Using a plastic bottle? It seems so simple. But this everyday item is a tiny engineering marvel. Let's see how it's made.

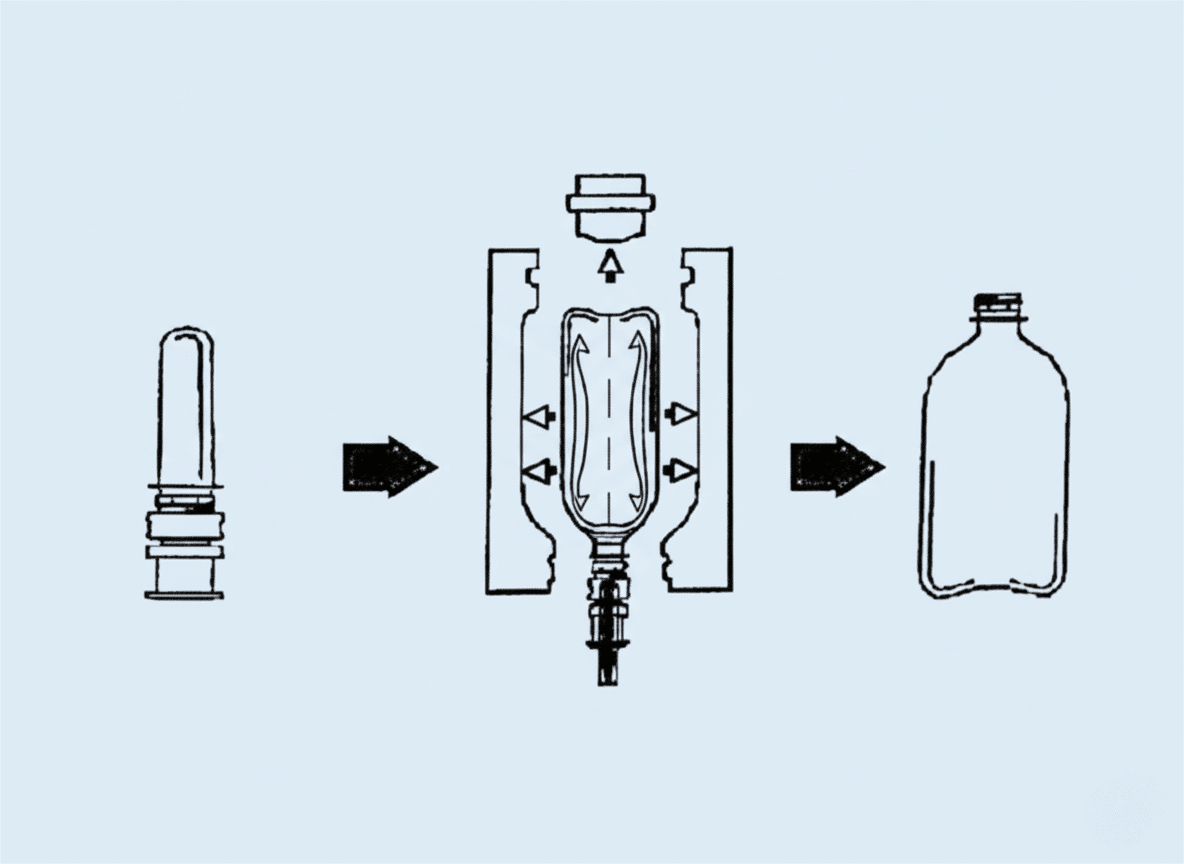

PET bottles are made using Stretch Blow Molding (SBM). This process takes a pre-made "preform," heats it to a precise temperature, stretches it lengthwise with a rod, and then inflates it with high-pressure air. This "biaxial stretching" aligns the PET molecules, creating a super-strong, clear container

This might sound simple, like blowing a balloon. But it's not. It's a high-speed, precision-controlled process. I've spent my career helping clients perfect this. Let's explore the science behind this everyday miracle.

More Than Just Plastic - The Humble Bottle as an Engineering Feat?

You use a PET bottle every day. It seems simple, just thin plastic. But it's a high-tech product, not just simple plastic.

A PET bottle is an engineering feat because it balances strength, clarity, low cost, and light weight. It uses material science (biaxial orientation) to be strong enough to hold pressure but thin enough to be cheap and light.

The Science in Your Hand

My insight is this: "Many people think making a bottle is just 'blowing a balloon.' But as an engineer, I see it as a precision 'dance' with physics. It is a millisecond-long performance of materials science, thermodynamics, and fluid dynamics. And it all has to be perfect, millions of times a day."

Let's break down why it is an engineering feat.

- Material Science: The process starts with choosing a very specific polymer, PET. This material has a unique property: it gets stronger when you stretch it (this is called strain-hardening). The entire manufacturing process is designed around this single property.

- Thermodynamics (Heat Science): The bottle-making process does not melt the plastic. It just heats it to a precise "glass transition temperature" (around 100°C). At this point, the PET is soft and rubbery, like taffy. This heating is an art. The heat must be perfectly even. If one spot is 5 degrees hotter, it will blow too thin and the bottle will fail.

- Mechanics and Fluid Dynamics: The process uses a solid steel rod (mechanics) and high-pressure air (fluid dynamics) at the same time. This combination, the "stretch" and the "blow," is what makes the bottle. The timing of these two forces must be perfect.

- Precision Manufacturing: A modern bottle blowing machine can make over 2,000 bottles per hour, per mold. The entire "dance" I mentioned happens in less than 3 seconds.

The Humble Deception

The finished bottle is a marvel. A standard 500ml soda bottle weighs only about 20 grams (less than an empty wallet). But it can easily hold the pressure of a carbonated drink, which is often 60 psi (4 bar). This is twice the pressure in your car's tires.

How can something so thin and light be so strong? The answer is engineering.

I often visit clients who see a bottle as a "container." I see it as a "pressure vessel." When a client has a problem, like bottles bursting in the warehouse, it's not a "plastic problem." It's an engineering problem.

- Maybe the oven lamps are unbalanced.

- Maybe the stretch rod speed is wrong.

- Maybe the air compressor pressure is unstable.

Let's look at the conflicting problems that this one small item solves.

| Engineering Challenge | How PET Bottle Engineering Solves It |

|---|---|

| Must Hold Pressure | Biaxial Orientation (aligning molecules) creates high strength. |

| Must Be Lightweight | The high strength allows for very thin walls (less material). |

| Must Be Clear | PET is a clear material, and stretching it improves clarity. |

| Must Be Cheap | The high-speed, automated stretch blow molding explained process. |

This is why a simple bottle is a true engineering feat. It solves many conflicting problems all at once. It is not just plastic; it is applied physics.

The "Magic" Material: Why PET is the Undisputed King?

Why are all soda and water bottles made of PET? Why not other plastics? You might think all clear plastics are the same. They are not.

PET (Polyethylene Terephthalate) is used because it has the perfect combination of properties. It is strong, lightweight, crystal clear, shatterproof, and 100% recyclable. It also has a good gas barrier, which keeps soda fizzy.

The Perfect Balance

My insight is this: "PET is not the best at any single thing. But it is the best balance of all the things we need. Choosing PET was the first and most important engineering decision."

Let's look at the properties that make PET the king. No other material can match this combination.

- Strength and Toughness: This is PET's superpower. As I mentioned, it strain-hardens. The more you stretch it (biaxially), the stronger it gets. This is why the stretch blow molding explained process was invented for PET. It turns a weak-ish material into a super-strong one.

- Clarity: It is "water-clear." Consumers want to see the product. Other plastics like Polypropylene (PP) are naturally hazy. Polyvinyl Chloride (PVC) is clear, but it has environmental and health concerns. Glass is clear, but it is heavy and it shatters. PET gives you the look of glass without the problems.

- Gas Barrier: This is the science behind PET bottles. A bottle's job is to protect its contents. PET is good at keeping Carbon Dioxide (CO2) in and Oxygen (O2) out.

- CO2 In: This is why your soda stays fizzy. The gas barrier traps the carbonation.

- O2 Out: This is why your juice or tea stays fresh. Oxygen is the enemy of flavor and vitamins. PET helps block it.

- Lightweight: This is a huge business decision. I have seen clients' shipping costs drop by 40% when they switched from glass. A truck can carry more product, not more packaging. This saves fuel and money at every step.

- 100% Recyclable: This is critical. PET is one of the most-recycled plastics in the world. It carries the #1 recycling code. It can be collected, melted down, and turned back into new PET bottles (this is called rPET).

- Safety: PET is globally approved as a food-safe material by all major health agencies. It is tough, stable, and does not contain BPA.

I am a mold and machine engineer. My job is to work with this material. I have to respect its properties. I know I cannot heat it too much, or it will crystallize and turn white. I know I must dry it perfectly. My entire job is about optimizing the potential that is already locked inside this amazing material.

No other plastic gives us this perfect balance of performance, cost, and recyclability. It's the king for a reason.

Step 1 Deep Dive: The Preform - More Than Just a "Test Tube"?

The bottle-making process starts with a "preform." It looks like a test tube. It's easy to ignore this step. But this is a mistake.

The preform is the "DNA" of the final bottle. It is made by injection molding. Its quality, especially its concentricity (even wall thickness) and drying, dictates the final bottle's strength. A tiny flaw here becomes a huge failure later.

The Bottle's "Genetic Code"

Before we can make a bottle, we must first make a preform. (This is a separate process, which you can read about in my other guide, "How PET Preforms Are Made"). For this article, we must understand why the preform's quality is so important.

My insight is: "The preform is the 'DNA' of the bottle. Any tiny defect in its genetic code will be amplified 10x in the final product. You can never make a good bottle from a bad preform."

There are three quality factors that are non-negotiable.

1. Perfect Drying:

I must repeat this. PET resin is hygroscopic (it absorbs water). Before the preform is ever made, that resin must be perfectly dried. If you melt wet PET, a chemical reaction called hydrolysis happens. This breaks the long, strong molecular chains. The plastic becomes brittle. I have seen clients' bottles shatter like glass. The cause was not the blowing process; the cause was bad drying before the preform was even made.

2. The Millimeter War (Concentricity):

This is the most critical quality factor. A preform is made in a preform mold. This mold has a "core" and a "cavity." The gap between them becomes the preform wall. "Concentricity" means this gap is perfectly even all the way around.

My Anecdote: "I had a client in Mexico. Their bottles were bursting on the filling line. Always on the same side. They blamed my blow bottle mold. They blamed my bottle blowing machine. I flew in. I did not look at their blowing machine. I took one of their preforms and a special tool (a wall thickness gauge). I measured it. The wall on one side was 2.9mm. The wall on the other was 3.1mm. A tiny 0.2mm difference."

"This tiny 0.2mm flaw, when stretched 10 times, becomes a massive thin spot on the bottle. That is where it failed. The problem was not my machine; the problem was their cheap, low-quality preform mold." This is a war of millimeters.

3. Gate Design:

The "gate" is the small spot at the bottom of the preform where the plastic was injected. A bad, sharp gate can be a weak point. It can also cause a high "AA" value, which can make bottled water taste strange.

We must start with a perfect "seed." Any bottle defect you see can almost always be traced back to a flaw in the preform.

| Preform Quality Factor | Why It's Critical | What It Affects |

|---|---|---|

| Perfect Drying | Prevents molecular breakdown (hydrolysis). | Bottle Strength, Clarity, Brittleness. |

| Concentricity | Ensures uniform wall thickness. | Bottle Strength, prevents bursting. |

| Gate Quality | Creates a stable base, ensures good taste. | Bottle Strength, Product Taste. |

"Garbage in, garbage out." This is the first rule of how PET bottles are made.

Step 2 Deep Dive: The Art of Stretching & Blowing - Molecular Engineering in Action?

This is the core magic. How does a small, thick "test tube" become a large, thin bottle? It's not just "blowing it up."

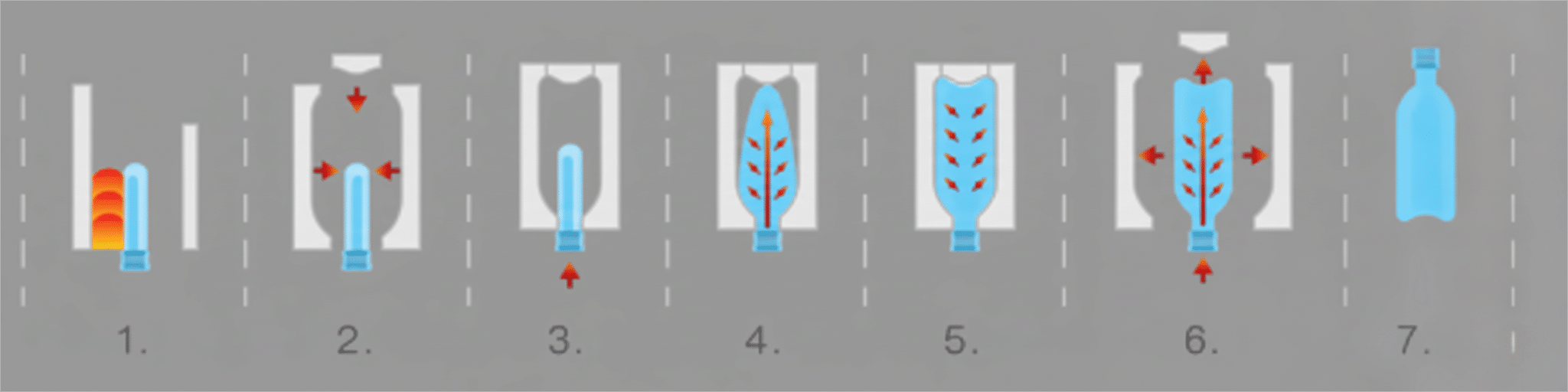

This is Stretch Blow Molding (SBM). The preform is heated, then stretched down by a rod (axial stretch) and out by air (radial stretch) at the same time. This "biaxial orientation" aligns the PET molecules into a strong, clear, grid-like structure.

Molecular Gymnastics

My insight: "This is not simple 'blowing.' This is a high-speed 'molecular gymnastics' routine. And the bottle blowing machine is the choreographer. We are telling the molecules exactly where to go and how to line up."

This is the PET bottle manufacturing process explained in detail. It has three parts:

Step 2a: The "Art" of Heating

The cold, hard preform is fed into a high-intensity oven. This oven uses infrared lamps.

This is not simple heating. It is "preferential heating."

- The Goal: We must heat the preform body to its "glass transition temperature" (around 100-110°C). At this temperature, the PET becomes soft and rubbery, like taffy.

- The Problem 1: The neck (with the threads) must stay cold. If it gets soft, it will deform. So, the necks are shielded from the heat.

- The Problem 2: The heat must be even. The lamps heat the outside. We must give the heat time to "soak" to the inside. If the outside is hot and the inside is cold, it will not stretch properly.

- My insight: "I spend most of my time with clients adjusting the oven. This is the art. We adjust the power of different lamps. We use fans. We are trying to 'paint' a perfect heat profile on the preform. This 'heat painting' determines the entire blow."

Step 2b: The "Science" of Stretching & Blowing

The hot, rubbery preform is quickly moved into the blow bottle mold. This mold is cold and has the final shape of the bottle.

Two things happen at the exact same time:

- Axial Stretch (Stretching): A steel "stretch rod" shoots down from the top. It pushes the bottom of the preform all the way to the bottom of the mold. This stretches the PET vertically (axially).

- Radial Stretch (Blowing): High-pressure air (up to 40 bar / 580 PSI) is blasted into the preform. This inflates the preform like a balloon, forcing it outward (radially) against the cold mold walls.

This air is not just one blast. It is usually two:

- Pre-Blow: A low-pressure (5-10 bar) puff of air. This starts to inflate the preform. It stops the preform from just stretching like spaghetti.

- High-Blow: The final, 40-bar blast. This forces the plastic into every sharp corner and detail of the mold.

The "Magic" of Biaxial Orientation

This is the why. Why do we do this?

In the preform, the PET molecules are a messy, random pile of "spaghetti." They have no order. They are weak.

- The Stretching (rod) pulls these spaghetti strands straight, lining them up vertically.

- The Blowing (air) pulls them sideways, lining them up horizontally.

- The Result: The molecules are no longer random spaghetti. They are a grid. They are an interwoven net.

This "biaxial orientation" (stretching in two directions) is what gives the bottle its amazing strength and its crystal clarity. We have engineered the material at a molecular level.

Step 2c: Cooling

The new bottle is held against the cold mold walls for about one second. The mold is connected to a powerful chiller. This "freezes" the molecules in their new strong, clear, grid-like shape.

The mold opens, the bottle is ejected, and the next hot preform comes in. This entire dance takes 2-3 seconds. This is the preform to bottle technology in action.

The Unsung Hero: Why Mold Design Dictates Bottle Performance?

We just talked about the SBM process. But where does this happen? It happens inside a tool. This tool, the blow bottle mold, is the unsung hero.

The blow mold does more than give the bottle its shape. Its design controls how the bottle is formed. Its cooling channels set the bottle's strength and cycle time. Its venting allows for sharp details.

A Tool, Not a Box

People think the mold is just a "shape." It is not. It is a complex machine.

1. The "Heat Exchanger" (Cooling)

My insight: "A mold is not a shape. A mold is a heat exchanger."

The mold's real job is to remove heat. And fast.

A hot plastic bottle is soft. It will deform. The mold must cool it instantly to "lock in" that molecular structure.

We design complex cooling channels inside the mold. Water from a chiller flows through these channels.

A good mold is a good heat exchanger. A great mold is a smart heat exchanger. For a square bottle, we will design extra cooling in the corners, because that is where heat builds up. The cooling design is the #1 factor in cycle time (speed) and quality (strength).

2. The "Air Manager" (Venting)

When 40-bar air inflates the bottle, where does the air already in the mold go?

It must escape. If it cannot, it gets trapped. This "air cushion" (trapped between the PET and the mold) prevents the plastic from touching the metal.

The result? The bottle is not fully formed. The details (like embossed logos) are soft. The base is not flat.

We design tiny "vents" (0.01mm slits) in the mold. They are too small for plastic, but big enough for air. A well-vented mold makes a crisp, sharp, perfect bottle.

3. The "Material" (Aluminum vs. Steel)

What is the mold made of? This is an engineering and economic choice.

- Aluminum (Aircraft Grade): Most PET blow molds are made of this. Why? It is light. It is easy to machine. And it transfers heat very fast (which means great cooling and fast cycles). This is perfect for high-speed water and soda bottles.

- Steel (P20 or S136): We use this for special cases. Molds for "hot-fill" bottles (which are filled with hot juice) must be steel. Molds with complex moving parts (like for handles) are often steel. Steel is more durable, but it is heavy and cools slower.

A client's beautiful PET bottle design must be translated by an engineer into a mold that can actually make it at high speed. This is where experience is everything.

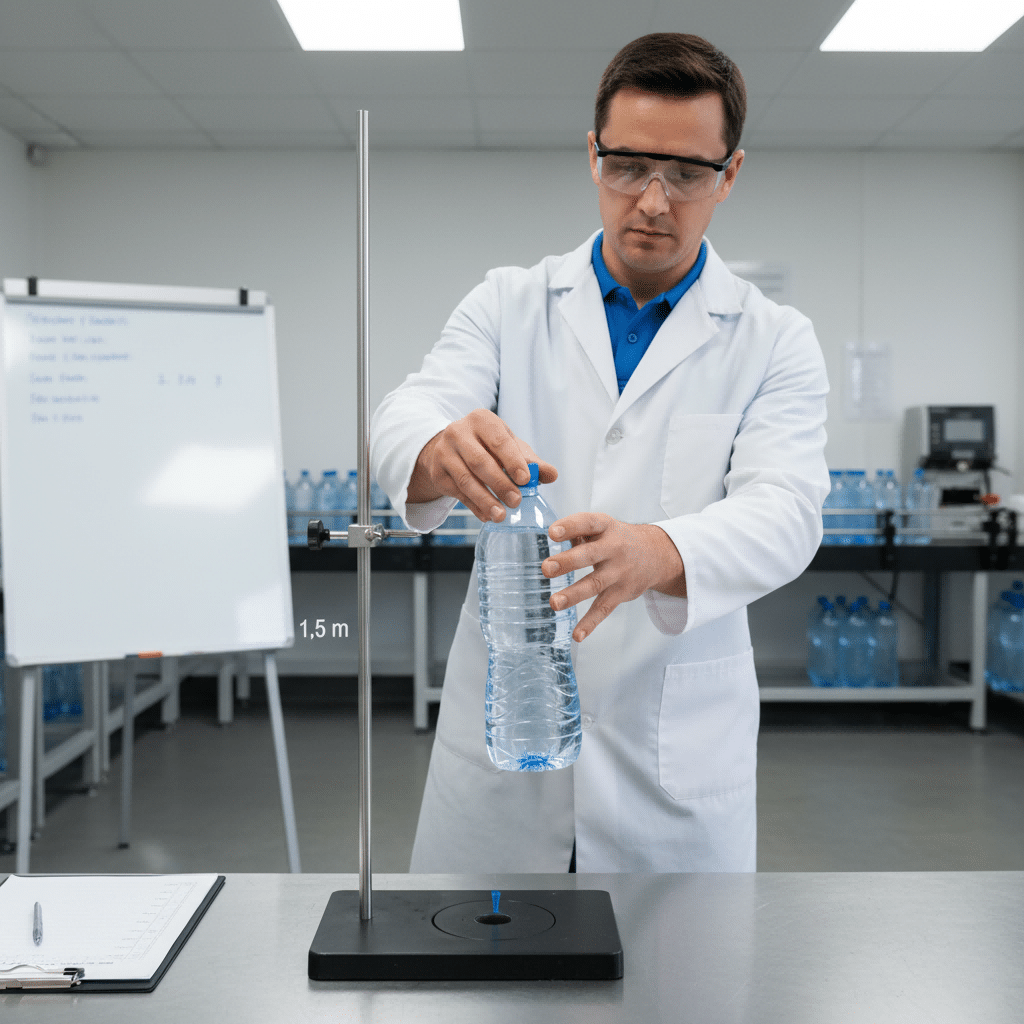

Quality Isn't Free: The Hidden Science of Bottle Testing?

The bottle is made. It looks perfect. But is it? A bottle that looks good can still fail in a warehouse or on a truck.

Quality is tested with science. Top-load testing (crushing) simulates stacking. Stress-crack testing (using chemicals) checks for weak spots. Burst testing checks pressure limits. These tests find failures before your customer does.

Finding Real-World Failure

My insight: "A bottle has a 'job.' Our tests make sure it can do its job. A bottle that looks good but fails a top-load test is a bad bottle."

We do not just look at the bottle. We try to destroy it.

1. Top-Load Test:

- What it is: We put the bottle in a machine and crush it from the top. We measure how much force (in kg or lbs) it can take before it buckles.

- Why: This simulates stacking in a warehouse. Your bottle might be at the bottom of a 10-foot-high pallet. It must be strong enough to hold the weight of all the bottles above it.

2. Stress-Crack (ESCR) Test:

- What it is: We fill the bottle with a mild caustic solution (a chemical). This chemical attacks any weak spots in the PET (areas of high stress, often in the base).

- Why: This is a brutal test. It finds hidden problems. A bottle that fails this test (it cracks or leaks) has a bad base design or was cooled improperly. This is one of the most common PET bottle defects we are asked to solve.

3. Burst Test:

- What it is: We fill the bottle with water, seal it, and increase the internal pressure until it explodes.

- Why: This is for soda bottles. It tells us the exact failure pressure. If the bottle bursts at 80 psi, but it needs to hold 90 psi, we have a process problem.

4. Wall Thickness Distribution:

- What it is: This is the most important test. We cut the bottle into 5 sections. We use a special gauge to measure the wall thickness at 20 different points.

- Why: This is the "report card" for our heating and stretching. We are looking for an even thickness. If we see a thin spot, we go back to the oven and adjust the lamps in that specific area to send more material there.

When a client has a quality problem, they show me the failed bottle. I do not just look at the bottle. I ask for the test data. The data tells me the story of how it was made.

From Single Bottle to Millions: The Engineering of Scale?

Making one perfect bottle is easy. But your business needs millions. How do you make 20,000 bottles every single hour, all of them perfect?

Scaling up requires high-speed automation. This means moving from simple "linear" machines (shuttle machines) to high-cavity "rotary" machines. These bottle blowing machines can have 10, 16, or even 24 molds on a giant spinning wheel, producing non-stop.

The Two Types of Machines

There are two main "levels" of how PET bottles are made.

1. Linear (Shuttle) SBM Machines:

- How they work: Preforms move in a straight line. They get heated, then "shuttle" into the blow mold (2-6 cavities), get blown, and shuttle out.

- Good for: Lower speeds (e.g., 2,000-8,000 bottles/hour). Startups. Custom or complex shapes. Large containers (like 5-liter jugs).

- My insight: "These are my favorite for startups. They are flexible. You can do quick 3D-printed sample molds. They are easier to operate and the blow bottle mold cost is lower."

2. Rotary SBM Machines:

- How they work: This is the "big leagues." The preforms are fed onto a spinning "carousel." The heating oven is a spinning wheel. The blow molds (e.g., 10 or 20 of them) are on another spinning wheel. Everything happens while moving at high speed.

- Good for: High speeds (e.g., 15,000 to 80,000+ bottles/hour). Standard bottles (water, soda). 24/7 production.

The Engineering Challenge of Scale

The challenge of scaling up is not just "speed." The challenge is consistency.

My insight: "Making one good bottle is not hard. Making 40,000 bottles per hour where every single bottle is identical... that is an incredible engineering challenge."

At this scale, everything is harder:

- Heat: The oven must be perfectly stable. A 1-degree temperature change can ruin thousands of bottles.

- Timing: On a rotary machine, the timing is in milliseconds. The stretch rod, the air, the mold closing—it must be perfect.

- Air: You need a massive amount of clean, high-pressure air. This requires a huge, specialized air compressor system.

- Data: You must have sensors everywhere, tracking every bottle.

My job changes when we scale. For a startup, I am a problem-solver. For a high-speed line, I am a process optimizer. I am looking for 0.1-second savings. I am looking for a 0.5% drop in scrap rate. At this scale, those tiny numbers equal thousands of dollars. This is why we provide total line solutions.

Master the Engineering, Master Your Bottle: Partnering for Success?

You've seen the science. It's more than just "blowing plastic." You are worried about getting it right. It seems complex.

Understanding the science behind PET bottles helps you choose the right partner. You are not just buying a machine. You are buying engineering expertise to turn these principles into a stable, profitable production line.

The Chain of Quality

This entire article shows a "chain" of engineering.

- It starts with the Material (PET).

- Then the Preform ("DNA").

- Then the Process ("Gymnastics").

- Then the Mold ("Heat Exchanger").

- Then the Testing ("Report Card").

- Then the Scale ("Consistency").

My insight: "A weak link breaks the whole chain. A bad preform (link 2) breaks the bottle (link 3). A bad mold (link 4) breaks the cycle time (link 6). A bad test (link 5) breaks your customer's trust."

This is why choosing a supplier is not a "simple purchase." You are choosing a partner.

- Does your partner ask about your PET bottle design?

- Do they understand how to match the preform mold to the blow bottle mold?

- Can they supply the whole system (the bottle blowing machine, the air compressor, the chiller?)

- Can they help you when you have bottle defects?

When you partner with iBottler, you are partnering with this engineering knowledge. We have seen all the failures. We know how to prevent them. We help you turn these complex principles into a simple, profitable reality.

If you want to make your bottle an engineering success, contact us. Let's build it together.

Conclusion

Making a PET bottle is a marvel of engineering. It turns simple pellets into strong, clear, and complex containers by mastering the science of biaxial orientation.

| Process Stage | Core Engineering Principle | Why It Matters |

|---|---|---|

| Material (PET) | Molecular Structure | Provides the "potential" for strength, clarity, and gas barrier. |

| Step 1 (Preform) | Injection Molding Precision | Creates the "DNA." Concentricity and good drying are essential. |

| Step 2 (SBM) | Biaxial Orientation (Stretch + Blow) | Aligns molecules into a "net," creating the final strength. |

| Tooling (Mold) | Thermal & Air Management | Controls the quality of the stretch and the speed of the cycle. |

| Quality (Testing) | Failure Mode Analysis | Verifies that the engineering principles resulted in a strong, functional bottle. |

Frequently Asked Questions (FAQ)

Q: What is the hardest technical part of making a PET bottle?

A: The most challenging part is usually the "heating" in Step 2. Getting the preform heated perfectly evenly—through its thickness and along its length—is the key to a good blow. This is where most process-tuning happens.

Q: Why are square bottles harder to make?

A: Square (or non-round) bottles are difficult because the material has to stretch further to reach the corners. This can make the corners very thin. It requires a special preform design and precise heating to push material to those corners.

Q: Does using rPET (recycled PET) make it harder?

A: High-quality rPET is very similar to virgin PET. However, it can be less stable from batch to batch. It is often more sensitive to heating and may require slightly different process settings and more frequent mold cleaning.

Q: What is a typical cycle time to make one PET bottle?

A: For a standard 500ml water bottle on a modern rotary bottle blowing machine, the total cycle time (preform in, bottle out) is about 2 to 3.5 seconds per bottle.

Q: Why do I, as a non-engineer, need to know this?

A: Understanding the basics helps you ask smarter questions. You can understand why one supplier's machine is more expensive. You can have a real conversation about quality, not just price. It helps you avoid bad investments.

🔗 Related Pages on Our Website

PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr