Picking the wrong preform neck size can derail your bottle project. You might face leaks or compatibility issues. Let me help you choose correctly from the start.

The right preform neck size ensures your PET bottles are sealed perfectly, work with your chosen caps, and are compatible with your filling equipment. Getting this detail correct is crucial for product integrity and production efficiency.

Choosing the right preform neck size can seem tricky with so many options available. It's a small detail with a big impact on your final product. I want to make this process easier for you. Let's look at what you need to know to make the best choice for your PET bottle project. This guide will help you navigate the options with confidence.

What Is Preform Neck Size and Why Does It Matter?

Struggling with bottle closures not fitting? This often means the preform neck size was overlooked. Understanding neck size is key to avoiding costly production errors.

Preform neck size refers to the specific dimensions of the threaded opening of a PET preform. It matters because it dictates cap compatibility, seal integrity, and even influences the bottle's overall performance and suitability for different contents.

When I first started in the PET bottle industry, I underestimated how critical the neck finish was. A client once approached me after ordering a large batch of preforms without double-checking the neck specification. They ended up with thousands of preforms that didn't match their existing caps. This was a costly lesson for them, and it highlighted for me just how fundamental this single specification is. The neck finish isn't just about the opening; it includes the thread type, height, and diameter. These elements must perfectly match the cap to create an effective seal. An improper seal can lead to leaks, product spoilage, or loss of carbonation. Beyond the cap, the neck size can also affect the bottle's strength and how it performs on the filling line. So, paying close attention to this detail from the very beginning of your project is incredibly important.

Key Dimensions of a Preform Neck

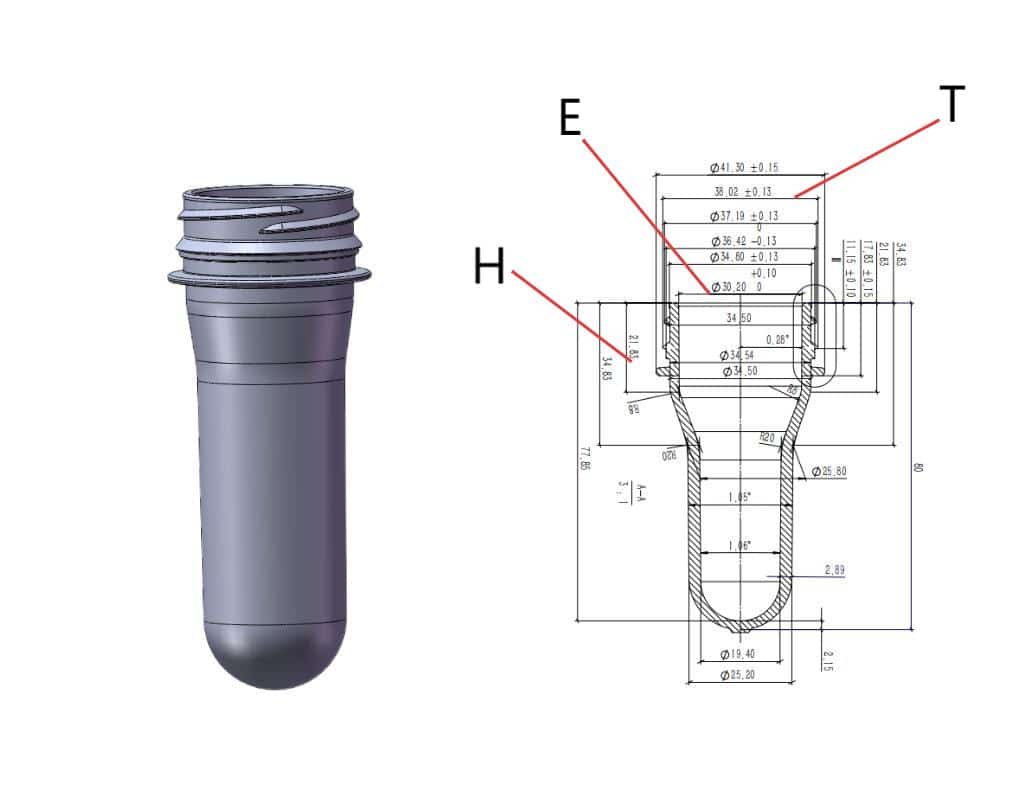

To understand neck size, you need to know these terms:

- "T" Dimension: The outside diameter of the thread. This is crucial for cap fit.

- "E" Dimension: The inside diameter of the neck. This affects how the product is dispensed.

- "H" Dimension: The height of the neck finish. This impacts the cap seal and overall bottle appearance.

- Thread Type: Describes the shape and pitch of the threads (e.g., 1881 PCO, 30/25).

Understanding these specific measurements helps ensure you select a preform neck that is truly compatible with your caps and bottling needs.

Common Preform Neck Types: PCO1810, PCO1881, 30/25 and More?

Confused by all the neck finish codes like PCO1810 or 30/25? You're not alone in this. Knowing these common types can simplify your selection process greatly.

PCO1810 and PCO1881 are standard neck finishes for carbonated soft drinks and water, differing mainly in weight and height. 30/25 is a lightweight neck popular for still water. Many other specialized neck finishes also exist.

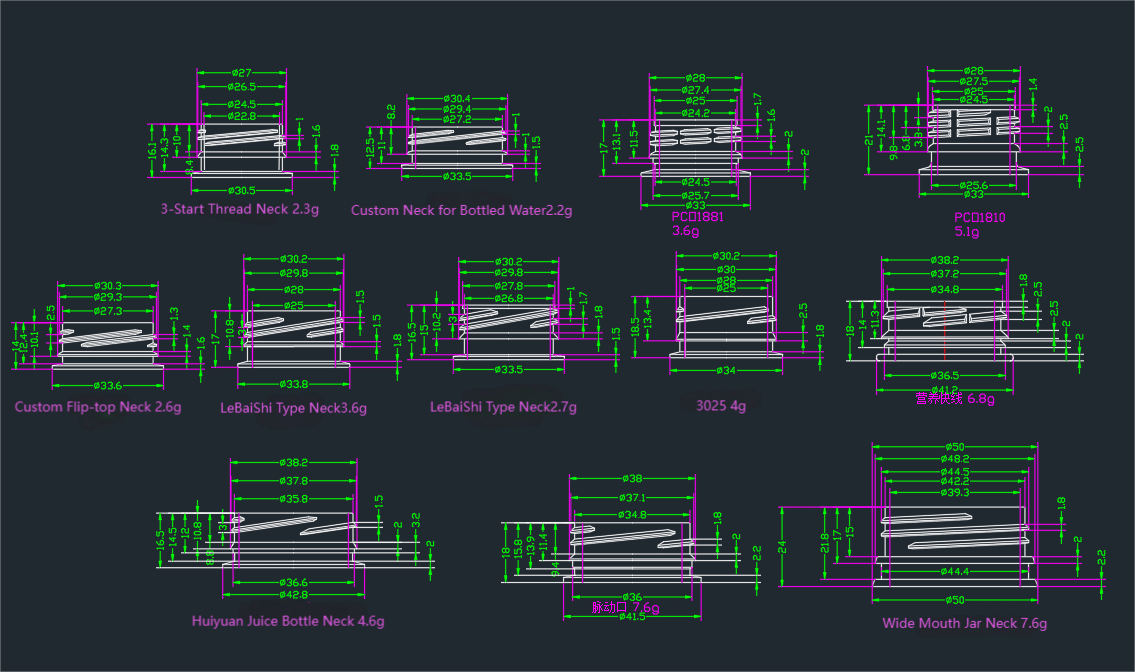

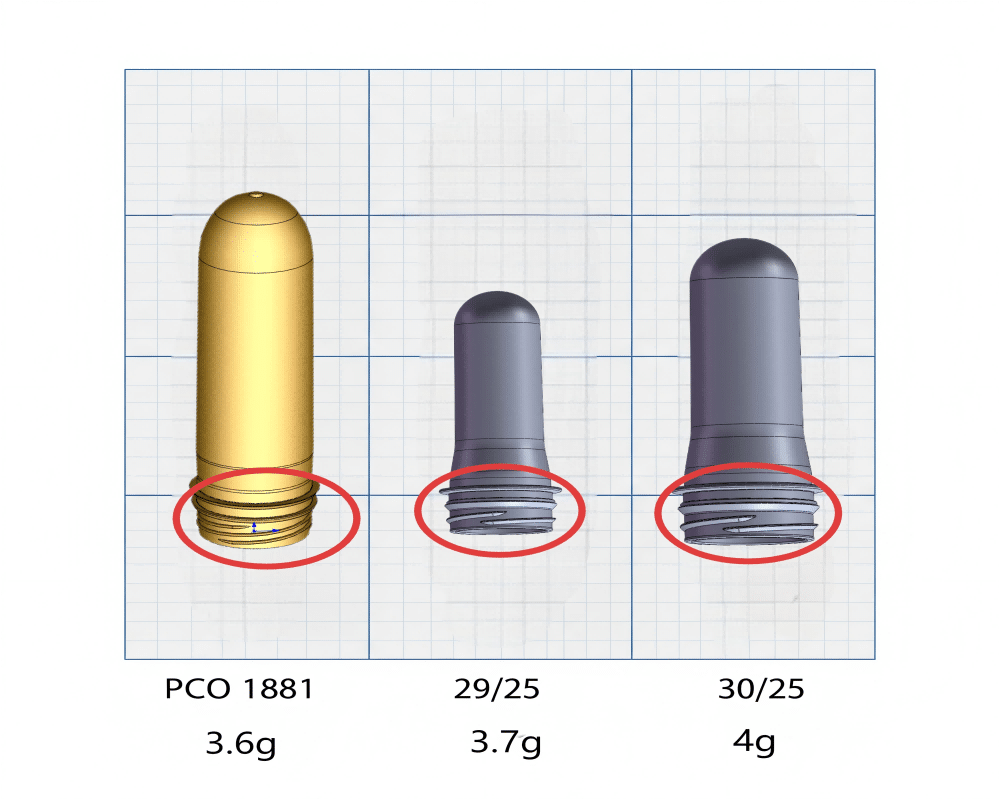

Let's explore some of the most frequently encountered preform neck types in the PET bottle industry. Each type has been designed with specific applications, cost considerations, and performance characteristics in mind. For instance, PCO stands for "Plastic Closure Only." The numbers that follow, like 1810 or 1881, refer to specific thread designs and dimensions standardized by the International Society of Beverage Technologists (ISBT). PCO1881 was developed as a lighter-weight alternative to PCO1810, saving material while still providing excellent performance for carbonated beverages. The 30/25 neck finish is known for its lower neck height and lighter weight, making it a cost-effective choice for single-serve still water bottles. Other common neck finishes include the 29/25, often used for water and juices, and various ALCOA finishes. There are also wider neck finishes, like 38mm or 48mm, which are typically used for juices with pulp, dairy products, or edible oils, as they allow for easier pouring and filling of more viscous products.

Overview of Popular Neck Finishes

| Neck Finish | Typical Application | Key Characteristics |

|---|---|---|

| PCO1810 | Carbonated Drinks, Water | Taller neck, robust, older standard |

| PCO1881 | Carbonated Drinks, Water | Shorter neck, lighter weight, newer standard |

| 30/25 | Still Water, Juices | Lightweight, short neck, cost-effective |

| 29/25 | Still Water, Juices | Similar to 30/25, alternative lightweight option |

| 38mm 2-start | Juices, Dairy, Hot-fill | Wider opening, good for thicker liquids, good seal |

| 26/22 | Water, Flavored Water | Lightweight, often for smaller bottle sizes |

Choosing the right type from this list depends heavily on your product, your bottling line, and your cost targets.

How to Match Preform Neck Size with Bottle Cap Specifications?

Worried your chosen preforms won't work with your caps? This mismatch is a common and costly problem. Ensuring they align is essential for success.

To match preform neck size with bottle caps, compare the "T," "E," and "H" dimensions and thread type of both. Always request samples of preforms and caps for physical fit testing before mass production.

I always tell my clients that precise matching is non-negotiable. It's not just about the numbers on a spec sheet; it's about how the cap and preform interact in reality. The thread profile is particularly important. A PCO1881 preform needs a PCO1881 cap. You cannot reliably use a PCO1810 cap on an 1881 neck, or vice versa, even if the diameters seem close. The thread engagement and height are different, which will lead to sealing problems. I recommend creating a checklist. Get the technical drawings for both the preform neck finish and the cap. Compare every single dimension. Pay attention to details like the number of thread turns and the specific sealing mechanism of the cap – does it use a liner, or is it a linerless design that relies on a plug or crab-claw seal? These features must be compatible with the preform neck. Once you have a theoretical match, the next step is crucial: physical testing. Get samples of the exact preforms and caps you plan to use. Test them under conditions that mimic your production and product lifecycle, including application torque, leak testing, and even drop tests if relevant.

Steps for Ensuring a Perfect Match:

- Obtain Technical Drawings: Get detailed specifications for both the preform neck and the cap.

- Compare Critical Dimensions:

- T-Dimension (Outer Thread Diameter)

- E-Dimension (Inner Mouth Diameter)

- H-Dimension (Neck Height/Cap Skirt Height)

- Thread Standard (e.g., PCO1881, 30/25)

- Verify Sealing Mechanism: Understand how the cap seals onto the neck (e.g., top seal, side seal, plug seal) and ensure compatibility.

- Request Samples: Always get physical samples of the preforms and caps.

- Conduct Fit Tests: Manually screw caps onto preforms. Check for smooth threading and a snug fit.

- Perform Leak Tests: Fill sample bottles and cap them. Test for leaks under pressure or different orientations.

- Check Application Torque: Ensure the cap can be applied with the correct torque on your capping machinery.

This systematic approach helps prevent expensive mistakes and ensures your product is secure.

Choosing the Right Neck for Water, Juice, Oil or Cosmetic Bottles?

Does your product type influence your preform neck choice? Absolutely, different products have different needs. Selecting the wrong neck can affect user experience and product safety.

Choose lightweight necks like 30/25 for still water, PCO1881/1810 for carbonated drinks and some juices, wider necks (e.g., 38mm) for viscous oils or juices with pulp, and specialized necks for cosmetics depending on dispensing needs.

The product you are bottling plays a huge role in selecting the appropriate neck finish. For simple still water, a lightweight and cost-effective option like the 30/25 or 29/25 is often preferred. These necks offer good sealing for non-pressurized contents and help reduce material costs. However, if you're bottling carbonated beverages, you need a neck finish that can handle the pressure, like the PCO1881 or the older PCO1810. These are designed for a secure seal that prevents carbonation loss.

For juices, especially those with pulp or thicker consistency, a wider neck such as a 38mm is generally better. This facilitates easier filling and pouring for the end-user. Edible oils also often use wider necks for similar reasons. Cosmetic products are a different category altogether. The neck choice here is heavily influenced by the dispensing mechanism – a pump, a sprayer, a dropper, or a simple screw cap. Each of these closures has specific neck requirements. For example, a lotion pump will usually require a neck like a 24/410 or 28/410, which are common standards in the cosmetics industry. The material of the cosmetic (e.g., aggressive chemicals) might also dictate preform material and thus influence neck choices compatible with those materials.

Product-Specific Neck Recommendations:

| Product Category | Common Neck Finishes | Key Considerations |

|---|---|---|

| Still Water | 30/25, 29/25, 26/22 | Lightweight, cost-effective, good seal for non-pressure |

| Carbonated Drinks | PCO1881, PCO1810 | Pressure resistance, carbonation retention |

| Juices (no pulp) | PCO1881, 30/25, 29/25 | Seal integrity, user convenience |

| Juices (with pulp) | 38mm, other wide necks | Easy pouring, filling viscous liquids |

| Edible Oils | 28mm, 38mm, specific oil necks | Pouring ease, seal against oil seepage |

| Dairy Products | 38mm, specialized dairy necks | Hygiene, easy pouring, sometimes tamper-evidence |

| Household Chemicals | 28/400, 28/410, CRCs | Chemical resistance, child-resistance (if needed) |

| Cosmetics (lotions) | 24/410, 28/410 | Pump compatibility, aesthetics, product viscosity |

| Cosmetics (sprays) | 18/410, 20/410, 24/410 | Sprayer compatibility, fine mist generation |

Always consider the product's viscosity, carbonation level, sensitivity to oxygen, and the desired user experience when making your choice.

Preform Neck Size and Its Impact on Filling Line Compatibility?

Will your chosen preform neck work with your current filling line? This is a critical question. Ignoring this can lead to major production headaches and costly equipment modifications.

Preform neck size directly impacts compatibility with filling nozzles, capping machinery, and neck handling systems on a bottling line. Changes in neck diameter or height may require adjustments or retooling of equipment.

This is where my experience with a Brazilian client really highlights the importance of neck size. They were successfully producing purified water using a specific preform neck size, and their OEM factory was set up for it. When they decided to launch a new soda water product, they initially insisted on using the same preform neck as their purified water. Their thinking was it would simplify their preform purchasing. However, I explained that most soda waters use PCO1810 or, more commonly now, PCO1881 neck finishes, which are designed for carbonated products. The filling process for carbonated drinks is different from still water, requiring equipment that can handle pressure. I advised them to first check if their current OEM factory could even produce soda water. If not, any new factory they partnered with would likely have filling lines optimized for standard carbonated beverage necks like PCO1881. After discussing with their current OEM, they realized they couldn't produce soda water there. They found a new contract manufacturer specializing in carbonated drinks, and this new partner's lines were indeed set up for PCO1881 necks. So, they ultimately chose the PCO1881, ensuring compatibility and product integrity. This story shows how the neck finish is tied not just to the bottle and cap, but to the entire production infrastructure.

Filling Line Considerations for Neck Size:

- Neck Handling: Star wheels and guides on the filling line are often designed for specific neck diameters and heights. A different neck may not be gripped or transported correctly.

- Filling Nozzles: The diameter of the filling nozzles must be appropriate for the inner diameter (E-dimension) of the preform neck to prevent spillage or ensure proper fill levels.

- Capping Heads: Capping chucks or heads are specific to cap types, which are in turn specific to neck finishes. A change in neck finish almost always means a change in capping head settings or parts.

- Sealing Mechanism: If the filling line includes in-line seal integrity testers, these might also be calibrated for specific neck/cap combinations.

- Line Speed and Efficiency: Properly matched components ensure smooth operation. Mismatches can lead to jams, downtime, and reduced output.

Always discuss your preform neck choice with your filling line operator or machinery supplier to confirm compatibility before making a final decision.

Weight vs. Strength: How Neck Size Affects Bottle Performance?

Does a lighter neck mean a weaker bottle? Not necessarily. The relationship between neck weight, design, and overall bottle strength is more complex than you might think.

Neck size and design influence the distribution of material in the preform, which affects the final bottle's top load strength and overall structural integrity. Lighter necks like PCO1881 can still offer excellent performance due to optimized designs.

When we talk about preform weight, a portion of that weight is in the neck finish itself. The trend in the industry has been towards lightweighting – reducing the amount of PET resin used in bottles and preforms to save costs and reduce environmental impact. Neck finishes have played a big part in this. For example, the PCO1881 neck finish was introduced as a lighter alternative to the PCO1810, offering significant material savings without compromising performance for carbonated beverages. While it's true that the neck area contributes to the bottle's top load strength (its ability to withstand vertical pressure, important for stacking), the design of the neck and shoulder area is as crucial as the weight. Modern neck finishes are engineered to provide maximum strength with minimal material. It's not simply a case of "more plastic equals more strength." The distribution of plastic, the thread profile, and the way the neck supports the cap all play a role. A well-designed lightweight neck can perform just as well as, or even better than, an older, heavier design. However, for some very demanding applications, or for very large bottles, a heavier neck might still be preferred for added robustness.

Factors Balancing Neck Weight and Bottle Strength:

- Neck Finish Design: Modern, optimized designs (e.g., shorter necks, modified thread profiles) can maintain strength with less material.

- Resin Distribution: The preform design dictates how resin is distributed during blowing, impacting wall thickness in critical areas including the shoulder and neck.

- Bottle Base Design: The base of the bottle also significantly contributes to overall strength and stability.

- Application: Carbonated beverages require necks that can withstand internal pressure, while hot-fill applications need necks that resist deformation at higher temperatures.

- Top Load Requirements: The expected stacking height of filled bottles will influence the required top load strength.

Ultimately, the goal is to achieve the necessary performance with the most efficient use of material. Testing is key to validate that a chosen neck/preform combination meets strength requirements.

Should You Use Standard Neck Finishes or Custom Designs?

Are you wondering if a standard neck is good enough, or if you need a custom design? This choice depends on your volume, budget, and branding goals.

Standard neck finishes offer cost savings, readily available caps, and proven compatibility. Custom designs provide differentiation and unique functionality but involve higher costs, longer lead times, and require custom cap development.

For most projects, especially for startups or small to medium volume productions, I strongly recommend sticking with standard neck finishes. The advantages are significant. Standard necks like PCO1881, PCO1810, or 30/25 have a vast ecosystem of readily available preforms and caps from multiple suppliers. This competition keeps prices reasonable and ensures supply chain security. Furthermore, these neck finishes are well-understood, their performance is proven, and they are compatible with most existing filling and capping equipment. This reduces risk and speeds up your time to market.

A custom neck finish, on the other hand, is a much bigger undertaking. It involves designing a unique neck profile, which then requires custom molds for both the preforms and the caps. This means significant upfront investment in tooling. Lead times will be much longer. While a custom neck can offer a unique branding element or solve a very specific functional challenge, the benefits must clearly outweigh these considerable costs and complexities. It's typically only viable for very high-volume products where the per-unit cost of custom tooling becomes negligible, or for luxury products where uniqueness is paramount. Before considering a custom neck, thoroughly evaluate if your objectives can be met with an existing standard or a slightly modified standard neck. Often, creative bottle body design can achieve the desired differentiation without the expense and hassle of a custom neck.

Comparing Standard vs. Custom Necks:

| Feature | Standard Neck Finishes | Custom Neck Designs |

|---|---|---|

| Cost | Lower (tooling, preforms, caps) | Higher (custom tooling, development) |

| Availability | High (many suppliers for preforms/caps) | Low (proprietary, single or few suppliers) |

| Lead Time | Shorter | Longer (design, tooling, testing) |

| Compatibility | Proven with standard equipment | May require custom filling/capping parts |

| Differentiation | Low (unless paired with unique bottle) | High (unique shape/functionality) |

| Risk | Lower (proven designs) | Higher (new design, potential issues) |

| Ideal For | Most applications, startups, SME | High volume, luxury, specific functional needs |

Carefully weigh these factors against your project's specific needs and resources.

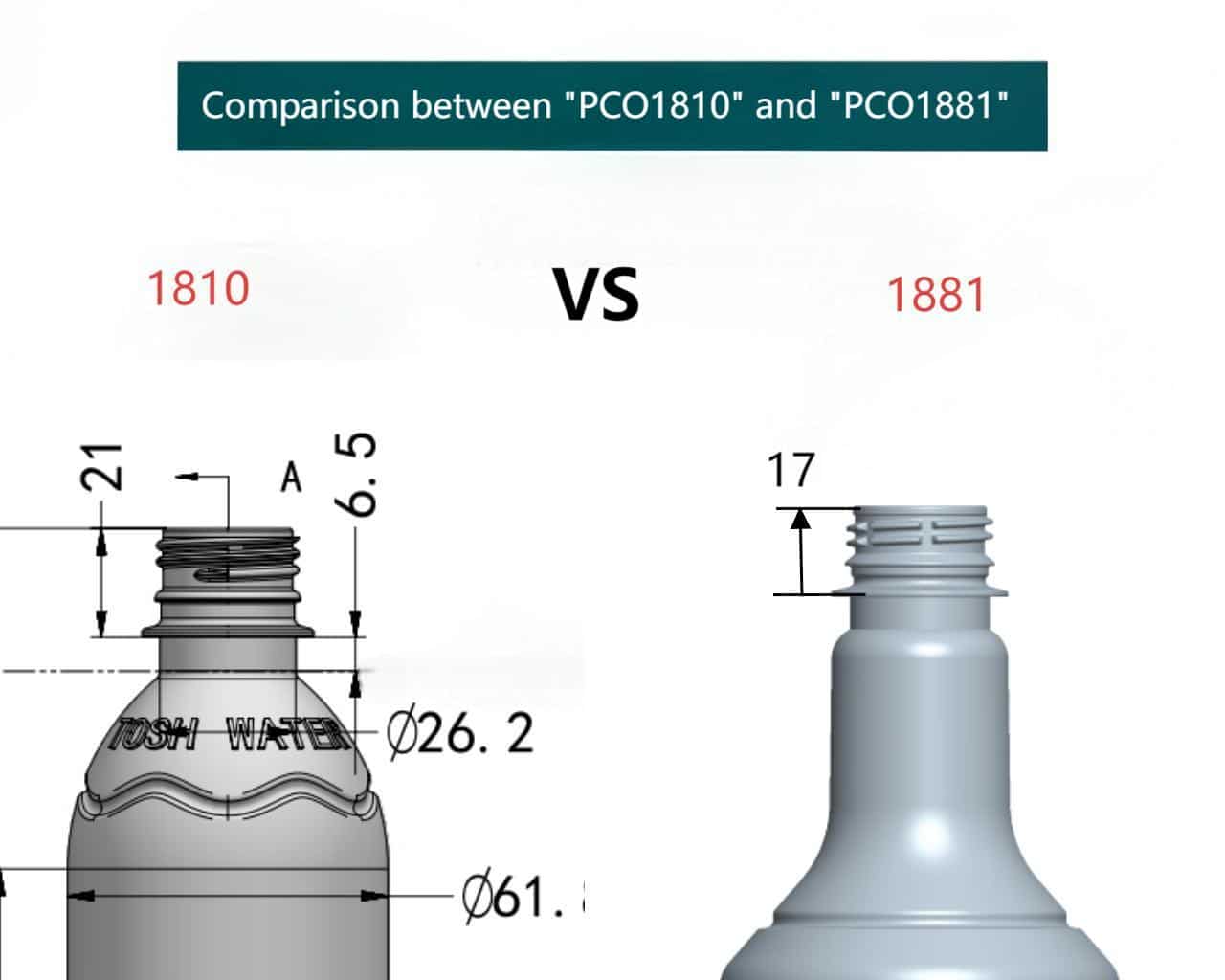

PCO1810 vs PCO1881, Which One Should You Choose?

Are you stuck between PCO1810 and PCO1881 for your beverage bottle? This is a common question. Let's clarify the differences to help you decide.

PCO1881 is generally the preferred choice over PCO1810 due to its lighter weight (cost and material savings) and comparable performance for carbonated and still beverages. However, PCO1810 might still be used for specific existing setups.

The PCO1810 and PCO1881 are both popular neck finishes, especially for carbonated soft drinks and water. PCO1810 is the older standard, characterized by a taller neck profile and slightly heavier weight. PCO1881 was introduced later as a "short neck" or "low profile" alternative. The primary motivation behind the PCO1881 design was material reduction. By making the neck shorter and optimizing the thread design, significant PET resin savings can be achieved per bottle without sacrificing the performance needed for carbonated products.

So, which one should you pick? In most new projects, PCO1881 is the go-to recommendation. It offers:

- Material Savings: Less PET resin per preform translates to lower cost and a better environmental footprint.

- Comparable Performance: It provides excellent seal integrity and pressure retention for carbonated beverages.

- Wide Availability: Caps and preforms for PCO1881 are widely available from many suppliers.

There are few scenarios where PCO1810 might still be considered. If you have a very old filling line or capping equipment that is specifically tooled for PCO1810 and cannot be easily or cheaply converted, you might stick with it. Also, if you have a large existing stock of PCO1810 caps, you might continue using PCO1810 preforms until that stock is depleted. However, for any new bottle design or production line setup, the industry trend is firmly towards PCO1881 and other lightweight neck finishes. I always advise clients to discuss with their machinery suppliers, but generally, transitioning to or starting with PCO1881 is a sound decision for both economic and ecological reasons.

Quick Comparison: PCO1810 vs. PCO1881

| Feature | PCO1810 | PCO1881 |

|---|---|---|

| Neck Height | Taller | Shorter ("short neck") |

| Weight | Heavier | Lighter |

| Material Use | More PET resin | Less PET resin (cost & eco savings) |

| Introduction | Older standard | Newer standard |

| Performance | Good for carbonation | Good for carbonation (often comparable) |

| Caps | Requires PCO1810 specific caps | Requires PCO1881 specific caps |

| Recommendation | Less common for new projects | Generally preferred for new projects |

Unless specific constraints dictate otherwise, PCO1881 is often the more efficient and modern choice.

Conclusion

Choosing the right preform neck size is vital for bottle integrity, compatibility, and cost. Consider product type, caps, and your filling line to make the best decision.

Frequently Asked Questions (FAQs)

1. Why can't I use a standard water bottle neck finish (like PCO 1881) for my carbonated soft drink or hot-fill tea?

While they may look similar, different neck finishes are engineered for specific applications.

- Carbonated Soft Drinks (CSD): These require a neck finish (like the PCO 1881) designed to handle high internal pressure. The thread profile and sealing surface are robust to prevent leaks and cap blow-off. Using a lighter, non-pressure-rated neck finish would be unsafe.

- Hot-Fill Products: These products are filled at high temperatures (around 85-95°C), which can distort standard PET. Hot-fill neck finishes are made with crystallized PET and often have a thicker profile to withstand the heat without deforming, ensuring a secure seal after the product cools and creates a vacuum.

2. What's the practical difference between a neck finish named "38/400" and one named "38mm 3-start"?

These naming conventions describe different aspects of the neck finish and typically apply to different industries.

- "38/400" is a standard from the Glass Packaging Institute (GPI). The "38" refers to the T-Dimension (the outer diameter of the threads in mm), and the "400" refers to the thread style (a standard single-turn thread). This is common for wider-mouth jars and non-pressurized beverages.

- "38mm 3-start" refers to a neck finish with a 38mm diameter but with a multi-start thread. This means there are three interwoven threads instead of one. The primary benefit is that the cap can be screwed on or off with a much shorter turn (e.g., a 1/3 turn instead of a full turn), which is often preferred for dairy or juice products for consumer convenience.

3. Is choosing the lightest possible neck finish always the best way to reduce costs?

Not always. While light-weighting is a key driver for cost savings (less resin per unit), it involves critical trade-offs. Choosing the lightest option without considering the entire bottle's lifecycle can lead to higher costs later. You must balance weight savings with:

- Top-Load Strength: The neck finish contributes significantly to the bottle's ability to withstand pressure during filling, capping, and stacking. An overly light neck can lead to crushed bottles on the production line.

- Consumer Perception: An extremely flimsy-feeling neck and cap can be perceived as low-quality by the end consumer.

- Sealing Integrity: The neck finish must be robust enough to guarantee a perfect seal with the chosen cap for the intended shelf life of the product.

4. How do I ensure the special cap I want (like a sports cap or lotion pump) will work with my preform?

You cannot assume compatibility. The cap and neck finish are a system that must be designed to work together.

- Get the technical drawings for both the preform neck finish and the desired cap.

- Share the drawings between suppliers. Your preform supplier and cap supplier should review each other's specifications to confirm a proper fit and seal.

- Conduct physical testing. Always get samples of both the preforms (blown into bottles) and the caps to perform application, removal, and leak tests before committing to a large production run.

5. What is the most overlooked factor when selecting a neck size that causes major problems in production?

The most commonly overlooked factor is the compatibility of the neck finish with the existing filling line, especially the capper. A company might choose a new, lightweight, or modern neck finish to save costs or update their look, only to find that:

- Their existing capper chucks or headsets are not designed for that specific thread profile or diameter.

- The bottle neck support guides on the conveyor are not the right size.

- The sorter cannot handle the new cap geometry.

Changing or re-tooling a capper can be extremely expensive and lead to significant downtime, often negating the cost savings from the new neck finish. Always audit your production line's capabilities before finalizing a neck size change.

PET Preform Neck & Weight Reference Guide

Date Published: May 30, 2025

Version: 1.1

Introduction

This guide is intended to provide bottle designers, procurement managers, and production personnel with a quick reference for common PET bottle applications, their corresponding neck finishes, and suggested preform weight ranges. Selecting the correct preform is the critical first step in developing a successful PET packaging solution.

Important Notice: The weights listed in this table are reference ranges based on industry averages. The final preform weight is highly dependent on multiple factors, including but not limited to: the final bottle design (round, square, custom shape), the presence of reinforcing ribs, required top-load strength, and the specific grade of PET resin used. A detailed bottle design analysis and blow molding trial are strongly recommended before finalizing preform specifications.

| Application Area | Common Neck Finish | Applicable Bottle Volume | Reference Weight Range (g) |

|---|---|---|---|

| Bottled Water | 29/25, 30/25 (Primary Standard) | 330 ml - 1500 ml | 8g - 22g |

| PCO 1881 / Short Neck (For Carbonated Water / Specific Brands) | 330 ml - 1500 ml | 9.5g - 25g | |

| Carbonated Soft Drinks (CSD) | PCO 1881 | 330 ml - 600 ml | 18g - 24g |

| PCO 1810 (Legacy standard) | 1000 ml - 2000 ml | 35g - 48g | |

| Hot-Fill (Juices/Teas) | 28mm Hot-Fill (Crystallized Neck) | 350 ml - 500 ml | 18g - 25g |

| 38mm Hot-Fill (Crystallized Neck) | 500 ml - 1500 ml | 28g - 42g | |

| Aseptic / Dairy | 38mm 2-Start / 3-Start | 250 ml - 1000 ml | 15g - 32g |

| Wide-Mouth Food Jars | 63/400 | 250 ml - 500 ml | 20g - 35g |

| 70/400 | 500 ml - 1000 ml | 35g - 60g | |

| 89/400 | 750 ml - 1500 ml | 55g - 85g | |

| Personal Care (Lotions, Soaps) | 24/410 | 100 ml - 300 ml | 10g - 18g |

| 28/410 | 250 ml - 750 ml | 15g - 28g | |

| Edible Oil | 29/21 | 500 ml - 1000 ml | 16g - 22g |

| 29/21, 32mm | 1.5 L - 5 L | 28g - 70g | |

| Bulk Water Jug (e.g., 5-Gallon) | 55mm Press-on / Screw | 18.9 L (5 Gallons) | 680g - 750g |

Glossary of Terms

- PCO 1881 / 1810: Industry standards published by the International Society of Beverage Technologists (ISBT), primarily for CSD. PCO 1881 is the newer, more lightweight standard.

- 29/25, 30/25: The leading industry standards for lightweight still water bottles, designed to save material costs while maintaining performance.

- Hot-Fill (Crystallized Neck): The neck finish is specially treated to be heat-resistant (appearing opaque white) to withstand high filling temperatures without deformation.

- XX/4XX (e.g., 63/400): A standard from the Glass Packaging Institute (GPI) where the first number is the outside thread diameter (in mm) and the second number refers to the thread style.

- X-Start: Refers to a multi-lead thread (e.g., 2 or 3 threads). This allows the cap to be secured or removed with significantly less rotation, improving consumer convenience.

Disclaimer

This guide was compiled by iBottler.com for reference purposes only and does not constitute a contractual offer or a technical guarantee of any kind. iBottler.com assumes no liability for any direct or indirect loss resulting from the use of the information in this guide. All specifications and applications should be finalized through detailed communication and physical testing with your suppliers.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

📞 Contact: Vivian

🏭 Zhongshan Jindong Machinery Co., Ltd.

🌍 www.ibottler.com

📧 Vivian@ibottler.com | 💬 WhatsApp: +86-13106288777

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr