Your product is great, but it's sitting on a crowded shelf. It needs to grab attention instantly. How can you make someone choose your bottle over all the others?

A PET bottle is your most powerful salesperson. In 2025, its design will be defined by three key trends: visible sustainability, minimalist geometry, and functional art. These elements transform a simple container into a brand statement that captivates consumers and drives sales.

I've seen countless brands struggle with this exact problem. They have a fantastic beverage, but their packaging just blends in. They think of the bottle as just a container, a cost to be minimized. But that's a huge mistake. The bottle is the first physical interaction a customer has with your brand. It's a tactile experience that can communicate quality, values, and story in a split second. Getting it right isn't just about aesthetics; it's about creating a connection that turns a first-time buyer into a loyal fan. Let's explore how you can make your bottle work for you.

Why Your Bottle is More Than a Container—It's Your Best Marketing Tool?

Your bottle sits on a real-world shelf, not a digital ad. It has seconds to make an impact. How do you make it count when you're surrounded by competitors?

A great bottle design does more than hold liquid; it communicates your brand's core message. It’s a silent, 24/7 marketing tool that tells a story of quality, sustainability, or innovation, directly influencing a customer's decision to buy right at the point of sale.

Think about the last time you were in a supermarket aisle. What made you pick up one product over another? Often, it's the packaging. The weight of the bottle, the feel of its texture, the way the light catches its shape—these are all subconscious cues. A flimsy, generic bottle whispers "cheap," while a thoughtfully designed, sturdy bottle screams "premium." This is not just about looks; it's about building perceived value before the customer even tastes the product. Your bottle is your physical handshake with the consumer. It needs to be firm, confident, and memorable. It’s your chance to make a first impression that lasts, turning a simple purchase into a brand experience.

The Silent Salesperson on the Shelf

In the bustling retail environment, your bottle is your primary brand ambassador. It doesn't have a voice, but it speaks volumes. Color, shape, and material all contribute to a narrative that consumers read in an instant. A bright, playful color scheme might target a younger demographic, while a sleek, dark bottle with clean lines appeals to a more sophisticated audience. The goal is to create an immediate emotional connection.

I often tell my clients to think of their bottle as a piece of real estate. Every square millimeter is an opportunity to communicate. The cap, the neck, the shoulder, the body—each part can be designed to reinforce your brand identity. For instance, a custom-embossed logo on the shoulder of the bottle adds a touch of elegance and signals a high-quality product. This is far more effective than just a printed label. It's a permanent feature of the package that can't be peeled off or ignored. This level of detail in a custom bottle design creates a powerful competitive advantage.

Building Brand Recall Through Touch and Sight

How do you make your brand unforgettable? You engage more than just the sense of sight. A unique shape or texture creates a memorable tactile experience. When a customer holds your bottle, they should be able to recognize it even with their eyes closed. This is the holy grail of packaging design—creating an iconic shape that is synonymous with your brand.

Consider these factors and how they contribute to brand identity:

| Design Element | Psychological Impact | Brand Message |

|---|---|---|

| Shape | Unique, ergonomic shapes create a memorable feel. | Innovation, user-centric, premium. |

| Weight | A slightly heavier preform can create a sturdier feel. | Quality, durability, substance. |

| Texture | Ribs, stippling, or smooth matte finishes engage touch. | Craftsmanship, natural, modern. |

| Transparency | Crystal-clear PET showcases the product's color and purity. | Purity, honesty, freshness. |

Achieving this requires a deep understanding of the manufacturing process. The right PET Bottle Mold Design Guide is essential for turning a creative vision into a tangible asset. It’s about balancing aesthetic appeal with structural integrity and production efficiency. A design that is both beautiful and manufacturable is the key to creating a bottle that not only looks good but also performs flawlessly on the production line and in the hands of the consumer.

Inspiration #1: "Visible Sustainability" – Designs That Wear Their Eco-Credentials Proudly?

Consumers are tired of greenwashing and empty promises. They want proof of your eco-commitment. How can your packaging show, not just tell, that you care about the planet?

Make your sustainable choices obvious and tactile. Use designs like integrated tethered caps, label-less bottles with embossed logos, and the unique, slightly imperfect texture of high-percentage recycled PET (rPET). These features make your eco-credentials a visible part of the brand experience.

The conversation around sustainability has shifted. It's no longer enough to have a small recycling logo hidden on the back of the label. Today's consumers are detectives; they are actively looking for brands that are genuinely committed to reducing their environmental impact. They want to see and feel the difference. Your bottle design is the perfect canvas to display this commitment. By making sustainability a core part of the design language, you build trust and appeal to a rapidly growing market of eco-conscious buyers. It's about being transparent and proud of the choices you've made.

The Rise of Tangible Eco-Design

For 2025, the biggest trend in sustainable bottle design is tangibility. It's about moving sustainability from a line item in a corporate responsibility report to a physical feature the consumer can interact with. It's a powerful way to build trust and brand loyalty.

Tethered Caps: Mandated in some regions and becoming a consumer expectation everywhere, tethered caps are a clear sign of responsible design. They prevent cap loss, reducing plastic litter. From a design perspective, this is not a limitation but an opportunity. The tethering mechanism itself can be elegantly integrated into the bottle's overall aesthetic, becoming a unique design feature rather than a clumsy add-on.

Label-Less Bottles: Removing the label entirely is a bold move that pays off. It simplifies the recycling process and creates a clean, minimalist look. The brand identity is communicated through embossing or debossing directly onto the blow bottle mold. This technique creates a premium, sculptural feel that stands out. It shows confidence in your product, letting the bottle’s shape and the liquid inside do the talking.

Celebrating rPET: In the past, brands tried to make recycled PET look exactly like virgin PET. The new approach is to celebrate its unique character. High-percentage rPET can have a slightly different color or a unique texture. Instead of hiding this, leading brands are highlighting it. They're using it as a storytelling tool, a visible badge of honor that says, "This bottle is part of the solution." The feel of an rPET bottle can be part of its charm.

Technical and Aesthetic Considerations

Integrating these features requires careful planning. For example, creating crisp, clear embossing on a bottle depends heavily on the quality of the mold and the precision of the bottle blowing machine. The pressure and temperature must be perfectly controlled to achieve the desired effect without compromising the bottle's strength.

Here is a quick comparison of these sustainable features:

| Feature | Consumer Benefit | Design Challenge | Manufacturing Focus |

|---|---|---|---|

| Tethered Cap | Convenience, reduces litter. | Integrating the tether elegantly without hindering user experience. | Precision in the preform mold for neck finish compatibility. |

| Label-Less | Easier recycling, clean aesthetic. | Creating clear, legible branding through embossing. | High-precision mold engraving and optimal blow molding parameters. |

| High-rPET Content | Reduces virgin plastic use. | Managing slight variations in material color and performance. | Material testing and process adjustments for rPET. |

Ultimately, visible sustainability is about authenticity. It’s about making choices that are good for the planet and communicating those choices clearly and beautifully through your packaging. It transforms your bottle from a simple container into a statement of your brand's values.

Inspiration #2: "Minimalist Geometry" – Creating a Premium Feel with Simple, Bold Shapes?

Your product is high-quality, but its generic round bottle makes it look cheap. How can you instantly signal "premium" and "modern" without a complex or expensive design?

Embrace minimalist geometry. Simple, bold shapes like squares, flat "flask" styles, and other non-traditional geometric forms create a powerful visual impact. Their clean lines and uncluttered surfaces convey sophistication and modernity, making the bottle itself feel like a premium object.

The power of minimalism lies in its confidence. It suggests that the product inside is so good, it doesn't need a loud, flashy package to sell it. This "less is more" philosophy resonates strongly with modern consumers who are overwhelmed by visual clutter. A simple geometric bottle stands out on the shelf precisely because of its simplicity. It creates a sense of order and intentionality. This approach isn't about being boring; it's about being deliberate and using shape as the primary element of your brand's identity.

The Power of Unconventional Shapes

For decades, the round bottle has been the default choice for beverages, primarily for its manufacturing efficiency and strength. However, breaking away from this norm is one of the most effective ways to make your product stand out.

The Square Bottle: Square or rectangular bottles have a distinctly modern and architectural feel. They feel solid and substantial in the hand. A key advantage is how they pack together on a shelf or in a shipping case. They create a clean, seamless "wall" of product, which is visually striking in a retail setting. The flat surfaces are also perfect canvases for crisp labels or direct embossing.

The Flat or "Flask" Bottle: These slim, wide bottles are designed for portability. They slip easily into a bag or pocket, making them ideal for on-the-go consumers. This shape has a trendy, almost fashion-accessory feel to it. It’s less about a traditional beverage container and more about a lifestyle product. The shape itself communicates a modern, active lifestyle.

Why Geometry Feels Premium

Our brains are wired to appreciate symmetry and clean lines. Geometric shapes feel intentional and well-crafted. They remove the "noise" and focus the consumer's attention on the fundamental form of the object. This is a principle that has been used in luxury product design for centuries, from watches to cars. Applying it to a PET bottle elevates the product from a disposable item to a desirable object.

Here’s how different geometric shapes can influence brand perception:

| Shape | Perceived Attributes | Ideal For |

|---|---|---|

| Square/Rectangular | Stable, Modern, Strong, Trustworthy | Premium spirits, mixers, high-end juices. |

| Cylindrical (Standard) | Classic, Efficient, Familiar | Mass-market sodas, water, everyday drinks. |

| Flat/Flask | Trendy, Portable, Sleek, Personal | Health shots, cold-brew coffee, functional drinks. |

| Triangular/Hexagonal | Unique, Innovative, Edgy | Energy drinks, niche beverages, limited editions. |

When considering a geometric design, it's crucial to work with engineers who understand the nuances of PET blow molding. Sharp corners, for instance, can be challenging. They can create weak spots or uneven wall thickness if not designed correctly. This is where a detailed PET Bottle Mold Design Guide becomes invaluable. It helps balance the bold aesthetic vision with the technical requirements of production, ensuring the final bottle is not only beautiful but also strong and reliable.

Inspiration #3: "Functional Art" – Ergonomic Designs That Enhance the User Experience?

A bottle looks great, but it's awkward to hold and messy to pour. This small annoyance can ruin the customer's experience. How can you make your bottle a pleasure to use?

Transform your bottle into a piece of functional art. Integrate ergonomic features like unique anti-slip textures, a comfortable waistline for easy gripping, or a cleverly designed neck that ensures a perfect pour every time. These details show you care about the user experience.

Good design is not just about how something looks; it's about how it works. When a bottle feels good in the hand, it creates a positive emotional association with your brand. The user experience doesn't start when the customer tastes the product; it starts the moment they pick the bottle up. A thoughtfully designed ergonomic bottle communicates a level of care and quality that goes beyond the surface. It’s a subtle but powerful way to build brand loyalty.

Ergonomics as a Design Statement

In a competitive market, every detail matters. Designing for user experience can be a key differentiator. It shows that you’ve thought about your customer's needs from start to finish.

Grip and Texture: Think beyond a smooth surface. A bottle for a sports drink could have a textured pattern that provides a secure grip, even with sweaty hands. A bottle for a thick sauce or syrup could have vertical ribs that help the user squeeze out the contents. These textures are not just functional; they add visual interest and a premium tactile quality. A custom pattern can even become a recognizable part of your brand identity.

The Perfect Pour: The design of the neck and opening is critical, yet often overlooked. For a carbonated beverage, the opening needs to be just right to control the fizz. For an oil or dressing, a specially designed spout can prevent messy drips. I worked on a project for a cooking oil brand where we tested several neck designs. The final version had a slight internal lip that caught the last drop of oil, preventing it from running down the side of the bottle. Customers loved it, and it became a key selling point. Understanding the options in a Preform Neck Size Guide is the first step in mastering the pour.

Shape and Balance: The overall shape of the bottle affects how it feels to hold and pour. A tall, thin bottle might look elegant but can be unstable. A short, wide bottle is stable but might be difficult for smaller hands to grip. A well-designed bottle has a low center of gravity for stability and a defined "waist" or grip area that fits comfortably in the hand.

When Function Becomes Beauty

The most successful designs are those where the functional elements are also the most beautiful parts of the design. Think of the iconic shape of a Coca-Cola bottle; its famous contoured shape was originally designed for a better grip. Over time, that functional choice became a world-renowned symbol of the brand.

Integrating these features requires a close collaboration between designers and engineers. An idea for a unique texture might look great on a screen but could cause problems during the molding process, leading to common PET blow molding defects. The key is to find the sweet spot where art and engineering meet. By focusing on creating a bottle that is a joy to use, you create a product that people will want to buy again and again.

From Inspiration to Blueprint: The Technical Challenges Behind a "Head-Turning" Design?

You have a brilliant, unique idea for a bottle. But you're worried. Can this complex, beautiful shape actually be mass-produced without issues? What are the hidden technical hurdles?

Translating a creative design into a physical bottle involves overcoming key technical challenges, especially with wall thickness distribution, structural strength, and material flow in the mold. A sharp corner or a deep emboss can easily become a weak point if not engineered correctly.

This is the critical stage where dreams meet reality, and it's where many great ideas fail. I've seen it happen. A client will bring me a beautiful 3D rendering, but it's essentially a piece of digital sculpture. It hasn't been designed for manufacturing. My job is to bridge that gap. We have to preserve the artistic vision while making sure the final bottle can withstand the pressures of filling, capping, shipping, and handling. It’s a puzzle, but with the right expertise, it's one that can be solved beautifully.

The Story of the Lion Bottle

I remember a passionate client from Dubai. He wanted to launch a new luxury beverage, and his vision was powerful: a bottle shaped like a majestic lion's head, a symbol of authority and strength in his culture. The initial designs were stunning, a true work of art. However, as we moved from concept to technical analysis, the challenges became clear.

- Wall Thickness: The intricate details of the lion's mane, nose, and ears created many sharp angles and deep recesses. In the blow molding process, the PET material would stretch unevenly over these features. Some areas would be dangerously thin, while others would be too thick, wasting material and creating cooling issues.

- Structural Integrity: The thin spots were potential failure points. The bottle would not be able to handle the internal pressure of a carbonated drink or the top-load pressure from stacking during shipping.

- Production Feasibility: Achieving such a complex shape would require extremely high blowing pressures and a very slow cycle time, making mass production incredibly expensive and inefficient.

We had to have a frank conversation. A literal lion-shaped bottle was not feasible if he wanted it to be safe, affordable, and mass-producible. But I didn't want to kill his dream. Instead, we worked together to find a compromise that kept the spirit of his vision. We developed a more traditional bottle shape with strong, elegant lines, but we designed a magnificent, deeply embossed lion head logo on the front. This gave him the powerful branding he wanted in a form that was both beautiful and manufacturable. We turned an impossible idea into a successful product by respecting the laws of physics and the realities of production. It's a reminder that a great blow bottle mold is born from both creativity and engineering discipline.

Key Technical Hurdles to Overcome

When you're pushing the boundaries of bottle design, these are the common challenges you'll face:

| Technical Challenge | Why It Happens | How to Solve It |

|---|---|---|

| Uneven Wall Thickness | The preform stretches non-uniformly over complex shapes and sharp corners. | Preform design optimization, strategic mold heating/cooling, precise blowing pressure control. |

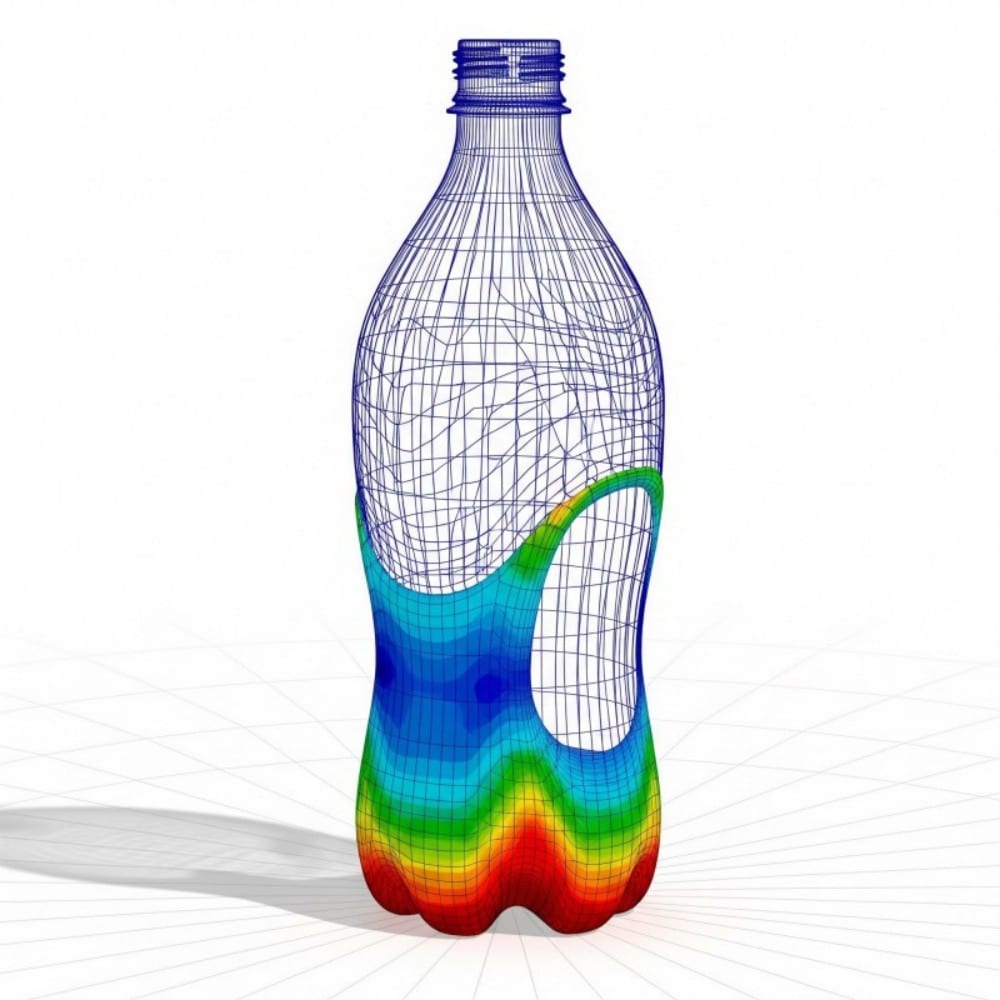

| Weak Base/Stress Cracking | High stress concentration in the base area, especially with non-round shapes. | Advanced base design (e.g., petaloid, star), careful material distribution analysis (FEA). |

| Poor Definition of Details | Insufficient pressure or incorrect temperature to force the PET into fine details like text or logos. | High-quality mold venting, optimized process parameters, using the right bottle blowing machine. |

| Difficult Mold Release | Complex shapes with undercuts can get stuck in the mold. | Designing with appropriate draft angles, high-quality mold polishing, two-stage opening mechanisms. |

Successfully navigating these challenges requires a deep understanding of the entire process, from preform to final bottle. It starts with a design that is created for manufacturing, not just for looks.

Our Process: How We Turn Your Inspired Design into a Perfect, Manufacturable Mold?

You know the technical challenges are real. You need a partner who can protect your creative vision while ensuring it works in the real world. What does that process look like?

We use a structured, collaborative process that moves from your initial concept to a production-ready mold. It includes Design for Manufacturability (DFM) analysis, rapid prototyping with 3D printed samples, and pilot mold testing to guarantee a perfect result.

The goal of our process is simple: no surprises. We want you to feel confident and informed at every stage. We believe in being transparent, showing you the "why" behind our engineering decisions. This isn't just about making a mold; it's about building a partnership to bring your product to life successfully. We act as the bridge between your marketing team's vision and the physical reality of the factory floor, ensuring that the final product is something everyone can be proud of.

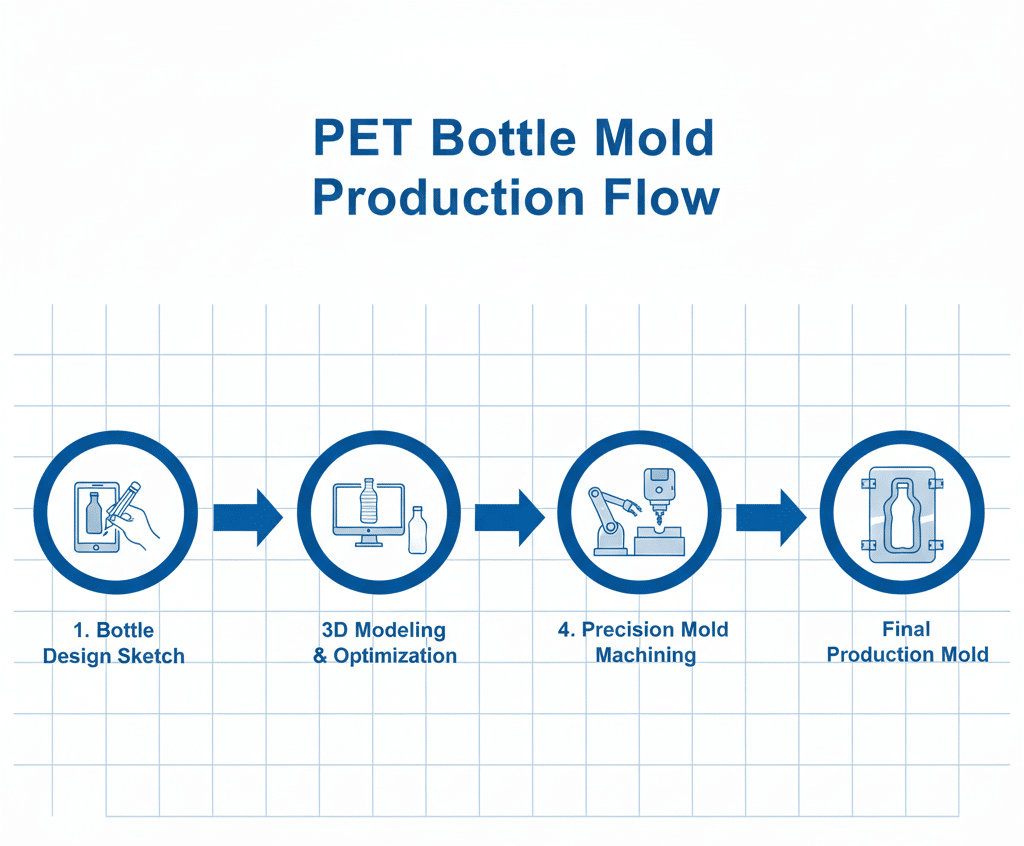

A Step-by-Step Journey from Idea to Reality

We've refined our process over many years and hundreds of projects. It's designed to be efficient, predictable, and focused on quality.

Step 1: Deep Dive & DFM Analysis

It all starts with your idea. You bring us your sketches, renderings, or even just a concept. We sit down with you to understand your brand, your target market, and your goals. Then, our engineers get to work. We perform a detailed Design for Manufacturability (DFM) analysis. Using advanced software, we simulate the blow molding process for your design. We identify potential problem areas—like the thin walls in the lion's mane from my earlier story—and propose solutions before any metal is cut. This proactive approach saves immense amounts of time and money.Step 2: 3D Prototyping and Validation

Seeing a design on a screen is one thing. Holding it in your hand is another. We create high-fidelity 3D printed prototypes. This allows you to feel the ergonomics, check the size and proportions, and see how it will look on a shelf. It's a crucial step for getting feedback from your team and making any final adjustments to the design. This rapid validation cycle ensures that the design is perfect before we commit to the expensive process of creating a steel mold.Step 3: Pilot Mold and Sample Testing

Once the design is finalized, we create a single-cavity pilot mold. This is a real, production-quality mold used to produce the first actual PET bottle samples. We test these samples rigorously for everything:- Volume: Does it hold the correct amount of liquid?

- Top-Load Strength: Can it withstand stacking?

- Leak Testing: Is the seal with the cap perfect?

- Drop Testing: Does it survive accidental drops?

We send these samples to you for final approval. This is your chance to see and test the exact bottle that will come off your production line.

Step 4: Production Mold Manufacturing

With your final approval, we begin manufacturing the multi-cavity production mold. We use high-grade materials and precision CNC machining to ensure that every cavity is identical and built to last for millions of cycles. We also ensure that the mold is a perfect fit for your specific equipment, as we have a vast database covering mounting dimensions for 80% of blow molding machines worldwide.

This methodical process removes the guesswork and risk from custom bottle design. It's a systematic approach that guarantees your innovative design is not just beautiful, but also robust, efficient to produce, and ready for market success.

A Note on Confidentiality: Protecting Your Brand's "Secret Weapon"?

Your new bottle design is your competitive edge, your secret weapon. The thought of it leaking to a competitor before launch is terrifying. How can you be sure your idea is safe?

We treat your design with the utmost confidentiality. The first step in our partnership is always signing a Non-Disclosure Agreement (NDA). This legally binding document ensures that your intellectual property is protected from the moment you share it with us.

For a brand investing in a unique, head-turning design, intellectual property is everything. This new bottle could be the cornerstone of your next marketing campaign and a major driver of growth. We understand that. The trust our clients place in us is something we take very seriously. Our reputation is built not only on the quality of our molds but also on our integrity. You can be confident that when you work with us, your "secret weapon" is safe.

Why an NDA is Non-Negotiable

A Non-Disclosure Agreement (NDA), also called a confidentiality agreement, is a formal contract between two parties—in this case, you (the client) and us (the manufacturer). Its purpose is straightforward: to prevent us from sharing your proprietary information with anyone else.

- What it Covers: An NDA typically covers all aspects of your project, including design sketches, 3D files, technical specifications, marketing plans, and even the very existence of the project.

- Why it's Important: In the early stages, you need to share detailed information with your manufacturing partner to get accurate quotes and feasibility analysis. The NDA allows you to have these open conversations without fear that your ideas will be stolen or copied.

- Our Policy: For us, it's standard practice. We will not engage in any detailed technical discussion about a new project without an NDA in place. It protects you, and it protects us by creating a clear, professional framework for our collaboration. We have strict internal protocols to ensure that access to your project files is limited to only the essential team members working on your mold.

I want to be very clear about this: as a mold manufacturer, we see many innovative designs and new products before they hit the market. Our business is not in selling bottle designs; our business is in making world-class blow bottle molds that bring your designs to life. We have a strict policy against sharing any client's design, even as an example of our work. The beautiful and innovative bottles you see in the market are the property of our clients, and we honor that completely. Your success is our success, and that relationship is founded on a bedrock of trust and confidentiality.

Conclusion: Start Designing Your Brand's Next Iconic Bottle Today?

Your bottle is the most crucial part of your brand's first impression. By embracing visible sustainability, minimalist geometry, and functional art, you can create a truly iconic design for 2025.

The journey from a simple idea to a head-turning bottle on the shelf is a partnership. It requires creativity, technical expertise, and a process built on trust. Now is the time to stop blending in and start standing out. Let's work together to create a bottle that not only holds your product but also defines your brand for years to come.

Frequently Asked Questions (FAQ)

1. I have an idea for a unique bottle. What is the very first step to determine if it's feasible to produce?

The very first step is a Design for Manufacturability (DFM) analysis. Before you invest in prototyping or tooling, our engineers will analyze your design concept using simulation software. We will assess its viability for the PET blow molding process, identifying potential issues like uneven wall thickness, sharp angles that could cause weakness, or features that would be difficult to mold. We then provide you with a detailed report and constructive suggestions to optimize the design for successful, efficient production while preserving your creative intent.

2. How much more does it typically cost to produce a truly custom, "head-turning" bottle compared to a standard stock bottle?

The primary cost difference is in the initial investment for the custom blow bottle mold, which can range from several thousand to tens of thousands of dollars depending on its complexity and the number of cavities. However, the per-bottle cost difference is often minimal once you are in mass production. While a complex design might slightly slow down the production cycle time on the bottle blowing machine, this is often offset by the ability to command a higher retail price and the increased sales that come from a superior shelf presence. Think of it as an upfront marketing investment that pays dividends with every bottle sold.

3. Are sustainable design options, like using a high percentage of rPET, significantly more expensive for a custom design?

Not necessarily. The cost of rPET (recycled PET) material can fluctuate, and is sometimes slightly higher than virgin PET, but this is a raw material cost, not a design cost. From a mold design perspective, creating a bottle for high rPET content does not add significant expense. The main consideration is in process optimization. Our team has extensive experience tuning the molding process to accommodate the unique properties of rPET, ensuring you can achieve your sustainability goals without compromising on quality or incurring major additional costs. Features like label-less embossing can even reduce long-term costs associated with label purchasing and application.

4. From a final design sketch to a physical prototype, what is a realistic timeline?

A realistic timeline to get from a finalized design to a physical prototype you can hold is typically 2 to 4 weeks. This process includes our detailed DFM analysis, design optimization, and the creation of a high-fidelity 3D printed sample. For a pilot mold that produces actual PET bottle samples, the timeline is longer, usually around 4 to 6 weeks. We prioritize a thorough process over speed to ensure the first samples are as close to perfect as possible, saving time and money in the long run.

5. What is a Non-Disclosure Agreement (NDA), and why is it important to sign one with my mold manufacturer before sharing my design?

A Non-Disclosure Agreement (NDA) is a legally binding contract that protects your confidential information. It obligates the manufacturer (us) not to share your unique bottle designs, technical specifications, or any other proprietary project details with third parties. It is critically important to sign an NDA before you share your design because your bottle's unique shape and features are valuable intellectual property (IP). The NDA gives you the legal security to have open, detailed technical discussions, ensuring your competitive advantage remains a secret until you are ready to launch. It is the foundation of a trusted professional partnership.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr