Struggling to pick the right PET bottle for your juice? The choice between hot-fill and cold-fill processes can be confusing, directly impacting your costs, brand image, and product quality.

The primary difference is temperature. Hot-fill sterilizes juice with heat (85-95°C) inside a special, heat-resistant bottle. Cold-fill uses other sterilization methods before filling into lighter, more flexible bottle designs at lower temperatures, preserving more flavor and nutrients. This choice defines your bottle's design, material, and cost.

This decision can feel overwhelming, especially if you're new to the beverage world. I remember a client from Malaysia who was an expert in bottled water but wanted to launch a new juice line. He came to me completely unsure whether to go with hot-fill or cold-fill. He saw it as a huge new challenge. We sat down, and I walked him through these exact same points, from the basic science to the long-term investment in equipment like a suitable bottle blowing machine. Understanding these fundamentals is the first step toward making a confident and profitable choice for your brand. This guide will walk you through everything you need to know, just as I did for him.

Fundamentals of Filling Tech: What's the Core Difference Between Hot-Fill and Cold-Fill?

Feeling lost in the technical jargon of juice filling? You know you need to bottle your product, but the terms "hot-fill" and "cold-fill" seem like two different languages.

Hot-fill uses high temperatures (85-95°C) during filling to sterilize the juice and bottle at the same time. Cold-fill, including ambient and aseptic methods, fills at lower temperatures, relying on separate sterilization processes to ensure product safety, which better protects the juice's original taste.

Dive Deeper: Process, Purpose, and Product Impact

To choose the right path for your juice, you have to understand how these two technologies work at a fundamental level. They aren't just about temperature; they represent different philosophies in preserving your product, each with distinct consequences for your final juice and your operations.

The Core Mechanics: Process and Temperature

Let's break down what happens in each process.

Hot-Fill: Imagine making jam at home. You boil the fruit and sugar and pour it hot into a jar to keep it from spoiling. Hot-filling works on a similar principle. The juice is heated to a high temperature, typically between 85°C and 95°C (185°F to 203°F). It is then immediately filled into the PET bottle. The cap is applied, and the bottle is tilted or laid on its side for a specific duration. This ensures the hot juice sterilizes the inside surface of the cap. Afterwards, the sealed bottle is cooled down, usually with a water spray. This rapid cooling creates a vacuum inside the bottle, which pulls the walls inward. This is a critical point we'll discuss later, as it heavily influences the bottle's design. The entire process is a form of commercial sterilization in the package itself.

Cold-Fill: This is a broader category that includes a few different methods, but the key is that the product is not hot when it enters the bottle.

- Ambient Cold-Fill: This is used for products that are naturally stable or contain preservatives (like citric acid or sodium benzoate). The juice is filled at room temperature into a standard, non-heat-resistant PET bottle. This method is simpler and cheaper but is only suitable for certain formulations.

- Aseptic Cold-Fill: This is the most advanced and sensitive method. Here, the product and the packaging are sterilized separately in a completely sterile environment. The juice is flash-pasteurized (UHT - Ultra-High Temperature) for a few seconds and then rapidly cooled. The bottles and caps are sterilized using chemical agents (like peracetic acid or hydrogen peroxide) or radiation. The filling and capping happen inside a sterile "cleanroom" chamber. Because the bottle never touches hot liquid, it can be extremely lightweight and creatively shaped.

I often use this table to show clients the basic differences:

| Feature | Hot-Fill | Ambient Cold-Fill | Aseptic Cold-Fill |

|---|---|---|---|

| Filling Temperature | 85°C - 95°C (185°F - 203°F) | ~20°C - 30°C (~68°F - 86°F) | ~20°C - 30°C (~68°F - 86°F) |

| Sterilization Method | Product heat sterilizes the package | Chemical preservatives in the product | Product and package sterilized separately |

| Bottle Type | Heat-set, reinforced, heavier PET | Standard, lightweight PET | Standard or ultra-lightweight PET |

| Shelf Life | 6-12 months | Varies; often shorter | 6-12+ months, often preservative-free |

| Initial Investment | Moderate | Low | Very High |

| Product Suitability | High-acid juices, teas, isotonic drinks | Juices with preservatives | Premium juices, milks, sensitive beverages |

The Strategic Choice: Purpose and Application

The method you choose depends entirely on your product and your brand goals.

Hot-fill technology was developed as a cost-effective way to achieve commercial sterility for high-acid beverages (pH below 4.6), like apple, orange, or cranberry juice, and many ready-to-drink teas. The high acidity of the product helps inhibit the growth of most bacteria, and the heat treatment takes care of the rest (yeasts and molds). It's a robust, reliable, and well-understood process. It's the workhorse of the juice industry for many shelf-stable products.

Cold-fill's purpose is different. Its primary goal is to minimize the thermal impact on the product. This makes it ideal for:

- Nutrient-Sensitive Products: Many vitamins, especially Vitamin C, are degraded by prolonged exposure to heat. Aseptic filling, with its rapid heat-then-cool cycle, preserves these nutrients far more effectively.

- Flavor-Delicate Products: Think of a fresh-squeezed orange juice versus a long-life juice. The "cooked" taste in some shelf-stable juices is a direct result of the heat treatment. Aseptic filling delivers a flavor profile much closer to the original fruit.

- Low-Acid Products: For products like coconut water, vegetable juices, or dairy-based drinks (which have a pH above 4.6), hot-filling is not sufficient to ensure safety. Aseptic filling is mandatory for these products to make them shelf-stable without refrigeration.

When my Malaysian client was trying to decide, I asked him, "What is the core promise of your new juice brand? Is it 'reliable and affordable' or 'premium, fresh, and all-natural'?" His answer to that question immediately pointed us toward one technology over the other.

The Final Result: Impact on Product Quality

The end consumer may not know what hot-fill or cold-fill means, but they can taste, see, and perceive the difference.

- Flavor and Aroma: This is the most noticeable difference. The prolonged heat of the hot-fill process can slightly alter the flavor profile of delicate juices. While perfectly acceptable and enjoyable for many products, it cannot match the fresh, vibrant taste that aseptic filling can preserve.

- Color: High temperatures can also affect the natural pigments in juice. Some colors may darken or change hue during hot-filling. A cold-filled product generally maintains a brighter, more natural color that looks more appealing on the shelf.

- Nutrition: As mentioned, heat is the enemy of certain vitamins. If your marketing message is centered on the health benefits and vitamin content of your juice, aseptic cold-fill is the superior choice for preserving that nutritional value.

- Additives: Because hot-filling is a powerful sterilization method, it often allows for a clean label with no preservatives. However, aseptic filling can achieve the same, if not better, result, creating a preservative-free product with a fresher taste. Ambient cold-fill, on the other hand, almost always relies on preservatives to ensure shelf stability.

Ultimately, the fundamental difference isn't just about hot or cold. It's about balancing product integrity, production cost, and brand positioning.

The First Design Challenge: Why Do Hot-Fill PET Bottles Need a Special Design?

You've seen them on the shelf: some juice bottles have strange panels and ribs, while others are perfectly smooth. Ever wonder why they are so different?

This isn't for looks. The special design of hot-fill PET bottles is essential to survive the extreme heat and subsequent vacuum pressure created during the filling process, preventing them from collapsing.

Dive Deeper: Engineering for Survival

A standard PET bottle, like one for water, would instantly deform into a shriveled mess if you tried to hot-fill it. The design of a hot-fill bottle is a masterclass in material science and structural engineering, specifically created to handle a triple threat: high heat, internal pressure, and external vacuum. Let's look at the three key areas where this special design is critical.

Resisting Heat Deformation: The Battle Against Heat and Vacuum

The biggest challenge is handling the dramatic temperature change. The process starts with the bottle being filled with juice close to boiling point, around 90°C. At this stage, the PET material softens slightly and the hot liquid and air inside expand, creating internal pressure. The bottle must be strong enough not to bulge.

The real trouble begins during cooldown. As the bottle and its contents cool from 90°C to room temperature, the liquid and the headspace gas contract significantly. This creates a powerful negative pressure, or vacuum, inside the bottle. This vacuum desperately wants to pull the bottle's walls inward, causing it to collapse. To fight this, engineers use several clever design tricks, which are detailed in our comprehensive PET bottle mold design guide.

- Vacuum Panels: These are the distinctive flat panels you see on the sides of many hot-fill juice or tea bottles. They are not just for decoration. These panels are specifically designed to flex inward in a controlled way as the vacuum forms. Instead of the whole bottle collapsing unpredictably, these panels absorb the pressure, maintaining the overall shape and integrity of the container. It's like having a designated "crumple zone" on a car.

- Reinforcement Ribs: You will often see horizontal or vertical ribs or grooves designed into the bottle walls. These act like the structural beams in a building. They add stiffness and rigidity to the bottle's structure, preventing it from buckling under the combined stress of heat and vacuum. The base of the bottle is also critical; it often features a specialized star or flower-shaped design with deep ribs to prevent it from being sucked upward and becoming unstable.

When I explain this to clients, I often ask them to imagine a simple plastic bottle. If you pour out some water and seal it, then put it in the fridge, you'll see it slightly buckle inward. Hot-filling creates this effect but a hundred times more powerfully. The bottle's design must anticipate and manage this force perfectly.

Crystallinity Control: The Secret of the Bottle Neck

While the body of the bottle needs to be strong yet flexible, the neck finish—the part with the threads where the cap goes—needs to be incredibly rigid and stable. It cannot deform at all. If the neck changes shape when the hot liquid is filled or when the cap is sealed, the seal will be compromised, leading to leaks and product spoilage.

The secret to a strong neck is controlling the crystallinity of the PET material.

- What is Crystallinity? In its natural, transparent state (amorphous), the polymer chains in PET are arranged randomly, like a bowl of spaghetti. When PET is heated and processed in a specific way, these chains can align themselves into organized, tightly packed structures. This state is called "crystalline." Crystalline PET is stronger, more rigid, and has a higher heat tolerance. It's also typically opaque or white.

- Heat-Setting the Finish: During the production of a hot-fill bottle, the main body is blown to be mostly amorphous (to stay clear), but the neck finish undergoes a separate process called heat-setting. The preform's neck is heated to a high temperature and held there, encouraging the polymer chains to crystallize. This makes the neck finish exceptionally stable and resistant to deformation, even at 90°C. You can often spot a heat-set neck by its slightly opaque or crystalline appearance compared to the clear body of the bottle. This is a critical step, and choosing the right preform neck size and standard is the first step in this process.

A perfect seal is non-negotiable, and it all starts with a perfectly stable, heat-set neck finish. Any mistake here can lead to massive product recalls.

Material and Gram Weight: Building a Heavier-Duty Bottle

You can't build a strong house with weak bricks. The same is true for hot-fill bottles. The design relies on using the right material and enough of it.

- Heat-Resistant PET Grade: While the base polymer is the same, PET resins intended for hot-fill applications often have different additives or co-polymers that increase their glass transition temperature (the temperature at which the material begins to soften). This gives the bottle a slightly higher heat resistance from the start.

- Higher Gram Weight: This is a simple but crucial factor. A hot-fill bottle of the same volume will almost always be heavier than a cold-fill bottle. For example, a 500ml cold-fill water bottle might weigh 12-15 grams. A 500ml hot-fill juice bottle might weigh 22-28 grams, or even more. This extra material provides the necessary bulk and wall thickness to contribute to the bottle's overall structural strength. It helps the bottle withstand the internal pressure during filling and the vacuum forces during cooling.

When we design a new hot-fill bottle, we don't just draw a shape. We use advanced computer simulations (Finite Element Analysis) to predict how the bottle will behave under heat and pressure. We can then optimize the placement of every gram of plastic, ensuring the ribs, panels, and wall thickness work together to create a bottle that is both strong and as cost-effective as possible. This is where partnering with an experienced designer of blow bottle molds becomes essential.

The Advantage of Cold-Fill: Greater Freedom in PET Bottle Design?

Tired of the design constraints of hot-fill bottles? Imagine creating a juice bottle that is as beautiful and unique as the product inside, without worrying about vacuum panels or heavy walls.

This is the world of cold-fill. Because it avoids high-temperature stress, cold-fill technology gives designers enormous freedom to create lightweight, visually stunning, and creatively shaped PET bottles that capture consumer attention.

Dive Deeper: Unleashing Creativity and Efficiency

When you remove the punishing requirements of heat and vacuum, a world of design possibilities opens up. The bottle's job is no longer to be a survivalist container; its primary role can shift to being a powerful marketing tool. For brands that want to stand out, communicate premium quality, or highlight sustainability, cold-fill design offers three powerful advantages.

The Economic and Ecological Edge: Lightweighting Potential

The single biggest advantage of cold-fill design is the potential for lightweighting. This refers to the process of reducing the amount of plastic (gram weight) in a container without compromising its performance. Since a cold-fill bottle doesn't need thick walls, heavy-duty ribs, or reinforced bases to fight a vacuum, it can be made significantly lighter than its hot-fill counterpart.

This has a cascade of positive effects:

- Direct Material Savings: PET resin is the main cost component of a bottle. If you can reduce the weight of a 500ml bottle from 25 grams (hot-fill) to 15 grams (cold-fill), you have just cut your raw material cost for that bottle by 40%. When my Malaysian client and I ran the numbers, the potential annual savings from lightweighting ran into the tens of thousands of dollars, which immediately caught his attention. For a high-volume producer, this is a massive, ongoing financial benefit.

- Reduced Carbon Footprint: Using less plastic is not just cheaper; it's better for the environment. A lighter bottle requires less energy to manufacture and less fuel to transport. This allows a brand to build a powerful eco-friendly narrative around its packaging, which is increasingly important to modern consumers. You can legitimately claim that your packaging uses less plastic and has a lower carbon footprint.

- Production Efficiency: Lighter preforms require less energy to heat and blow in the bottle blowing machine. The cooling cycle can also be faster, potentially leading to higher output rates (bottles per hour).

This lightweighting potential is the primary driver for many companies, especially those producing high volumes, to invest in aseptic cold-fill technology despite the higher initial cost of the production line. The long-term savings on material can provide a very attractive return on investment.

The Artist's Canvas: Versatile Shapes and Brand Expression

Hot-fill bottle design is driven by engineering constraints. Cold-fill bottle design is driven by marketing imagination. Free from the need for vacuum panels and rigid structural ribs, the surface of a cold-fill bottle becomes a smooth canvas.

This freedom allows for:

- Complex and Elegant Curves: Designers can create bottles with sleek contours, ergonomic grips, and unique silhouettes that are simply impossible with hot-fill. Think of the smooth, flowing lines of a premium smoothie bottle or the iconic shape of a specialty juice brand. These shapes create a distinct visual identity on the shelf.

- Embossing and Debossing: Brands can incorporate detailed logos, patterns, or textures directly into the bottle's surface. This adds a tactile element to the consumer experience and communicates a sense of quality and sophistication. An embossed logo feels much more premium than a simple printed one.

- Unique Footprints: The bottle's base and shoulder can be designed for more than just stability. They can be shaped to create a unique profile that is instantly recognizable.

I once worked on a project for a children's juice brand. We used cold-fill design to create a bottle shaped like a friendly cartoon fruit character. The shape was fun, easy for small hands to hold, and stood out dramatically in the juice aisle. This would have been unthinkable with hot-fill technology. The ability to create a bottle that tells a story and connects emotionally with the consumer is a powerful branding tool that cold-fill fully enables. Validating such a unique design is easy with modern methods like 3D printed samples to rapidly validate blow mold designs, allowing us to perfect the feel and look before committing to expensive tooling.

The Window to the Product: Superior Clarity and Aesthetics

A key goal of beverage packaging is to make the product itself look as appealing as possible. For a vibrant, colorful fruit juice, this means showcasing its color with maximum clarity.

Cold-fill bottles excel in this area:

- Uninterrupted Transparency: Because the walls are smooth and free of the visual disruption caused by vacuum panels and heavy ribs, cold-fill bottles offer crystal-clear transparency. This acts like a perfect window, letting the natural color and quality of the juice shine through. The product looks fresher and more appetizing.

- Higher Gloss: The molding process for standard PET bottles often results in a higher surface gloss compared to the specialized heat-set bottles. This enhances the perception of clarity and gives the bottle a premium, jewel-like appearance on the shelf.

- Better Label Application: A smooth, straight, or gently curved bottle wall is the ideal surface for applying labels. Whether it's a full-body shrink sleeve or a pressure-sensitive label, the application is cleaner and more effective, without the need to work around complex panel geometries. A perfectly applied label contributes significantly to the overall perception of quality.

When a consumer is scanning a crowded supermarket shelf, these aesthetic factors make a huge difference. A bottle that is clear, bright, and beautifully shaped is more likely to be picked up. Cold-fill design gives brands the best possible tools to win that crucial first moment of choice.

In-Depth Cost Analysis: Comparing Molds, Materials, and Production Line Investment?

You understand the technical differences, but what about the bottom line? Choosing between hot-fill and cold-fill is a major financial decision with long-term consequences for your business.

The upfront cost of a hot-fill line is lower, but the cost per bottle is higher. An aseptic cold-fill line has a massive initial investment, but it saves you money on every single bottle you produce.

Dive Deeper: A Complete Financial Breakdown

To make a smart decision, you need to look beyond the price tag of the filling machine. The total cost of ownership involves the molds, the raw materials, and the production line itself. Let's break down each component to see where the money goes.

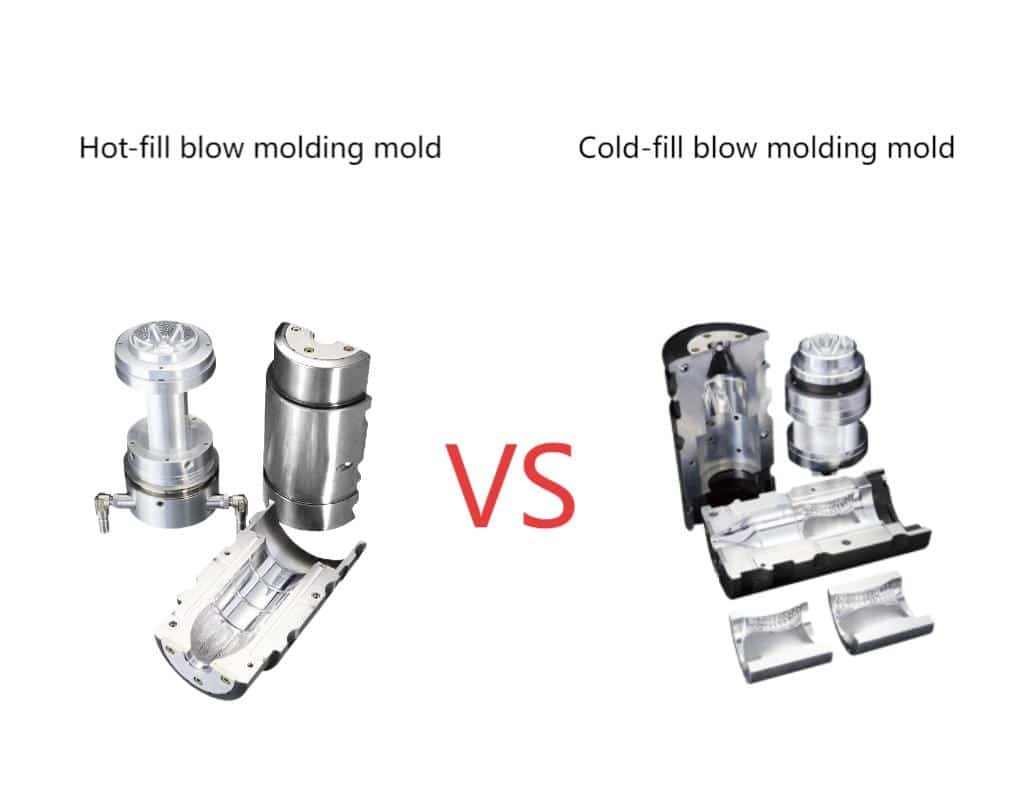

The Starting Point: Mold Costs and Complexity

The first piece of custom equipment you'll need is the blow mold, which shapes the heated preform into your final bottle. This is where the first cost difference appears.

Hot-Fill Molds: As we've discussed, hot-fill bottles have complex designs with vacuum panels, reinforcement ribs, and specialized base structures. This complexity translates directly into the mold manufacturing process.

- Design & Engineering: More engineering hours are needed to design and simulate these features to ensure they perform correctly.

- Machining: The mold, typically made from aircraft-grade aluminum or steel, requires intricate machining using advanced CNC machines to create these detailed features. This takes more time and skill.

- Cooling Channels: Hot-fill molds also need more complex and efficient cooling channels to manage the higher temperatures of the blow molding process. Linking them to a powerful chiller system is essential for cycle time and bottle quality.

All these factors mean a high-quality hot-fill blow bottle mold will cost significantly more than a cold-fill mold for a bottle of the same size.

Cold-Fill Molds: Cold-fill bottles, with their simpler, smoother surfaces, require less complex molds. The design and machining processes are more straightforward, leading to lower manufacturing costs and faster lead times.

When budgeting for a new project, the mold is a key capital expenditure. For a startup or a brand testing a new product, the lower mold cost for cold-fill can be an attractive advantage, assuming they use a co-packer with an existing cold-fill line.

The Ongoing Expense: Unit Bottle Cost

This is where the long-term economics really diverge. The cost of a single bottle, produced millions of times over, has a huge impact on your product's profit margin.

The primary driver here is the gram weight.

Hot-Fill's Material Penalty: As established, hot-fill bottles need to be heavier to provide structural integrity. That extra 5, 10, or even 15 grams of PET resin per bottle adds up fast. Let's say PET resin costs $1,500 per ton (or $1.50 per kilogram).

- A 25g hot-fill bottle has a raw material cost of $0.0375.

- A 15g cold-fill bottle has a raw material cost of $0.0225.

That's a difference of 1.5 cents per bottle. If you produce 20 million bottles a year, that's $300,000 in extra material cost annually just for choosing hot-fill. This was the exact calculation that made my Malaysian client pause and seriously re-evaluate his initial plan to go with the "simpler" hot-fill route.

Cold-Fill's Material Advantage: The ability to lightweight is cold-fill's superpower in terms of operational costs. The savings are direct, substantial, and recurring. Over the lifetime of a product, these savings can far exceed the initial difference in equipment investment.

The Big Ticket Item: Production Line Investment

This is the largest capital expense and where the roles are reversed.

Hot-Fill Line Investment (Moderate): A hot-fill line consists of a blowing machine, a heater for the juice, the filler, a capper, a cooling tunnel, and labeling/packing equipment. While it's a significant investment, the technology is mature and widely available from many suppliers. The cost is considerable but manageable for many established companies.

Ambient Cold-Fill Line Investment (Low): This is the cheapest route. It requires a blower, filler, capper, and downstream equipment. It doesn't need a large pasteurizer or cooling tunnel, making it the most accessible option, but it limits you to products that are shelf-stable with preservatives.

Aseptic Cold-Fill Line Investment (Very High): An aseptic line is in another league. The heart of the system is the sterile zone. This requires:

- Aseptic Filler & Capper: This machinery operates within a microbiological isolator, essentially a sealed, sterile chamber.

- Sterilization Systems: You need equipment to sterilize the bottles, caps, and the product separately before they enter the sterile zone.

- Cleanroom Environment: The entire filling area must be maintained as a cleanroom with filtered air and positive pressure, similar to a surgical operating room.

The cost of an aseptic line can be 3 to 5 times higher than a comparable hot-fill line. This is a massive barrier to entry and is typically only undertaken by large companies or those specializing in premium, sensitive products. However, they gain ultimate flexibility, superior product quality, and the lowest possible unit bottle cost.

Here is a summary cost comparison:

| Cost Category | Hot-Fill | Ambient Cold-Fill | Aseptic Cold-Fill |

|---|---|---|---|

| Mold Investment | High | Low | Low |

| Unit Bottle Cost (Material) | High | Low | Lowest |

| Line Equipment CAPEX | Moderate | Low | Very High |

| Energy Consumption | High (Heating & Cooling) | Low | High (Sterilization & Cleanroom) |

| Operational Complexity | Moderate | Low | Very High (Requires specialized staff) |

The choice is a strategic trade-off. Hot-fill offers a lower entry barrier for producing shelf-stable, high-acid juices. Aseptic cold-fill demands a huge investment but pays back with material savings and superior product quality, opening doors to premium markets.

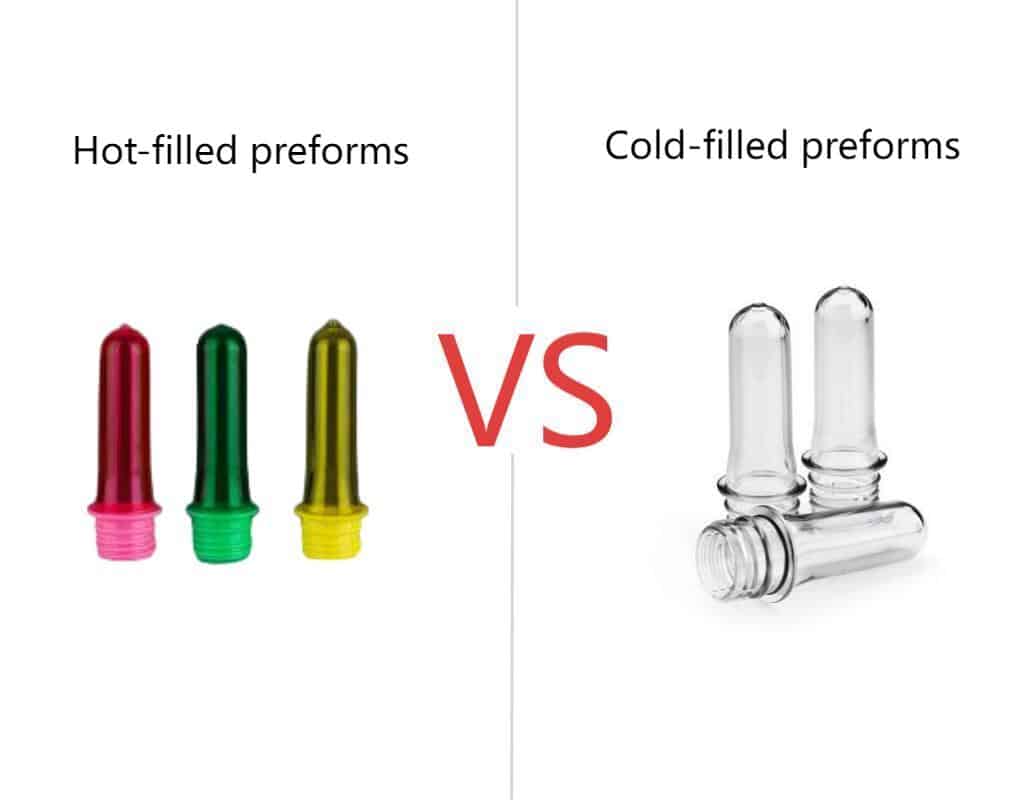

The Decisive Role of the Preform: How to Choose It for Different Processes?

Think the bottle is the star of the show? The unsung hero of your packaging is actually the preform—the small, test-tube-shaped piece of plastic that gets blown into the final bottle.

Choosing the right preform is not just a detail; it's a critical decision that defines the quality, strength, and cost of your final bottle. A hot-fill bottle requires a fundamentally different preform from a cold-fill bottle.

Dive Deeper: The Blueprint for Your Bottle

The preform is the genetic blueprint of the bottle. Its design, material, and weight dictate the final outcome of the blow molding process. Getting this stage right is essential, and it requires a deep understanding of how a small tube of plastic transforms into a full-size container.

Blueprint for Strength: Preform Design Differences

At first glance, preforms might look similar, but the ones destined for hot-fill are engineered very differently. The goal is to ensure that when the preform is stretched and blown, the plastic is distributed precisely to create the strong, reinforced bottle needed.

Weight and Wall Thickness: The most obvious difference is weight. A hot-fill preform is significantly heavier and has thicker walls than a cold-fill preform for the same bottle volume. This extra material is the foundation for the bottle's final strength.

Stretch Ratios: This is a crucial technical parameter. Stretch ratio refers to how much the preform is stretched in length (axial ratio) and in width (hoop ratio) during blowing.

- In a cold-fill bottle, designers aim for high stretch ratios. Stretching the PET orients the polymer chains (strain-induced crystallization), which gives the bottle strength, allowing for a lighter weight.

- In a hot-fill bottle, the stretch ratios are typically lower. The design relies more on the sheer thickness of the plastic and the molded-in structural features (ribs, panels) rather than on stretch-induced strength. The preform's design ensures that even with less stretching, enough material ends up in critical areas like the corners, base, and under the support ring.

Preform-to-Bottle Geometry: The shape of the preform itself is matched to the final bottle design. For a hot-fill bottle with vacuum panels, the preform might be designed to be thicker in the areas that will become those panels, providing the material needed to absorb the vacuum force. Designing the right preform mold is a highly specialized skill that balances these ratios with the final application.

I often show clients a computer simulation of the blowing process. They can see how a poorly designed preform leads to thin spots in critical areas, which would cause the bottle to fail during hot-filling. This visual makes them understand why the preform design is so foundational.

The Right Stuff: Material Selection

Not all PET is created equal. The specific grade of PET resin used to make the preform is another critical choice.

Standard PET: Used for cold-fill applications like water, soft drinks, and some juices with preservatives. This resin provides excellent clarity and strength for general-purpose bottles.

Heat-Resistant PET (Hot-Fill Grade): For hot-fill preforms, a special grade of PET is used. This is often a copolymer, meaning a second monomer (like isophthalic acid (IPA) or cyclohexanedimethanol (CHDM)) is added to the main PET polymer structure. These comonomers disrupt the polymer chains just enough to slow down the rate of crystallization during blowing. This gives the material a higher glass transition temperature (Tg), meaning it softens at a higher temperature. This enhanced thermal stability is essential for the bottle to maintain its shape when filled with 90°C liquid.

The choice of resin is a trade-off between performance and cost. Heat-resistant grades are more expensive, which further contributes to the higher unit cost of a hot-fill bottle.

The Power of Partnership: Supplier Synergy

You cannot design a bottle in isolation. The bottle design, preform design, and blow molding process are a tightly integrated system. A change in one area has a direct impact on the others. This is why collaboration is key.

Integrated Design: When we take on a new project, we don't just ask for a bottle drawing. We start a conversation about the product, the filling process, the production line, and the brand's goals. My conversation with the Malaysian client wasn't just about hot-fill vs. cold-fill; it was about ensuring that whatever bottle we designed, he could find a preform and blowing machine that were compatible.

Experienced Suppliers: Working with an experienced supplier who understands this entire ecosystem is crucial. They can:

- Recommend the optimal preform weight and design for your bottle.

- Advise on the correct grade of PET resin.

- Help you fine-tune the blow molding machine parameters (temperatures, pressures, timings) to get a perfect bottle every time.

- Help you troubleshoot common issues, drawing on a deep knowledge of PET blow molding defects and their solutions.

Prototyping and Testing: Before you invest in expensive production molds, you must test the entire system. This involves creating prototype molds, blowing sample bottles from the chosen preform, and subjecting them to rigorous testing—including hot-filling, capping, cooling, and drop tests. This validation step is non-negotiable for ensuring a successful launch.

Choosing a preform is not like picking an item off a shelf. It's the first step in a complex manufacturing process that requires foresight, technical expertise, and a strong partnership with your suppliers.

Brand & Market: How Does Bottle Design Influence Consumer Purchasing Decisions?

You've perfected your juice recipe, but will customers actually pick it up? In a crowded supermarket aisle, your bottle is your first—and sometimes only—salesperson.

The design of your bottle is not just a container; it's a powerful marketing message. It directly shapes how consumers perceive your brand's quality, values, and personality, strongly influencing their decision to buy.

Dive Deeper: The Silent Sales Pitch on the Shelf

Never underestimate the power of packaging. Studies have shown that a significant percentage of purchasing decisions are made at the point of sale. Your bottle has just a few seconds to grab a shopper's attention and communicate everything about your brand. Here's how the design choices, often dictated by hot-fill or cold-fill processes, play a crucial role in this silent sales pitch.

The Battle for Attention: Shelf Appeal

The first job of your bottle is to get noticed. The supermarket shelf is a battlefield of colors, shapes, and messages. A generic or uninspired bottle will simply blend into the background.

The Cold-Fill Advantage in Shape: As we've discussed, cold-fill technology allows for immense creative freedom. This is a huge marketing advantage. A brand can design a bottle that is:

- Ergonomic: Comfortable and pleasing to hold.

- Iconic: Instantly recognizable, even without the label. Think of the classic Coca-Cola bottle shape.

- Thematic: Shaped to evoke the product inside, like a bottle with a subtle orange-peel texture for an orange juice.

This ability to create a unique and tactile shape helps a product stand out from a sea of generic, panel-clad hot-fill bottles.

The Hot-Fill Challenge: While hot-fill bottles are limited by their structural requirements, good design can still make a difference. Clever use of the label area, a unique cap color, or subtle texturing can help a hot-fill bottle look more premium. However, it's undeniably harder to achieve a truly distinctive silhouette.

I once worked with a startup launching a premium cold-pressed juice. They opted for an aseptic cold-fill process specifically because they wanted a tall, slender, crystal-clear bottle that looked more like a high-end cosmetic product than a standard juice. Their unique bottle shape became a core part of their brand identity and justified a higher price point. They understood that you first sell the bottle, then you sell the juice inside.

The Modern Consumer's Concern: The Eco-Friendly Narrative

Today's consumers, especially younger generations, are increasingly making choices based on a brand's environmental and social values. Packaging plays a huge role in this.

Lightweighting as a Green Story: A key benefit of cold-fill design is the ability to lightweight the bottle. This is a powerful marketing tool. A brand can communicate a clear, simple, and verifiable environmental message:

- "Our new bottle uses 30% less plastic."

- "Lighter packaging means a smaller carbon footprint."

This resonates with eco-conscious shoppers and can be a deciding factor for purchase. It shows that the brand is thoughtful and responsible.

Recyclability and Materials: While both hot-fill and cold-fill PET bottles are 100% recyclable, the "less is more" message of a lightweight cold-fill bottle is often easier for consumers to understand and appreciate. Brands can further this narrative by incorporating recycled PET (rPET) into their bottles, creating a closed-loop story of sustainability.

When talking to brands, I always ask about their target consumer. If they are aiming for the Whole Foods crowd, a strong sustainability story is not just a "nice to have," it's essential. The lighter weight and eco-friendly potential of cold-fill bottles provide a much more compelling story to tell.

The Psychology of Packaging: Perceived Value

The quality of your packaging is often seen as a direct reflection of the quality of your product. A cheap-looking bottle signals a cheap product, regardless of how good the juice actually is.

Clarity, Gloss, and Quality: The superior clarity and gloss of a smooth-walled cold-fill bottle create a perception of premium quality. The juice looks brighter and fresher. The smooth surface allows for perfect label application, without wrinkles or bubbles. Every detail contributes to a feeling of high value.

Tactile Experience: The feel of the bottle in a consumer's hand matters. A heavy, rigid hot-fill bottle can communicate sturdiness and reliability. A sleek, smooth cold-fill bottle can communicate elegance and modernity. The tactile experience should align with the brand's desired image. For example, a 3D printed sample bottle can allow brand managers to actually feel the bottle's ergonomics and texture before committing to production.

Price Justification: A well-designed, high-quality package can help justify a higher price point. If a consumer is deciding between two orange juices, and one is in a standard, paneled hot-fill bottle and the other is in a beautiful, crystal-clear, custom-shaped cold-fill bottle, they will intuitively believe the latter contains a higher quality product and will be more willing to pay more for it.

Your bottle design is an investment in your brand's equity. It's a tangible asset that works for you on the shelf every single day. Choosing a filling technology is therefore not just a production decision; it's a core marketing decision.

Common Design Pitfalls: Mistakes to Avoid in Both Processes?

You've chosen your filling process and are excited to design your bottle. But a great concept can quickly turn into a production nightmare if you overlook a few crucial details.

Whether you choose hot-fill or cold-fill, several common design pitfalls can lead to unstable bottles, poor labeling, and a frustrating experience for your customers, ultimately damaging your brand's reputation.

Dive Deeper: Engineering for a Flawless Experience

A successful bottle design is one that looks good, performs flawlessly on the production line, and is easy for the consumer to use. Avoiding common pitfalls requires thinking about the bottle's entire lifecycle, from the conveyor belt to the consumer's fridge. Here are three of the most common and costly mistakes I've seen, and how to avoid them.

The Foundation of Stability: The Unstable Base

A bottle that wobbles or tips over easily is a disaster. It will cause constant jams on a high-speed production line, leading to costly downtime and wasted product. On the retail shelf, it looks sloppy. In a consumer's home, it's an annoyance that can lead to spills.

- The Center of Gravity: A tall, thin bottle with a narrow base is inherently less stable. The bottle's overall shape must be designed with a low center of gravity to ensure it's stable.

- The 'Push-Up' or 'Punt': The concave area at the bottom of the bottle is critical. Its depth and shape affect stability.

- The Contact Surface: The very bottom of the bottle that touches the shelf or conveyor is the most important part. For most PET bottles, this is not a flat surface but a ring or a series of "feet." These points must be perfectly level and wide enough to provide a stable stance. Even a tiny, imperceptible imperfection in the blow bottle mold can lead to a wobbly bottle.

- Hot-Fill Specifics: For hot-fill bottles, the base design is even more critical. It often has deep ribs (a "star" or "petaloid" base) not only for stability but also to resist the vacuum pressure that tries to suck the bottom upward during cooling. If this design is weak, the bottle can develop a "rocker bottom," where the center of the base bulges out, making it completely unstable.

Before finalizing any design, we run stability tests. We place prototype bottles on angled surfaces and on moving belts to see how they perform. It's a simple test that can prevent a massive headache later.

The Face of Your Brand: A Poor Labeling Area

Your label carries your brand name, your story, and essential product information. If it can't be applied cleanly and smoothly, the entire package looks cheap and unprofessional.

- The 'Label Panel': Designers must intentionally create a dedicated area for the label. This area should ideally be a perfect cylinder or have a very slight, uniform taper. Complex curves, reverse tapers, or ridges in this area can cause major problems for labeling machines.

- Wrinkles and Bubbles: If a label is applied over an uneven surface, it will inevitably trap air, causing bubbles or wrinkles. This is a common issue when designers prioritize a fancy shape without considering how the label will wrap around it.

- Shrink Sleeves vs. Pressure-Sensitive: The type of label you plan to use influences the bottle design. A full-body shrink sleeve can conform to more complex shapes than a traditional wrap-around paper or plastic label. However, even shrink sleeves struggle with sharp angles or compound curves. The bottle must be designed with the chosen labeling method in mind from day one.

I often see beautiful bottle concepts that are impossible to label effectively. We had a client who wanted a bottle shaped like a twisted piece of fruit. It looked great as a 3D rendering, but we had to work extensively on the design, creating a subtly smoother central section just for the label, to make it manufacturable. Checking these details with a physical 3D printed prototype is invaluable for spotting potential labeling issues early.

The Final Interaction: A Bad User Experience

The consumer's final interaction with your package can make or break their perception of your brand. If the bottle is difficult to open, awkward to hold, or messy to pour from, it leaves a lasting negative impression.

- Cap and Neck Finish Compatibility: This is a surprisingly common and serious error. There are many different standards for neck finishes (the threads on the bottle). For example, an 1881 neck finish requires a specific type of 1881 cap. Using a mismatched cap can lead to leaks, difficulty opening, or a cap that strips its threads and won't reseal properly. Choosing the right preform neck size and ensuring it matches your chosen cap is a critical technical checkpoint.

- Ergonomics and Grip: How does the bottle feel in your hand? Is it easy to hold, especially for children or elderly consumers if they are your target audience? A large, smooth bottle can be slippery and hard to grip. Incorporating a subtle indented grip area can make a huge difference in user-friendliness.

- Opening and Pouring: The force required to twist off the cap (the "torque") should be just right—secure enough to prevent leaks, but easy enough to open without a struggle. The design of the neck and mouth of the bottle should also allow for a smooth, glug-free pour.

These "small" details are anything but. They are the final touchpoints of your brand. Ignoring them is a classic pitfall that can undo all the hard work you put into your product and packaging design. Thoroughly testing for these human factors is just as important as testing for technical performance. Many of these issues are preventable if you have a deep understanding of common PET blow molding defects and their solutions.

Making the Final Choice: A Checklist to Help You Decide?

Feeling overwhelmed by the options? Let's simplify it. Choosing the right bottle design and filling process comes down to answering three key questions about your business.

To make the best decision, you need a clear understanding of your product's needs, your financial reality, and your brand's identity. This checklist will guide you to the right choice.

Dive Deeper: A Strategic Decision Framework

This final choice is a balancing act between science, finance, and marketing. There is no single "best" answer, only the answer that is best for your specific situation. Let's walk through the decision framework I use with my clients, like the one in Malaysia, to bring clarity to this complex choice.

Checklist Item 1: Product Characteristics

The nature of your juice itself will immediately rule out some options. Your product is the non-negotiable starting point.

| Ask Yourself... | If You Answered A... | If You Answered B... |

|---|---|---|

| A) High-Acid (pH < 4.6) like apple, orange, cranberry juice or B) Low-Acid (pH > 4.6) like vegetable juice, coconut water, milk blends? | A) You can use Hot-Fill, Ambient Cold-Fill (with preservatives), or Aseptic Cold-Fill. | B) You must use Aseptic Cold-Fill for a shelf-stable product. Hot-fill is not sufficient to kill dangerous bacteria like Clostridium botulinum in a low-acid environment. |

| A) Contains heat-sensitive vitamins (like Vitamin C), delicate flavors, or natural colors or B) Is a robust flavor profile (like grape or apple) that is less affected by heat? | A) Aseptic Cold-Fill is strongly recommended to preserve nutrients and a fresh taste/look. This is key for premium, "fresh," or "all-natural" positioning. | B) Hot-Fill is a perfectly viable and cost-effective option. The impact on the flavor and color will be minimal and acceptable for many consumers. |

| A) A "clean label" with zero preservatives is essential for my brand or B) Using common preservatives (like sorbates or benzoates) is acceptable? | A) Your choice is between Hot-Fill and Aseptic Cold-Fill, as both can create a preservative-free, shelf-stable product. | B) Ambient Cold-Fill becomes an option. It's the cheapest process but may not align with a "natural" brand image. |

The Verdict: If your juice is low-acid or you are marketing a premium product based on its fresh taste and nutritional value, the path strongly leads toward Aseptic Cold-Fill. If you have a high-acid juice and are targeting a broader market where value is key, Hot-Fill is a very strong contender.

Checklist Item 2: Budget and Scale

This is the reality check. Your financial resources and production volume will heavily influence what is feasible.

What is your upfront capital investment budget for equipment?

- Low: Your best option is to work with a co-packer (a contract packer). You can find co-packers with all types of lines (hot-fill, aseptic, etc.). This allows you to produce your product without buying the machinery yourself. Your bottle design choice will depend on what capabilities the co-packer has.

- Moderate: You can likely afford to set up your own Hot-Fill line. The technology is mature and the investment is more manageable than aseptic.

- High: You can consider investing in your own Aseptic Cold-Fill line. This is a major strategic decision. It requires a significant budget but gives you maximum control, the lowest long-term cost per bottle, and the highest product quality. I advise clients like my friend in Malaysia to create a 5-year financial model to see if the material savings from aseptic will eventually pay back the massive initial investment.

What is your projected annual production volume?

- Low (e.g., < 1 million units/year): The high cost of an aseptic line is very difficult to justify. Working with a co-packer is almost certainly the best financial decision.

- High (e.g., > 10 million units/year): At this scale, the math starts to change. The recurring savings from lightweighting your bottles with a cold-fill process can be enormous. A high-volume business is the ideal candidate to benefit from the long-term ROI of an aseptic line. For these volumes, you need a robust production plan, including reliable air systems to power your blow molding operations efficiently.

The Verdict: Don't let ambition outpace your budget. Be realistic. For most new entrants, partnering with a co-packer is the smartest way to start. For established players with high volumes, a detailed financial analysis is needed to compare the Total Cost of Ownership (TCO) of a new hot-fill line versus an aseptic line.

Checklist Item 3: Brand Positioning

Finally, who are you and what do you want your customers to think of you? Your package is your ambassador.

What is your brand's core message?

- "Traditional, Reliable, Great Value": The sturdy, familiar look of a hot-fill bottle can align well with this message. It communicates safety and shelf-stability in a way consumers understand.

- "Modern, Premium, Innovative, Healthy, Sustainable": The design freedom of cold-fill is almost essential for this positioning. You can create a sleek, beautiful, lightweight bottle that looks and feels premium. The eco-friendly story of "less plastic" is a powerful asset for this type of brand.

Who is your target consumer?

- Price-conscious families: They are looking for a good, safe product at a fair price. The benefits of a hot-filled product often meet their needs perfectly.

- Health-conscious millennials and Gen Z: They scrutinize labels, value sustainability, and are often willing to pay more for products that align with their values (freshness, low processing, eco-friendly). This audience is the prime target for aseptically-filled products in lightweight, stylish packaging.

Where will you sell your product?

- Major Supermarkets: You'll be competing on a crowded shelf. Shelf appeal is critical. A unique bottle shape (cold-fill) can provide a significant advantage in getting noticed.

- Health Food Stores / Premium Grocers: In this environment, the expectation for high-quality, minimally processed products is the standard. An aseptic, preservative-free juice in a lightweight, eco-friendly bottle is practically a requirement to be taken seriously.

The Verdict: Your brand positioning must be consistent. It's jarring to see a brand claim to be "all-natural and fresh" while using packaging that doesn't reflect that promise. Let your brand's identity be the final filter for your decision.

By systematically going through this checklist, you can move from a state of confusion to one of clarity, choosing the process and design that perfectly aligns your product, your finances, and your brand.

Conclusion

Choosing between hot-fill and cold-fill is a foundational decision for your juice brand. It's a trade-off between the lower initial cost of hot-fill and the superior quality and design freedom of cold-fill.

Frequently Asked Questions (FAQ)

1. Is hot-fill safe for all juices?

No, hot-filling is only safe for high-acid beverages with a pH below 4.6. The combination of heat and acidity prevents the growth of harmful microorganisms. For low-acid juices like carrot juice, coconut water, or vegetable blends, aseptic cold-filling is mandatory to ensure the product is shelf-stable and safe from dangerous bacteria like Clostridium botulinum.

2. Can I use a lightweight, fancy-shaped bottle for a hot-filled juice?

No, this is a dangerous mistake. A standard, lightweight cold-fill bottle is not designed to withstand the two main stresses of the hot-fill process: the high temperature of the liquid and the intense vacuum pressure that forms during cooling. Using the wrong bottle will cause it to severely deform, shrink, or even collapse, leading to product loss and a potential safety hazard. Hot-fill bottles require a special heat-set, reinforced design and heavier gram weight.

3. Why is an aseptic cold-fill production line so much more expensive?

The high cost of an aseptic line comes from the need to create and maintain a completely sterile environment for filling. This involves three key, expensive components that a hot-fill line doesn't need:

- Separate Sterilization Systems: You need separate industrial systems to sterilize the juice (UHT pasteurizer), the bottles (often with a chemical rinse), and the caps before they come together.

- Aseptic Filling Chamber (Isolator): The filling and capping must happen inside a sealed, sterile chamber that is free from any airborne contaminants. This is like a miniature, automated operating room.

- Cleanroom Infrastructure: The entire area housing the aseptic filler must be maintained as a high-level cleanroom, with filtered air, positive pressure, and strict sanitation protocols.

This complexity and precision engineering result in a capital investment that can be 3 to 5 times higher than a conventional hot-fill line.

4. How much lighter can a cold-fill bottle be compared to a hot-fill bottle?

The weight difference can be substantial and represents a major long-term cost saving. Here's a typical comparison for a 500ml (16.9oz) bottle:

| Bottle Type | Typical Gram Weight Range | Potential Weight Reduction |

|---|---|---|

| Hot-Fill PET Bottle | 22g - 30g | N/A (Baseline) |

| Standard Cold-Fill PET Bottle | 15g - 20g | 25% - 40% |

| Ultra-Lightweight Cold-Fill PET Bottle | 12g - 15g | 40% - 50%+ |

For a high-volume product, reducing the bottle weight by 10 grams can translate into hundreds of thousands of dollars in annual savings on PET resin costs alone.

5. If I am a startup, which option is best for me?

For almost all startups, the most practical and financially sound approach is to partner with a contract packer (co-packer) rather than buying your own production line. This eliminates the massive upfront capital investment. Your decision then shifts to finding a co-packer with the right capabilities for your product.

- If your product is high-acid and you want to launch quickly with a lower-risk, proven technology, find a co-packer with a hot-fill line.

- If your brand is built on premium quality, freshness, and a "clean label," find a co-packer with an aseptic cold-fill line. The cost per unit will be higher, but it will align with your brand promise.

This strategy allows you to get your product to market and test its success before committing millions of dollars to your own manufacturing facility.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr