Struggling with leaking bottles or production jams? The problem might be a tiny detail you overlooked. Getting the neck finish right is the key to a perfect product launch.

A PET preform neck finish is the specific design of the bottle's opening, defined by its diameter, thread style, and height. Matching it correctly to a cap is absolutely essential to create a perfect seal, prevent leaks, and ensure your production line runs smoothly.

I've seen many new bottling plants face frustrating setbacks. They invest in top-of-the-line equipment but then struggle with issues like leaking products during shipping or caps that are too hard for customers to open. Almost every time, the root cause is a mismatch between the PET preform's neck and the cap. This guide is built from my years of experience helping clients avoid these costly mistakes. Let's walk through everything you need to know, step-by-step, to ensure your bottle and cap are a perfect match from the very beginning.

What Is a PET Preform Neck Finish and Why Does It Matter?

Are you confused by terms like "28/410" or "30/25"? This confusion is common, but a misunderstanding here can lead to choosing the wrong components and causing major production problems.

A PET preform neck finish is simply the technical term for the top part of the preform where the cap screws on. It’s defined by precise specifications, and getting it right is a make-or-break factor for your final product.

To make this simple, I always tell my clients to think about three core elements. Understanding these is the first step to mastering cap and bottle compatibility.

The Core Elements of a Neck Finish

Neck Diameter (in mm): This is the most basic measurement. It's the outer diameter of the threads. When you hear "28mm," "30mm," or "38mm," this is what it refers to. It's the first thing you must match with your cap.

Thread Style (e.g., 410, 415): This number describes the thread design. For example, a "410" finish means the cap turns about one full rotation to close. A "415" finish is taller and takes about one and a half turns. This detail affects how the cap seals and how it feels to the consumer when they open it.

Industry Standard (e.g., PCO, BPF, ISBT): These are acronyms for standards organizations that ensure a "28mm PCO 1881" neck finish from one manufacturer is identical to another's. This standardization is crucial for consistency across the global supply chain. When you design a new product, you need to decide which standard to follow.

The neck finish you choose dictates everything that follows. It impacts the cap you can use, the performance on your filling line, and even the safety of your product. Investing in a high-quality preform mold that adheres strictly to these standards is one of the most important decisions you will make.

| Factor | Impact of Correct Neck Finish | Consequence of Mismatch |

|---|---|---|

| Sealing Integrity | An airtight, secure, and leak-proof seal. | Product leakage, spoilage, and potential contamination. |

| Cap Compatibility | A secure fit with the intended cap. | Caps won't screw on, pop off under pressure, or crack. |

| Production Efficiency | Smooth, fast operation on capping machines. | Costly downtime, machine errors, and manual intervention. |

| Consumer Experience | The bottle is easy to open and securely re-close. | Customer frustration and a perception of low quality. |

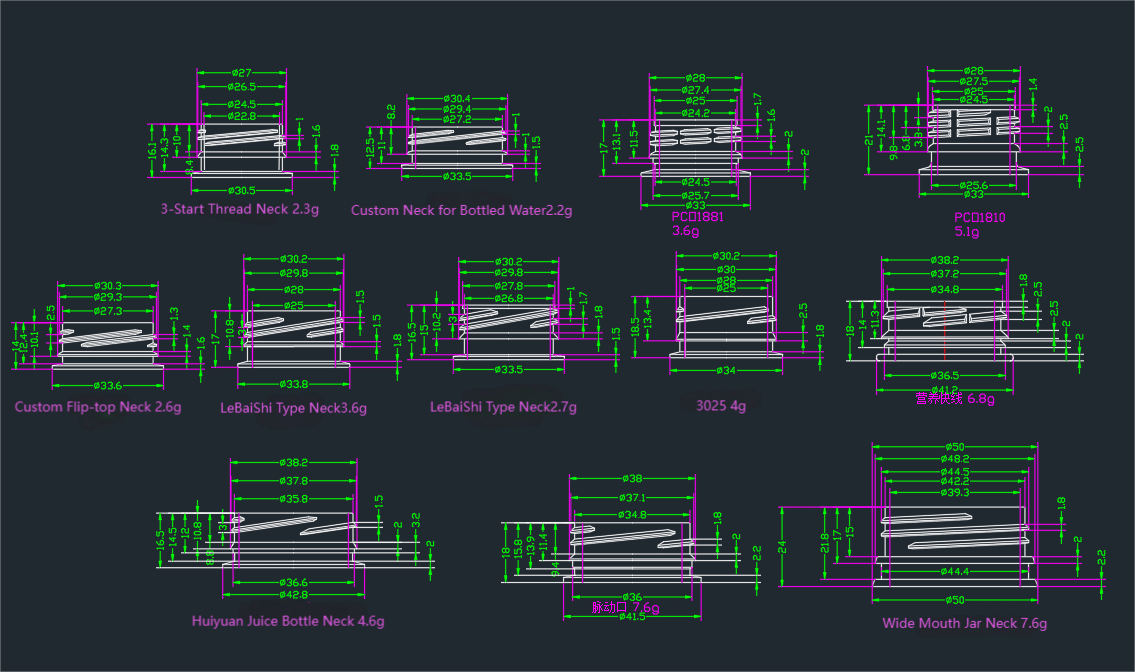

What Are the Common PET Preform Neck Finish Types in the Market?

Walking into the world of neck finishes feels like alphabet soup. PCO, ROPP, 30/25... making the right choice seems overwhelming. But if you choose one that's wrong for your product, you risk a failed launch.

The market offers many PET neck finish types, but you will likely only ever need to use a few. The most common types include 28mm PCO 1881 for sodas, 30/25 for water, and 38mm for juices. Each is engineered for a specific purpose and seal.

Let's break down the most popular neck finishes I see my clients using every day. This will help you understand which one is likely the best fit for your product.

Neck Finishes for Beverages

The beverage industry relies heavily on standardized necks to ensure safety and efficiency.

28mm PCO 1810 / 1881: "PCO" stands for "Plastic Closure Only." The 1810 was the long-time standard for carbonated soft drinks and water. In recent years, the market has shifted to the "1881" finish. It's shorter and uses less plastic, making it a lighter, more cost-effective, and environmentally friendly option that still holds carbonation perfectly. If you are bottling soda or sparkling water, 1881 is the modern standard.

30/25: This is the undisputed king of the still-water market in many regions. It's even lighter than the 28mm PCO 1881, offering significant savings in resin costs. The "25" refers to its low height. If you're launching a standard bottled water brand, this is almost certainly the neck finish you will use.

38mm 2-Start or 3-Start: When you see a wider mouth on a bottle of juice, iced tea, or a dairy drink, it's often a 38mm neck. The "start" refers to the number of threads. A 3-start thread allows the cap to be secured with a shorter turn, which is convenient for consumers. This wider opening is better for thicker liquids and is often required for hot-fill processes where product integrity is paramount.

Neck Finishes for Other Applications

Once you move outside of beverages, the needs change, and so do the neck finishes.

- 24/410 and 28/410: These are the workhorses of the personal care, cosmetic, and household chemical industries. Their versatile thread design makes them perfect for a wide range of closures, from simple screw caps to lotion pumps, fine mist sprayers, and flip-top caps. If your product needs to be pumped or sprayed, you will likely be using one of these.

Here is a simple table to help you visualize the differences.

| Neck Finish | Common Application | Key Feature & Benefit |

|---|---|---|

| 28mm PCO 1881 | Carbonated Drinks, Water | Shorter height, lightweight design holds pressure well. |

| 30/25 | Still Bottled Water | Extremely lightweight, very cost-effective for high volumes. |

| 38mm 3-Start | Juices, Teas, Dairy | Wider opening for easy pouring, strong seal for hot-fill. |

| 24/410 | Lotions, Soaps, Cleaners | Highly versatile, compatible with many dispensing pumps and sprayers. |

Choosing the correct neck finish is the first step in designing a successful product. Once you know the neck, you can design the perfect bottle and source the right blow bottle mold to produce it.

How Are Bottle Cap Types Designed to Match Specific Neck Finishes?

Do you think any 28mm cap will fit any 28mm bottle? This is a very common and costly mistake. A cap is a piece of precision engineering, designed to match one specific neck finish and one only.

Caps are meticulously engineered to be the perfect counterpart to a neck finish. A screw cap's internal threads must be a mirror image of the bottle's external threads. For example, a 28/410 cap is made only for a 28/410 neck.

Let's look inside a cap to understand why this compatibility is so rigid and non-negotiable. It's a system where every detail has a purpose.

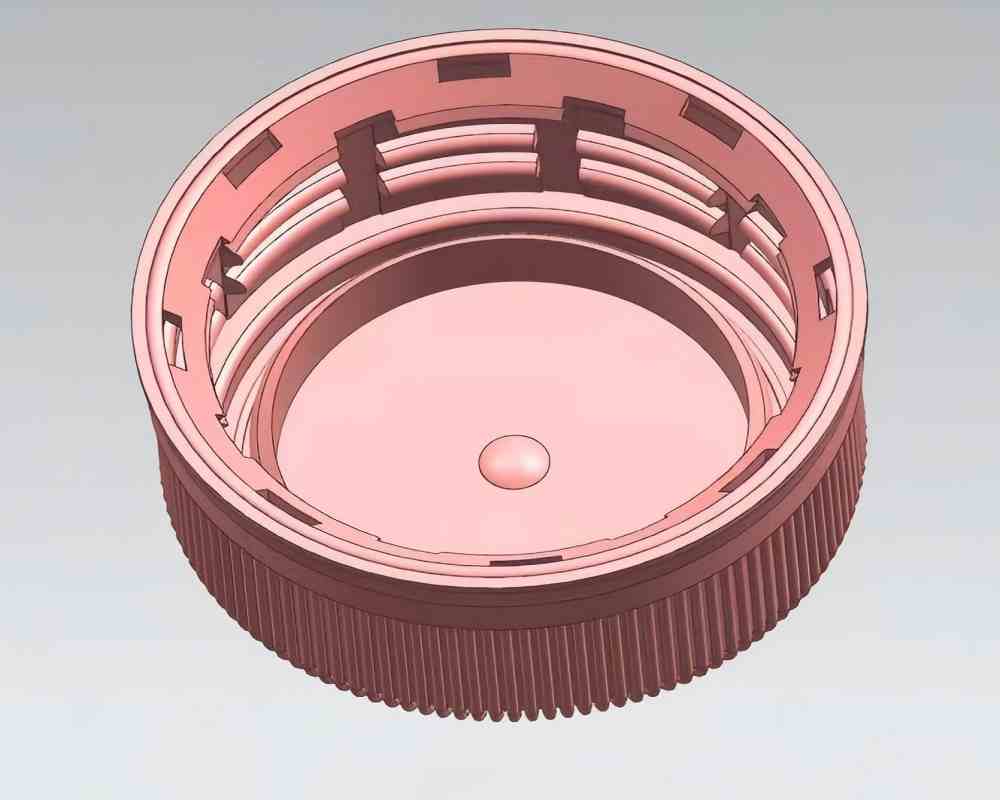

The Anatomy of a Cap

A cap is more than just a piece of plastic. It's a multi-functional component designed to seal, secure, and provide a good user experience.

Internal Threads: These are the "negative" or inverse of the threads on your PET preform neck. They must align perfectly to screw on smoothly and create the initial seal. A mismatch here will cause cross-threading, where the cap goes on crooked and fails to seal.

Sealing Mechanism: A simple screw-on action is not enough to guarantee a leak-proof seal, especially for carbonated or sensitive products. Caps use two main types of seals:

- Liners: These are discs of material (like foam or foil) inside the top of the cap. An induction liner, for example, is heat-sealed to the bottle's rim during capping, creating a hermetic, tamper-evident seal.

- Linerless Designs: Many modern caps have a sealing ring or "plug" molded directly into their inner surface. This ring presses firmly against the inside or top edge of the bottle neck to create the seal. This design is common in water and beverage caps.

Tamper-Evident (TE) Band: This is the plastic ring at the base of the cap that breaks away the first time the cap is opened. For the TE band to work, it must fit perfectly over the locking ring on the preform neck. If the dimensions are wrong, the band might not engage, or it could break during the capping process.

The fundamental rule is this: one neck standard, one cap standard. You simply cannot force a 24/410 lotion pump onto a bottle with a 24/400 neck finish, even though they have the same diameter. The thread style is different, and it will fail. This principle is central to achieving true cap and bottle compatibility.

Why Does a Neck and Cap Mismatch Cause Leaks, Cracks, and Production Downtime?

You've produced thousands of beautiful bottles, but you get a call from your distributor that pallets are arriving wet. The culprit? A tiny mismatch between the neck and the cap. This is a real nightmare that costs you far more than just lost product.

A mismatch between the neck and cap directly leads to an insecure seal, causing leaks. Applying the wrong torque to force a fit can crack the cap or the neck. On the production line, this incompatibility results in constant jams, alarms, and costly downtime.

I want to share some of the real-world problems I've helped clients solve. These aren't theoretical issues; they are expensive, frustrating realities that can often be traced back to the initial choice of preform and cap.

The Real-World Consequences of a Mismatch

Product Leaks and Contamination: This is the most obvious and damaging consequence. Even a slow leak can ruin an entire case of product. For food, beverage, or cosmetic items, a broken seal means the product is no longer sterile and must be thrown away. This erodes profits and can damage your brand's reputation.

Application Torque Failures: "Application torque" is the force used by the capping machine to tighten the cap. A mismatch makes it impossible to get this right.

- Too Loose: If the cap and neck threads don't engage properly, the cap may feel tight but can easily vibrate loose during transportation.

- Too Tight: Trying to over-tighten a mismatched cap can cause "stress cracking," where fine fractures appear in the plastic. This can happen to the cap or the neck finish itself. The consumer might not be able to open the bottle, or the tamper-evident band might break before it even leaves your factory.

Production Line Chaos: Your bottle blowing machine might be running perfectly, but if the capper downstream is struggling, your entire line's efficiency plummets. I remember a client who tried to save a fraction of a cent per cap by using a "close-enough" standard from a new supplier. Their filling line, rated for 10,000 bottles per hour, was running at half speed because operators had to manually inspect and tighten caps. The machine was constantly faulting. They lost thousands of dollars in downtime before we came in and fixed the root cause: a fundamental neck and cap mismatch. We sourced the correct caps, and their line was back to full speed within a day.

These scenarios show that a small oversight in how to match bottle neck and cap can have huge financial and operational consequences.

How Do You Match Neck Finish with Capping Machines for Technical Success?

Your bottles and caps have arrived, and the samples seem to fit perfectly when twisted by hand. But when you load them into your production line, the capping machine starts rejecting bottles. The machine itself is a critical, and often forgotten, part of the compatibility equation.

Your capping machine's chucks or rollers must be precisely machined for the specific cap and neck diameter you are using. Furthermore, the machine's torque settings must be calibrated to match the neck's material, thread pitch, and sealing requirements.

Getting the mechanical and software settings on your capper right is just as important as choosing the right physical components. Let's look at the technical requirements for success.

Calibrating Your Capping Line

A capping machine is not a "one size fits all" piece of equipment. It needs to be finely tuned for your specific bottle and cap combination.

Capping Head / Chuck: This is the part of the machine that physically grips the cap to spin it onto the bottle. It must match the cap's diameter and external features (like ribbing) perfectly. A chuck designed for a smooth-sided 38mm cap will slip on a ribbed 28mm cap. Using the wrong size chuck is a primary cause of capping failures.

Torque Control: This is the single most critical setting. Torque is the rotational force applied to tighten the cap.

- Too little torque results in a loose cap and a poor seal.

- Too much torque can strip the threads or crack the cap/neck, a phenomenon called "over-torquing."

The correct torque value depends on the neck finish standard, the cap material, and whether the product is carbonated. Carbonated beverages, for example, require a higher application torque to resist the internal pressure.

Top Load: This is the downward force the machine applies to the cap and bottle during the tightening process. It ensures the bottle doesn't spin and that the cap's liner or seal engages correctly. Too much top load can crush a lightweight preform neck or damage the bottle shoulder.

Common Capping Machine Issues from Mismatches

When the cap, bottle, and machine settings are not in perfect harmony, you will see a host of problems on your line. Your entire production, from the bottle blowing machine to the palletizer, can come to a halt.

| Capping Issue | Common Cause | Solution |

|---|---|---|

| Skidding / Slipping | Capping chuck doesn't match cap profile; incorrect top load. | Use the correct chuck for the cap; adjust top load settings. |

| Cross-Threading | Misalignment of bottle and cap; incorrect chuck speed. | Check bottle alignment on the conveyor; adjust machine timing. |

| Cracked Caps | Excessive application torque; wrong chuck size. | Reduce torque settings; verify correct chuck is installed. |

| Inconsistent Torque | Worn out chuck clutches; fluctuating air pressure. | Perform regular machine maintenance; check air supply. |

Achieving a smooth-running production line requires a holistic view where the preform, cap, and capper are all seen as one integrated system.

How Should You Design Preforms with the Right Neck for Your Cap and Market?

Don't start by designing your dream bottle in a vacuum. This is a backward approach and a recipe for expensive rework. Your market, your product, and your cap choice must come first, as they dictate the neck finish you need.

You must first decide what your product is and who your customer is. This will help you choose the right type of cap (e.g., a simple screw cap, a sport cap, or a lotion pump). That cap choice then dictates the required PET preform neck finish.

I always advise my clients to work backward from the consumer. It's a simple but powerful shift in thinking that prevents major headaches down the road.

A Market-First Approach to Design

Let's walk through the logical workflow I use with my clients when they are developing a new product line.

- Define the Product & User: What is the product? Let's say it's a premium honey. How will the user interact with it? They need a clean, drip-free way to dispense it.

- Choose the Cap: Based on the user need, a flip-top cap with a silicone valve is the ideal choice. You would then source this cap from a reliable supplier and get its exact technical specifications. Let's say it's a 38/400 flip-top cap.

- Define the Neck Finish: The cap choice has now made the decision for you. Your bottle must have a 38/400 neck finish. There are no other options.

- Design the Preform & Bottle: Now, and only now, do you design the preform and the bottle. You design a preform that has the correct weight for your bottle size and incorporates a perfect 38/400 neck. This might require a

custom preform neck designand a new preform mold. Finally, you design the body of the bottle around this neck.

My Personal Advice for Newcomers

I see this all the time with my turnkey line customers. They are experts in their product, but new to the bottling industry. That's why they come to us. I had a client in Saudi Arabia who was setting up a complete 12,000 bottle-per-hour water line. They were understandably nervous about getting all the small details wrong.

They knew they wanted a standard 550ml bottle, but that was it. We sat down and worked backward. For the regional water market, the 30/25 neck finish is the dominant standard for its efficiency and low cost. So, we specified a lightweight 18-gram PET preform with a 30/25 neck. Then, we sourced the perfectly matching blue caps and even managed getting their logo printed on them.

He asked me, "Why should I have you source the preforms and caps when I can find suppliers online?" My answer was simple: "Because when we provide it as a system, the risk of a mismatch is zero. If there is any issue, you make one call to me, and I solve it." This bottle cap matching service is about more than just convenience; it's about guaranteeing success and saving our clients from the complex and frustrating process of trial and error. Before you invest heavily in a blow bottle mold, make sure your cap and neck are confirmed.

What's on the Quality Control Checklist for Neck-Cap Compatibility?

You've received samples of your new custom preforms and caps. They look great and seem to fit. But how do you know they are truly compatible for mass production? Don't wait to find out when you have a million units on the line. A simple QC checklist prevents a future disaster.

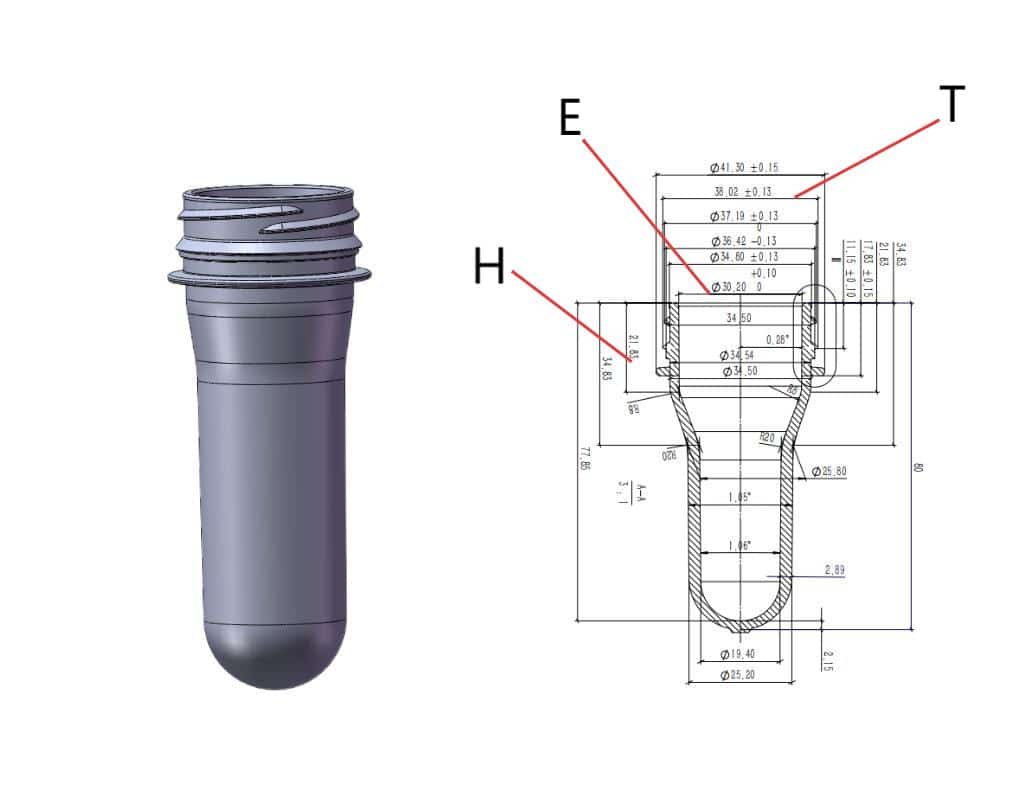

A robust quality control checklist is non-negotiable. It must include using calipers to verify the neck diameter, checking thread precision against drawings, performing multiple manual screw-on tests, and conducting a conclusive pressure or leak test.

These checks must be performed at the sample stage, before you approve the final tooling for your preform mold. This is your last chance to catch a problem when it's cheap and easy to fix.

Your Essential Pre-Production QC Protocol

I insist that all my clients perform these tests. It takes a little time upfront but can save you tens of thousands of dollars and weeks of delays.

| Test | Tool / Method | Acceptance Criteria | Purpose |

|---|---|---|---|

| Dimensional Check | Digital Calipers | Measure the key dimensions of the neck finish (thread diameter 'T', neck height 'H', etc.). Must be within the specified tolerance (e.g., ±0.1mm) of the engineering drawing. | To ensure the most basic fit is correct. |

| Thread Profile Check | Profile Projector or a thread gauge. | The shape and pitch of the threads must match the technical drawing exactly. | Guarantees that the threads will engage correctly and smoothly. |

| Go/No-Go Gauge Test | A set of precision-machined gauges. | The "Go" gauge should fit perfectly. The "No-Go" gauge should not. | A quick, reliable, pass/fail test for thread dimensions. |

| Practical Application Test | Manually apply the cap. | The cap should screw on and off smoothly at least 5-10 times without binding, jumping, or feeling loose. The tamper-evident band should engage correctly. | Simulates real-world consumer use and identifies functional issues. |

| Seal Integrity Test (Leak Test) | Fill the bottle with water (add a bit of coloring for visibility), apply the cap using a hand-held torque wrench to the specified torque. Invert the bottle and leave it for at least 30 minutes, preferably 24 hours. | There should be zero leakage. Check for any moisture around the cap. | The ultimate test of the seal's performance. |

| Torque Test | Digital Torque Tester | Measure both the application torque (force to seal) and the removal torque (force to open). | Ensures the values are within the specified range for both production efficiency and consumer ease-of-use. |

Completing this checklist provides the confidence you need to approve your custom preform neck design and move forward into mass production. Never skip this step.

Need Help with Custom Preform Neck Design and Cap Matching?

Are you feeling overwhelmed by all these technical details of threads, torque, and tolerances? The good news is, you don't have to be the expert. Partnering with one is the fastest and safest path to a successful product launch.

We offer a complete bottle cap matching service. My team and I can help you design a custom PET preform neck, recommend and source perfectly compatible caps, and review your existing designs to prevent costly errors before they happen.

Over the years, I've seen it all. I understand that for most of my clients, their expertise is in creating a fantastic beverage, sauce, or lotion, not in the fine points of packaging engineering. Especially for those investing in a full production line—from the bottle blowing machine to the filler and packer—the packaging details can be daunting. Our job is to make that part simple and foolproof for you.

How We Can Be Your Technical Partner

Think of us as an extension of your product development team. We handle the technical packaging challenges so you can focus on growing your business.

Here's how our bottle cap matching service can help you:

Custom Preform Neck Design: Do you have a unique cap that requires a special, non-standard neck finish? We have the expertise to design a preform that works. We'll engineer the preform and the corresponding preform mold to ensure it's a perfect match and runs efficiently in production.

Compatible Cap Sourcing: Don't spend weeks vetting dozens of cap suppliers. With our extensive network in the industry, we can quickly recommend and source the exact caps that will work flawlessly with your preforms, often at a better price than you could find on your own.

Free Design & Drawing Review: This is one of the most valuable services we offer. Before you spend a single dollar on tooling, send us your bottle, preform, or cap drawings. My technical team and I will provide a free review to flag any potential compatibility risks. We can spot issues with thread engagement, seal surfaces, or tamper-evident band designs that could cause major problems later.

Sample Matching and Testing: The best way to be 100% certain is to test a physical sample. Send us your caps, and we can produce preform samples to match. Or, send us your preforms, and we can find and test the right caps. We take the guesswork out of the equation.

Let us handle the technical details. Your success is our success.

Conclusion

In short, meticulously matching your PET preform neck to the right cap is not a small detail—it is fundamental. Getting this right from the very beginning ensures a successful, leak-proof, and efficient bottling operation.

Frequently Asked Questions (FAQ)

1. What is the single most common reason for leaking bottles?

The most common reason I see is a mismatch in the thread standard between the cap and the bottle neck. For example, using a 28/400 cap on a 28/410 neck. While the diameter is the same, the thread height and pitch are different, preventing a secure seal and almost guaranteeing leaks under pressure or during transport.

2. Can I use a 28/400 cap on a 28/410 bottle neck, or vice-versa?

No, you absolutely should not. Although they share the same 28mm diameter, the "400" and "410" refer to different thread styles and heights. A 28/410 neck is taller than a 28/400. Forcing a mismatched cap on will either strip the threads or fail to create a proper seal. Always match the full specification, not just the diameter.

3. How does a hot-fill process affect my choice of neck finish?

Hot-filling involves filling the bottle with product at a high temperature (around 85-95°C). The bottle neck must be robust enough to withstand this heat without deforming, which would compromise the seal. Wider neck finishes like the 38mm are often preferred for hot-fill because they provide a larger, more rigid sealing surface. Additionally, the preform itself must be designed for hot-fill, often with a crystallized neck and heavier weight.

4. What is the real difference between a PCO 1810 and a PCO 1881 neck finish?

Both are 28mm neck finishes primarily used for carbonated beverages. The PCO 1810 is the older, taller, and heavier standard. The PCO 1881 is the newer, "short-neck" version. It uses significantly less plastic, making the preform lighter and cheaper to produce while still providing excellent sealing performance for pressurized drinks. Most new beverage lines today are built around the more efficient 1881 standard.

Appendix: Quick Reference Guide for Cap Selection

To help you visually connect neck finish standards with real-world market applications, we have compiled the following table. This guide recommends the most common and suitable cap types and their corresponding neck finishes based on various product categories.

| Application Area | Common Bottle Type | Recommended Cap Type | Common Neck Finish | Key Features & Considerations |

|---|---|---|---|---|

| Beverages | Mineral / Purified Water |

|

|

|

| Carbonated Soft Drinks (CSD) |

|

|

| |

| Juice / Tea / Sports Drinks |

|

|

| |

| Food / Condiments | Edible Oil / Soy Sauce |

|

|

|

| Ketchup / Honey / Salad Dressing |

|

|

| |

| Personal Care / Cosmetics | Shampoo / Body Wash |

|

|

|

| Toner / Serum / Cleansing Oil |

|

|

| |

| Disinfectant / Cleaner |

|

|

|

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

📞 Contact: Vivian

🏭 Zhongshan Jindong Machinery Co., Ltd.

🌍 www.ibottler.com

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr