Struggling with how to make PET wide-mouth jars? It can seem complex with all the machine choices and process details. I'm here to break it all down for you, simply and clearly.

Producing PET wide-mouth jars effectively involves selecting the right blow molding machine, often a specialized automatic or semi-automatic unit. The process starts with PET preforms, which are heated, then stretched and blown into a mold to achieve the final jar shape and size.

The shift from glass to PET for jars is a big trend I'm seeing. Just recently, a new client contacted me. They wanted a plan to switch five of their glass jar designs to PET. Their main questions were about the production process, the investment in blow molding machines and molds, and the cost per jar. These are common worries, and understanding the basics is the first step to making a smart choice. This guide will walk you through the essential aspects, so you feel confident about moving forward with PET wide-mouth jar production.

Key Takeaways for PET Wide-Mouth Jar Production

| Aspect | Key Consideration | Importance |

|---|---|---|

| Machine Type | Specialized wide-mouth blow molder (automatic/semi-automatic) | Crucial for efficient, quality production |

| Process | Preform heating, stretching, blowing | Core of jar formation |

| Preform Molds | Specific molds for wide-mouth preforms are usually needed. | Impacts final jar quality and cost |

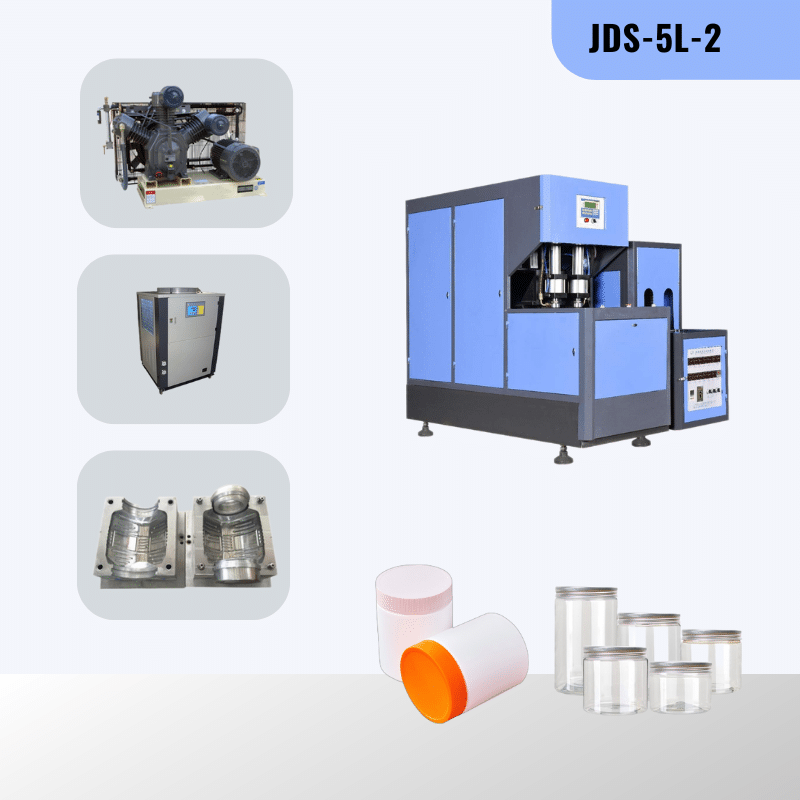

| Production Line | Includes blow molder, preform feeder, air compressors, chillers, conveyors. | Ensures smooth, continuous operation |

| Cost Factors | Machine type, cavitation, automation level, auxiliary equipment. | Budget planning and ROI calculation |

| Narrow vs. Wide-Mouth | Different stretching mechanisms and preform handling. | Affects machine design and capabilities |

| Customization | Molds can be customized for various shapes and sizes. | Brand differentiation and product appeal |

| Capacity & Efficiency | Output depends on machine model, jar size, and mold cavitation. | Meeting demand and optimizing production costs |

| After-Sales Support | Essential for installation, training, maintenance, and troubleshooting. | Long-term operational success |

| Design Assistance | Many suppliers offer help with preform and jar design. | Optimizing performance and material usage |

What Type of Blow Molding Machine Is Used for PET Wide-Mouth Jars?

Wondering which machine is right for your PET wide-mouth jars? It's a key question for anyone starting out. You need a machine designed for this specific type of container.

For PET wide-mouth jars, you typically need a reheat stretch blow molding (RSBM) machine. These can be fully automatic or semi-automatic. Automatic machines are better for high volumes, while semi-automatic ones suit smaller production runs or startups.

When I talk to clients about producing PET wide-mouth jars, the first thing we discuss is the type of blow molding machine. It's not quite the same as making narrow-neck bottles. The machine needs to handle the wider preform opening and ensure even material distribution, which is critical for the structural integrity of a jar.

Key Features of Wide-Mouth Jar Blow Molders

- Specialized Preform Handling: The mechanisms that load and hold the preforms are designed for wider necks. This is different from machines that only handle standard bottle preforms.

- Stretching System: The stretching rod (or mandrel) and the way it stretches the preform axially are adapted for the shorter, wider body of a jar. The goal is to get good material distribution on the base and sidewalls.

- Blowing Process: The blowing pressure and timing might also be adjusted. For jars, achieving a flat and stable base is very important, as is the clarity of the container.

- Mold Clamping Unit: The clamping unit must be robust enough to handle the forces involved in blowing wider containers.

I remember a client who initially thought they could adapt a narrow-neck machine. We quickly realized that for the quality and consistency they needed for their food jars, a dedicated wide-mouth machine was the only way to go. It prevented a lot of potential headaches with thin spots or uneven jar bases.

Most commonly, you'll be looking at two-stage reheat stretch blow molding machines.

- In the first stage (often done by a separate supplier), PET resin is injection molded into preforms. These preforms look like thick-walled test tubes with the finished neck threads already formed.

- In the second stage, which is what your blow molding machine does, these preforms are reheated, stretched, and blown into the final jar shape.

There are also single-stage machines that do both injection molding of the preform and blow molding of the jar in one integrated unit. However, for wide-mouth jars, especially in larger volumes, two-stage machines are more common and often more flexible. They allow you to source preforms from specialized suppliers if you don't want to make them yourself. This can be a good way to start, as preform production is a precise process.

The choice between automatic and semi-automatic really depends on your production needs.

- Automatic machines handle everything from preform loading to jar ejection. They offer higher output rates and lower labor costs per jar. If you're looking at producing many thousands of jars per hour, this is the direction you'll likely head.

- Semi-automatic machines require manual loading of preforms and sometimes manual transfer between heating and blowing stations. They have a lower initial investment but higher labor involvement and lower output. They can be a good starting point for smaller businesses or for producing specialty jars in lower quantities.

So, the type of machine is crucial. It's not just any blow molder; it needs to be one suited for the unique demands of wide-mouth PET jars. We always advise looking at the specific design features that cater to jar production.

How Much Does a PET Wide-Mouth Jar Blow Molding Machine Cost?

Worried about the investment for a PET jar machine? It's a big factor in your decision, and costs can vary quite a bit. Understanding what influences the price is key.

The cost of a PET wide-mouth jar blow molding machine can range from tens of thousands to several hundred thousand dollars. Price depends on automation level, capacity (cavities), brand, and included auxiliary equipment.

When clients ask me about the cost, like my recent client planning to switch from glass, I explain that it's not a one-size-fits-all answer. The budget for a PET wide-mouth jar blow molding machine is a significant consideration, and it's influenced by several important factors.

Main Factors Affecting Machine Price:

Automation Level:

- Semi-Automatic Machines: These are the most budget-friendly upfront. You might find basic models starting from around \$15,000 to \$50,000. They require manual labor for loading preforms and sometimes unloading jars. Their output is lower. I often see startups or companies with very small production needs considering these.

- Fully Automatic Machines: These machines offer much higher production rates and consistency, with minimal manual intervention. Prices for these can start from \$60,000 and go up to \$300,000 or even more for very high-capacity, multi-cavity systems from premium brands. The investment is higher, but the cost per jar can be lower in large-scale production.

Production Capacity (Number of Cavities):

- A mold can have one or more cavities. A 2-cavity machine will produce two jars per cycle, while a 4-cavity machine produces four. More cavities mean higher output but also a more complex and expensive machine and mold. A small automatic machine might have 1 or 2 cavities. Larger ones can have 4, 6, or even more, significantly impacting the price.

Machine Brand and Origin:

- Machines from well-established manufacturers in Europe, North America, or Japan tend to be more expensive due to their technology, build quality, and service. Machines from manufacturers in China or Taiwan can offer more competitive pricing, and many provide excellent quality and support. I always tell clients to research the manufacturer's reputation and after-sales service, regardless of origin.

Technology and Features:

- Advanced features like preferential heating (for oval or complex shapes), sophisticated control systems (like Siemens or Beckhoff PLCs), energy-saving components (servo motors instead of hydraulics), and quick mold change systems will add to the cost. For wide-mouth jars, precise heating and stretching control are very important, so these features can be worth the investment.

Auxiliary Equipment:

- The blow molder itself is just one part. You'll also need:

- Preform Molds: These are custom-made for your jar design and are a separate cost.

- Blow Molds: Also custom. The number of cavities in your blow mold matches the machine's capability.

- Air Compressors: You'll need both high-pressure (for blowing) and low-pressure (for machine operation) air. This can be a substantial part of the investment.

- Air Dryer and Filters: Clean, dry air is crucial for PET blowing.

- Water Chiller: To cool the molds and the preform necks.

- Preform Feeder/Orientor (for automatic machines): To automatically load preforms.

- Conveyors: To move preforms and finished jars.

- Sometimes these are quoted as a package, but often they are itemized. It’s important to get a full picture of the total investment.

- The blow molder itself is just one part. You'll also need:

When my client for the five glass jar lines asked for a budget, we broke down these elements. For their expected volume, a 2-cavity or 4-cavity automatic machine made sense. We then looked at options from different suppliers, considering not just the upfront machine cost but also the running costs, efficiency, and the supplier's support capabilities. It's an investment, so thinking long-term is essential. You need to balance the initial cost with the desired output, quality, and operational efficiency.

Can I Produce PET Jars with a Semi-Automatic Blow Molding Machine?

Thinking about starting small or have limited capital? A semi-automatic machine might seem like a good option. But can it really handle PET wide-mouth jars effectively?

Yes, you can produce PET wide-mouth jars with a semi-automatic blow molding machine. These are suitable for lower production volumes, startups, or when flexibility for different jar sizes is more critical than high speed.

This is a common question, especially for businesses just entering the PET jar market or those with smaller, niche product lines. The good news is, yes, semi-automatic machines are definitely capable of producing quality PET wide-mouth jars. I've worked with several clients who started this way.

How Semi-Automatic Machines Work for Jars:

A typical semi-automatic setup for PET wide-mouth jars involves a few distinct steps, with some manual intervention:

- Preform Heating: Preforms are manually loaded onto a conveyor or into a heating oven. The machine heats the preforms to the correct temperature. The heating process is critical, and good semi-automatic machines will still have precise temperature control zones in their ovens to ensure even heating.

- Transfer to Mold: Once heated, the operator manually transfers the hot preforms from the heater to the blow mold, which is located in the blowing station.

- Blowing: The operator closes the mold and initiates the blowing cycle. The machine then stretches and blows the preform into the jar shape.

- Ejection/Removal: After blowing and a short cooling period, the mold opens, and the operator manually removes the finished jar.

Advantages of Using a Semi-Automatic Machine for Jars:

- Lower Initial Investment: This is the most significant advantage. Semi-automatic machines cost considerably less than their fully automatic counterparts, making them more accessible for small businesses or for testing new products.

- Flexibility: They can often be easier to set up and change over for different jar sizes and shapes, provided you have the corresponding molds. This is great if you have a diverse product range in smaller quantities.

- Smaller Footprint: Generally, these machines take up less space, which can be important in smaller facilities.

- Simpler Operation and Maintenance: With fewer automated components, they can be easier to understand, operate, and maintain, potentially reducing the need for highly specialized technicians.

Considerations and Limitations:

- Lower Output: Production speed is limited by the manual steps. You might produce a few hundred to perhaps a thousand or so jars per hour, depending on the jar size, machine design, and operator efficiency. This is much lower than automatic machines.

- Higher Labor Cost per Jar: Because of the manual operation, the labor component in the cost of each jar will be higher.

- Operator Dependency and Consistency: The skill and consistency of the operator can affect the quality and output. Even heating is automated, but the speed of transfer and cycle initiation relies on the operator.

- Not Ideal for Very High Volumes: If you need to produce tens of thousands of jars per day, a semi-automatic machine will likely become a bottleneck.

I recall a client who made artisanal jams. They started with a very small semi-automatic machine. It was perfect for their initial volumes. As their business grew, they eventually upgraded to a small automatic machine, but the semi-automatic unit allowed them to enter the market with PET jars without a massive upfront cost. They learned a lot about the process on that machine too. So, for the right application – lower volumes, budget constraints, or high product variety – a semi-automatic machine is a perfectly viable way to produce PET wide-mouth jars.

What’s the Difference Between Wide-Mouth and Narrow-Neck Blow Molding?

You might wonder if any PET blow molder will do. Are wide-mouth jars really that different from narrow-neck bottles in terms of production? Understanding this helps in choosing the right equipment.

The main differences are in preform design (wider opening, different length-to-diameter ratio for jars), the stretching process (shorter, wider stretch), and often the heating profile required to evenly distribute material in a jar's shoulders and base.

When I explain this to clients, I emphasize that while the basic principle of reheat stretch blow molding is the same, the specifics for wide-mouth jars versus narrow-neck bottles are quite distinct. These differences impact machine design, process parameters, and preform characteristics.

Key Distinctions:

Preform Design:

- Narrow-Neck Bottles: Preforms are typically longer and more slender relative to their neck opening. The L/D (length to diameter) ratio of the preform body is higher.

- Wide-Mouth Jars: Preforms have a much larger neck opening relative to their overall length. They are often shorter and "stubbier." The neck finish itself is, of course, wider to accommodate the jar opening. This significantly changes how the preform behaves during heating and stretching.

- My experience: Getting the preform design right for a wide-mouth jar is critical. If the preform isn't designed well, you can end up with issues like thin bases, uneven wall thickness, or problems with the jar's shoulder area.

Heating Process:

- Narrow-Neck Bottles: Heating profiles are optimized to distribute material along a longer body.

- Wide-Mouth Jars: Achieving even heating, especially around the thicker neck area and ensuring enough heat reaches the part of the preform that will form the jar's shoulder and base, can be more challenging. Specialized heating ovens with precise zone control are important. Sometimes, different types of heating lamps or reflectors are used to focus heat appropriately. Preferential heating might be needed if the jar is not round.

Stretching Mechanism and Ratio:

- Narrow-Neck Bottles: The stretch rod travels a longer distance relative to the preform's diameter, leading to higher axial stretch ratios.

- Wide-Mouth Jars: The axial stretch is typically less (because jars are often shorter than bottles of similar volume), but the hoop stretch (radial expansion) is significant. The stretch rod itself might be designed differently, sometimes with a larger diameter head, to properly engage the wider preform base. The machine kinematics for the stretching process are tailored for this.

Blow Mold Design:

- Narrow-Neck Bottles: Molds are designed for taller, slimmer shapes.

- Wide-Mouth Jars: Molds accommodate shorter, wider bodies. The design of the base is very important for jar stability. The neck area of the mold precisely forms the threads and sealing surface for the wide closure.

Machine Adaptations:

- Preform Handling: As mentioned earlier, the grippers, spindles, and transfer mechanisms in an automatic machine must be able to handle the wider preform necks securely.

- Ejection: Safely ejecting a wide, sometimes less stable, jar might require different ejection mechanisms than for a taller, more rigid bottle.

A client once asked if they could just use wider preforms on their existing bottle machine. While it might seem possible in theory for very slightly wider necks, for true wide-mouth jars, the machine is just not designed for it. The heating wouldn't be optimal, the stretch rod might not work correctly, and the preform holders wouldn't fit. It’s like trying to bake a cake in a bread loaf pan – you might get something, but it won’t be what you intended. So, yes, the processes are related, but specialized machines and tooling are key for successful wide-mouth jar production.

Do I Need a Separate Preform Mold for Wide-Mouth Jars?

You've got the blow molder, but what about the preforms? Do wide-mouth jars mean you need entirely different preform molds? This is an important cost and supply chain consideration.

Yes, you will almost certainly need a separate, specifically designed preform mold for wide-mouth jars. Preform design (neck finish, weight, length, diameter) is critical and unique to the final jar specifications, differing significantly from narrow-neck bottle preforms.

This is a point I always clarify early on. The preform is the starting point of your PET jar, and its design is just as crucial as the blow mold. You can't typically use a preform designed for a narrow-neck bottle to make a wide-mouth jar, or even a preform for one type of jar to make a significantly different jar.

Why Specific Preform Molds are Essential:

Neck Finish: This is the most obvious difference. A wide-mouth jar has a much larger neck diameter and a specific thread pattern designed for wide closures (lids). The preform mold creates this exact neck finish. You can't change the neck finish during the blow molding process; it's fixed from the preform stage.

- Example: A 500ml water bottle might have a 28mm PCO neck. A 500ml food jar might have a 63mm, 70mm, or even 89mm neck. These require completely different preform neck sections in the mold.

Preform Weight and Material Distribution: The amount of PET material in the preform (its weight) determines the final weight and thickness of the jar. Wide-mouth jars often require specific wall thicknesses for stacking strength, hot-fill capability (if needed), or barrier properties. The preform mold dictates this starting weight and influences how material is distributed before blowing.

- The length and diameter of the preform body are also engineered to achieve the desired stretch ratios and final jar dimensions. A short, wide jar will need a different preform profile than a tall, narrower jar, even if the neck is the same.

Stretch Ratios: As discussed before, wide-mouth jars have different stretch characteristics. The preform's length and diameter are designed in conjunction with the blow mold to ensure the PET material stretches correctly without over-stretching (leading to thin spots) or under-stretching (leading to thick, unoptimized sections).

Resin Type: While most PET jars use standard PET resin, some applications (like hot-fill or those needing enhanced gas barriers) might use specialized PET grades. The preform mold process parameters (like injection temperature and cycle time) might need to be optimized for these resins.

Investment in Preform Molds:

- Cost: Preform molds are high-precision tools, typically made from hardened steel, and represent a significant investment. The cost depends on the number of cavities (how many preforms are made per cycle), the complexity of the preform design, and the mold manufacturer. A single-cavity R&D preform mold might cost a few thousand dollars, while multi-cavity production molds (e.g., 32, 48, 72 cavities or more) can cost hundreds of thousands of dollars.

- Lead Time: Designing and manufacturing a new preform mold can take several weeks to a few months.

When my client wanted to convert their five glass jar lines to PET, a key part of my proposal was the design and procurement of new preform molds for each jar type. Even if two jars had the same volume, if their neck finish or overall shape was different, they would likely need distinct preforms and thus distinct preform molds. Sometimes, if jars are very similar in shape and only differ slightly in height with the same neck, you might be able to use the same preform, but this is less common for significantly different designs.

So, budgeting for and planning the lead time for dedicated preform molds is a critical step in setting up PET wide-mouth jar production. It's an upfront cost, but it’s fundamental to getting the quality and specifications you need for your final product.

What Is the Full Production Line for PET Wide-Mouth Jars?

You're thinking beyond just the blow molder. What other equipment makes up a complete production line for PET wide-mouth jars? Knowing this helps plan your space and budget.

A full production line for PET wide-mouth jars includes the blow molding machine, preform feeding system, high and low-pressure air compressors, air dryers/filters, a water chiller, blow molds, and potentially conveyors and packing equipment.

When I work with clients to set up a new PET jar production, like the one wanting to switch from glass, we don't just look at the blow molder in isolation. We map out the entire line. A smooth, efficient operation depends on all the components working together.

Core Components of a PET Wide-Mouth Jar Production Line:

- PET Preforms: These are your raw material for the blow molder. You'll either purchase them from a supplier or have an in-house injection molding setup to produce them (which is a whole separate line).

- Preform Feeding System (for automatic machines):

- Hopper/Elevator: Stores and elevates preforms.

- Orientor/Unscrambler: Sorts preforms and aligns them correctly (neck up) to be fed into the heating section of the blow molder.

- Reheat Stretch Blow Molding Machine: This is the heart of the line. It takes the preforms, heats them, stretches them, and blows them into the final jar shape.

- Blow Molds: Installed within the blow molding machine. These are custom-designed for your specific jar shape and size.

- Air Supply System (The Lungs of the Operation):

- High-Pressure Air Compressor: Provides compressed air (typically 25-40 bar / 360-580 psi) for the final blowing stage, which forms the jar. The size (capacity in CFM or m³/min) depends on the machine's consumption.

- Low-Pressure Air Compressor: Provides compressed air (typically 7-10 bar / 100-145 psi) for the pneumatic operation of the blow molding machine itself (e.g., cylinder movements).

- Air Receiver Tanks: Store compressed air to ensure a stable supply.

- Air Dryers (Refrigerated or Desiccant): Essential to remove moisture from the compressed air. Wet air can cause defects in PET jars and damage pneumatic components.

- Air Filters: Remove oil, dust, and other contaminants from the air. Clean air is critical.

- Water Chiller System:

- Provides chilled water (typically 5-15°C / 41-59°F) to cool the blow molds and the preform necks during the heating process. Proper cooling is vital for cycle time, jar quality, and mold longevity. The chiller capacity is matched to the heat load of the machine and molds.

- Conveying Systems:

- Infeed Conveyors (for preforms if not directly coupled with feeder).

- Outfeed Conveyors: Transport finished jars from the blow molder to the next stage (e.g., quality inspection, labeling, filling, or packing). Air conveyors are common for empty PET containers.

- Quality Control Equipment (Optional but Recommended):

- Leak testers, vision systems for inspecting defects, manual gauges.

- Downstream Equipment (Depending on your operation):

- Labeling machines, filling machines, capping machines, packing equipment (baggers, case packers).

When budgeting for a PET jar line, it's crucial to account for all these auxiliary systems. Their cost can be a significant portion of the total investment. For example, the compressed air system alone (compressors, dryers, tanks, piping) can be quite substantial. I always advise getting detailed quotes for each component and ensuring they are correctly sized for your chosen blow molder and production targets. Proper layout planning for material flow and maintenance access is also key. Thinking about the entire line ensures you're setting up for success from day one.

What Size and Capacity of Jars Can Be Made with Your Machine?

You need to make sure the machine can handle your specific jar requirements. What sizes and capacities are typically possible, and what determines this?

Machines for PET wide-mouth jars can typically produce a range from small spice jars (e.g., 100ml) up to large food containers (e.g., 5 liters or more). The specific machine model, its clamping force, heating capacity, and mold design determine the exact size and capacity limits.

This is a critical question I address with every client, including the one looking to replace their glass jars. "Your machine" is a general term here, as different machine manufacturers and models have different specifications. However, I can outline the general capabilities and what factors you should look for when matching a machine to your jar needs.

Factors Determining Jar Size and Capacity Capabilities:

Machine Model and Specifications:

- Maximum Neck Diameter: Machines designed for wide-mouth jars will specify the largest preform neck diameter they can handle. This directly impacts the maximum opening of your jar.

- Maximum Container Volume: Manufacturers usually state a maximum theoretical container volume (e.g., up to 2 liters, up to 5 liters).

- Maximum Container Diameter and Height: There will be physical limits to how wide or tall a jar the mold clamping area and machine frame can accommodate.

- Clamping Force: Larger jars require greater clamping force to keep the mold halves securely closed against the blowing pressure. A machine with higher tonnage can generally make larger containers.

- Heating Oven Capacity: The oven must be able to effectively and evenly heat the specific size and weight of preform required for your target jar. Larger preforms need more heating power and potentially longer ovens.

Blow Mold Design:

- While the machine provides the capability, the actual jar produced is defined by the blow mold. You need a mold designed for each specific jar size and shape you want to produce.

- The number of cavities in the mold also relates to jar size. For very large jars, you might only have a single-cavity mold, even on a machine that could handle two smaller cavities.

Preform Design:

- The preform must be appropriately sized (weight, length, diameter) for the target jar. A tiny preform cannot make a huge jar, and an oversized preform will lead to issues in a small jar. Machine suppliers can often help determine the optimal preform for a given jar.

Typical Range of Jar Sizes:

- Small Jars: 100ml to 500ml (e.g., for spices, creams, single-serve foods). Many standard wide-mouth machines can handle these with multi-cavity molds.

- Medium Jars: 500ml to 2 Liters (e.g., for peanut butter, pickles, sauces, powders). These are very common, and many machines are optimized for this range.

- Large Jars: 2 Liters to 5 Liters, and sometimes even larger (e.g., for bulk food items, protein powders, institutional use). Producing these often requires larger machines with higher clamping force and specialized handling. For very large containers, single-cavity operation is common.

When my client with the five glass jar types approached me, one of their jars was a large 3-liter container. We had to ensure the machines we considered were explicitly rated for that volume and diameter. Another jar was a small 200ml one. For this, we looked at how many cavities the same machine could run to maximize output.

So, when you're talking to machine suppliers, always provide them with the detailed specifications of the jars you intend to produce:

- Volume

- Neck diameter and thread type

- Overall dimensions (height and diameter)

- Target weight

- Any special features (e.g., handle, specific base design)

This information will allow them to recommend the most suitable machine model and confirm its capability to produce your desired range of PET wide-mouth jars. It's always better to have a little more capacity than you currently need if expansion is a possibility.

How Many Bottles Per Hour Can the Machine Produce?

Efficiency is key. You need to know the production output. How many jars can a typical machine produce in an hour, and what influences this rate?

The output of a PET wide-mouth jar blow molding machine can range from a few hundred jars per hour (for semi-automatic or single-cavity machines) to several thousand per hour (for multi-cavity automatic machines). Key factors include machine type, number of cavities, and jar size/complexity.

This is always a top question, directly related to production planning and cost-effectiveness. "How many jars can I make?" is fundamental. The answer, as you might expect, varies widely.

Factors Influencing Production Rate (Jars Per Hour - JPH):

Machine Type (Automation Level):

- Semi-Automatic Machines: Output is heavily dependent on operator speed for loading preforms and removing jars. Typically, you might see rates from 300 to 1200 JPH, depending on the machine's heating capacity and the number of blowing stations (some semi-auto machines have two blowing stations fed by one heater).

- Fully Automatic Machines: These are designed for continuous production and have much higher outputs.

Number of Mold Cavities:

- This is a primary driver for automatic machines. The theoretical output is often calculated as:

(3600 seconds per hour / Cycle Time in seconds) * Number of Cavities - For example, a 4-cavity machine with a 6-second cycle time would have a theoretical output of:

(3600 / 6) * 4 = 600 * 4 = 2400 JPH - Common configurations for automatic wide-mouth jar machines are 1, 2, 4, or 6 cavities. High-speed lines for narrow-neck bottles can have many more, but for jars, the physical size often limits cavity numbers.

- This is a primary driver for automatic machines. The theoretical output is often calculated as:

Cycle Time:

- This is the total time it takes for the machine to complete one full production sequence (heating, transferring, stretching, blowing, cooling, ejecting).

- Factors affecting cycle time:

- Jar Size and Weight: Larger, thicker jars require longer heating times and longer cooling times within the mold.

- Preform Design: A well-designed preform that heats efficiently can reduce cycle time.

- Machine Efficiency: The speed of mechanical movements, efficiency of the heating oven, and responsiveness of the control system all play a part.

- Cooling Capacity: Efficient mold cooling (from the chiller) is crucial to solidify the PET quickly so the jar can be ejected without deformation, enabling shorter cycle times.

Jar Complexity:

- Simple round jars usually run faster than complex shapes or jars requiring special processing like preferential heating.

Operational Efficiency (Overall Equipment Effectiveness - OEE):

- The theoretical output is rarely achieved 100% of the time. Factors like scheduled maintenance, unscheduled downtime, mold changes, material issues, and quality checks will reduce the actual output. A good OEE for blow molding might be 80-90%.

Typical Output Ranges for Automatic Machines:

- 1-Cavity Automatic: Around 600 - 1000 JPH (often for very large jars or specialized production)

- 2-Cavity Automatic: Around 1000 - 2000 JPH

- 4-Cavity Automatic: Around 2000 - 4000 JPH

When my client needed to plan for replacing five glass jar lines, we calculated the required hourly output for each PET jar type to meet their market demand. This directly influenced our decision on the number of cavities needed for each mold and the overall capacity of the blow molding machine we'd select. For some high-volume jars, a 4-cavity setup was essential. For a lower-volume specialty jar, a 2-cavity setup on the same machine (by changing molds) was sufficient.

So, to get an accurate idea of output, you need to discuss your specific jar (size, weight, design) and your annual volume requirements with machine suppliers. They can then propose a machine and mold configuration with a realistic JPH estimate.

Is the Mold Customizable for Different Jar Shapes?

You want your jars to stand out. Can the molds be made to create unique shapes, or are you limited to standard designs? This is key for branding.

Yes, blow molds for PET wide-mouth jars are highly customizable. You can design molds to produce a vast array of shapes, including round, square, rectangular, oval, or even more irregular custom designs, incorporating features like handles or embossed logos.

Absolutely! This is one of the great advantages of PET blow molding. The ability to customize the mold allows you to create distinctive jar shapes that can enhance your brand identity and product appeal on the shelf. When I work on new PET jar projects, like the client moving from glass, unique design is often a major consideration.

How Mold Customization Works:

Jar Design Phase:

- It starts with your jar concept. This can be a sketch, a 3D model, or just an idea. You'll work with a designer (often the machine/mold supplier can offer this service, or you can use an independent design firm) to create a detailed 2D and 3D CAD model of your desired jar.

- Considerations during design:

- Functionality: Easy to hold, stable base, appropriate opening for the product, lid compatibility.

- Aesthetics: Brand look and feel, shelf impact.

- Manufacturability: The design must be blow-moldable. Very sharp corners, extreme undercuts, or impossible draw ratios might need to be adjusted. An experienced mold designer will guide this.

- Material Efficiency: Optimizing the design to use the minimum amount of PET while maintaining strength.

- Labeling Area: Flat or smoothly curved surfaces for easy label application.

- Embossing/Debossing: Logos or text can often be incorporated directly into the mold surface.

Preform Design (if a new one is needed):

- The chosen jar design will dictate the optimal preform. A new custom jar shape may require a new custom preform to ensure proper material distribution.

Blow Mold Manufacturing:

- Once the jar and preform designs are finalized, the blow mold is manufactured.

- Material: Blow molds are typically made from aircraft-grade aluminum (for good thermal conductivity and machinability) or sometimes stainless steel for certain applications or longer life.

- Cavities: The mold will have the number of cavities your machine is designed for (e.g., 1, 2, 4 cavities). Each cavity will be an exact negative of your jar shape.

- Cooling Channels: Intricate cooling channels are designed within the mold to allow chilled water to circulate efficiently, which is vital for fast cycle times and good jar quality.

- Venting: Tiny vents are incorporated to allow air trapped between the PET and the mold surface to escape during blowing.

What Can Be Customized?

- Overall Shape: Round, square, hexagonal, oval, flask-shaped, etc.

- Surface Textures: Smooth, ribbed, stippled (though smooth is most common for clarity).

- Embossed or Debossed Details: Brand names, logos, patterns, fill lines. This is a great way to add a premium feel or security.

- Integrated Handles: For larger jars, handles can be molded in.

- Stacking Features: Bases and tops designed to allow stable stacking.

I remember a client who wanted to launch a premium honey product. They wanted a jar that looked almost crystalline. We worked with a mold maker to design a hexagonal jar with very clean, sharp-looking edges (as sharp as PET allows) and an embossed bee logo on the shoulder. The custom mold was a key part of their product's success because it looked so different from standard round jars.

So, yes, customization is very much possible. The main limitations are usually the practicalities of the blow molding process itself and the cost of designing and manufacturing a more complex mold. But for creating a unique product, it's often a worthwhile investment.

Conclusion

Producing PET wide-mouth jars involves specific machines and a clear process. Understanding your options for equipment, molds, and the full production line helps you make informed decisions for your business.

Frequently Asked Questions (FAQs)

Q1: What kind of after-sales support do you (or suppliers) typically provide?

A1: Reputable machine suppliers usually offer comprehensive after-sales support. This often includes installation assistance, commissioning of the machine, operator training (on machine operation and basic maintenance), a warranty period (typically one year), access to spare parts, and technical support (phone, online, or on-site visits for troubleshooting). When I help clients choose a supplier, the quality and responsiveness of their after-sales support are major factors. It's crucial for long-term, smooth operation.

Q2: Can you (or suppliers) help design the preform and jar?

A2: Yes, many machine and mold manufacturers offer design services or have partnerships with design experts. They can help you design an optimal PET wide-mouth jar based on your requirements (volume, product type, branding) and then design the corresponding preform for best performance and material efficiency. This is a valuable service, especially if you're new to PET packaging. For my client switching from glass, we collaborated closely with the machine supplier to adapt their existing glass jar aesthetics into PET-friendly designs and ensure the preforms were perfectly matched.

Q3: What is the typical lead time for a PET wide-mouth jar blow molding machine?

A3: Lead times can vary significantly based on the supplier, the complexity of the machine, and current order backlogs. For standard semi-automatic machines, it might be 4-8 weeks. For fully automatic machines, especially if they require some customization, lead times of 3 to 6 months are common. Custom molds (both preform and blow molds) will also have their own lead times, typically 6-12 weeks, which can run concurrently with machine production.

Q4: What are the main advantages of PET jars over glass jars?

A4: The trend of switching from glass to PET, which my new client is doing, is driven by several advantages PET offers:

- Lightweight: PET jars are significantly lighter than glass, reducing transportation costs and making them easier to handle.

- Shatterproof: PET is virtually unbreakable, improving safety in production, transit, and for the end-user (especially important for food products or in households with children).

- Lower Cost: Often, PET jars can be more cost-effective to produce and transport.

- Design Flexibility: PET allows for complex shapes and designs.

- Clarity: Modern PET offers excellent transparency, similar to glass.

- Recyclability: PET is widely recycled (check local facilities).

Q5: Do I need special utilities for a PET blow molding line?

A5: Yes. Beyond standard electricity, you will need a robust compressed air system (both high and low pressure, clean and dry air) and a water chilling system. The power requirements for the machine, compressors, and chiller should be carefully planned. Some facilities might also need specific foundation requirements for larger machines, though this is less common for typical jar machines compared to very large industrial equipment.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr