hungry machines.

The high-pressure air compressor has to squeeze a massive volume of air to 30-40 bar to stretch the PET. The industrial chiller works constantly to pump cold water through the blow bottle mold, solidifying the plastic in milliseconds. Forgetting these is like calculating the cost of a car trip but only including the gasoline for the engine, forgetting the energy needed for the air conditioning and headlights.

Unmasking the Real Energy Hogs

To accurately forecast your operational expenses, you must sum the power consumption of the entire production line, not just the centerpiece machine. Let's look at a typical setup for a semi-automatic line producing around 1,500 bottles per hour.

The power ratings are not constant; they represent the machine's potential draw. The actual consumption, or "working power," is typically 60-70% of the rated power. However, for conservative cost planning, it's wise to understand the maximum potential.

Typical Power Consumption Breakdown for a Small-Scale Line:

| Equipment | Rated Power (kW) | Estimated Working Power (kW @ 65%) | Percentage of Total Consumption | Role in Production |

|---|---|---|---|---|

| High-Pressure Air Compressor | 18.5 kW | 12.0 kW | ~54% | Provides 40-bar air to stretch the preform into the bottle shape. The "lungs" of the operation. |

| Industrial Chiller | 7.5 kW | 4.9 kW | ~22% | Circulates cold water to cool the mold, setting the bottle's final shape and clarity. |

| Blow Molding Machine | 5.0 kW | 3.2 kW | ~14% | Heats the preforms and clamps the mold. |

| Preform Dryer | 3.0 kW | 2.0 kW | ~9% | Removes moisture from PET material before heating to prevent defects. |

| TOTAL | 34.0 kW | 22.1 kW | 100% | Full Production Line |

As you can see, the blow molder itself accounts for only about 14% of the total energy usage. The air compressor and chiller together consume over 75% of the power. This is a game-changing realization for your cost sheet.

Calculating Energy Cost Per Bottle:

Let's use the total working power from our table.

- Total Working Power: 22.1 kW

- Local Electricity Price (example): $0.15 per kilowatt-hour (kWh)

- Bottles Produced per Hour: 1,500

- Cost per Hour:

22.1 kW * $0.15/kWh = $3.32 per hour - Energy Cost per Bottle:

$3.32 / 1,500 bottles = $0.00221 per bottle

This $0.00221 is your second hidden cost. When you combine it with depreciation, the true cost of your bottle is already significantly higher than just the price of the preform. Accurate energy calculation is not optional; it's fundamental to your financial survival.

Hidden Cost #3: The Price of Imperfection (Production Scrap Rate)?

Do you assume every preform you buy will become a perfect, sellable bottle? In the real world of manufacturing, waste is a fact of life, and every scrapped bottle is a direct hit to your bottom line.

The production scrap rate is the percentage of unusable products generated during manufacturing. You must account for the cost of wasted materials (preforms) and the energy used to produce these failed bottles in your total cost calculation.

No production line is 100% efficient. During the initial setup and tuning of a new blow bottle mold, you will inevitably produce scrap. When you switch between different bottle designs, there will be a changeover period that generates waste. Even during stable production, there will be occasional defects. These aren't just discarded plastic; they are lost money. Each scrapped bottle consumed a preform, electricity, machine time, and labor.

I advise my clients to be realistic, not just optimistic. Budgeting for a scrap rate of 1-2% is a standard, responsible practice. For a new operation or one with frequent mold changes, it might even be slightly higher initially. Acknowledging this cost prevents you from underpricing your product and ensures your revenue targets are based on the number of sellable bottles, not the total number of preforms you process. Thinking you'll have zero waste is a recipe for a financial shortfall.

How to Factor Scrap into Your Unit Cost

Calculating the cost of scrap isn't just about the lost preform. You've also spent money on depreciation and energy to create that faulty bottle. The most straightforward way to account for this is to spread the cost of the lost units across the successful ones.

The logic is simple: if you want to get 100 good bottles but have a 2% scrap rate, you actually need to start the process for about 102 bottles. Therefore, the total cost of making those 102 bottles must be absorbed by the 100 good ones you can actually sell.

Formula:

Cost Adjusted for Scrap = (Material Cost + Production Cost) / (1 - Scrap Rate)

Let's build on our previous examples. Assume:

- Preform Cost: $0.020 per piece

- Depreciation Cost per Bottle: $0.00177

- Energy Cost per Bottle: $0.00221

- Assumed Scrap Rate: 2% (or 0.02)

Step-by-Step Impact Analysis:

Calculate Initial Cost per Bottle (before scrap):

$0.020 (Preform) + $0.00177 (Depreciation) + $0.00221 (Energy) = $0.02398

Apply the Scrap Rate Formula:

Cost Adjusted for Scrap = $0.02398 / (1 - 0.02)Cost Adjusted for Scrap = $0.02398 / 0.98Cost Adjusted for Scrap = $0.02447

Calculate the Added Cost of Scrap:

$0.02447 - $0.02398 = $0.00049 per bottle

This $0.00049 is your third hidden cost. It's the "Price of Imperfection." This added cost seems tiny, but for a production of 1 million bottles, that's an extra $490 in hidden costs you hadn't budgeted for.

Common Causes of Scrap and How to Mitigate Them:

| Scrap Cause | Description | Mitigation Strategy |

|---|---|---|

| Cold Spots | Uneven heating of the preform leads to thin or thick sections in the bottle. | Ensure all heating lamps are functional and properly calibrated in your blow molder. |

| Pearlescence/Haze | The PET is over-stretched or stretched at the wrong temperature, causing a cloudy appearance. | Optimize heating settings and blowing pressure. A good PET bottle mold design can also help. |

| Off-Center Gates | The injection point on the preform is not centered, leading to uneven material distribution. | Inspect preform quality upon delivery. Work with a reputable preform mold supplier. |

| Water Contamination | Moisture in the PET material hydrolyzes during heating, weakening the bottle. | Use a high-quality preform dryer and ensure it's operating at the correct temperature and time. |

By understanding the causes, you can work to reduce your scrap rate over time. For more in-depth solutions, reviewing common PET blow molding defects and their fixes is a crucial step for any production manager. However, you should never assume your scrap rate will be zero. Always include it in your cost calculations.

Hidden Cost #4: The Long-Term Cost of Maintenance & Spare Parts?

Is your financial plan only focused on the day of purchase? A manufacturing line is a living system that requires continuous care, and the costs for maintenance and spare parts are guaranteed expenses, not possibilities.

Every machine has wearable components that will need replacement. The long-term cost of maintenance includes lubricants, seals, heating lamps, and other spare parts. This predictable expense must be budgeted for and allocated as a small cost to every bottle produced.

I always tell my clients that a reliable supplier doesn't just sell you a machine; they partner with you for its entire lifecycle. Part of that partnership is being transparent about future costs. A machine that never needs a new part doesn't exist. From the simple O-rings in the pneumatic system to the expensive heating lamps in the oven, parts wear out. It's a fundamental law of mechanics.

Ignoring these costs is like buying a car and not budgeting for oil changes, new tires, or brake pads. For a while, everything seems fine, but eventually, the lack of maintenance leads to a major, expensive breakdown. In manufacturing, this breakdown means a stopped production line. Budgeting for maintenance isn't just good financial practice; it's essential for ensuring reliability and longevity.

Budgeting for the Inevitable

So how do you budget for something that hasn't happened yet? You rely on experience and supplier guidance. A good supplier will provide you with a list of recommended spare parts and their expected lifespan under normal operating conditions.

You can create an annual maintenance budget as a percentage of the total equipment cost. A common rule of thumb in the industry is to budget 1% to 3% of the initial equipment capital cost per year for maintenance and spare parts. For a more precise calculation, you can itemize the most common wear parts.

Sample Annual Spare Parts Budget for a Semi-Automatic Line:

| Component | Quantity in Machine | Lifespan (Hours) | Replacements per Year (2400 hrs) | Cost per Unit | Annual Cost |

|---|---|---|---|---|---|

| Heating Lamps | 20 | 3,000 hrs | 16 | $50 | $800 |

| Sealing Rings (Main) | 4 | 2,000 hrs | 5 | $30 | $150 |

| Solenoid Valves | 10 | 8,000 hrs | 3 | $80 | $240 |

| Filters (Air/Water) | 5 | 1,000 hrs | 12 | $20 | $240 |

| Lubricants/Grease | N/A | As needed | N/A | N/A | $200 |

| TOTAL | $1,630 |

This is a simplified example, but it illustrates the process. The actual parts list will be more extensive.

Adding Maintenance Cost to Your Bottle:

Let's use our running example:

- Estimated Annual Maintenance Cost: $1,630

- Total Annual Production (2,000 BPH 8h/day 300 days): 4,800,000 bottles

- Maintenance Cost per Bottle:

$1,630 / 4,800,000 bottles = $0.00034 per bottle

This $0.00034 is your fourth hidden cost. It's the micro-payment every bottle makes towards the future health of your production line. Proper maintenance of both your machine and your blow bottle mold not only prevents costly downtime but also ensures consistent quality. A well-maintained mold produces better bottles with less scrap. Don't let this small but critical cost catch you by surprise.

Hidden Cost #5: The Cost of a Stopped Line (Downtime & Inefficiency)?

Do you think costs stop when your machine stops? Your biggest fixed expenses—rent and labor—keep draining your bank account every second your production line isn't making sellable products.

Downtime is any period when the machine is not producing bottles. The cost of downtime is your total fixed overhead (labor, rent, etc.) during that non-productive time. High downtime drastically increases the effective cost of each bottle you do produce.

This is perhaps the most dangerous hidden cost because it's variable and can spiral out of control. Your operator's salary, your factory lease, and your electricity bill for the lights don't pause when you stop to change a mold or fix a jam. These costs continue to pile up.

Think about it this way: if your fixed costs are $50 per hour and you produce 2,000 bottles in that hour, the fixed cost per bottle is $0.025. But what if the machine is down for 30 minutes of that hour for a difficult mold change? You still paid $50, but you only produced 1,000 bottles. Your fixed cost per bottle has now doubled to $0.05. That's the brutal math of downtime. I've seen inefficient operations with costs ballooning simply because their line was idle too often.

Calculating the High Price of Inactivity

To control this cost, you first have to measure it. You need to calculate your "Cost of Downtime per Hour."

Formula:

Cost of Downtime per Hour = (Hourly Labor Cost + Hourly Rent/Overhead)

Let's create a scenario:

- Operator Salary: $20/hour

- Factory Rent + Utilities (allocated per hour): $15/hour

- Total Fixed Costs per Hour: $35

This means every hour your machine is not running, you are losing $35. Now, let's see how this impacts your bottle cost based on production efficiency. Production Efficiency is the percentage of time the machine is actually running as scheduled.

Impact of Downtime on Unit Cost (Based on an 8-hour day):

| Production Efficiency | Productive Hours | Downtime Hours | Total Bottles Produced (at 2,000 BPH) | Total Fixed Cost (8 hrs @ $35/hr) | Fixed Cost Per Bottle |

|---|---|---|---|---|---|

| 95% (Excellent) | 7.6 hrs | 0.4 hrs | 15,200 | $280 | $0.0184 |

| 85% (Average) | 6.8 hrs | 1.2 hrs | 13,600 | $280 | $0.0206 |

| 70% (Poor) | 5.6 hrs | 2.4 hrs | 11,200 | $280 | $0.0250 |

As you can see, dropping from excellent to poor efficiency increases your fixed cost per bottle by over 35%. This is a massive difference that can erase your profit margin.

Common Causes of Downtime:

- Mold Changes: Switching from one bottle design to another.

- Unplanned Maintenance: A part fails unexpectedly.

- Operator Inexperience: Difficulty diagnosing and fixing minor issues.

- Material Shortages: Running out of preforms.

- Poor Mold Fit: Wasting time trying to get an incompatible mold to work. Ensuring you have proper mounting dimensions for blow molding machines is critical to minimizing changeover time.

Reducing downtime is key to profitability. This involves training your operators well, scheduling preventive maintenance, and streamlining your processes like mold changes. One powerful way to validate a design before committing to expensive tooling is by using 3D printed samples to rapidly validate blow mold designs, which can prevent time-wasting adjustments later on. Every minute you save is money earned.

The Complete Formula: Calculating Your True 500ml Bottle Cost?

Are you ready to finally see how all these pieces fit together? Let's move beyond simplistic guesses and build a comprehensive formula that reflects the true, total cost of producing a single bottle.

The complete bottle cost formula combines direct costs (preform, labor) with allocated indirect costs (depreciation, total energy, scrap, maintenance). This provides a realistic unit cost essential for accurate pricing, budgeting, and profitability analysis.

This is the moment where we deliver on the promise from the beginning. We'll assemble all five of those hidden costs, along with the more obvious ones, into a single, powerful calculation. This formula is the tool that my Singaporean client used to realize that self-production was his best path forward. It's the difference between a business plan based on hope and one based on reality.

First, let's look at the overly simple formula that many people mistakenly use:

"Simple" Cost = Preform Price + (Machine Energy Cost / BPH) + (Operator Salary / BPH)

Now, let's build the True Cost Formula, incorporating everything we've discussed.

The True Cost Formula Breakdown

The True Cost is calculated by summing all your hourly costs and dividing by the number of good bottles produced per hour.

1. Calculate Total Hourly Production Cost (C_h):

C_h = (Hourly Preform Cost) + (Hourly Energy Cost) + (Hourly Labor Cost) + (Hourly Depreciation) + (Hourly Maintenance)

2. Calculate Good Bottles Per Hour (B_g):

B_g = (Rated Bottles Per Hour) * (Production Efficiency %) * (1 - Scrap Rate %)

3. Calculate True Cost Per Bottle (C_b):

C_b = C_h / B_g

Let's plug in all the numbers from our previous examples to calculate the cost for a 500ml PET bottle.

Input Variables Table:

| Variable | Description | Example Value |

|---|---|---|

| Preform Price | Cost per preform | $0.020 |

| Rated BPH | Bottles Per Hour (machine capacity) | 2,000 |

| Total Power | Combined working power for all equipment | 22.1 kW |

| Electricity Cost | Price per kWh | $0.15 |

| Labor Cost | Operator salary per hour | $20.00 |

| Depreciation Cost | Calculated hourly depreciation | $3.54 |

| Maintenance Cost | Calculated hourly maintenance budget | $0.68 ($1630 / 2400 hrs) |

| Efficiency % | Production uptime percentage | 85% (0.85) |

| Scrap Rate % | Percentage of failed bottles | 2% (0.02) |

Calculation Steps:

C_h(Total Hourly Cost):- Hourly Preform Cost:

2000 BPH * $0.020 = $40.00 - Hourly Energy Cost:

22.1 kW * $0.15 = $3.32 - Hourly Labor Cost:

$20.00 - Hourly Depreciation:

$3.54 - Hourly Maintenance:

$0.68 - Total

C_h:$40.00 + $3.32 + $20.00 + $3.54 + $0.68 = $67.54

- Hourly Preform Cost:

B_g(Good Bottles Per Hour):2000 * 0.85 * (1 - 0.02)1700 * 0.98 = 1666

C_b(True Cost Per Bottle):$67.54 / 1666 =$0.0405

Our final, true cost per bottle is $0.0405. Remember our initial "simple" cost was just the preform price of $0.020. The hidden costs more than doubled the price. This is the number you can confidently take to the bank.

Conclusion: From Hidden Costs to Controllable Profits?

By understanding and calculating these five hidden costs, you move from risky guesswork to confident planning. You can now control your profitability because you are measuring what truly matters.

Frequently Asked Questions (FAQ)

1. For a new PET bottling line, what is a realistic or "acceptable" percentage to budget for the production scrap rate?

For a new production line, budgeting for a scrap rate of 0.5% to 1% is a realistic and safe starting point. This range is considered acceptable in the industry. Initially, during the first few weeks of operation, the rate might be slightly higher (3-4%) as your team learns the machine and fine-tunes the parameters for your specific PET bottle mold design. As operations stabilize and your team gains experience, you should aim to reduce this to under 0.5% for a highly efficient line.

2. Of these 5 hidden costs, which one do startups most commonly underestimate or forget completely?

From my experience, the most commonly and severely underestimated hidden cost is #2: The Power Bill You Didn't Expect (Auxiliary Equipment). Nearly every new entrepreneur is shocked when they realize their high-pressure air compressor and chiller consume multiples of the energy used by the blow molding machine itself. They budget for the molder's power draw but are unprepared for the total energy consumption of the entire line, which can lead to a significant, negative impact on their projected profitability.

3. How can a reliable machine supplier help me predict these hidden costs before I make a purchase?

A reliable, transparent supplier acts as a partner, not just a seller. They should proactively help you predict these costs. For example, at iBottler, we provide:

- Clear Energy Data: We provide detailed power consumption specifications not just for the bottle blowing machine but also for the recommended auxiliary equipment like the air compressor and chiller.

- Recommended Spares List: We provide a list of common wear-and-tear parts, their expected lifespans, and their costs, allowing you to build an accurate maintenance budget from day one.

- Efficiency Estimates: Based on the complexity of your blow bottle mold and stated production goals, we can help you estimate a realistic production efficiency rate and scrap rate to use in your business plan.

A good supplier gives you the data you need to calculate your true costs before you commit.

4. What is a standard lifespan (in years) to use when calculating the depreciation for a new blow molding machine?

A standard and conservative useful lifespan to use for calculating the depreciation of a new PET blow molding machine is 8 to 10 years. While a well-maintained machine can certainly last longer, using a 10-year timeframe for financial planning is a common and prudent accounting practice. This ensures you are not overstating the asset's value over time and are adequately planning for its eventual replacement. Factors that can affect this include the number of operating hours per day, the quality of your maintenance program, and the technical complexity of the machine.

5. Now that I'm aware of these hidden costs, what is the single most effective way to reduce the total cost per bottle?

The single most effective way to reduce the total cost per bottle is to maximize production efficiency and minimize downtime. While you can negotiate prices for preforms and electricity to a certain extent, your greatest control lies in your operations. Every other cost (labor, depreciation, maintenance, overhead) is spread across the number of good bottles you produce. By keeping the machine running and producing high-quality bottles for the maximum amount of scheduled time (i.e., increasing your B_g or Good Bottles Per Hour), you shrink the allocated cost on each individual unit. This has a more dramatic impact on your bottom line than saving a fraction of a cent on a preform. Also, consider the bottle design, a good starting point is to understand how to choose the right preform neck size, as this can impact weight and cost.

PET Bottle True Cost Calculator

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

📞 Contact: Vivian

🏭 Zhongshan Jindong Machinery Co., Ltd.

🌍 www.ibottler.com

📧 Vivian@ibottler.com | 💬 WhatsApp: +86-13106288777

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr