Frustrated with waste eating into your profits? A high scrap rate feels like an unavoidable cost of business. But it quietly sabotages your bottom line and production capacity every single day.

A 0.5% scrap rate isn't a sign of success; it's a symptom of hidden inefficiencies. Achieving a 0.1% rate is possible by focusing on details beyond visible defects, like preform stability, precise heating, servo-driven accuracy, and empowering your operators with data. This isn't just about saving material; it's about unlocking your factory's true potential.

I've been in the PET packaging industry for over 16 years, and my company, iBottler, has seen it all. Just last month, I got an email from an engineer in Australia. He was struggling with a 1% scrap rate on a 6-cavity machine running at 9,000 bottles per hour (BPH). That’s 90 failed bottles every hour. A staggering amount of waste. His problem reminded me that what many consider a "good" scrap rate is often far from optimal. The industry standard we should all aim for is 0.1%, or just one bad bottle in a thousand. This journey from a seemingly low 0.5% to a truly elite 0.1% is what separates the average from the excellent. It's a path I've walked with many clients, and today, I want to share my personal playbook with you.

| Key Takeaway | Why It Matters |

|---|---|

| Calculate Hidden Costs | A 0.5% scrap rate isn't just wasted plastic; it's lost machine time, energy, and orders. |

| Focus on Preform Stability | Microscopic variations in IV value and weight are the real culprits behind defects. |

| Dynamic Heating is Key | Static heating parameters can't adapt to environmental changes, causing inconsistency. |

| Embrace Servo Precision | Servo motors offer microsecond accuracy that pneumatic systems can't match. |

| Invest in Your Molds | High-quality molds with proper cooling and venting are crucial for speed and quality. |

| Empower Your Operators | Train operators to be your first line of defense with data-driven quality checks. |

| Don't Neglect Auxiliaries | Your air compressor and chiller can bottleneck the performance of your main machine. |

| Adopt a Mindset of Excellence | Getting to 0.1% is a discipline, a continuous pursuit of perfection in every detail. |

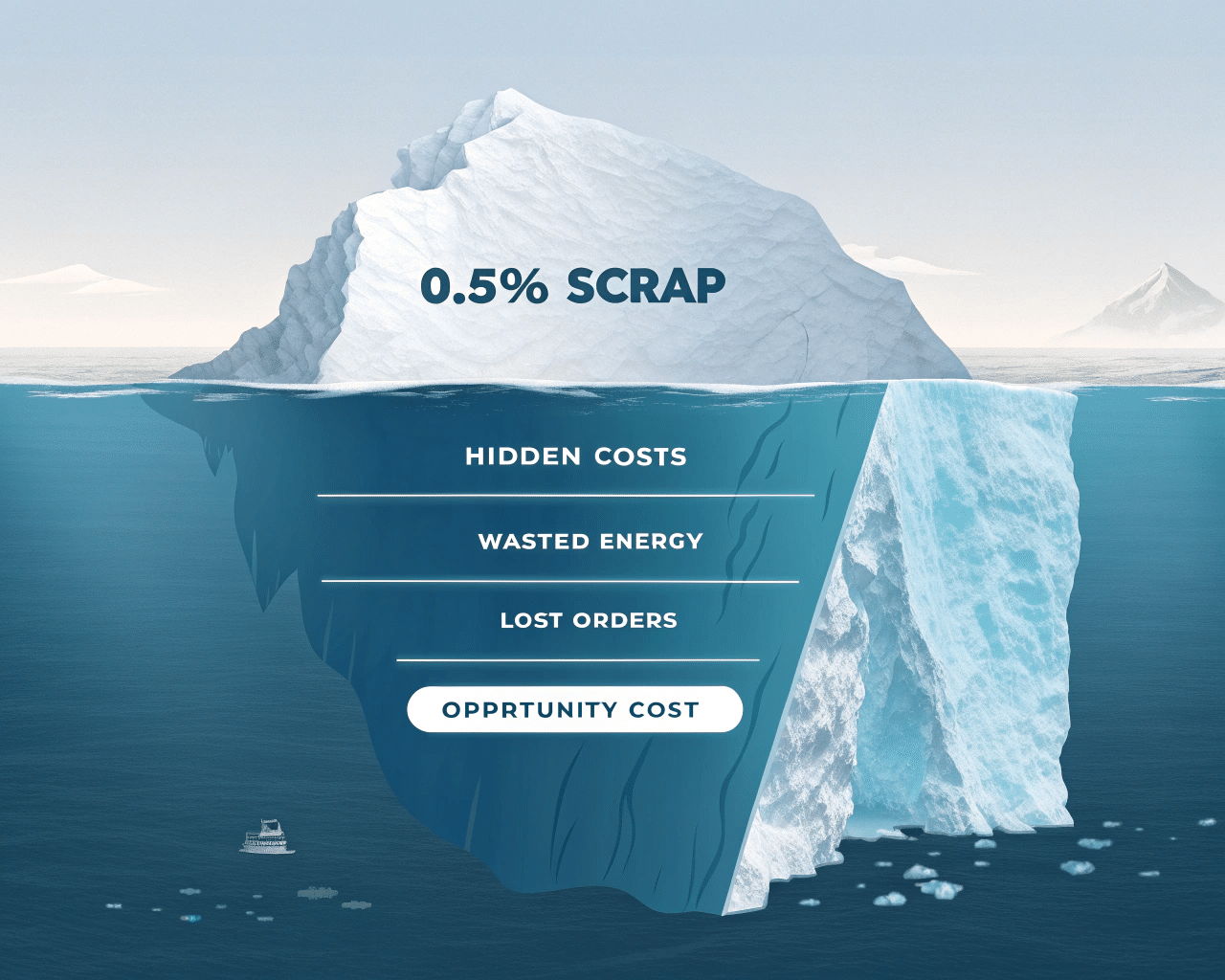

Think a 0.5% Scrap Rate is "Good Enough"? Let's First Calculate the "Hidden Costs" You're Ignoring?

Struggling to justify the investment to lower your scrap rate? The number "0.5%" looks small on paper, making it easy to ignore. But this small percentage hides a massive financial drain.

This seemingly minor scrap rate translates into shocking annual losses in raw materials, energy, and labor. More importantly, it represents lost production time that you could have used for new, profitable orders. It's a hidden factory tax you pay every single day.

Dive Deeper: The True Cost of "Just 0.5%"

Let’s get real and do some math. I always walk my clients through this exercise, and the final number never fails to open their eyes. It’s one thing to talk about waste; it’s another to see its full price tag.

The Tangible Costs: Material, Energy, and Labor

Let's imagine a typical scenario. You have a medium-speed production line.

- Machine: A standard automatic bottle blowing machine.

- Output: 10,000 bottles per hour (BPH).

- Operation: 20 hours a day, 300 days a year.

- Preform Weight: 20 grams.

- Scrap Rate: 0.5% (which is 5 per thousand, or 5‰).

First, let's calculate the number of scrapped bottles per year:

10,000 BPH * 20 hours/day * 300 days/year * 0.005 = 300,000 scrapped bottles per year.

Now, let's convert that to wasted material:

300,000 bottles * 20 grams/bottle = 6,000,000 grams = 6,000 kilograms = 6 metric tons.

What's the cost of that PET resin? Prices fluctuate, but let's use a conservative estimate of $1,300 per ton.

6 tons * $1,300/ton = $7,800 per year.

That's just the plastic. What about the electricity to heat and blow those 300,000 failed bottles? Calculating the exact energy per bottle is complex, but a rough industry figure is about 0.025 kWh per bottle.

300,000 bottles * 0.025 kWh/bottle = 7,500 kWh.

At an industrial electricity rate of, say, $0.12 per kWh:

7,500 kWh * $0.12/kWh = $900 per year.

So far, we're at $8,700 in direct, measurable waste. This doesn't even account for the labor cost of handling the scrap, the wear and tear on the machine for producing nothing of value, or the cost of disposal. It all adds up.

The Intangible Killer: Opportunity Cost

Here’s the part that most people miss. Those 300,000 scrapped bottles took time to produce. How much time?

300,000 bottles / 10,000 BPH = 30 hours.

You spent 30 hours of production time this year making garbage. That's almost four full work shifts. What could you have done with those 30 hours? You could have produced another 300,000 good bottles for a client. If each bottle has a profit margin of just $0.01, that's an additional $3,000 in pure profit you lost.

This is the real killer. It's not just the money you throw away on scrap; it's the money you failed to earn because your machine was busy making that scrap. Your production capacity is one of your most valuable assets. Every moment it spends on defective products is a moment it's not generating revenue. When a client comes to you with a rush order, can you take it? Or is your schedule so tight because of this built-in inefficiency that you have to say no? That's the opportunity cost, and it's often much larger than the direct cost of the wasted plastic. You might be seeing some of these issues, and our guide on common PET blow molding defects can be a starting point to identify them.

The Gateway to Better Business

When I talk to my clients, I frame it this way: "Stop thinking of 0.1% as a cost-saving target. Start thinking of it as the price of admission." Admission to what? To the high-end market.

Want to produce bottles for pharmaceuticals? For premium cosmetic brands? For organic juices with high-value contents? These clients don't just prefer a low scrap rate; they demand it. They require process stability, impeccable quality control, and the documentation to prove it. A 0.5% scrap rate tells them your process is unstable. It signals risk.

Achieving and maintaining a 0.1% scrap rate is a powerful statement. It tells the world that you have mastered your process. It demonstrates that you value precision and quality above all else. It becomes your most powerful sales tool. It's no longer a conversation about the price per bottle; it's a conversation about reliability and partnership. This is the "entrance ticket" that allows you to bid on the most profitable orders. This is how you transform your factory from a commodity producer into a high-value manufacturing partner.

Stop Just Looking for Black Dots. The Real Devil is in IV Value and 0.1g Weight Fluctuations?

Do your quality checks focus mainly on visible flaws like black specks or bubbles? This is a common mistake. You are catching problems far too late in the process.

The true source of many bottle defects lies in tiny, invisible variations in your raw material: the PET preforms. Inconsistent Intrinsic Viscosity (IV) and minuscule weight differences are the hidden variables that disrupt your entire production, forcing constant adjustments and creating scrap.

Dive Deeper: The Unseen Influence of Preform Stability

For years, I've watched factory managers get frustrated with their machines, blaming the equipment for inconsistent bottle quality. More often than not, they are pointing the finger in the wrong direction. A blow molding machine is an amplifier. It takes a preform and magnifies everything about it—both its good qualities and its hidden flaws. The pursuit of a 1‰ scrap rate begins long before the preform enters the oven. It begins with a ruthless focus on the quality and consistency of the preforms you use.

Why IV Value is the Master Variable

Beginners spot black dots. Pros track IV value. Intrinsic Viscosity (IV) is a measure of the molecular weight of the PET polymer. In simple terms, it tells you the length of the polymer chains. Why does this matter? Because the IV value directly dictates how the material will behave when heated and stretched.

- High IV Value: Longer polymer chains. The material is stronger but harder to stretch. It requires more heat or pressure.

- Low IV Value: Shorter polymer chains. The material is weaker and flows more easily. It requires less heat.

The problem isn't necessarily having a high or low IV, but having an inconsistent one. Imagine your process is perfectly tuned for a preform with an IV of 0.82 dL/g. If the next batch of preforms from your supplier has an IV of 0.80 dL/g, that material will overheat and flow too much in the mold. You'll get thin spots, maybe even holes. If the next batch is 0.84 dL/g, it won't stretch enough, leading to thick, heavy bottles or incomplete formation.

This is why your operators are constantly tweaking the heating parameters. They are compensating for the inconsistency of the raw material. I always tell my clients to have a serious talk with their preform supplier. Don't just ask for a "good price." Demand a Certificate of Analysis (COA) with every single batch that specifies the IV value and, more importantly, the range of deviation. A top-tier supplier can provide preforms with an IV deviation of just ±0.01 dL/g. This stability is the foundation of a stable process. If you're sourcing preforms, it might be time to think about a high-quality preform mold to control this variable in-house.

The 0.1 Gram Rule

Weight is the second pillar of preform quality. "But it's just a few tenths of a gram," some might say. In blow molding, a tenth of a gram is a mile. The blow molding process stretches the preform to many times its original size. Any small variation in weight, which represents a difference in the amount of material, gets magnified enormously.

Let's say one preform is 20.0g and the next is 20.2g. That's a 1% weight difference. After blowing, that 1% can translate into a 5% or even 10% difference in wall thickness in a critical area of the bottle. A 20.0g preform might produce a perfect bottle. The 20.2g preform, processed with the exact same parameters, will result in a different material distribution—thicker in some areas, thinner in others. This can lead to stress cracking, poor top-load strength, or volume variations.

I insist that my clients' receiving quality control teams weigh preforms to a precision of one decimal place (0.1g). Randomly sample at least 20 preforms from each new batch. Record the weights. If you see a standard deviation greater than 0.1g, it's a red flag. Your process will be inherently unstable. When designing a new product, the preform's weight and neck size are among the first and most critical decisions you will make.

The Enemy You Can't See: Moisture

Here’s a story. A client in Southeast Asia was facing a massive spike in scrap during the rainy season. They checked everything—the machine, the mold, the air pressure. Nothing had changed. The problem? Their preform storage warehouse wasn't climate-controlled.

PET is hygroscopic, meaning it absorbs moisture from the air. When a damp preform goes into the oven, that moisture turns to steam. During the stretching process, this water molecule hydrolyzes the PET, breaking the long polymer chains. This drastically lowers the IV value of the material at the moment of blowing.

The result is a brittle, hazy bottle that fails quality checks. They were essentially ruining their high-quality preforms just by storing them improperly. The solution was simple, but not obvious at first: install industrial dehumidifiers in the preform warehouse and ensure preforms are stored in sealed, lined containers. A dehumidifier might seem like a minor expense, but it saved that client's high-value orders. It’s a detail that separates the amateurs from the pros.

Most Factories I've Seen Fail Because of Their "Set-It-and-Forget-It" Heating Parameters?

When was the last time you adjusted your machine's heating profile? If your answer is "a few months ago," you've found a major source of your scrap rate problem.

Relying on a single, static set of heating parameters is a recipe for inconsistency. The ideal processing window for PET is incredibly narrow, and it's affected by countless environmental factors that change not just season to season, but hour to hour.

Dive Deeper: Heating is a Dynamic, Living Process

The oven section of a blow molding machine is its heart. It's where the preform is carefully prepared for its transformation. Treating this section with a "set-it-and-forget-it" mentality is one of the most common and costly mistakes I see in factories around the world. Perfect heating isn't a fixed destination; it's a dynamic process of constant, subtle adjustment.

Your Enemy: The Changing Environment

A factory is not a perfect laboratory. It's a living environment.

- Ambient Temperature: A preform sitting in the hopper on a hot summer afternoon is already warmer than one on a cold winter morning. It will require less energy from the lamps to reach the ideal blowing temperature. If you use the same heating power, the summer preform will be overheated.

- Time of Day: The temperature inside your plant at 7 AM after a cool night is different from the temperature at 3 PM when the sun has been beating down and all the machinery has been running for hours. This requires micro-adjustments throughout the day.

- Voltage Fluctuations: Is your factory's power supply perfectly stable? In many places, it isn't. A small dip in voltage can reduce the energy output of your heating lamps, leading to under-heated preforms. A spike can cause overheating.

An experienced operator develops a "feel" for this, but "feel" doesn't get you to a 0.1% scrap rate. Data does. I train teams to log the ambient temperature and make small, documented adjustments to the overall heating percentage (e.g., -1% power for every 5°C rise in ambient temp). It sounds tedious, but it replaces guesswork with a system.

The ROI of Closed-Loop Control

"Don't be cheap on the heating system," I tell my clients. "It will pay you back faster than you think." Many older or budget machines use open-loop heating. You set the power percentage for the lamps, and that's what they deliver, regardless of the actual preform temperature. It's simple, but dumb.

A modern bottle blowing machine should have a closed-loop heating system. This involves an infrared pyrometer (a non-contact thermometer) placed at the exit of the oven. This pyrometer measures the actual surface temperature of every single preform. It then feeds this information back to the controller, which automatically adjusts the lamp power in real-time to ensure every preform exits the oven at the exact target temperature, say 105°C.

Let's do a quick calculation. A good technician might cost you $40,000 a year. Their job often involves constantly tweaking the machine to chase stability. A closed-loop heating system might be a $10,000 option or upgrade. If this system eliminates just half of the scrap caused by thermal instability (a very conservative estimate), it could save you $4,000-$5,000 a year in material alone. Add the value of the technician's time, which can now be used for more proactive maintenance, and the system pays for itself in well under two years. It's one of the most logical investments you can make.

The Slow Death of a Heating Lamp

Here's a detail that even experienced managers miss: heating lamps have a lifespan, and they don't just suddenly burn out. They degrade slowly over time, a phenomenon called "luminous decay." An infrared lamp that's a year old might look like it's working perfectly, but it could be putting out 10-15% less energy than when it was new.

Your operator's natural reaction? They slowly creep up the power percentage on the control panel to compensate. After a year, you might be running the lamps at 75% power to get the same heating effect you used to get at 65%. This not only consumes more electricity but also puts more stress on the electrical components.

You can't see luminous decay with your eyes. The preform is the only thing that "sees" it. The only way to combat this is with a proactive maintenance plan.

| Lamp Maintenance Schedule | Action | Rationale |

|---|---|---|

| Weekly | Clean lamp reflectors and cooling fans. | Dust and residue absorb heat and reduce reflective efficiency. |

| Every 3,000 Hours | Check lamp electrical connections for tightness. | Loose connections can cause arcing and premature failure. |

| Every 4,000 - 5,000 Hours | Replace all lamps. | Replace before significant luminous decay affects process stability. |

Treat your lamps as a consumable item with a fixed service life, just like the oil in your car. Waiting for them to cause problems is reactive. Replacing them on a schedule is proactive. This is the mindset required for achieving an elite level of quality control.

Why Is Your Machine Always "Almost Perfect"? The Answer is Millisecond Precision from Servo Motors?

Does your machine produce good bottles, but with occasional, unexplainable defects? Do you struggle to maintain consistent wall thickness or a perfect neck finish? The issue may not be your process, but your hardware.

The difference between a 0.5% and 0.1% scrap rate often lies in a level of precision that traditional systems can't deliver. The answer is the microsecond-level accuracy and repeatability that only a fully servo-electric system can provide.

Dive Deeper: The Unmatched Precision of Servo Technology

I've worked with hundreds of machines over my career, from old hydraulic beasts to the latest all-electric wonders. The single biggest leap in blow molding technology has been the shift to servo motors. For those chasing the final few tenths of a percent in performance, it's not just an upgrade; it's a game-changer.

The Dancer vs. The Weightlifter

Let's use an analogy I often share with clients.

Traditional Pneumatic/Hydraulic Machines: These are like a "strongman" or a "weightlifter." They are powerful and can get the job done. They use air or oil pressure to slam things open and shut—stretching rods, mold clamps, etc. The control is basic: "on" or "off," "fast" or "slow." There's a lot of force, but not a lot of finesse. They do their best to hit the right position every time, but there are always slight variations due to pressure fluctuations, valve response times, and temperature changes in the hydraulic fluid. They are "trying their best."

Full Servo-Electric Machines: These are like a "ballet dancer." Every movement is driven by a precision electric motor controlled by a computer. Instead of just slamming open or shut, the controller tells the motor exactly where to go, how fast to get there, and what path to take. The motor has an encoder that reports its exact position back to the controller thousands of times per second. If it's off by even a fraction of a millimeter, the controller corrects it instantly. It's not "trying its best"; it is on a "mission to be perfect."

This difference is crucial. When you're trying to control material distribution in a bottle wall that is less than a millimeter thick, "almost" isn't good enough. You need absolute, repeatable precision, cycle after cycle, million after million.

Where Servo Matters Most

If you're considering an upgrade, where should you invest your money? I tell my clients to focus on the two actions that have the biggest impact on bottle quality: stretching and clamping.

Servo-Driven Stretching: The stretch rod is what pulls the preform vertically just before the high-pressure blow. The speed and timing of this action are critical for axial material distribution (how thick the bottle is from top to bottom).

- In a pneumatic system, the rod just shoots down.

- In a servo system, you can program a complex stretch profile. You can have it start slow, accelerate, and then decelerate just before it touches the bottom. This level of control allows you to put the material exactly where you need it, thinning it in some places and leaving it thicker in others. This is essential for lightweighting bottles without sacrificing strength and for producing complex shapes.

Servo-Driven Clamping: A servo-driven mold clamp doesn't just open and close. It moves with incredible speed, smoothness, and precision. This reduces vibration, which can affect the preforms waiting in the oven. More importantly, it provides a perfectly consistent locking force. It also allows for advanced functions like "preferential cooling," where you can slightly open the mold for a fraction of a second to release gas before clamping shut again, improving the surface finish of the bottle.

When you invest in a modern servo bottle blowing machine, you are fundamentally buying control. You are eliminating variables that are inherent in older, fluid-powered designs. This is how you move from fighting defects to engineering them out of the process from the very beginning. It's also critical to ensure your tooling is up to the task. The precision of a servo machine means that any concern about whether the blow mold will fit the machine becomes even more important, as tolerances are much tighter.

| Feature Comparison | Pneumatic/Hydraulic System | Full Servo-Electric System |

|---|---|---|

| Precision | Moderate, affected by pressure/temp | Extremely high, microsecond-level digital control |

| Repeatability | Good, but with inherent variations | Excellent, virtually identical movement every cycle |

| Control | Basic (On/Off, Fast/Slow) | Advanced (Variable speed, acceleration, position) |

| Energy Consumption | High, compressor/pump runs constantly | Lower, motors only draw significant power when moving |

| Noise Level | High (hissing air, pump whine) | Very low |

| Maintenance | Leaks, filters, fluid changes | Primarily electronic, minimal mechanical wear |

| Investment Cost | Lower | Higher |

| Best For | Simple shapes, less critical apps | High-speed, lightweight, complex, high-quality bottles |

The Most Expensive "Money-Saving" Mistake: Treating Your Mold Like a Simple Iron "Shape"?

Have you ever invested heavily in a top-of-the-line machine, only to cut corners on the mold to save a few thousand dollars? This is one of the most common and costly mistakes I see.

A blow mold is not just a passive "iron shape." It is an active, high-performance tool that dictates your cycle time, bottle quality, and ultimately, your profitability. Thinking of it as a simple commodity is a recipe for failure.

Dive Deeper: Your Mold is a High-Tech Machine

I've had this conversation more times than I can count. A client will show me their brand new, state-of-the-art blowing machine, and then they'll point to a cheap, poorly designed mold sitting next to it. It’s like buying a Ferrari and putting budget tires on it. You will never, ever get the performance you paid for. A high-quality blow bottle mold isn't an expense; it's the single most critical investment in your entire production line.

A Good Mold Breathes

When high-pressure air inflates the hot PET against the mold cavity walls, the air that's already in the cavity needs to escape. If it can't get out fast enough, it gets trapped between the bottle and the mold wall. This trapped air prevents the PET from making perfect contact with the mold surface, resulting in a number of problems:

- Poor surface finish or hazy spots.

- Incomplete definition of details, like embossed logos.

- Inefficient cooling, as the air acts as an insulator.

A great mold "breathes" through carefully designed and machined vent slots. These are tiny channels, often just 0.03-0.05mm deep, cut into the parting line surfaces and other strategic areas of the mold. They are small enough to let the air out, but too small for the molten PET to flow into. The design and placement of these vents is an art form, perfected through experience and simulation. A cheap mold will have too few vents, or vents in the wrong places. This is a primary reason why one mold can produce a crystal-clear bottle at a 2.0-second cycle time, while another produces a hazy bottle and needs a 2.5-second cycle time just to look acceptable. That half-second difference, over millions of cycles, is an enormous amount of lost production. A proper PET bottle mold design process considers this from day one.

Your Mold's "Cardiovascular System": The Cooling Channels

The single biggest portion of the blow molding cycle is cooling time. This is the time the bottle must spend in contact with the cold mold walls to solidify enough to be ejected without deforming. The faster you can pull heat out of the plastic, the faster your cycle time.

The "cardiovascular system" of your mold is its network of cooling water channels.

- A Bad Mold: Uses simple, straight-drilled holes that are easy to machine. The water flow is slow and uneven. Some parts of the mold are cold, while others are warm. This leads to inconsistent cooling, which can cause warping and internal stresses in the bottle.

- A Good Mold: Features complex, interconnected cooling channels that are designed using fluid dynamics simulation. They follow the contour of the bottle shape to ensure that every single part of the mold surface is cooled evenly and intensely. This uniform and rapid heat extraction is what allows you to shave those critical tenths of a second off your cycle time, while also producing a more stable, higher-quality bottle. For anyone serious about performance, asking your mold maker about their cooling design philosophy is non-negotiable. It's so important, we have a whole article on why molds need a chiller.

The Doctor's Check-up: Proactive Mold Maintenance

I treat my molds like high-performance engines. They require regular, meticulous maintenance. One of the most unique things we do at iBottler is a regular "endoscopy" on our molds. We use a small, flexible borescope camera—the same type of tool a doctor uses—to inspect the inside of the cooling channels.

Why? Over time, even with filtered water, mineral deposits and rust (scale) can build up on the inside walls of the channels. This scale is an insulator. Just 1mm of scale can reduce the heat transfer efficiency by over 10%. Your chiller is working harder, your cycle time is getting longer, and you don't know why. By inspecting the channels regularly, we can spot this buildup long before it becomes a problem and schedule a chemical flush or professional cleaning.

This might sound extreme, but this is the level of detail required to stay at the top. It's about preventing problems, not just fixing them. This proactive approach, which also includes regularly checking vent depths and polishing cavity surfaces, is what keeps a mold running like new for millions of cycles. Sometimes the best way to ensure this is to work with a partner who can even provide 3D printed samples to validate the design before cutting steel.

Give Your Operator a Stopwatch and Calipers: Make Them Your First Line of Defense?

Who is the most important person in your fight against scrap? Is it the quality manager? The production supervisor? The engineer? I believe it's the machine operator.

Too many factories treat their operators like button-pushers. This is a massive waste of potential. By training, empowering, and equipping your operators to be the first line of quality defense, you can catch deviations long before they turn into piles of scrap.

Dive Deeper: From Button-Pusher to Process Owner

For years, the prevailing management philosophy in many plants was to simplify the operator's job as much as possible. The thinking was that this would reduce errors. In reality, it created disengaged employees who had no ownership of the process. My approach is the exact opposite. I want my operators to be the smartest people in the room when it comes to their machine. I want them to understand not just what to do, but why they are doing it.

Training Beyond the "Start/Stop" Button

Most operator training consists of showing them how to start the machine, stop the machine, and clear a jam. This is not training; it's basic orientation. To truly reduce scrap, your training needs to go much deeper.

I insist that every operator on my team can answer these questions:

- What does the IV value of a preform mean, and why does it matter?

- If the top of the bottle is too thin, which heating lamps should you adjust and in which direction?

- What are the top 5 most common bottle defects, what causes them, and what is the first corrective action?

- Why is the temperature of the cooling water important?

When an operator understands the "why," they stop being a passive observer and become an active problem-solver. They can spot a trend of the bottle's shoulder getting slightly hazy and know to check the temperature of the preform neck before it becomes a major issue. They can hear a slight change in the sound of the high-pressure air release and know to check for a leak. This level of engagement is impossible if they only know the start and stop buttons.

The Power of a Checklist and a Caliper

"Trust, but verify" is a good mantra. Giving operators knowledge is the first step. Giving them the tools and the structure to use that knowledge is the second. I am a huge believer in operator-led Statistical Process Control (SPC). It sounds complicated, but in practice, it's very simple.

We create a simple checklist. Every hour, on the hour, the operator must take 5 bottles from the conveyor. They then perform a series of quick tests right there at the machine using basic tools:

- Visual Inspection: Check for haze, black specks, short shots, etc.

- Weight Check: Weigh the bottle on a gram scale.

- Key Dimension Check: Use digital calipers to measure critical dimensions. For a standard water bottle, this might be the overall height, the base diameter, and the wall thickness at a specific point.

They record these numbers on the checklist. The sheet has the target value and the acceptable upper and lower control limits printed right on it.

| Hourly Operator Quality Check (Example) | |||||||

|---|---|---|---|---|---|---|---|

| Time: 14:00 | Operator: John D. | ||||||

| Check | Bottle 1 | Bottle 2 | Bottle 3 | Bottle 4 | Bottle 5 | Target | Limits |

| Weight (g) | 20.1 | 20.0 | 20.1 | 20.2 | 20.1 | 20.0g | +/- 0.2g |

| Height (mm) | 210.5 | 210.4 | 210.5 | 210.6 | 210.5 | 210.5mm | +/- 0.3mm |

| Base Thickness (mm) | 0.45 | 0.46 | 0.44 | 0.45 | 0.46 | 0.45mm | +/- 0.05mm |

This simple act does two things. First, it creates a real-time data stream of your process stability. You can see trends developing long before they go out of specification. Second, it gives the operator ownership. The checklist isn't for me; it's for them. It's their tool to keep the process in control.

The Conversation Changes

The most rewarding part of this approach is how the communication on the factory floor changes.

- Before: An operator would come to me and say, "The machine is acting up again. The bottles just don't look right." This is subjective and not helpful.

- After: An operator comes to me and says, "Boss, for the last two hours, the average weight has trended up by 0.15 grams, and I'm starting to see the base thickness approach the upper limit. I've already checked the preform batch, and it's the same. I think we may need to slightly decrease the heating in zone 2."

This is a conversation between two professionals. The operator isn't just reporting a problem; they are presenting data, analysis, and a potential solution. They feel empowered and respected. When your team reaches this level of proactive engagement, you know that a 0.1% scrap rate is not just a fantasy, but an achievable goal.

Your Main Machine is Useless if Your Air Compressor and Chiller are Holding It Back?

You've invested in the best blow molding machine and the highest quality molds. Yet, you're still chasing inconsistent quality and can't reach your target cycle times. Have you checked your support equipment?

Your main machine is only one part of the equation. The performance of your entire production line is often limited by the "boring" auxiliary equipment: your air compressor system and your water chiller.

Dive Deeper: The Shortest Plank in Your Barrel

I often use the "barrel effect" analogy with my clients. Imagine your production capacity is a wooden barrel. The height of each plank represents the capacity of a piece of equipment—the main machine, the mold, the chiller, the compressor. The barrel can only hold as much water as its shortest plank allows. In my experience, the shortest planks in most factories are the auxiliary systems. People pour money into the long planks (the blow molder) and neglect the short ones.

High-Pressure Air: The Lifeblood of Your Process

Blow molding requires a significant volume of clean, dry, high-pressure air (typically 30-40 bar or 435-580 psi). This air is not just "air"; it's a critical process utility. Any contamination in it is like injecting poison directly into your product.

Oil Contamination: Most standard compressors have some oil carryover. If this oil gets into the high-pressure air stream, it gets blasted into your bottle. It can cause a strange taste or odor in the final product (a catastrophic failure for a beverage company) and can also build up a sticky film inside your machine's valves and your mold's venting slots, causing them to malfunction over time. Your high-pressure system must have a series of high-quality coalescing and carbon tower filters specifically designed for high-pressure, breathable air.

Water Contamination: When you compress air, the moisture in it condenses into liquid water. If this water isn't removed, it will cause major problems. It can cause rust and corrosion inside your expensive machine and molds. Worse, when blasted into the hot preform, it has the same effect as moisture in the PET material itself—it hydrolyzes the polymer, making the bottle brittle. A high-pressure refrigerated or desiccant air dryer is not an optional accessory; it is a mandatory component of a professional setup. A properly designed cost-efficient air system is fundamental.

Pressure Drop: Does your machine run great for a while and then suddenly start producing thin or incompletely formed bottles? Check your air pressure. If your compressor and storage tanks are undersized, the pressure can drop significantly after a few cycles. The machine is ready for the next "blow," but the air pressure hasn't recovered yet. This starves the process of the force it needs. You need to size your compressor and receiver tanks not for the average air consumption, but for the peak demand of the blowing cycle.

The Chiller: Your Unsung Hero of Productivity

Have you ever had to slow down your machine on a hot summer day? If so, the problem is almost certainly your chiller. As I mentioned before, cooling is the longest part of the cycle. Your chiller's job is to supply the mold with a continuous flow of cold water (or a water-glycol mix) at a stable temperature, typically 8-12°C (46-54°F).

- Undersized Chiller: An undersized chiller can't remove heat from the water fast enough. The temperature of the water returning to the mold starts to creep up. If the water going in is 10°C but the water coming out is 15°C and the chiller can only cool it back down to 11°C, your mold is now running 1°C warmer. This means it will take longer to cool the bottle. You're forced to either extend your cooling time (slowing down production) or risk ejecting a bottle that is too warm and will deform.

- Flow Rate Issues: It's not just about temperature; it's about flow rate. You need enough pressure and flow to push the water through the complex cooling channels of your mold turbulently. Turbulent flow scrubs the channel walls and pulls heat away much more effectively than smooth, laminar flow. Clogged filters, an undersized pump, or pipes that are too small can all kill your flow rate and cripple your cooling performance.

Investing in a properly sized, high-quality chiller and air compressor system isn't "extra" cost. It is fundamental to unlocking the full speed and quality potential of the expensive main machine and molds you've already paid for. Neglecting them is like trying to win a race with a flat tire.

Final Thoughts: The Challenge to 1‰ is More Like a Discipline, and We're In It Together?

Getting from 5% scrap to 1% is about good management and technology. But the journey from 0.5% (5‰) down to 0.1% (1‰) is something else entirely. It’s a culture.

It's a relentless, almost obsessive pursuit of perfection in every single detail. It’s a discipline practiced by every person on the team, from the warehouse to the operator to the manager.

The tips in this article are just a small sample of the lessons my team at iBottler and I have learned over the past 20 years. They are born from countless hours on factory floors, solving real-world problems. The path to 0.1% is challenging, but it is achievable, and it transforms your entire operation.

If you are on this journey and facing a challenge that’s keeping you up at night, I genuinely want to hear about it. Send me a message. Let's tackle that goal of 1‰ together.

Conclusion

Reducing your scrap rate from 0.5% to 0.1% requires a radical shift. You must move from fixing visible defects to obsessively controlling invisible variables in preforms, heating, and machine precision.

Frequently Asked Questions (FAQ)

1. I don't have the budget for a new servo machine. Where should I start?

Start with what you can control. The biggest impact for the lowest cost comes from two areas. First, become ruthless about your incoming preform quality. Have a serious discussion with your supplier about batch-to-batch consistency for IV value and weight. Start measuring and tracking it yourself. Second, empower your operators. The cost of a few digital calipers and a training program is minimal compared to the scrap it can prevent. Turning your operators into data-driven process owners is your most powerful, low-cost weapon.

2. How long does it take to see results after implementing these changes?

Some changes bring immediate results. For example, stabilizing your preform storage with a dehumidifier can solve moisture-related issues within a day. Implementing hourly operator quality checks can start catching deviations within the first shift. Other changes, like upgrading a mold or installing a closed-loop heating system, are longer-term projects. The overall cultural shift to a "0.1% mindset" is a gradual process, but you should see a measurable drop in your scrap rate within the first 3 months if you are consistent.

3. My operators are resistant to doing more checks and paperwork. How do I get them on board?

This is a common challenge, and it stems from them feeling like they are being given "more work." The key is to reframe it. First, explain the "why" behind the checks. Show them how a small weight variation leads to the defects they hate dealing with. Second, make them part of the solution, not just the problem-finders. When their data helps solve a long-standing issue, celebrate that success publicly. Third, ensure the data they collect is actually used. If they see their logs are just filed away and ignored, they will stop caring. When a manager uses their checklist to have an informed discussion, it shows respect and validates their effort. It becomes a tool for them, not a chore for management.

4. Is a 0.1% (1‰) scrap rate truly possible for all bottle types and shapes?

It is an aggressive target, but for most standard beverage and CPG bottle designs, it is an achievable benchmark with modern equipment and rigorous process control. Extremely complex, asymmetric, or very lightweight bottles may present a greater challenge, and a stable rate of 0.2% might be considered excellent in those specific cases. However, 0.1% should always be the goal you strive for. It acts as a "true north" that forces you to constantly improve and question every part of your process. If you can't reach it, you will at least understand exactly which design constraint or process variable is holding you back.

5. We produce many different bottles and change molds frequently. How can we maintain stability?

High-mix, low-volume production is the ultimate test of a process. The key here is creating a "recipe" system. For every single mold, you must have a documented sheet with all the ideal parameters: preform type, heating profile, stretch rod speed, blow pressures and times, cooling water temperature, etc. When you change a mold, you load this exact recipe. This eliminates guesswork. The second key is to invest in quick-change systems (SMED - Single-Minute Exchange of Die) to minimize the downtime and chaos of changeovers. A well-organized, documented changeover process is critical to returning to a stable, low-scrap production state as quickly as possible.

reduce blow molding scrap rate, 0.1% scrap rate, blow molding optimization, operational excellence manufacturing, PET bottle defects, high precision blow molding, statistical process control (SPC) blow molding, servo blow molding machine, preform micro-defects, blow molding process capability, Cpk improvement, manufacturing waste reduction, high quality bottle production, iBottler

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

🔗 Learn More about Blow Molding Auxiliary Equipment

To better understand the supporting equipment used in blow molding production, here are some helpful resources:

Air Compressor – Wikipedia

Key equipment providing high-pressure air for bottle blowing.Chiller – Wikipedia

Helps maintain stable mold temperatures during production.Refrigerated Dryer – Wikipedia

Removes moisture from compressed air to ensure stable blowing conditions.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr