Your budget is tight, and the pressure is on. That low-price quote for a blow mold looks like the perfect solution. But this initial saving often hides a much larger, more painful expense down the line.

The true cost of a blow mold isn't its purchase price. It's the total cost of ownership, including downtime, wasted preforms, and constant repairs. A cheaper mold often leads to a higher cost per bottle, silently eating away at your profits over its entire, often shortened, lifespan.

That incredibly low price on the quotation can feel like a huge win. It's a number you can show your boss, a clear saving that makes you look good. But I've seen this story play out too many times, and the ending is never happy. It’s a short-term gain that almost always leads to long-term pain. This isn't just a theoretical problem; it's a real-world crisis for businesses that fall into the low-price trap. Let's break down exactly where these hidden costs come from and how they can cripple your operation.

The Low-Price Illusion: Why Are We Wired to Chase the Cheapest Deal?

Facing tight budgets, you need to cut costs. A mold quote that's 40% lower than others seems like an obvious choice. It feels responsible, but is it really? This thinking is a dangerous trap.

A low initial price creates a powerful psychological pull. It overshadows the long-term value and total cost of ownership. We are conditioned to see the immediate saving, not the future expenses that will inevitably follow a poorly made tool.

Just a few months ago, I got a call from a potential client in Ireland. He sounded exhausted and frustrated. He sent me pictures of an 8-cavity mold that was covered in rust after just over a month of production. His story is a perfect example of this illusion. He had a great relationship with his bottle blowing machine supplier, but their quote for a new mold seemed too high. So, he went on Google and found a factory in Taizhou that offered him a price that seemed too good to be true. And it was. The initial saving he celebrated quickly turned into a cascade of problems and expenses that far outweighed what he had "saved". This story isn't unique. It happens every day. The allure of a low upfront price is strong, but it's an illusion that distracts from the real goal: producing bottles efficiently and profitably for years to come. The initial price is just the tip of the iceberg; the real costs are lurking just below the surface. Understanding this illusion is the first step toward making a smarter investment.

The Psychology of a "Good Deal"

Our brains are wired to respond to discounts and low prices. It triggers a sense of satisfaction, of having outsmarted the system. In many consumer purchases, this works out fine. If a cheap t-shirt wears out quickly, the loss is minimal. But in an industrial setting, the stakes are completely different. A blow bottle mold is not a disposable item; it's the heart of your production line. It is a long-term asset that should generate revenue for millions of cycles. When we apply consumer shopping logic to industrial procurement, the results can be disastrous. The low price isn't a "good deal" if the tool fails to perform its primary function reliably.

Setting the Scene: The Quote That Looks Too Good to Be True

The Irish client’s journey started with that tempting quote. It was clean, simple, and significantly lower than the competition. What it didn't show were the compromises made to achieve that price. It didn't mention the lower-grade steel, the simplified cooling channels, or the rushed machining process. He saw a number, not the story behind it. This is how the illusion works. It presents a simple, attractive figure while hiding the complex, costly reality. He thought he was saving money on an asset, but he was actually buying a liability. The problems started the moment the mold arrived.

Hidden Cost #1: Unplanned Downtime - The Silent Profit Killer?

Your production line is down again. The cheap mold is jammed, and every minute it sits idle, money is vanishing into thin air. This isn't just an inconvenience; it's a direct attack on your profitability.

Unplanned downtime is the single most expensive hidden cost. You calculate it simply: (Lost Units per Hour) x (Profit per Unit) x (Hours of Stoppage). This number grows alarmingly fast, turning a "cheap" mold into your most expensive problem.

My client in Ireland learned this the hard way. His problems started before he even began production. The mounting data for the mold was wrong. The connectors didn't fit his machine. He had to hire a local machine shop to fix these basic errors, causing a significant delay before the first bottle was even produced. This was his first taste of unplanned downtime, and it was a direct result of the mold maker cutting corners. They didn't bother to confirm the critical dimensions of his equipment. A reliable supplier knows that ensuring a perfect fit is the first step. In fact, many experienced mold makers have a library of specifications; we, for example, have the mounting dimensions for 80% of blow molding machines worldwide to prevent this exact problem. This initial delay cost him precious time and money, eroding his product launch schedule and postponing his return on investment.

Calculating the Devastating Cost of Downtime

Let's put some real numbers to this. It’s crucial to understand that downtime isn't just "lost time"; it's lost revenue. We can create a simple table to visualize the impact.

Downtime Cost Calculation Example

| Metric | Value |

|---|---|

| Machine Output | 2,000 Bottles per Hour (2-cavity) |

| Profit per Bottle | $0.05 |

| Revenue per Hour | $100 |

| Hours of Downtime per Week | 5 hours |

| Weekly Lost Revenue | $500 |

| Annual Lost Revenue | $26,000 |

As you can see, just five hours of stoppage a week—a common scenario with a problematic mold—can cost you over $26,000 a year. This figure, which is more than 20 times the cost of a good mold, doesn't even include paying your staff to stand around or the overtime needed to catch up. The "cheap" mold is suddenly looking incredibly expensive. These aren't just jams or mechanical failures. Poorly designed cooling channels can extend cycle times by a second or two. It doesn't sound like much, but over millions of cycles, it adds up to a massive loss in production capacity. This is another form of downtime—a permanent reduction in your potential output.

The Cascading Effect on Your Business

The financial loss is only the beginning. The ripple effects of downtime can damage your entire business.

- Delayed Shipments: When production stops, you can't fulfill orders on time. This leads directly to penalties from retailers and distributors.

- Unhappy Customers: Consistently late shipments will destroy the trust you have with your customers. They rely on you to keep their shelves stocked. If you can't deliver, they will find someone who can.

- Damaged Reputation: Word travels fast. Becoming known as an unreliable supplier can be the kiss of death in a competitive market. It takes years to build a good reputation and only a few missed shipments to ruin it.

My Irish client experienced this firsthand. The initial installation delays meant his new product launch was pushed back, missing a key seasonal window. This didn't just cost him initial sales; it gave his competitors an unchallenged market for weeks. The silent profit killer had struck before he ever made a sale.

Hidden Cost #2: Wasted Preforms & Poor Quality Bottles?

You see it in the scrap bin: a growing pile of deformed, useless bottles. This isn't just plastic; it's wasted money in the form of perfectly good preforms. A low-cost mold often struggles with precision, turning your valuable preforms directly into trash.

The bottle production process starts with PET resin being injection molded into a preform. That preform is then heated and blown into a bottle. Therefore, every single defective bottle means one preform is completely wasted. A high defect rate equals a high rate of preform waste, directly increasing your cost of goods sold.

.png)

After finally getting his mold installed, my Irish client faced his next nightmare: the bottle quality was terrible. Worse, the bottle capacity was wrong. The mold was designed to produce a 550ml bottle, but it was consistently producing bottles that were 15ml short. In the food and beverage industry, product volume is strictly regulated. You can have more, but you can never have less than what's stated on the label. He was forced to scrap his entire first run of 550ml labels and print new ones for 530ml. This was a huge, unexpected expense and another major delay. A quality mold maker avoids this through a rigorous PET bottle mold design guide, ensuring that volume and performance are perfect before any metal is cut.

The Tangible Cost of Wasted Preforms

Let's quantify this waste. The cost of a preform, whether you produce it in-house or purchase it, is a significant part of your cost per bottle. A high defect rate directly inflates this cost.

Imagine a scenario with a high-rejection rate:

- Target Production: 1,000,000 bottles

- Cost per Preform: $0.02 (This cost varies if self-made or purchased)

- Total Preform Cost (Ideal): $20,000

Now, let's introduce a 5% defect rate, which is common for a low-quality mold:

- Wasted Preforms: 50,000 units

- Direct Financial Loss: 50,000 * $0.02 = $1,000

- Extra Production Time: ~25 hours (at 2,000 bottles/hr), the cost of which is not included here.

This is a simplified calculation. It doesn't include the energy and high-pressure air consumed to produce the defective bottles or the labor to handle the scrap. These are very real costs that add up quickly. If you are struggling with these issues, understanding the root causes is key. Many of these common PET blow molding defects have clear solutions that can save you a fortune.

The Intangible Costs of Poor Quality

Beyond the direct material waste, poor bottle quality has other serious consequences.

- Inconsistent Performance: Bottles with uneven wall thickness can fail during filling, capping, or transportation. A bottle that bursts on the pallet or in the customer's hand can be a disaster for your brand.

- Top-Load Strength: Carbonated beverages and certain packaging methods require bottles to have a specific top-load strength to prevent collapse. A poorly made mold often fails to produce bottles that meet these critical specifications.

- Increased Labor Costs: When your defect rate is high, you can't rely on automated packing. You have to assign employees to manually inspect and sort bottles, adding a significant labor cost that shouldn't exist. My client had to do this, paying staff to stand at the end of the conveyor belt and check every single bottle, an inefficient and expensive solution to a problem that should have been solved in the mold's design phase.

Hidden Cost #3: Soaring Maintenance & Shortened Lifespan?

Your technician is working on the same mold again. It seems like every week, another component needs to be replaced or adjusted. A low-cost mold isn't a one-time purchase; it's an ongoing subscription to expensive maintenance and spare parts.

Poorly made molds use inferior materials that wear out quickly. This means constant repairs, high labor costs for your technicians, and a steady stream of invoices for replacement parts that should have lasted for years.

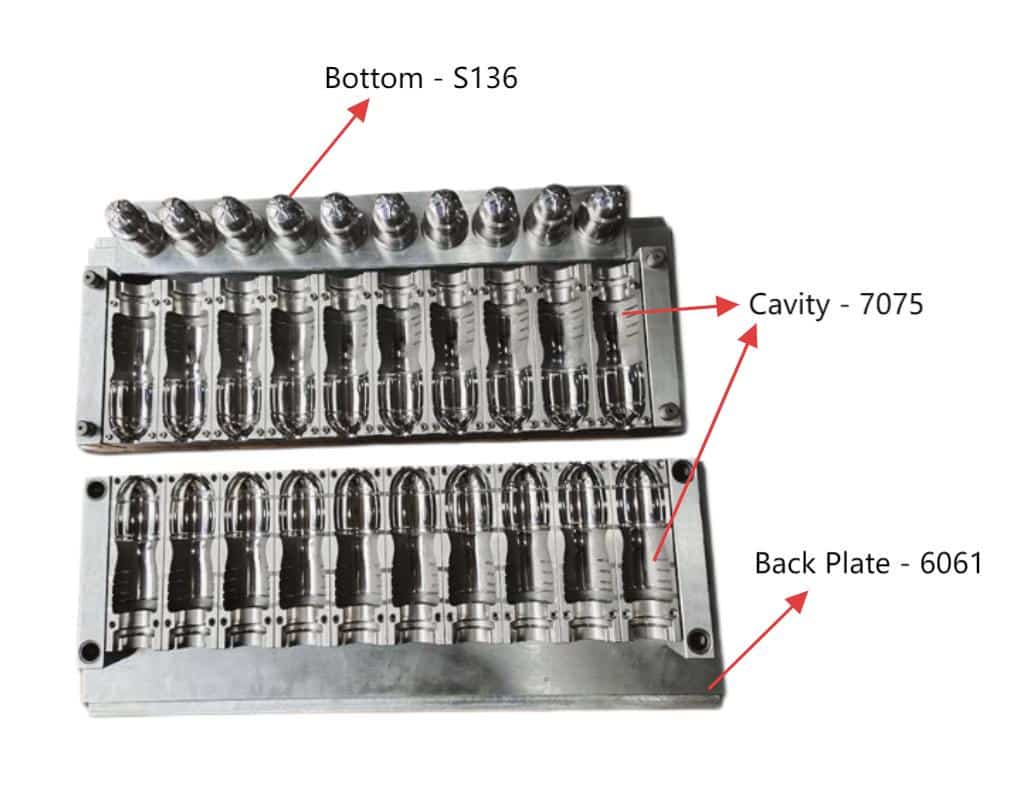

The final straw for my Irish client was the rust. After only one month of production, the mold was already showing significant corrosion. This was shocking and unacceptable. It was a clear sign that the mold maker had used cheap, inappropriate material, likely a low-grade P20 steel instead of the more durable 7075 aircraft aluminum or stainless S136 steel. The rust wasn't just a cosmetic issue. It can transfer to the bottles, creating defects and potentially contaminating the product. It also accelerates the wear and tear on the mold's critical surfaces, drastically shortening its life. He realized that this tool, which was supposed to be a multi-year asset, was likely going to fail completely long before it ever paid for itself. He was facing the ultimate hidden cost: having to scrap the "cheap" mold and reinvest in a new, quality one far ahead of schedule.

The Vicious Cycle of Repairs and Replacements

A well-made mold from a reputable PET mold supplier is designed for longevity with minimal intervention. It uses high-quality, durable components. A low-cost mold does the opposite.

- Inferior Components: They might use cheaper, off-brand heaters, valves, or seals. These components are not built to withstand the rigors of high-volume production and will fail prematurely.

- Inferior Materials: As my client discovered, the choice of material is paramount. Using cheap, non-stainless, or soft materials is a common cost-cutting tactic that leads to rapid wear, corrosion, and dimensional inaccuracies.

- High Labor Costs: Your most skilled technicians are a valuable resource. Do you want them spending their time innovating and improving your processes, or constantly fixing the same problematic mold? Every hour they spend on emergency repairs is an hour not spent on value-added activities. This is a significant drain on your operational efficiency.

The Ultimate Cost: Premature Mold Failure

Every blow mold has a designed lifespan, typically measured in millions of shots or cycles. A high-quality mold should meet or exceed this guarantee. A low-cost mold almost never will.

Lifespan Comparison: Low-Cost vs. High-Value Mold

| Feature | Low-Cost Mold | High-Value Mold |

|---|---|---|

| Guaranteed Lifespan | 1 million shots (often not honored) | 3-5 million shots (guaranteed) |

| Actual Lifespan | ~500,000 - 800,000 shots | 3-5 million+ shots |

| Cost | $700 | $1,200 |

| Cost per 1M Shots (Actual) | ~$1,167 ($700 / 0.6M) | ~$300 ($1,200 / 4M) |

This table clearly illustrates the flaw in focusing on the initial price. The low-cost mold fails at just half its promised life, forcing a complete reinvestment. When you look at the actual cost over a realistic production volume, the "expensive" high-value mold is almost four times cheaper. You paid less upfront, but you'll pay far more in the long run. My client was facing this exact scenario. He had paid for a mold that he now considered unusable. His initial "saving" had completely evaporated, and he was back to square one, needing to buy another mold, but this time with the painful wisdom of his expensive mistake.

The Root Cause: Where Did the "Hidden Costs" Come From?

These hidden costs don't appear out of nowhere. They are a direct result of specific choices and compromises made during the mold's design and manufacturing process to achieve that tempting low price.

The problems stem from three main areas: using improper materials, simplifying the design to save time, and lacking the precision needed for a reliable tool. Understanding these root causes is key to avoiding them in the future.

When I talked with the Irish client, we pieced together the evidence. The rust pointed to the wrong material choice. The capacity issues pointed to a flawed design and a lack of proper simulation. The installation problems pointed to a complete lack of precision and quality control. The mold wasn't just cheap; it was fundamentally compromised in every critical area. The manufacturer didn't just cut a corner; they cut every corner they possibly could. This is the harsh reality behind many "too good to be true" prices. The savings are achieved by sacrificing the very qualities that make a mold a productive and profitable asset.

Improper Materials: The Foundation of Failure

Many people confuse the materials for preform molds and blow molds. Preform molds endure extreme injection pressure and wear, so they require high-hardness tool steels like S136 or 718H. Blow molds are completely different; their core requirements are rapid heat exchange and durability. This is exactly where low-cost manufacturers cut corners.

Common Blow Mold Materials Compared

| Material Type | Advantages | Disadvantages | Best For |

|---|---|---|---|

| P20 Steel | Very cheap, easy to machine. | Low hardness, wears easily, will rust, poor thermal conductivity. | The choice of low-cost factories, only suitable for very short runs or prototypes. |

| 7075 Aircraft Aluminum | Excellent thermal conductivity (fast cooling = short cycles), lightweight. | Softer than steel, less wear-resistant, higher cost. | The mainstream choice for high-performance PET bottle molds. |

| S136 Stainless Steel | High hardness, extremely wear-resistant, completely rust-proof. | Most expensive, thermal conductivity is worse than aluminum, difficult to machine. | Special applications like blowing corrosive materials (PVC) or for extremely long life. |

The rust on my client's mold strongly suggests the manufacturer used the cheapest P20 steel, which is completely unsuitable for a humid production environment and whose poor thermal conductivity also limits production speed.

Simplified Design: The Enemy of Efficiency

A great deal of a mold's performance comes from its design, particularly the cooling and venting systems. Rushing this stage saves the manufacturer time and money but costs you dearly in production.

- Poor Cooling: The cooling channels in the mold are critical for removing heat from the preform, which directly dictates the cycle time. Low-cost molds often have simple, straight-drilled cooling lines. A high-value mold will have complex, conformal cooling channels that follow the shape of the bottle, ensuring fast, even cooling—especially important for maximizing the benefit of thermally conductive 7075 aluminum.

- Inadequate Venting: Vents are tiny channels that allow air trapped in the mold to escape as the plastic is blown in. If venting is poor, you get defects like incomplete filling or burn marks on the bottle. Proper venting design requires expertise and precise machining, which are often skipped in a rush to the bottom on price.

Lack of Precision: Cutting Corners in Machining

The final piece of the puzzle is precision. A blow mold is a high-precision tool where tolerances are measured in microns.

- CNC Machining: The cavities must be machined with extreme accuracy to ensure consistent bottle volume and perfect parting lines. Low-cost manufacturers may use older machines, dull cutting tools, or run the machines faster than recommended to save time, all of which sacrifice precision.

- Final Fitting: The two halves of the mold and all moving components must fit together perfectly. Poor fitting leads to flash (a thin web of excess plastic on the bottle) and premature wear on the mold. The installation problems my client had were a classic sign that this final quality control step was completely ignored.

The Antidote: Shifting from "Price" to "Cost-Per-Bottle"?

How do you avoid this trap? You must change your mindset. Stop asking "What is the price of this mold?" and start asking "What will my cost-per-bottle be with this mold?"

The goal isn't to find the cheapest mold; it's to find the mold that produces the cheapest bottles over its lifetime. This requires a simple shift in perspective from a one-time purchase price to the total cost of ownership.

This shift is the key to making a smart investment. It moves the conversation away from a simple, misleading number (the price) and towards a holistic view of value and performance. You can use a simple formula to guide your thinking: True Mold Value = (Total Lifetime Output) / (Total Lifetime Cost). The mold with the lowest cost per bottle is always the winner, even if its initial price is higher. It is a more reliable and profitable asset for your business. Let's build a worksheet to see how this plays out in the real world.

The Total Cost of Ownership (TCO) Worksheet

To make this tangible, let's compare our two molds over a three-year period, using our new, realistic pricing.

3-Year TCO Comparison: Low-Cost vs. High-Value Mold

| Cost Factor | Low-Cost Mold ($) | High-Value Mold ($) | Notes |

|---|---|---|---|

| Initial Purchase Price | 700 | 1,200 | The initial "saving" is $500. |

| Year 1 Costs | |||

| Downtime Cost | 5,000 | 250 | (Based on a few hours/week vs. minutes/week) |

| Preform Waste Cost | 2,000 | 200 | (5% vs. 0.5% defect rate) |

| Maintenance & Parts | 500 | 0 | Frequent parts vs. warranty period. |

| Year 2 Costs | |||

| Downtime Cost | 7,000 | 250 | Problems worsen over time. |

| Preform Waste Cost | 3,000 | 200 | |

| Maintenance & Parts | 800 | 100 | Seals, minor adjustments. |

| Year 3 Costs (Mold Fails) | |||

| Downtime Cost | 8,000 | 250 | |

| Preform Waste Cost | 4,000 | 200 | |

| Maintenance & Parts | 1,000 | 100 | |

| Reinvestment Cost | 700 | 0 | Mold fails and needs replacement. |

| TOTAL LIFETIME COST | 32,700 | 2,750 | The true cost over 3 years. |

This table paints a dramatic picture. The low-cost mold, over just three years, ends up costing almost 12 times more than the high-value mold. The initial $500 "saving" leads to over $30,000 in additional costs and losses. This is the power of TCO analysis. It exposes the illusion of the low price.

Calculating Your Cost-Per-Bottle

Now, let's take it a step further to the ultimate metric: cost-per-bottle.

High-Value Mold:

- Total Output (3 years @ 4M shots/yr): 12,000,000 bottles

- Total Cost: $2,750

- Mold Cost Per Bottle: $2,750 / 12,000,000 = $0.00023

Low-Cost Mold:

- Total Output (fails in Year 3): Let's be generous and say 2,000,000 bottles total.

- Total Cost: $32,700

- Mold Cost Per Bottle: $32,700 / 2,000,000 = $0.01635

The result is staggering. From a tooling cost perspective, the bottle produced by the high-value mold is more than 70 times cheaper. When you multiply this difference by millions of bottles, you are talking about a massive impact on your company's profitability. This is the irrefutable mathematical argument for investing in quality.

How Can You Vet a Supplier and Uncover Potential Hidden Costs?

You understand the importance of value over price. Now, how do you identify a supplier who can deliver that value and help you spot the red flags of a low-cost trap?

It comes down to asking the right questions and demanding detailed information. A quality supplier will welcome this scrutiny because they are confident in their process. A low-cost supplier will often be vague and evasive.

Your vetting process is your defense against future problems. It’s where you do the detective work to separate the true partners from the mere sellers. My conversation with the Irish client would have been very different if he had taken these steps initially. He would have discovered the material deficiencies and design shortcuts before he ever sent a deposit. A good supplier isn't just selling you a mold; they are providing a manufacturing solution and should be able to prove its worth on paper before you commit. This means acting like a consultant, not just a salesperson.

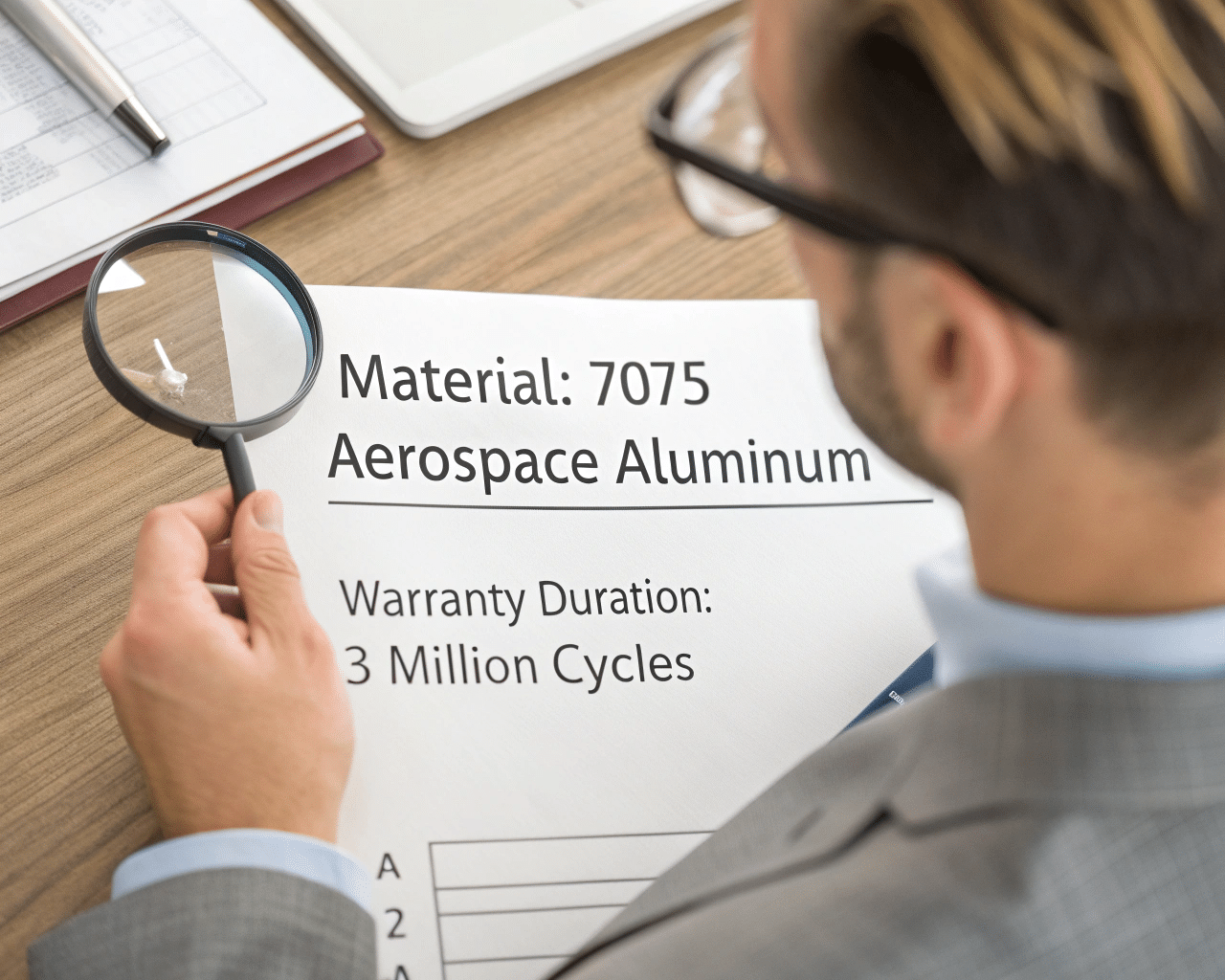

Demand a Detailed Quotation

A one-line quote with a price is a huge red flag. A professional quotation should be a detailed technical document. Insist that it includes:

- Material Specifications: It must clearly state the specific material for the mold body (core, cavity) and base (e.g., "Mold Body: Alcoa 7075 Aircraft Aluminum"). Vague terms like "high-quality alloy" are unacceptable.

- Component Brands: The quote should list the brands for key components like valves, cylinders, and seals. This prevents them from substituting cheaper, unreliable parts.

- Guaranteed Lifespan: A reputable supplier will provide a clear, written guarantee for the mold's lifespan in millions of shots. This holds them accountable for the quality of their work.

- Design Details: It should mention key design features like conformal cooling, venting strategy, and the type of surface treatment that will be applied.

Verify Their Expertise and Track Record

Don't just take their word for it. A supplier's experience is written in their past projects.

- Ask for Case Studies: Request specific examples of molds they have built for products similar to yours. A good case study will include the challenges, the solution they provided, and the results (e.g., cycle time reduction, defect rate improvement).

- Request Customer References: Ask to speak with current clients, preferably in your industry or region. This is the most powerful tool you have. Ask these references about the mold's performance, the supplier's after-sales support, and if they would buy from them again.

- Evaluate Their Technical Communication: When you discuss your project, do they ask intelligent questions? Do they offer suggestions to improve your bottle design? Or are they just trying to close the sale? A true partner will engage with you on a technical level. They should be able to discuss things like selecting the right preform neck size for your application or how they can help you validate your design rapidly using 3D printed samples.

The "Consultant vs. Seller" Test

This is a simple but effective mental model.

- A seller wants to sell you what they have. They focus on price and features. Their goal is the transaction.

- A consultant wants to solve your problem. They focus on your application, your production goals, and your total cost of ownership. Their goal is your long-term success.

Choose the consultant. Their initial price might be higher, but their value in preventing hidden costs is immeasurable. They will be the ones to point out a potential flaw in your bottle design or suggest a more efficient preform, saving you money in the long run. They are not just building a mold; they are building a partnership.

Investing in Value: The Ultimate Path to Profitability and Peace of Mind?

The final decision is clear. A high-value mold is not an expense. It is a predictable, reliable, profit-generating asset that forms the foundation of a successful production operation.

Investing in quality from the start gives you the most valuable thing of all: peace of mind. It frees you from the constant firefighting of a problematic production line, allowing you to focus on what truly matters.

When you invest in a quality asset, you are buying predictability. You know it will arrive on time and fit your machine. You know it will produce high-quality bottles at an efficient cycle time. You know it will run for millions of shots with only routine preventive maintenance. This predictability is the bedrock of a healthy business. It allows you to forecast accurately, meet customer demands confidently, and plan for future growth. After his terrible experience, my Irish client understood this. His second mold purchase would not be about price. It would be about securing a reliable partner who could guarantee long-term value and help him rebuild his business.

The True Benefit: Freedom to Grow

Think about all the time and energy that goes into managing a faulty mold:

- Time spent on the phone with the supplier (who may or may not be helpful).

- Time spent sourcing emergency spare parts.

- Time spent explaining delays to angry customers.

- Time spent managing the morale of a frustrated production team.

Now, imagine all that time and energy is given back to you. What could you do with it?

- Focus on Marketing and Sales: Develop new markets and find new customers.

- Innovate New Products: Spend time on R&D to stay ahead of the competition.

- Optimize Your Broader Operations: Improve logistics, streamline your supply chain, or upgrade other parts of your facility, like your air compressor system.

- Strategic Planning: Work on your business, not just in your business.

A reliable mold buys you this freedom. It hums along in the background, consistently making you money, while you focus on the high-level activities that drive growth. It transforms your production floor from a source of stress into a source of strength.

The Final Call to Action: Choose a Partner, Not a Price Tag

Your next blow mold is a critical investment in the future of your company. The choice you make will have repercussions for years to come. Don't let a tempting low price today lock you into a future of high costs, stress, and missed opportunities.

Look beyond the quote. Analyze the total cost of ownership. Scrutinize your potential suppliers. Ask the tough questions and demand transparent answers. Choose a partner who understands that their success is tied to yours. Choose a partner who is committed to engineering value and reliability into every component. Choose a partner who will deliver not just a mold, but a profitable and predictable manufacturing future.

Conclusion

That low-price mold is not a saving. It's a loan with punishingly high interest, paid through downtime, waste, and stress. Invest in value, not price, for true long-term profitability.

Frequently Asked Questions (FAQ)

1. What are the main material differences for blow molds, like P20, 7075 Aluminum, and S136?

These three materials represent different tiers of quality and application. P20 steel is the lowest-cost option, but it is soft, wears easily, and will rust, making it a hallmark of low-price molds with a very short lifespan. 7075 aircraft aluminum is the mainstream, high-value choice for PET blow molding; its excellent thermal conductivity allows for faster cooling and shorter cycle times, boosting efficiency. S136 stainless steel is for special applications, like blowing corrosive materials (e.g., PVC) or for molds requiring extreme wear resistance; it's very durable and rust-proof but is the most expensive and has poorer thermal conductivity than aluminum.

2. What is a reasonable price range for a high-quality, 2-cavity 500ml PET bottle mold?

While prices vary based on bottle complexity, component brands, and the supplier, a reasonable benchmark for a high-quality, 2-cavity mold (made with 7075 aircraft aluminum and quality components, with a guarantee of 3 million+ shots) is typically in the range of $800 to $1,500 USD. If you receive a quote significantly below this range, for example, under $700, it should be treated as a major red flag, as it very likely means severe compromises have been made on materials or critical processes.

3. How many shots (cycles) should I realistically expect from a high-value blow mold?

A high-value blow mold, for instance one made from 7075 aircraft aluminum, should come with a written guarantee from the supplier. You should realistically expect a guaranteed lifespan of at least 3 million shots. With proper maintenance, many of these molds can run effectively for 5 million shots or even more. In contrast, a low-cost P20 steel mold might be "rated" for 1 million shots but often begins to have significant problems around the 500,000-shot mark.

4. What are the biggest red flags to watch for in a supplier's quotation?

The biggest red flags are vagueness and a lack of detail. Specifically, watch for:

- A price that is dramatically lower than all other competitors.

- Vague material specifications like "high-quality alloy" instead of specifically naming "7075 Aircraft Aluminum" or "P20 Steel".

- No mention of component brands for key moving parts like valves and cylinders.

- The absence of a clear, written lifespan guarantee in millions of shots.

- Unwillingness to provide customer references or relevant case studies.

5. How soon can I expect to see a return on investment (ROI) from choosing a high-value mold over a low-cost one?

You begin to see the ROI almost immediately. While the initial investment is higher ($500 extra in our example), the savings from avoiding downtime, material waste, and repairs start accumulating from day one. As shown in the TCO analysis, the extra cost of a high-value mold is often paid back many times over within the first year by preventing just a few hours of downtime per month. The true, massive ROI comes over the full life of the mold, where it can end up being more than 10 times cheaper overall than its "low-cost" counterpart.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr