Are you struggling to find a PET bottle mold that lasts and performs? It's a common problem. Many businesses invest in molds only to face constant issues.

Finding a top-quality PET bottle mold means you're actually looking for a skilled and trustworthy mold manufacturer. The mold's precision, how long it lasts, and how well it works with your machines all come down to the maker's expertise.

Choosing the right PET bottle mold can feel overwhelming. But, if you know what to look for, you can find a mold that truly meets your needs. This is about more than just the mold; it's about finding a partner who understands your production goals. Let's explore how you can make a smart choice.

How much does a bottle mold cost?

Worried about the price tag of a new bottle mold? Many factors influence the cost, making it a complex question. It's not just an expense, but an investment.

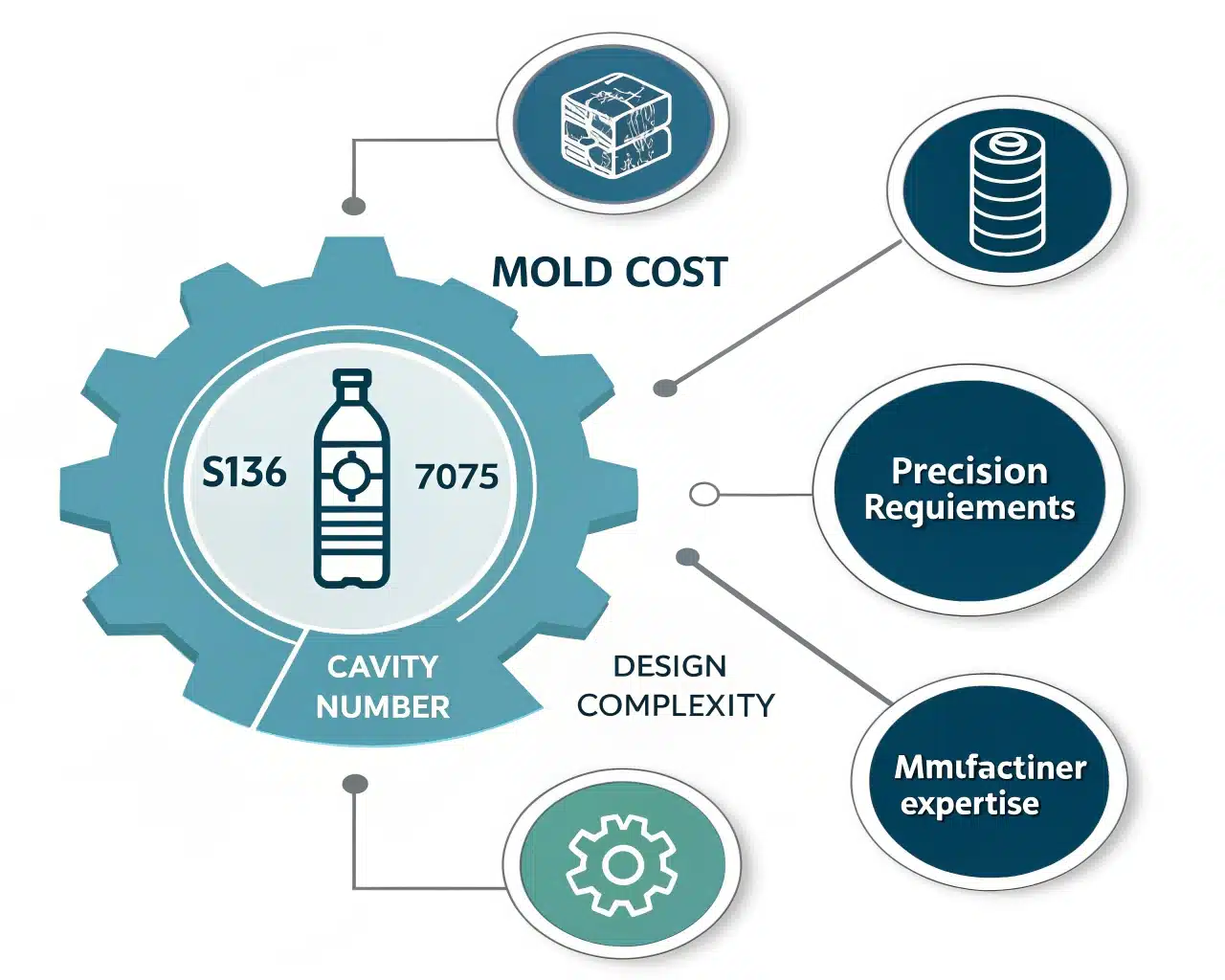

A PET bottle mold's price depends on material, cavity count, design complexity, and the manufacturer's skill. Cheaper isn't always better, as quality affects your final product and operational efficiency. Consider the long-term value.

When I first started in this industry, I looked for the cheapest mold. I thought I was saving money. That cheap mold caused so many problems. We had a lot of bad bottles and the machine was often stopped. It cost me more in the long run. Then, I learned that investing in a quality mold from a good manufacturer saves money because it works well for a long time.

The cost of a PET bottle mold isn't a simple number. Several things decide the final price.

First, the mold material is a big factor. As I learned from experience, manufacturers mostly use 7075 aircraft aluminum or S136 stainless steel.

- 7075 Aluminum: This material is lighter than steel. It also transfers heat quickly. This makes it good for production lines that need to be fast or medium-fast. It usually costs less than S136 steel.

- S136 Stainless Steel: This steel is very hard and lasts a long time. It's great if you need bottles with very exact shapes and high quality. It costs more, but its long life can make it worth it.

- Some older molds used iron, but that's not common now because it doesn't perform as well. For special rotary machines, molds might use 6061T aluminum. This aluminum gets a hard coating to make it wear better and handle heat well.

Second, the number of cavities in the mold changes the price. A mold can make one bottle at a time or many bottles at once. More cavities mean the mold is bigger and more complex to make, so it costs more. But, it also means you can make more bottles faster. So, for big production, a mold with more cavities can be cheaper per bottle.

Third, the bottle design's complexity affects the cost. A simple, smooth bottle mold is easier to make than a mold for a bottle with fancy shapes, detailed logos, or special screw threads for the cap. The more complicated the design, the more time and skill it takes to carve the mold, so the price goes up.

Fourth, the precision needed also plays a part. If your bottles need to be extremely accurate in size and thickness, the mold must be made with very high precision. This requires better machines and more skilled workers, adding to the cost.

Fifth, the manufacturer's experience and location can change the price. A well-known manufacturer with a lot of experience might charge more. But they often provide better design, service, and a more reliable mold. Also, molds made in different countries can have different costs because labor and materials prices vary.

It's important to think beyond just the initial price. A cheap mold might break down often. It might need a lot of repairs. It might also produce bottles that aren't good quality, meaning you waste material and time. So, a more expensive, high-quality mold can actually save you money by working reliably for years and making good bottles consistently. You are looking for good value and a dependable partner, not just the lowest price.

Here’s a simple table to summarize:

| Cost Factor | Impact on Price | Why it Matters for Quality & Longevity |

|---|---|---|

| Mold Material (e.g., S136 vs. 7075) | High / Medium | Durability, precision, cycle time, corrosion resistance |

| Number of Cavities | Increases with count | Production output rate vs. initial investment |

| Bottle Design Complexity | Increases with complexity | Feasibility, part quality, tool life |

| Precision Tolerances | Increases with tightness | Bottle quality, consistency, reduced waste |

| Manufacturer Reputation | Can increase price | Reliability, support, design expertise, mold life |

Thinking about these points helps you ask the right questions. It helps you understand that the true cost includes the mold's performance over its entire life.

What is the difference between HDPE bottle and PET bottle?

Are you wondering if HDPE or PET is right for your bottles? These two plastics look similar sometimes, but they have different strengths. Choosing the right one matters.

PET bottles are usually clear and strong, great for drinks. HDPE bottles are often milky or colored, tougher, and good for detergents or milk. Their differences affect how they are molded and used.

I remember a client who wanted to package a new type of juice. They liked the look of a clear PET bottle but were worried about how fragile it might seem. We discussed the properties, and they realized PET was strong enough and showed off their colorful juice perfectly. Understanding these materials helps make the best choice for the product.

PET and HDPE are two of the most common plastics for bottles. Let's look at them more closely.

PET (Polyethylene Terephthalate)

- Look and Feel: PET is usually very clear, like glass. It's also quite rigid and strong for its weight.

- Good For: It's excellent at keeping oxygen and carbon dioxide out. This is why it's used for soda, water, juice, and food containers like peanut butter jars. It doesn't change the taste of food or drinks.

- Recycling: PET is one of the most recycled plastics in the world. You'll often see it labeled with the number 1 recycling code. Recycled PET (rPET) can be used to make new bottles or other products like clothes.

- Making Bottles: PET bottles are typically made using a process called Injection Stretch Blow Molding (ISBM). This process first makes a small tube called a preform. Then, this preform is heated, stretched, and blown into the final bottle shape inside a mold. PET molds need to be designed for specific temperatures and pressures used in this process.

HDPE (High-Density Polyethylene)

- Look and Feel: HDPE is naturally milky or translucent but can also be colored. It feels more flexible than PET and is quite tough. It can resist cracking well.

- Good For: It's very good at resisting chemicals. This makes it perfect for bottles holding milk, detergent, shampoo, bleach, motor oil, and industrial chemicals. It's also used for things like pipes and plastic lumber.

- Recycling: HDPE is also widely recycled. It has the number 2 recycling code.

- Making Bottles: HDPE bottles are often made using Extrusion Blow Molding (EBM). In this process, a hot tube of plastic (called a parison) is pushed out from a machine. A mold then closes around this tube, and air is blown in to shape the bottle. Some HDPE bottles are also made by Injection Blow Molding (IBM), which is a bit different. Molds for HDPE need to account for how this plastic shrinks and flows.

Here’s a comparison:

| Feature | PET (Polyethylene Terephthalate) | HDPE (High-Density Polyethylene) |

|---|---|---|

| Clarity | Excellent (clear, glass-like) | Translucent to opaque (milky) |

| Rigidity | More rigid | More flexible |

| Barrier (O2, CO2) | Good | Poor |

| Barrier (Moisture) | Moderate | Good |

| Impact Resistance | Good | Very good, tougher |

| Chemical Resistance | Moderate | Excellent |

| Typical Molding | Injection Stretch Blow Molding (ISBM) | Extrusion Blow Molding (EBM), IBM |

| Common Uses | Drinks, food jars, salad dressing | Milk, detergents, shampoos, oil bottles |

| Recycle Code | #1 | #2 |

Understanding these differences is important. If you need a PET bottle, you need a PET bottle mold. An HDPE mold won't work correctly for PET, and vice-versa. The type of plastic dictates the design of the mold and the machine used.

How do you Mould plastic bottles?

Ever wondered how a plastic bottle gets its exact shape? It's a precise process. For PET bottles, it usually involves heating, stretching, and blowing.

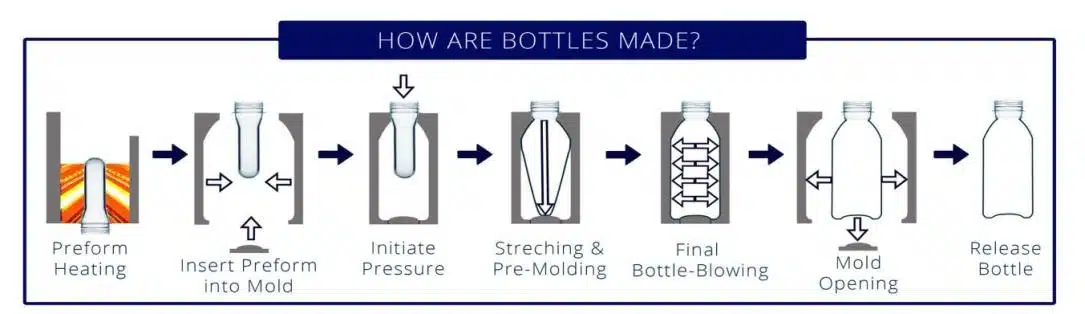

Making PET bottles typically uses Injection Stretch Blow Molding. First, a test-tube-like "preform" is made. Then, this preform is heated, stretched, and air blows it into the bottle mold. The mold's design is key.

The first time I visited a large bottling plant, I was amazed. Rows of shiny preforms went into a machine and came out as perfectly formed bottles in seconds. It looked like magic, but it's clever engineering. Knowing how this works helps you talk to mold makers. You'll understand what makes a good PET bottle mold.

Most high-quality PET bottles, like those for water and soda, are made using a process called Injection Stretch Blow Molding (ISBM). This is usually a two-step process:

Step 1: Making the Preform (Injection Molding)

This step happens first and uses a special preform mold.

- Drying PET Resin: Tiny plastic pellets (PET resin) are dried thoroughly. If there's any moisture, the final bottle won't be strong or clear.

- Melting and Injecting: The dry resin is melted down into a hot, liquid plastic. This liquid PET is then injected under high pressure into a mold. This mold has multiple cavities, each shaped like a small, thick-walled test tube with the bottle's neck threads already formed. This is the "preform."

- Cooling: The preforms are cooled quickly in the mold so they keep their shape.

- Ejecting: The cooled preforms are removed from the preform mold. They can be stored and used later or moved directly to the next step.

Step 2: Making the Bottle (Stretch Blow Molding)

This step uses the PET bottle mold (or blow mold) that we are focusing on.

- Reheating Preforms: The preforms are heated again. This time, they are heated very carefully so that some parts are hotter than others. This allows them to stretch correctly.

- Placing in Blow Mold: The hot preforms are quickly moved into the bottle blow mold. This mold has cavities shaped like the final bottle.

- Stretching: A long rod, called a stretch rod, pushes down into the preform. It stretches the preform lengthwise (axially).

- Blowing: At the same time, or just after stretching, high-pressure air is blown into the preform. This air pushes the stretched plastic outwards (radially) against the cold walls of the blow mold cavity. This shapes the plastic into a bottle.

- Cooling: The bottle cools very quickly once it touches the cold mold walls. This sets its shape.

- Ejecting: The mold opens, and the finished bottle is taken out.

Now, the type of blowing machine you use is very important. It affects how the PET bottle mold needs to be designed.

- Two-Step Semi-Automatic Machines: An operator might load preforms by hand and remove finished bottles. These machines are simpler and slower. The molds are often simpler too.

- Two-Step Fully-Automatic Linear Machines: These machines do everything automatically. Preforms are loaded, heated, stretched, blown, and ejected in a line. They are faster, and the molds need to be strong and precise.

- Two-Step Rotary High-Speed Machines: These are the fastest. Preforms move on a spinning wheel through heating, blowing, and ejection stations. The molds are usually very specialized, often made from materials like 6061T aluminum with a hard coating for wear and good heat transfer. They need excellent cooling systems built into the mold structure.

So, when you talk to a mold maker, you need to tell them what kind of machine you have or plan to buy. The mold's structure, its cooling system, and how it opens and closes must match your machine. A good mold maker will understand this. They'll also choose the right materials for your mold – like 7075 aluminum for speed and good heat movement, or S136 steel for very long life and high precision. They will also pay attention to small details like the bottle neck thread type, the holes for mounting the mold to the machine, and the connections for cooling water. These details make sure the mold works perfectly.

Can plastic bottles get moldy?

Are you concerned about mold growing in your plastic bottles? It's a valid question, especially for reusable bottles. The good news is the plastic itself usually isn't the problem.

Plastic like PET is not a food source for mold. However, if tiny bits of drink or food are left inside with moisture, mold can grow on those residues. Proper cleaning is key.

I once found an old water bottle in my gym bag that I'd forgotten for weeks. Sure enough, there was some fuzzy stuff inside! But it was clear the mold was growing on the tiny bit of sports drink I'd left in there, not on the plastic itself. A good wash, and the bottle was fine, though I decided to be more careful about emptying and rinsing them out!

So, can plastic bottles themselves get "moldy"? The direct answer is generally no. The plastics commonly used for bottles, like PET (polyethylene terephthalate) or HDPE (high-density polyethylene), are synthetic polymers. They don't provide the nutrients that mold needs to grow. Mold needs organic matter (food) and moisture to thrive.

What does happen is that residues inside the bottle can grow mold.

- If you leave a little bit of juice, milk, sports drink, or any sugary liquid in a bottle, that can become food for mold spores that are naturally in the air.

- If you seal the bottle with moisture trapped inside, even from just rinsing with water and not drying, this creates the damp environment mold loves.

- This is especially true for reusable bottles if they aren't cleaned and dried thoroughly between uses. Areas like the threads of the cap or complex shapes inside the bottle can be harder to clean.

How does PET bottle mold quality relate to this?

While the mold itself doesn't prevent mold growth on residues, a high-quality PET bottle mold can produce bottles that are easier to keep clean:

- Smooth Internal Surface: A well-made, highly polished mold will create bottles with very smooth inner surfaces. Smooth surfaces are less likely to trap tiny particles of food or drink. They are also easier to clean effectively. If the mold surface is rough or has imperfections, the bottle surface will also be rough, making it easier for residues to stick.

- Bottle Design: Sometimes, very complex bottle shapes with sharp internal corners or crevices can be harder to clean thoroughly. While the mold just makes the shape it's designed for, a good mold manufacturer might offer advice. If a design seems like it will be very difficult to clean and prone to trapping residue, they might discuss this with you. Of course, often the design is fixed by branding needs.

- Neck and Closure Area: A high-quality mold will produce the neck threads very accurately. This means the cap will seal tightly. A good seal prevents leaks and can also help keep airborne mold spores out if the bottle is empty and capped. However, the cap and thread area itself can still trap moisture and residues, so it needs cleaning.

Prevention is the Best Strategy:

- For single-use bottles: Ensure they are emptied as much as possible before recycling or disposal.

- For reusable bottles:

- Rinse them out promptly after use.

- Clean them regularly with soap and warm water. A bottle brush can help reach all areas.

- Allow them to dry completely with the cap off.

- The Mold Tool Itself: The steel or aluminum mold used to make bottles also needs care. If not maintained, it could get rust (if not stainless) or build-up from the plastic. But this is about maintaining the tool, not mold growing on the plastic it produces.

So, while the plastic of a PET bottle is resistant to mold, the bottle's contents or residues can support mold growth. A high-quality mold contributes to a high-quality bottle with features like a smooth surface, making it easier for the end-user to keep it clean.

Key Considerations When Choosing Your PET Bottle Mold Supplier?

Feeling lost in the search for a PET bottle mold supplier? It's more than just comparing prices. You are choosing a long-term manufacturing partner.

To choose wisely, look for a supplier with true manufacturing capability, not just a trading office. Their understanding of blow molding machines and mold materials is crucial for your success.

I learned this the hard way. My first few molds were from a company that just traded them. When I had technical questions or needed adjustments, they couldn't help much. They were just middlemen. Later, I found a manufacturer that made their own molds and understood the blowing machines. The difference was night and day. They helped me optimize the mold for my specific machine and process. That's the kind of partner you need.

Finding the right PET bottle mold supplier is a critical step. It's not just about buying a piece of metal; it's about forming a relationship that can impact your production for years. Here’s what I’ve learned to focus on:

-

Understand Your Own Needs First (Before You Talk to Suppliers)

- Your Blowing Machine: This is so important. You must know the exact type of PET blow molding machine you are using or plan to buy. Is it a two-step semi-automatic, a fully-automatic linear machine, or a high-speed rotary machine? This information dictates many things about the mold: its overall structure, how the cooling system needs to be designed, and the way the mold opens and closes. A mold for a rotary machine is very different from one for a semi-auto machine.

- Your Bottle Specifications: Have your bottle design ready. Know the exact neck finish (screw thread type), the volume, the weight, and any special features. The more detail you have, the better a supplier can help you.

-

Become Familiar with Mold Materials

- You don't need to be an expert, but know the basics. The main materials are 7075 aircraft aluminum and S136 stainless steel.

- 7075 aluminum is lighter and conducts heat very well. This is good for faster production cycles on medium to high-speed machines.

- S136 steel is harder, more durable, and resists corrosion. It's excellent for molds that need to last a very long time or produce bottles with extremely high precision. It generally costs more.

- Iron molds are mostly outdated.

- For rotary machines, a special grade of aluminum like 6061T alloy, often with a hard anodized surface treatment, is common. This treatment improves wear resistance and heat efficiency.

- Knowing this helps you discuss options with the supplier and understand their recommendations.

- You don't need to be an expert, but know the basics. The main materials are 7075 aircraft aluminum and S136 stainless steel.

-

Confirm Critical Mold Parameters

- There are small details that are very important for making sure the mold will work correctly:

- Bottle Neck Finish: The exact model of the screw thread for the cap.

- Mold Installation Dimensions: The size and location of mounting holes must match your machine.

- Cooling Water Channel Connections: The type and size of fittings for the cooling water.

- Getting these wrong means the mold might not fit your machine, or you won't be able to use it efficiently. A good supplier will ask for this information or help you determine it.

- There are small details that are very important for making sure the mold will work correctly:

-

Choose a Manufacturer, Not Just a Trader

- This is a big one for me. Try to find a company that actually manufactures the molds in their own factory. Some companies are just trading companies; they buy molds from one factory and sell them to you.

- A true manufacturer has direct control over quality, design, and the production process. They will have engineers and technicians who understand molds deeply. If you have a problem or need a modification, they are much better equipped to help you.

-

Look for Integrated Expertise (Machines and Molds)

- If you can find a company that makes both PET blowing machines and PET bottle molds, that's often a great advantage.

- They will have a much better understanding of how the mold needs to perform as part of the whole blowing system. They can optimize the mold design to perfectly match the machine's characteristics. This can lead to better bottle quality, faster cycles, and fewer problems.

-

Think Beyond the Quotation

- The price is important, but also consider:

- Technical Support: Will they help you if you have questions during setup or operation?

- After-Sales Service: What kind of warranty or repair services do they offer?

- Partnership Potential: Do they seem interested in your success? Are they willing to share their knowledge?

- The price is important, but also consider:

Here's a quick checklist to help you evaluate potential suppliers:

| Supplier Checklist Factor | Importance | What to Ask / Look For |

|---|---|---|

| Own Factory / Manufacturing Base | Very High | "Do you make these molds in your own factory? Can I see it?" |

| Experience with Your Machine Type | Very High | "Have you made molds for [Your Machine Model/Type] before?" |

| Material Knowledge & Options | High | Discuss material pros/cons for your bottle and volume. |

| Understanding of Key Parameters | High | Do they ask detailed questions about neck, mounting, etc.? |

| Design & Engineering Capability | High | Do they have engineers? Can they help optimize design? |

| Makes Both Molds & Machines | Bonus | "Do you also manufacture blow molding machines?" |

| References / Case Studies | Medium | Can they share examples of similar projects or clients? |

| After-Sales Support / Warranty | High | What happens if there's an issue? What's covered? |

Remember, you are not just buying a mold. You are looking for a reliable manufacturing partner who understands your needs and can provide a high-quality tool that will help your business succeed. Taking the time to find the right supplier is an investment that will pay off.

Conclusion

Finding a high-quality PET bottle mold means choosing a skilled, reliable manufacturing partner. Know your machine, understand mold basics, and look beyond just the price. It's about lasting value.