Starting a new bottle project is exciting. But a tiny detail on the bottom, if overlooked, can create major problems with recycling and quality control for your business later on.

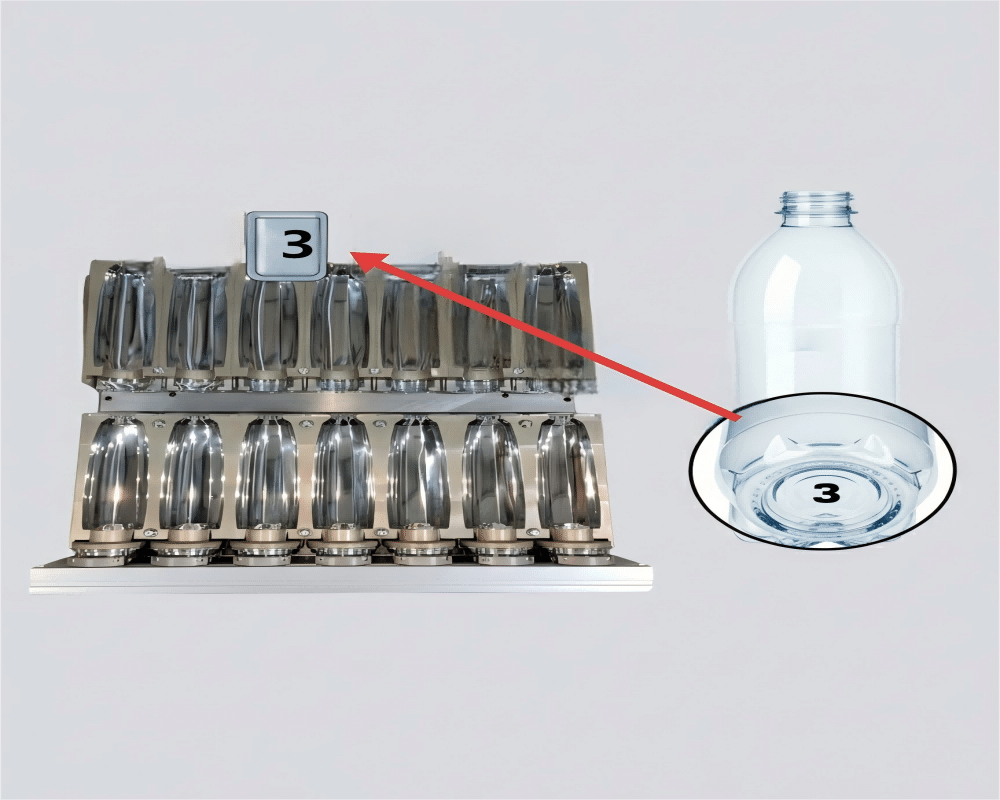

Properly specifying base markings for your new blow mold involves two key elements: including the essential, legally required recycling codes and the highly recommended cavity numbers for traceability. This simple step ensures compliance, dramatically simplifies quality control, and makes your entire production process smoother and more profitable.

I've been in the PET blow molding industry for 16 years, and I've seen how these small details can make or break a project. Many newcomers don't realize that these engravings aren't just for decoration; they are a critical part of a professional manufacturing process. Getting them right from the start is one of the easiest ways to ensure your product is successful. Let's walk through exactly what you need to know to specify these markings like a seasoned pro.

Getting Started: Why This Small Detail on the Bottle Base is So Important?

It's easy to overlook bottle base markings when you're focused on the overall bottle design. But this small oversight can lead to recycling fines and quality control nightmares down the road.

These small markings are critically important for two main reasons: legal and environmental compliance through recycling symbols, and massive operational efficiency through traceability marks like cavity numbers. They allow you to meet regulations and instantly find faulty mold cavities, saving time, money, and protecting your brand's reputation.

I remember a conversation with a new client from South Africa. We were reviewing the final drawings for his first blow bottle mold, and he pointed to the symbols on the base. He said, "I don't need these. This must be an idea from your designer, but my bottle is simple." He saw it as an unnecessary complication. I took a moment to explain the story behind those little numbers and triangles. I told him to imagine his new factory, with his shiny new bottle blowing machine running at full speed, producing thousands of bottles an hour. Then, his quality control team finds a bottle with a tiny leak. Without a number on the bottom of that bottle, he would have to shut down the entire production line. His team would then have to guess which of the mold's cavities was the bad one. This could take hours of wasted time, wasted material, and lost profit.

Then, I painted another picture. Imagine the same leaky bottle, but this time it has a small number "6" on the bottom. The operator sees it, looks at the mold, and knows immediately that cavity number 6 is the problem. The fix is quick, targeted, and production is back online in minutes instead of hours. The client was silent for a moment, and then he understood completely. He wasn't just buying a mold; he was investing in an efficient production system. That conversation taught me that what is obvious to me after 16 years is often a new and vital piece of information for my clients.

This small detail on the bottle base serves three fundamental purposes. First is legal and environmental responsibility. Governments and retailers around the world have regulations that mandate recycling information on packaging. The small chasing-arrows symbol is your product's passport, allowing it to be sold in many markets and giving consumers the information they need to recycle it correctly. Without it, you risk fines or having your product rejected by major distributors. Second is operational efficiency, as illustrated by my story. In a multi-cavity mold, which is standard for any serious production, these numbers are your roadmap for troubleshooting. They are the key to minimizing downtime and are one of the most effective tools for tracking and solving common PET blow molding defects.

Finally, these markings are about brand protection and consumer trust. A bottle that includes clear, correct information communicates professionalism. It shows you are a responsible manufacturer who cares about the product's entire lifecycle. In the rare event of a product recall, traceability marks like date wheels can help you isolate a specific batch, saving you from having to recall every single product you've shipped. This isn't just a technical detail; it's a core component of a comprehensive PET bottle mold design guide, and getting it right from the beginning is a simple step that pays dividends for years to come.

What Markings are Absolutely Essential? (The "Must-Haves")?

When you're launching a new bottle, the list of tasks can feel endless. You want to ensure you're meeting all the basic legal and industry requirements without making a costly mistake.

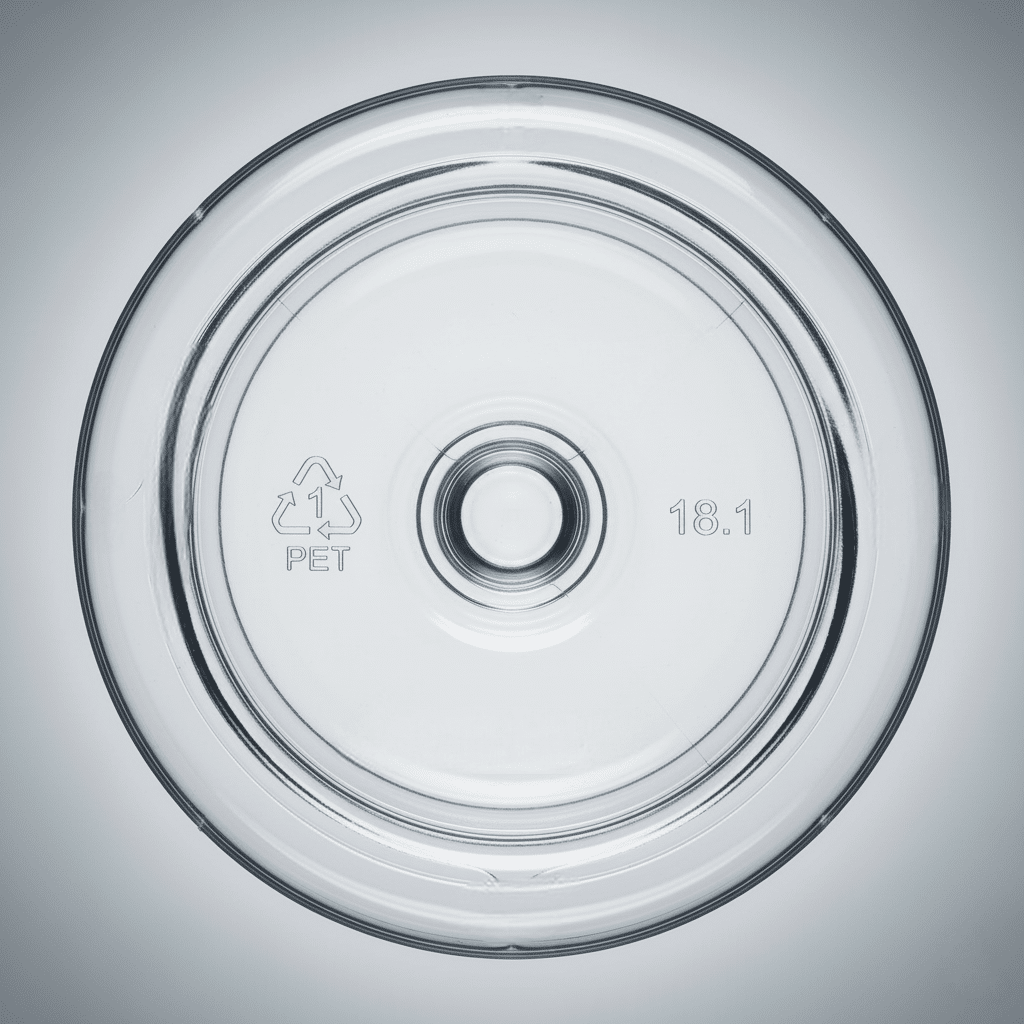

The single most essential marking you must have on your plastic bottle is the resin identification code, which is the formal name for the recycling symbol. For PET bottles, this is the number '1' inside the chasing arrows triangle, usually with "PET" or "PETE" engraved underneath.

This symbol is not just a suggestion; in many parts of the world, it's a legal requirement. It's part of a system called the SPI Resin Identification Code, which was developed by the Society of the Plastics Industry (SPI) in 1988. The purpose is simple: to help recycling facilities quickly sort different types of plastics. Each plastic has different properties and must be processed separately. Mixing plastics during recycling can ruin the entire batch of recycled material, making it worthless. This little symbol is the universal language that sorting machines and workers use to do their job correctly.

Let's break down what these codes mean. While your focus might be on PET, it's helpful to understand the whole system to see why it's so important.

The 7 Main Plastic Resin Codes

| Code | Abbreviation | Plastic Name | Common Uses in Packaging |

|---|---|---|---|

| 1 | PET or PETE | Polyethylene Terephthalate | Soft drink bottles, water bottles, food jars (peanut butter, etc.) |

| 2 | HDPE | High-Density Polyethylene | Milk jugs, detergent bottles, shampoo bottles |

| 3 | V or PVC | Polyvinyl Chloride | Rarely used for bottles today due to environmental concerns |

| 4 | LDPE | Low-Density Polyethylene | Squeezable bottles, plastic films and wraps |

| 5 | PP | Polypropylene | Ketchup bottles, yogurt containers, medicine bottles |

| 6 | PS | Polystyrene | Disposable cups, take-out containers (not typically blow-molded) |

| 7 | OTHER | Other Plastics | Multi-layer bottles, various other plastics not in 1-6 |

As you can see, your PET bottle falls squarely into category #1. This is the most widely recycled plastic in the world, primarily for beverage containers. When you specify this symbol for your mold, you are doing three things at once. First, you are complying with packaging regulations. Second, you are enabling your bottle to have a second life. When a consumer puts your bottle in their recycling bin, the sorting facility can easily identify it as valuable PET and route it to the correct processing stream. This material can then be turned into rPET (recycled PET), which can be used to make new bottles or other products like textiles and carpeting. Third, you are signaling to your customers that you are an environmentally responsible brand, which is an increasingly important factor in purchasing decisions.

When you give instructions to your mold maker, you need to be specific. Don't just say "add the recycling symbol." You should state clearly: "Please engrave the standard SPI Code 1 symbol with the text 'PET' on the base of each cavity." This removes any ambiguity and ensures you get exactly what you need. This is a non-negotiable, foundational requirement for almost any PET bottle entering the market today.

What Markings are Highly Recommended? (The "Smart-to-Haves")?

You have covered the legal basics with the recycling symbol. But what simple, nearly-free addition to your mold can save you thousands of dollars in troubleshooting and lost production time?

The single most valuable recommended marking is the mold cavity number. By engraving a unique number (e.g., 1, 2, 3...) on the base corresponding to each cavity in the mold, you create instant traceability that allows you to pinpoint the source of quality issues in seconds.

This is the point I stress most with new clients, like the one I mentioned from South Africa. The value of this tiny number is difficult to appreciate until you've experienced a production problem without it. Let me paint a more detailed picture with a story of two hypothetical factories.

Factory A: The Factory of Guesswork

Factory A decides to save a tiny amount of time and effort by not adding cavity numbers to their new 16-cavity blow bottle mold. Production starts, and everything looks great. An hour later, a quality inspector pulls a bottle from the line and finds a thin, almost invisible line of plastic near the base—a sign of a potential leak. The line is stopped. The maintenance manager is called over. They have 16 identical cavities sitting inside a very hot mold. Where did the bad bottle come from? They have no idea.

Their process is now a painful one:

- They shut down the multi-thousand-dollar bottle blowing machine, and production of thousands of bottles per hour grinds to a halt.

- They must wait for the mold, which runs at high temperatures, to cool down enough to be safely opened and inspected. This can take a significant amount of time.

- A technician then has to visually inspect every single one of the 16 cavities, looking for a tiny scratch or flaw in the steel that could be causing the problem. This is like finding a needle in a haystack.

- After maybe an hour or two of searching, they find the culprit, fix it, and then begin the slow process of heating the mold back up to operating temperature.

In this scenario, hours of production are lost, thousands of potentially bad bottles that were made before the problem was found have to be quarantined or scrapped, and the entire team is frustrated.

Factory B: The Factory of Precision

Factory B invested in adding cavity numbers. When their quality inspector finds the exact same defect, they turn the bottle over and see a small "12" engraved on the bottom. The entire situation changes.

- The inspector immediately reports, "We have a defect coming from cavity 12."

- The maintenance manager knows exactly where to look. They can stop the machine for a very short period, go directly to the 12th cavity, address the issue, and restart production.

- The downtime is reduced from hours to mere minutes. The amount of wasted product is minimal because the problem was identified and located so quickly.

This isn't just about one incident. Over the life of a mold, which can be millions of cycles, this time savings adds up to a tremendous amount of money. Furthermore, it allows for data-driven quality control. Your team can log defects by cavity number. If you notice that 70% of your defects over a month come from cavity #12, you know there is a deeper problem with that specific cavity—perhaps a cooling channel is clogged or a component is wearing out—that needs a more permanent solution. This is how you move from being reactive to being proactive in your maintenance, which is the hallmark of a modern, efficient factory. Adding this number is one of the smartest and cheapest forms of insurance you can buy for your production line.

Understanding the Symbols: What Do These Markings Actually Mean for You?

You see symbols and numbers on the bottom of every plastic bottle you pick up. But what's the real story they tell? For a brand owner, they are a language that speaks to regulators, consumers, and your own production team.

Recycling symbols are your statement of compliance and environmental stewardship, ensuring your bottle can be legally sold and properly recycled. Cavity numbers are your internal secret weapon for quality control, giving you a direct line to trace any defect back to its exact origin in seconds.

Let's decode the deeper meaning of these marks for every stakeholder involved in your bottle's journey, from the factory floor to the recycling bin. Understanding these perspectives is key to appreciating why this is not just a technical step, but a strategic one.

The Recycling Symbol's Story: A Public Promise

- For the Regulator: When a government agency or environmental authority sees the #1 PET symbol on your bottle, it's a simple checkmark. It means your product is properly identified according to packaging laws. It tells them you have done your due diligence and are participating correctly in the waste management ecosystem. For them, it means compliance.

- For the Consumer: For the average person, this symbol is a clear, simple instruction. It cuts through confusing language and says, "I am made of a valuable, recyclable material. Please put me in the correct bin so I can be used again." This empowers the consumer to act responsibly and builds a positive association with your brand. A brand that makes recycling easy is seen as a brand that cares.

- For the Recycling Facility: This symbol is the starting point for their entire business process. At a modern Material Recovery Facility (MRF), bottles fly down conveyor belts at incredible speeds. Optical sorters scan the bottles and identify them by the type of plastic they are made of. The engraved symbol is a universal, reliable confirmation. It ensures your PET bottle joins the stream of other PET bottles, where it can be cleaned, shredded, and turned into valuable rPET flakes. Without this symbol, your bottle becomes a contaminant and is likely destined for a landfill. The symbol is its ticket to a second life.

The Cavity Number's Story: An Internal Diagnostic Tool

- For the Machine Operator: On the front lines of production, the cavity number is a tool of clarity. When a bad bottle appears, there is no panic or guesswork. The operator simply looks at the number, reports it, and knows that a solution is on the way. It turns a potentially stressful shutdown into a routine, manageable task. It empowers them to be an active part of the quality control process.

- For the Quality Manager: This number is a single, powerful data point. When collected over time, these data points tell a story. The quality manager can create charts that track the performance of every single cavity. They can see trends, such as "Cavity #4 starts producing bottles with a slight haze after 3 hours of continuous operation," which might indicate a localized cooling issue. This transforms quality control from random inspection into a science. It allows for predictive maintenance, where problems are fixed before they even lead to defects. This data is invaluable for troubleshooting any of the many possible common PET blow molding defects.

- For the Business Owner: Ultimately, the cavity number translates directly to the bottom line. It means less material waste, significantly less machine downtime, higher overall output, and a more reliable and predictable production process. It is a tiny feature that costs virtually nothing to implement in a new mold, yet it protects the entire manufacturing investment. In my experience, the most successful and profitable bottling operations are the ones that are obsessive about these kinds of details. They understand that operational excellence begins with superior tools, and a numbered mold is a superior tool.

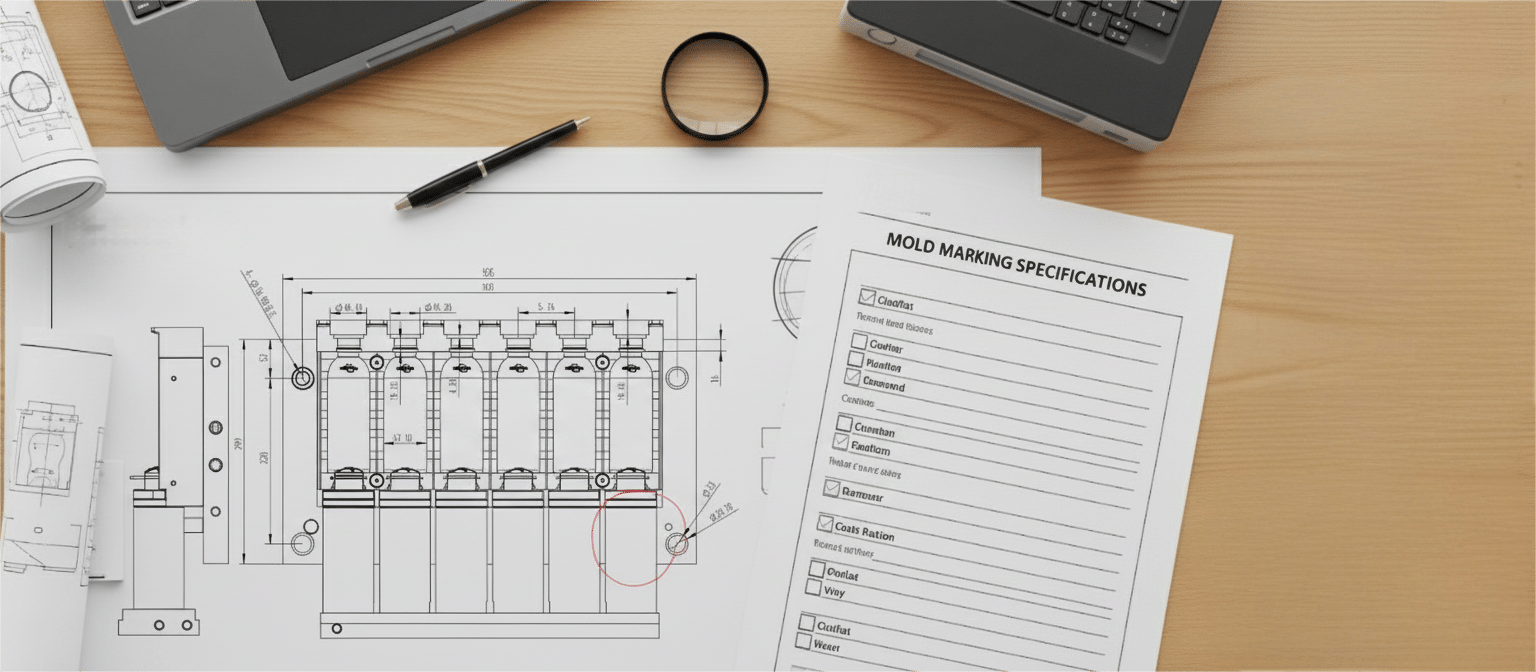

How to Give Clear Instructions to Your Mold Factory (A Simple Checklist)?

You understand the importance of the markings and you know exactly what you need. But how do you communicate this information to your mold supplier to ensure that nothing gets lost in translation?

Avoid verbal or vague requests. Provide your mold factory with a simple, written specification sheet or checklist. Clearly state the exact recycling symbol required, the full range of cavity numbers, and the precise placement for any custom logos to eliminate ambiguity.

The biggest source of error in manufacturing is not poor workmanship; it's poor communication. Your mold maker is an expert in machining steel, but they are not an expert in your specific brand requirements or the local regulations of your target market. A vague instruction like "add the standard markings" leaves too much room for interpretation. One person's "standard" might be different from another's. Clarity is your responsibility as the client, and it is the key to getting exactly what you want.

To make this process foolproof, I always advise my clients to put their requirements in a simple email or document that can be referenced by everyone involved. Think of it as a mini-contract specifically for the base markings. This document should be sent to the supplier and you should request that they confirm it and, most importantly, incorporate the details into the final mold drawing that you approve before any steel is cut.

Here is a template you can adapt and use. It's designed to be simple, direct, and unambiguous.

Template: Base Marking Specification Sheet

To: [Mold Supplier's Name/Engineering Department]

From: [Your Name/Company]

Date: [Current Date]

Project: [Your Project Name, e.g., 500ml Round Water Bottle]

Purchase Order #: [Your PO Number, if applicable]

Subject: Mandatory Base Marking Specifications for New Blow Mold

Dear Team,

Please find below the precise specifications for the engravings on the base of our new blow bottle mold. We request that a detailed view of the base layout, including these markings, be included in the final design drawings for our formal approval.

1. Recycling Symbol (Mandatory Requirement):

- Symbol Type: SPI Resin Identification Code #1. This must be the standard three chasing arrows forming a triangle with the numeral "1" in the center.

- Text Underneath Symbol: "PET"

- Placement: Please position this symbol prominently on the bottle base, away from the center gate point, as per common industry standards for legibility.

2. Cavity Numbers (Mandatory Requirement):

- Mold Configuration: This is a [e.g., 8]-cavity mold.

- Numbering Scheme: Please engrave sequential numbers from "1" to "[e.g., 8]". Each cavity must be marked with its own unique number.

- Font and Size: Use a simple, clean, sans-serif font (e.g., Arial). The character height should be approximately 3mm for clear legibility.

- Placement: Please position the cavity number near the outer perimeter of the base.

3. Brand Logo (If Applicable):

- File Attached: [e.g., "OurLogo_V3.step"]

- Placement: Please engrave our brand logo in the direct center of the bottle base.

- Size: The logo should be scaled to a maximum diameter of [e.g., 20mm].

Please confirm receipt of these instructions. We look forward to reviewing them on the approval drawing.

Thank you,

[Your Name]

The Golden Rule: If it's not on the drawing, it doesn't exist. A verbal conversation or a brief email is not enough. The final, approved engineering drawing is the single source of truth for the project. Before you sign off, use a red pen or digital markup tool to circle the base markings on the drawing and check them against your specification sheet. This final check is your last chance to catch an error before it's permanently machined into a very expensive piece of steel. This disciplined approach, which is a core part of any good PET bottle mold design guide, prevents costly mistakes and ensures a smooth production start.

A Quick Note on Logos, Date Wheels, and Other Custom Marks?

You have mastered the essential markings for compliance and quality control. Now, let's explore how you can make the base of your bottle work even harder for your brand and your operations.

Beyond the basics, you can add custom marks like your brand logo to increase recognition, or functional marks like date wheels. Date wheels are modular inserts that stamp production dates onto bottles, providing critical traceability for batch control and shelf-life management.

While the recycling symbol and cavity number are about fundamentals, these custom marks are about adding value. They can elevate your packaging from a simple container to a more sophisticated and informative brand asset. Let's look at the most common options.

1. Your Brand Logo

This is the most popular custom mark. Engraving your logo on the base of the bottle is a subtle but powerful way to reinforce your brand identity. It communicates a sense of quality and ownership over the entire package.

- Purpose: Branding, professionalism, and reinforcing brand ownership.

- How it's Done: You will need to provide your mold maker with a vector-based digital file of your logo. The best formats are STEP or DXF, as these can be read directly by the CNC milling machines that cut the mold. Avoid sending pixel-based files like JPG or PNG.

- Expert Tip: Simpler is better. Highly intricate logos with very fine lines or small text may not reproduce cleanly in the molding process. Bold, clean logos work best. Also, discuss the engraving depth with your designer. An engraving that is too deep can potentially create a weak spot in the bottle. A skilled designer knows how to balance visual appeal with structural integrity.

2. Date Wheels: The Ultimate Traceability Tool

For many industries, especially food, beverage, and pharmaceuticals, a date wheel is not just an option; it's a necessity.

- What it is: A date wheel is a precision-made, interchangeable insert that fits into the mold base. It consists of multiple concentric rings (or a central pointer with an outer ring) that can be manually rotated to indicate the year, month, and day of production.

- How it Works: Before starting a production run, a machine operator or technician uses a special tool to turn the inserts to reflect the current date. Every bottle produced during that shift or day will now have that specific date permanently molded into its base.

- Why it's a Game-Changer:

- Batch Control: It allows you to track exactly when a product was made.

- Food Safety & Shelf Life: It's essential for managing "best by" or "expiration" dates.

- Efficient Recalls: Imagine you discover an issue with a batch of ingredients used on a specific Tuesday. With a date wheel, you can issue a targeted recall for only the bottles marked with that date, rather than having to recall months' worth of product. This can save your company from financial disaster and immense brand damage.

3. Other Custom Markings

The possibilities are broad, and can be tailored to your specific operational needs.

- Plant or Production Line Codes: If your product is made in multiple factories or on multiple lines, a simple code (e.g., "F1" for Factory 1, "L2" for Line 2) can be added for even more granular traceability.

- Material Information: For brands focused on sustainability, you can engrave messages like "100% rPET" or "Please Recycle" to communicate your environmental commitment directly to the consumer.

- Dot Molds (for Preforms): A similar traceability concept exists for the preform mold itself, where tiny dots on the gate point of the preform identify which cavity it came from. This allows quality control to start even before the bottle is blown.

Adding these custom features is easiest and most cost-effective when done during the initial mold design phase. Thinking about these options early, and even validating them with 3D printed samples, ensures they are integrated perfectly into the final tool.

A Litmus Test for a Professional Supplier: Proactive Communication About Markings?

How can you identify a top-tier mold supplier from an average one, even before you have spent any money? The answer is surprisingly simple: listen to the questions they ask you.

A truly professional mold supplier will not passively wait for your instructions. They will proactively ask you about your requirements for recycling codes, cavity numbering, regional standards, and traceability during the initial design review. Their questions demonstrate their experience and their investment in your success.

In my 16 years of business, I have seen that suppliers generally fall into one of two categories. Recognizing which category a potential partner falls into can save you from immense frustration.

The Passive Order-Taker

This type of supplier functions like a vending machine. You give them a design, they give you a price. They will build exactly what is on your drawing, and nothing more. If you forgot to add the legally required recycling symbol for your market, that is your problem, not theirs. If you didn't ask for cavity numbers, you won't get them. They fulfill the letter of the contract, but they don't look out for your best interests. This approach is incredibly risky for you as the client, especially if you are new to the industry. You don't know what you don't know, and a passive supplier will let you make critical mistakes.

The Proactive Partner

A proactive supplier sees your project's success as their own success. When you send them your bottle design, their engineering team will review it and come back to you with thoughtful questions. Their communication will sound something like this:

- "We see your company is based in Europe. We should use the standard PET symbol, and would you also like to add a food-safe symbol if this is for beverages?"

- "This is a 12-cavity mold design. We strongly recommend adding cavity numbers 1 through 12 on the base for quality control. We have included this in our draft drawing for your review."

- "To ensure a perfect fit in your machine, could you confirm the model? We have a large database of mounting dimensions for 80% of blow molding machines worldwide and can guarantee compatibility."

This kind of communication is the single biggest indicator of a supplier's expertise and professionalism. It shows that they have been through this process hundreds of times and have learned to anticipate the needs and potential pitfalls their clients might face.

How to Use This as a Vetting Tool

As you evaluate potential mold suppliers, make this a conscious part of your screening process. During your first technical calls or email exchanges, pay close attention.

- Do they bring up the topic of base markings themselves?

- Do they ask about your target market to ensure compliance?

- Do they explain why they recommend certain features, like cavity numbers?

- Do they talk about the whole system, including the need for a proper chiller or an efficient air system?

If a supplier remains silent on all these points and simply returns a price, consider it a major red flag. It may suggest a lack of experience, a focus on cutting corners, or a business culture that is not centered on the client's long-term success. A supplier who guides you through these details isn't just selling you a mold; they are investing their expertise in your product's quality, compliance, and ultimate market success. This partnership is the true foundation of a successful project.

Conclusion: A Clear Request is the First Step to a Perfect Mold?

We have journeyed through the what, why, and how of specifying bottle base markings. So, what is the single most important lesson to take with you for your next project?

The quality of your final mold begins with the quality of your initial request. Providing a clear, detailed, and unambiguous specification for your base markings sets a professional tone for the entire project and prevents costly, irreversible errors from the very start.

As the client, you are the leader of your project. Never assume your supplier knows what is in your head. Your clarity is what drives a successful outcome. The process we have discussed is a microcosm of the entire mold-making journey. It starts with you, the brand owner, having a clear vision, and then communicating that vision effectively to your technical partners.

Let’s recap the key takeaways in a simple, final summary table. This is your cheat sheet for specifying base markings on every project moving forward.

Final Summary of Bottle Base Markings

| Marking | Category | Purpose | My Expert Advice |

|---|---|---|---|

| Recycling Symbol (e.g., #1 PET) | Essential (Must-Have) | Legal Compliance, Environmental Responsibility, Consumer Information | This is non-negotiable. Always specify the exact code for your plastic material. In most countries, this is your product's license to be on the shelf. |

| Cavity Number (e.g., 1, 2, 3...) | Highly Recommended (Smart-to-Have) | Quality Control, Defect Traceability, Production Efficiency | This is the highest ROI feature you can add. It costs nothing in a new mold and will save you thousands of dollars and countless hours of downtime over the life of the tool. |

| Brand Logo | Optional (Value-Add) | Brand Recognition, Professionalism, Brand Ownership | A fantastic way to enhance your product's perceived quality. Use a clean, bold design and provide it in a proper vector format (STEP or DXF) for the best results. |

| Date Wheel Insert | Optional (Value-Add) | Batch Control, Food Safety, Recall Management, Traceability | If your product is for human consumption (food, beverage, pharma) or has a defined shelf life, I consider this an essential tool for protecting your business and your customers. |

Do not be intimidated by these technical details. By taking the time to create a clear set of instructions for something as seemingly small as base markings, you are establishing a standard of precision and thoroughness for the entire project. You are telling your supplier that you are a professional who values details, and this will elevate the quality of the work you receive in return. A clear request is always the first, and most important, step toward a perfect mold.

Conclusion

Properly specifying base markings isn't a small detail; it's a foundational step. It ensures your product is compliant, streamlines your quality control, and sets the stage for a successful launch.

Frequently Asked Questions (FAQ)

1. Is there an international standard that dictates the size and placement of recycling symbols on bottles?

There is no single, rigid international standard for the exact size and placement, which often leads to slight variations. However, the SPI Resin Identification Code system itself (the chasing arrows with the number) is the globally accepted convention. The best practice is to make the symbol large enough to be clearly legible on the base of the bottle, typically ranging from 8mm to 15mm in height, depending on the base diameter. A good mold supplier will be able to recommend a suitable size based on your specific bottle design.

2. How does a "date wheel" insert work in a blow mold, and is it expensive to add?

A date wheel is a precision-machined, modular insert that fits into a pocket cut into the mold base. It typically has rotatable rings or an arrow that can be manually adjusted to point to the correct day, month, and year. The cost to add a date wheel to a new mold is relatively low, as the pocket is machined during the primary manufacturing process. However, trying to retrofit a date wheel into an existing, hardened steel mold is much more complex and expensive, as it requires specialized machining. It is far more cost-effective to include it in the initial design.

3. Can deep engravings for markings on the bottom of the mold create weak points in the final bottle?

Yes, this is a valid concern. Any sharp internal corners or excessively deep engravings can act as "stress concentration points" in the plastic, potentially making the base of the bottle weaker and more susceptible to cracking under pressure or upon impact. However, an experienced mold designer mitigates this risk by using appropriate engraving depths (deep enough to be clear, but not structurally compromising) and by designing the engraved characters and logos with rounded (radiused) corners instead of sharp ones. This allows the plastic to flow more smoothly and reduces stress.

4. If I need to change a logo on the mold base later, is it possible to modify the existing mold?

Yes, it is possible, but it requires skilled toolmaking work. The typical process involves TIG welding to fill the cavity of the old logo with a matching tool steel. The area is then carefully machined flat again. Finally, the new logo is CNC-engraved into the repaired area. While feasible, this modification is significantly more expensive and time-consuming than getting the logo right during the initial mold build. It's a good option if a rebrand is necessary, but it's best to finalize your logo before cutting steel.

5. What file format (e.g., DXF, STEP) should I provide to the mold manufacturer for my custom logos or symbols?

You should always provide custom logos or symbols in a vector-based format. The most common and preferred formats in the industry are STEP (.stp or .step), which is a 3D model format, or DXF (.dxf), which is a 2D vector format. These files contain mathematical lines and curves, which a CNC machine can read directly to create precise toolpaths for engraving. You should avoid sending pixel-based formats like JPEG (.jpg), PNG, or BMP, as these have to be manually traced by the mold designer, which can introduce errors and increase costs.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr