You are running a high-speed production line, but frequent stops for mold maintenance are killing your efficiency. The problem always seems to be the same: the bottom of the mold is worn out again, causing quality issues.

The primary reason for premature blow mold failure is wear and tear on the mold base. We solve this by incorporating a high-hardness stainless steel insert into the aluminum mold body. This hybrid design absorbs impact and abrasion, dramatically extending the mold's lifespan and ensuring consistent bottle quality.

I've been in the PET blow mold manufacturing business for over 20 years. Our factory, Zhongshan Jindong Machinery Co., Ltd. (branded as iBottler), was one of the first in China to specialize in this field. Over these two decades, I've seen countless molds come and go. I've listened to feedback from hundreds of customers, and one story kept repeating itself: the mold bottom always fails first. This isn't just an inconvenience; it's a major drain on resources and productivity. That's why we dedicated ourselves to finding a permanent solution. This article explains the journey, the engineering behind our decision, and why this one small detail makes a world of difference for your investment.

A universal problem: why is the mold base the first point of failure?

Your production line is humming, then suddenly an alarm sounds. The line stops. You find out a blow bottle mold needs urgent maintenance. This downtime is frustrating and costly.

The mold base is the weakest link in the entire blow molding process. It consistently fails before any other part. This single point of failure causes production delays, increases maintenance costs, and can even lead to inconsistent bottle quality that hurts your brand's reputation.

Let's dive deeper into the technical reasons behind this persistent problem. The mold base is subjected to a brutal combination of forces that no other part of the mold experiences with the same intensity. We can break this down into two main culprits: high-frequency mechanical impact and high-pressure sealing abrasion.

The Hammer Effect: High-Frequency Mechanical Impact

Think of your bottle blowing machine as a high-speed mechanical hammer. The two halves of the mold clamp together with incredible force, thousands of times per day. For a machine running at 1,000 bottles per hour per cavity, that's 24,000 impacts in a single day. Over a year, we're talking about millions of cycles.

The mold base, specifically the bottom sealing surface, bears the brunt of this impact. Every time the mold closes, the two bottom faces slam together to create a perfect seal around the preform. This repetitive, high-force collision is mechanically identical to hitting a piece of metal with a hammer over and over again. This process leads to several types of material fatigue and failure:

- Micro-Deformation: Even though you can't see it with the naked eye, each impact causes a tiny deformation in the metal. Over millions of cycles, these microscopic changes add up. The soft aluminum begins to "mushroom" or flatten out, changing the critical dimensions of the sealing surface.

- Work Hardening and Brittleness: In some metals, this repeated impact can cause work hardening, making the surface more brittle. This can lead to the formation of micro-cracks, which eventually grow and can cause parts of the mold base to chip or flake off.

- Alignment Issues: As the base deforms, it can affect the overall alignment of the mold halves. This misalignment can lead to uneven clamping pressure, which exacerbates wear on other parts of the mold and can cause bottle defects like uneven wall thickness.

I remember a client in the beverage industry who was using standard all-aluminum molds. They were calling us every four to six months for a major mold overhaul. Their maintenance team was constantly re-polishing and sometimes even re-machining the mold bottoms. The downtime was a nightmare for their production schedule. When we analyzed their failed molds, the evidence was clear: the aluminum on the bottom had deformed by a measurable amount, leading to a poor seal and leaky bottles.

The Sandpaper Effect: High-Pressure Sealing Abrasion

Once the mold is clamped shut, the next stage is injecting high-pressure air, often up to 40 bar (or 580 PSI), into the preform. This high-pressure air forces the hot, soft PET plastic to expand and take the shape of the mold cavity. The mold base has the critical job of sealing the bottom of the preform to prevent this high-pressure air from escaping.

This sealing action creates a significant amount of abrasive wear. The bottom edge of the preform is pressed against the mold base with immense force. Any tiny imperfections or dust particles trapped between the preform and the mold act like sandpaper. This constant, high-pressure rubbing slowly grinds away the surface of the mold base.

Here's a breakdown of the abrasive forces at play:

| Force Component | Description | Consequence on an Aluminum Base |

|---|---|---|

| Direct Pressure | High-pressure air forces the preform edge directly onto the mold base surface. | Causes gradual compression and material loss. |

| Frictional Rubbing | As the pre-form stretches, there can be slight movements against the seal surface. | Creates scratches and grooves, degrading the seal quality. |

| Thermal Cycling | The mold base is rapidly heated by the preform and then cooled. | This can cause microscopic expansion and contraction, adding to material stress. |

Aluminum, being a relatively soft metal, is particularly vulnerable to this kind of abrasive wear. Over time, a groove or a worn patch develops on the sealing surface. Once this happens, the seal is no longer perfect. High-pressure air can begin to leak, leading to a host of common PET blow molding defects. This is one of the most common reasons we see for declining bottle quality in high-volume production. The bottom line is that the combination of being hammered shut and sand-papered by the sealing process makes the mold base the sacrificial part of the system, destined for a short life unless it's made from a much stronger material.

The material dilemma: are all-aluminum or all-steel molds the answer?

You need a new mold. The salesperson offers you two options: a cheaper, faster all-aluminum mold or a durable, expensive all-steel mold. Which one do you choose? It feels like a trap.

You're forced to compromise. Choosing an all-aluminum mold means accepting frequent wear and tear. Choosing an all-steel mold means sacrificing production speed and paying a higher upfront cost. Neither option is ideal for a manufacturer who needs both durability and efficiency to stay competitive.

This choice has been a fundamental challenge in the mold-making industry for decades. As a factory that has built thousands of blow bottle mold sets, we at Jindong have had to master the properties of both materials. To truly understand why neither is a perfect solution on its own, we need to look at their characteristics in detail. It’s a classic engineering trade-off between thermal performance and mechanical durability.

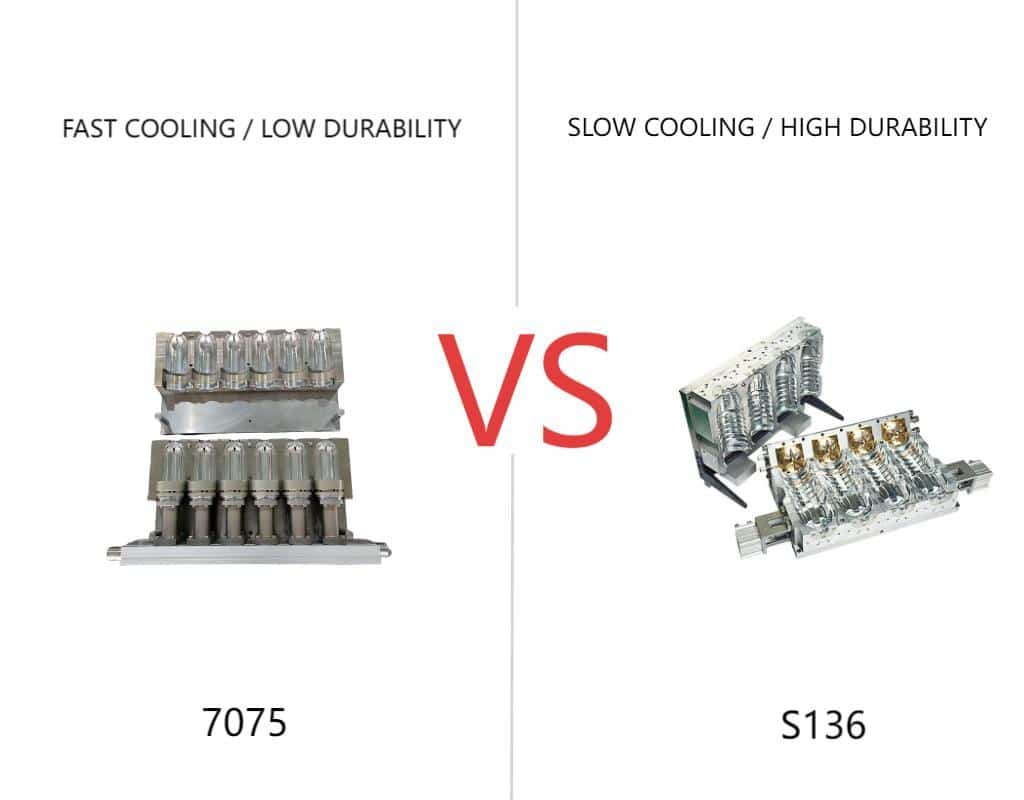

The Case for All-Aluminum Molds

The primary advantage of aluminum, specifically high-grade aviation aluminum alloys like 7075, is its exceptional thermal conductivity. In blow molding, speed is money. The faster you can cool the molded bottle from its molten state to a solid, stable form, the shorter your cycle time can be. A shorter cycle time means more bottles produced per hour.

Let's look at the numbers. The thermal conductivity of 7075 aluminum is around 130 W/mK (Watts per meter-Kelvin). For comparison, P20 steel, a common mold steel, has a thermal conductivity of only about 29 W/mK. This means aluminum can transfer heat away from the hot PET plastic more than four times faster than steel. This rapid cooling is essential for several reasons:

- Shorter Cycle Times: The cooling phase is often the longest part of the blow molding cycle. Faster cooling directly translates to higher output. This is why aluminum is the preferred material for high-volume applications like water and CSD (carbonated soft drink) bottles. A dedicated chiller connection is crucial to maximize this advantage.

- Improved Bottle Clarity: Rapid, even cooling helps prevent the formation of large crystal structures in the PET, resulting in a clearer, more transparent bottle.

- Lighter Weight and Easier Handling: Aluminum is about one-third the density of steel. A lighter mold is easier for technicians to handle, faster to install, and puts less strain on the clamping mechanism of the bottle blowing machine.

However, this amazing thermal performance comes at a steep price in terms of durability. Aluminum is a soft metal. On the Rockwell hardness scale, 7075 aluminum typically measures around 87 HRB, while hardened P20 steel can be over 30 HRC (which is significantly harder). This softness means it is highly susceptible to the impact and abrasion we discussed earlier. The sealing surfaces dent, the parting lines wear down, and the mold's lifespan is inherently limited, especially in high-volume, 24/7 operations.

The Case for All-Steel Molds

On the other side of the spectrum, we have all-steel molds. Their main selling point is raw strength and durability. Steel is incredibly hard and wear-resistant. A well-made steel mold can withstand millions upon millions of cycles with minimal degradation of its critical surfaces.

This makes steel the go-to choice for specific applications:

- Molds with Long, Thin Cores: For bottles with complex shapes or very narrow sections, the strength of steel is needed to prevent core deflection under pressure.

- Abrasive Resins: When molding materials other than PET that might be more abrasive, steel is a necessity.

- Lower Volume, High-Value Products: For applications where cycle time is less critical than absolute mold longevity (e.g., custom cosmetic jars), steel is a viable option.

But this durability comes with significant downsides for high-speed PET bottle production:

- Slow Cooling and Longer Cycles: As mentioned, steel's poor thermal conductivity is its Achilles' heel. The slow heat transfer means longer cooling times are required, which extends the overall cycle time and reduces output.

- Higher Cost: Steel is more expensive as a raw material, and it is much harder and slower to machine. The time and tooling costs for creating a steel mold are substantially higher than for an aluminum one.

- Heavy Weight: A steel mold can be three times heavier than an identical aluminum mold. This requires more robust lifting equipment, puts more stress on the molding machine, and can even limit the size of the mold that can be run on a particular machine.

Here is a summary of the trade-offs:

| Feature | All-Aluminum Mold | All-Steel Mold | The Ideal Scenario |

|---|---|---|---|

| Thermal Conductivity | Excellent (Fast Cooling) | Poor (Slow Cooling) | Excellent |

| Durability / Wear Resistance | Poor | Excellent | Excellent |

| Weight | Light | Heavy | Light |

| Machining Speed | Fast | Slow | Fast |

| Initial Cost | Lower | Higher | Lower |

| Typical Lifespan | 1.5 - 3 Million Cycles | 10+ Million Cycles | 5-8+ Million Cycles |

This table clearly illustrates the dilemma. For years, manufacturers had to choose one set of benefits and accept the corresponding set of drawbacks. If you wanted speed, you sacrificed lifespan. If you wanted lifespan, you sacrificed speed. This was the accepted reality of the industry. But at Jindong (iBottler), based on decades of customer feedback, we refused to accept this compromise. We knew there had to be a better way.

The innovative solution: how does a hybrid design provide the best of both worlds?

You feel stuck between choosing a fast but fragile aluminum mold or a tough but slow steel one. What if you didn't have to compromise? Imagine a mold that combines the best qualities of both materials.

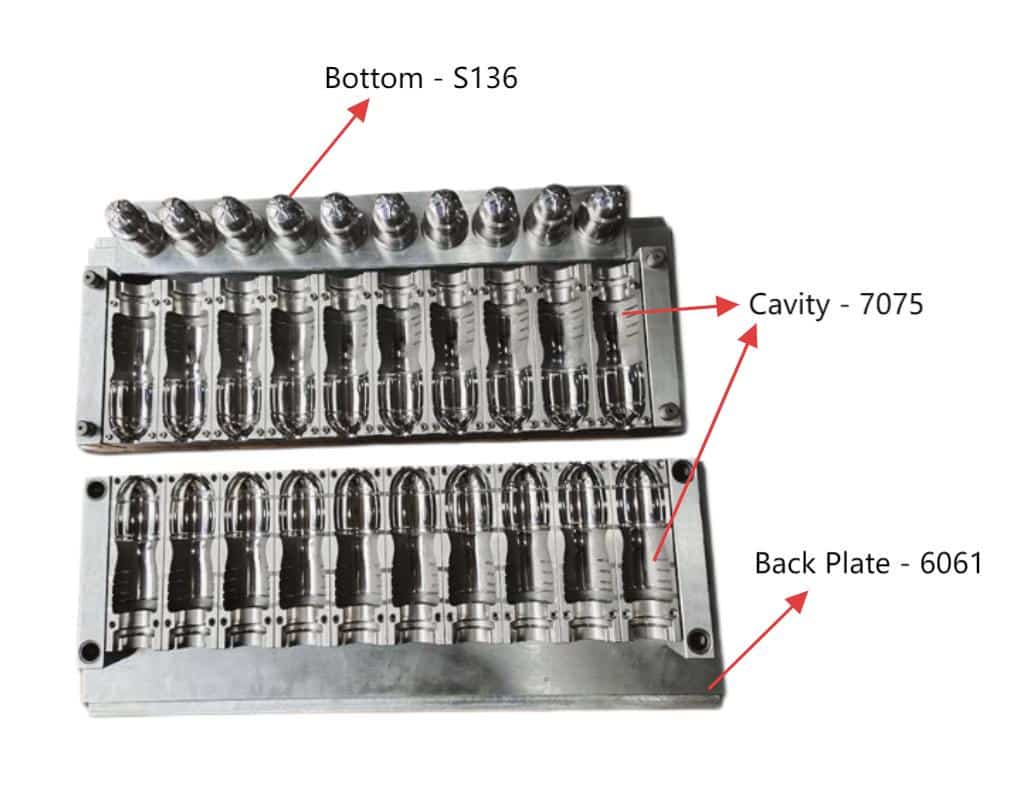

We developed a hybrid design that gives you exactly that. Our engineering philosophy at Jindong is simple: use the right material for the right job. We combine a lightweight, fast-cooling aviation aluminum body with a super-hard stainless steel base insert. This gives you the speed of aluminum and the durability of steel in one mold.

This concept of a "bi-metal" or hybrid design isn't just a gimmick; it's a fundamental shift in how to approach blow mold construction. It stems from a core engineering principle we live by at Jindong (iBottler): don't force a single material to do everything. Instead, analyze the specific function of each component and select the material that is perfectly optimized for that task.

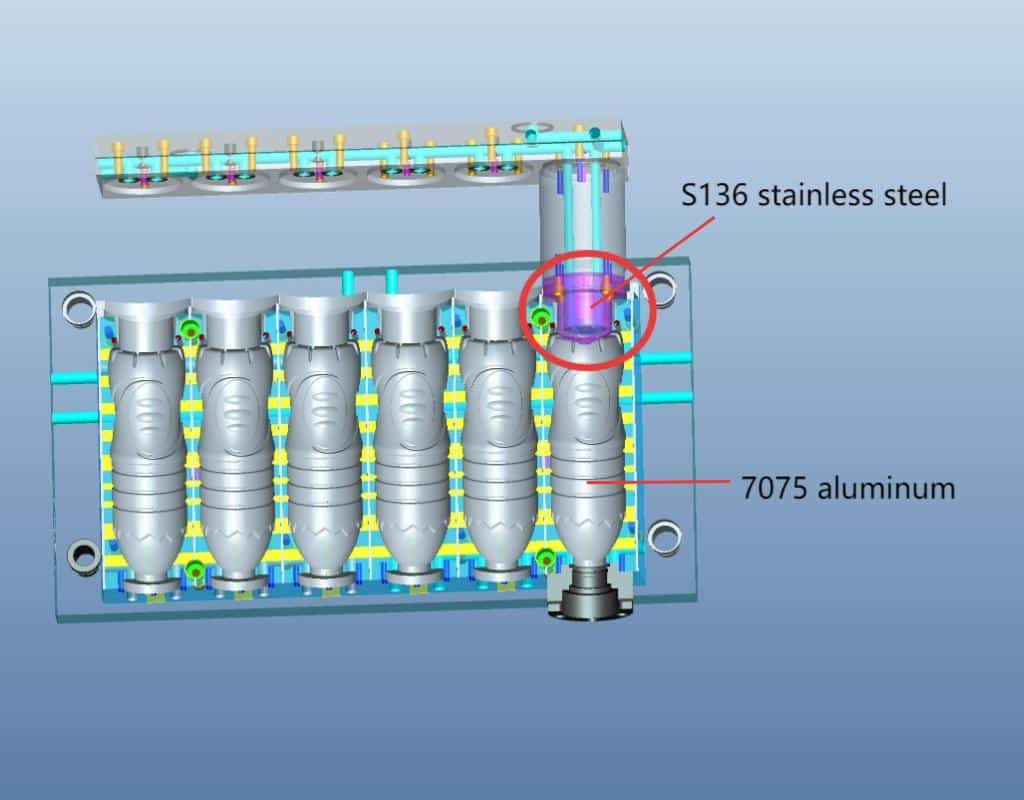

Our Engineering Philosophy: Optimized Material for Each Function

A blow mold is not a single, uniform block. It's a system with different parts performing very different jobs.

- The Mold Body: Its primary job is to define the shape of the bottle and, most importantly, to remove heat from the PET as quickly as possible. The goal here is maximum thermal conductivity.

- The Mold Base/Sealing Surface: Its primary job is to withstand immense, repetitive mechanical impact and high-pressure abrasion. The goal here is maximum hardness and wear resistance.

When you look at it this way, using a single material for the entire mold is a huge compromise. All-aluminum molds sacrifice the durability of the base for the thermal performance of the body. All-steel molds sacrifice the thermal performance of the body for the durability of the base. Neither is optimal.

Our solution is to de-couple these functions. We let each material do what it does best.

- For the Mold Body, we use 7075 Aviation Grade Aluminum. This alloy offers one of the best combinations of thermal conductivity and strength-to-weight ratio available. It allows us to build a lightweight mold that cools the bottle walls with incredible speed and efficiency, enabling the shortest possible cycle times. This is the engine of your production speed.

- For the Mold Bottom Insert, we use High-Hardness Stainless Steel. We select a specific grade of stainless steel that can be hardened to a high level on the Rockwell scale. This component is precision-machined to fit perfectly into the aluminum body. This steel insert acts as a shield, taking all the punishment from the mold closing impact and the high-pressure sealing. It is the armor of your mold.

I remember when we first proposed this to a new customer who was producing millions of water bottles a month. They were skeptical. They were used to buying cheaper, all-aluminum molds and just accepting that they'd have to replace them every year or so. We explained our philosophy. We showed them a sample of our hybrid blow mold design. We told them, "Let the aluminum do the cooling, and let the steel take the beating." The crucial part of our pitch, and a core part of our business model, was that we offered this superior technology at no extra cost. We believe this durability should be the standard, not a premium add-on. They decided to give it a try. A year later, they called us not for a repair, but to order more sets for their other production lines. The original mold was still running like new.

Visualizing the Hybrid Construction

To make this concept clear, imagine a high-performance sports car. The chassis might be made of lightweight carbon fiber for agility and speed, but the brake discs are made of high-friction ceramic or steel to handle extreme heat and wear. You would never make the whole car out of brake disc material, nor would you make the brakes out of carbon fiber. You use the best material for each specific job.

Our hybrid mold applies the same logic. The aluminum body is the lightweight chassis, and the stainless steel insert is the high-performance brake disc. They are two different materials working together in a single, highly-effective system. The steel insert is not simply glued in; it's a feat of precision engineering. It is machined with extremely tight tolerances and often secured with high-tensile bolts, ensuring a perfect fit and efficient heat transfer between the steel and the aluminum. This meticulous assembly is key to the design's success and is something we've perfected over many years of refinement. This approach allows us to confidently provide a solution that truly solves the core problem of mold bottom wear without compromising on production speed.

Technical breakdown: how exactly does the steel insert preserve the mold?

So, a steel insert at the bottom sounds like a good idea, but you're wondering how it works in practice. It seems simple, but does it really protect the main part of the mold?

The hardened stainless steel insert acts as a sacrificial shield. It is specifically designed to absorb 100% of the direct impact and abrasive forces from the sealing process. This prevents the softer aluminum body from ever coming into contact with these destructive forces, preserving its shape and integrity for millions of cycles.

To fully appreciate the effectiveness of this design, let's break down the physics and material science at play. The magic lies in the vast difference in material properties between the stainless steel we use for the insert and the 7075 aluminum that makes up the mold body.

A Shield Against Impact: The Role of Hardness

The single most important property here is hardness. Hardness is a measure of a material's resistance to localized plastic deformation, such as a dent or a scratch. As I mentioned before, 7075 aluminum is relatively soft. Hardened stainless steel, on the other hand, is exceptionally hard.

- 7075 Aluminum: Rockwell Hardness ~87 HRB

- Hardened Tool Steel/Stainless Steel: Rockwell Hardness >50 HRC (significantly harder than HRB scale)

When the two mold halves clamp shut, the two steel inserts meet. Because of their extreme hardness, they do not deform. The immense impact energy is distributed across their surface and absorbed without causing the microscopic dents and mushrooming that plague aluminum bases. The steel effectively acts as an anvil, an unyielding surface that can take the hammer blow of the mold closing cycle again and again, millions of times, without changing its shape.

This has a critical secondary benefit: it preserves the integrity of the entire mold structure. The aluminum body is essentially a precisely machined frame that holds the mold cavity. By protecting its base from deformation, we ensure that the entire frame remains dimensionally stable. The mold halves continue to align perfectly, the parting lines meet precisely, and the cooling channels maintain their optimal shape. We are essentially isolating the delicate, high-performance aluminum body from the most violent part of the production cycle. Many issues with blow mold fit can be traced back to deformation that starts at the base.

An Armor Against Abrasion: Resisting Wear and Tear

The second function of the steel insert is to resist the "sandpaper effect" of the high-pressure sealing process. The hardness of the steel also makes it incredibly resistant to abrasion and scratching.

When the 40-bar air pressure slams the PET preform against the mold base, the steel surface doesn't give.

- The sharp edge of the preform cannot easily cut or groove the hardened steel.

- Any microscopic debris trapped in the seal is crushed or brushed aside without scratching the insert's surface.

- The surface remains smooth and polished, ensuring a perfect, leak-free seal every time.

This directly prevents a major category of common PET blow molding defects, such as:

- Base Leaks: A worn base allows air to escape, resulting in an under-blown bottle that must be scrapped.

- Inconsistent Base Thickness: An imperfect seal can cause uneven stretching of the PET in the base area, leading to weak spots.

- "Angel Hair" or Flashing: Tiny strands of plastic can be forced into the worn grooves of a damaged mold base, creating quality defects.

By ensuring a perfect seal for millions of cycles, the steel insert guarantees consistent and repeatable bottle quality.

Freeing the Aluminum to Do Its Job: Efficient Cooling

With the steel insert handling all the mechanical stress, the aluminum body is freed up to do the one thing it does better than any other practical material: cool the bottle. The primary function of the mold body is heat exchange. The design of the cooling channels, the flow of the chilled water, and the thermal conductivity of the aluminum are all optimized for one purpose – to pull heat out of the PET plastic as fast as humanly possible.

A question we often get is whether the steel insert creates a "hot spot" at the base because steel is a poor conductor of heat. This is a valid concern and something we have engineered a solution for. The steel insert is designed to be relatively thin and is in direct, high-pressure contact with the large mass of the aluminum body. The heat from the bottle base travels through the thin steel insert and is then rapidly wicked away by the highly conductive aluminum body, which is connected to the main cooling channels. While the transfer is slightly slower than through solid aluminum, the effect on the overall cooling time of the base is negligible, especially when compared to the massive gains in mold lifespan and bottle quality. The aluminum acts as a giant heat sink, ensuring the entire mold, including the base, stays at the optimal operating temperature. This synergy is a key part of our successful PET bottle mold design guide.

Benefit #1: how is mold lifespan and ROI dramatically extended?

You're looking at the quote for a new mold, and the upfront cost is a significant investment. You need to be sure that it will last long enough to provide a strong return. An all-aluminum mold might be cheaper initially, but will it cost you more in the long run?

The answer is yes. A cheaper mold that wears out quickly is a false economy. Our hybrid mold design is built for longevity, delivering a much higher return on your investment (ROI). The stainless steel base is the key to this extended lifespan.

A Jindong (iBottler) hybrid mold can reliably achieve a lifespan of 5 to 8 million cycles, and sometimes even more with proper care. This is typically 2 to 3 times longer than a standard all-aluminum mold under the same production conditions. This longevity fundamentally changes the economic calculation of your investment.

Let's move beyond simple statements and look at the real-world financial impact. The best way to evaluate a major equipment purchase like a blow mold is by calculating its Total Cost of Ownership (TCO). The initial price tag is only one part of the story. A true accounting must include the costs of maintenance, downtime, and replacement over the mold's entire life.

Calculating the Total Cost of Ownership (TCO)

The formula is simple: TCO = Initial Cost + (Maintenance Costs x Lifespan) + (Downtime Costs x Lifespan) - Salvage Value

Let's run a hypothetical comparison for a single-cavity mold over a period of 8 million cycles.

Scenario A: Standard All-Aluminum Mold

- Lifespan: Let's be generous and say 2.5 million cycles. This means you will need to buy 3.2 molds (let's round down to 3 complete refurbishments/replacements) to reach 8 million cycles.

- Initial Cost: Let's say $5,000 per mold. Total purchase cost = $15,000.

- Maintenance: These molds require frequent polishing and occasional re-welding/machining of the base. Let's estimate a major service every 1 million cycles at a cost of $800 (labor + materials). Total maintenance = ($800 x 2 services/mold) x 3 molds = $4,800.

- Downtime: Each major service might take the mold offline for 24 hours. If your line produces 1,000 bottles/hour and your profit per bottle is $0.01, downtime cost is 24 x 1000 x $0.01 = $240 per day. Total downtime cost = $240 x 2 services x 3 molds = $1,440.

Total Cost for All-Aluminum (8M Cycles) = $15,000 + $4,800 + $1,440 = $21,240

Scenario B: Jindong (iBottler) Hybrid Mold

- Lifespan: A conservative 8 million cycles. You only need to buy one mold.

- Initial Cost: Because of our philosophy, we don't charge a premium. Let's say the cost is comparable, maybe slightly more for argument's sake: $5,500. Total purchase cost = $5,500.

- Maintenance: The steel base requires virtually no re-polishing or repair. Routine cleaning and inspection are all that's needed. Let's budget for one preventative maintenance check over its life at $500. Total maintenance = $500.

- Downtime: One scheduled maintenance day. Total downtime cost = $240.

Total Cost for Hybrid Mold (8M Cycles) = $5,500 + $500 + $240 = $6,240

The ROI Analysis

| Cost Factor | All-Aluminum Mold (8M Cycles) | Jindong (iBottler) Hybrid Mold (8M Cycles) | Savings with Hybrid Mold |

|---|---|---|---|

| Mold Purchases/Replacements | $15,000 | $5,500 | $9,500 |

| Maintenance Costs | $4,800 | $500 | $4,300 |

| Downtime Costs | $1,440 | $240 | $1,200 |

| TOTAL COST OF OWNERSHIP | $21,240 | $6,240 | $15,000 |

As you can see, over the full production run, the hybrid mold isn't just slightly cheaper; it represents a massive 70% reduction in the total cost of ownership. The initial price difference becomes completely irrelevant. The money you save on replacements, maintenance labor, and, most importantly, lost production time, goes directly to your bottom line.

I've had this exact conversation with company owners and plant managers. I once worked with a large co-packer who ran their lines 24/7. They were replacing their all-aluminum molds for their most popular bottle shape every 14 months. It was just accepted as a standard operating cost. We replaced one of their lines with our hybrid molds. Three years later, I visited their plant, and the same mold was still in the machine, running flawlessly. The plant manager told me that the single mold had saved them the cost of two brand new molds and over a week of accumulated downtime. This is not just a marginal improvement; it is a fundamental change in production economics. When you invest in a durable PET bottle mold with a high-longevity design, you are investing in predictable, long-term profitability.

Benefit #2: how can you reduce maintenance costs and production downtime?

Your production schedule is tight. Unplanned downtime is your worst enemy. Every time you have to stop the line to pull a mold for repairs, you are losing money and falling behind on orders.

The constant need to repair and re-polish the base of an all-aluminum mold is a major source of this unplanned downtime. It's a recurring headache for maintenance teams and a drag on overall plant efficiency.

The extreme wear resistance of the stainless steel base in our hybrid molds virtually eliminates this problem. By designing the primary failure point out of the system, we drastically reduce the need for frequent repairs. This translates directly into more uptime, more predictable production schedules, and lower labor costs for your maintenance department.

Let's get specific about what "maintenance" on a worn aluminum mold base actually involves and why our design allows you to avoid it. The life of a maintenance technician dealing with all-aluminum molds is a constant battle against entropy.

The Cycle of Aluminum Mold Base Repair

When an aluminum base starts to wear, the production line manager will notice an increase in quality defects. A technician is then called to diagnose the problem. This is what their workflow typically looks like:

- Stop Production: The entire blowing line has to be shut down. This includes the bottle blowing machine, preform feeder, and downstream conveyors.

- Cool Down and Removal: The mold is hot, so it needs time to cool before it can be safely handled. Then, the heavy mold must be unbolted and carefully removed from the machine.

- Diagnosis and Repair: The technician will inspect the base.

- Minor Wear: If the wear is minor, they might be able to re-polish the surface by hand using abrasive pads to restore the smooth finish. This is a temporary fix at best.

- Moderate Wear: If a groove has formed, hand-polishing won't work. The mold has to be taken to the workshop. A skilled technician might be able to use a TIG welder to carefully add aluminum material back into the worn area.

- Severe Wear: After welding, the base must be re-machined on a CNC mill or surface grinder to make it perfectly flat and restore the correct dimensions. This is a highly skilled and time-consuming job.

- Re-installation and Heat Up: The repaired mold is brought back to the line, installed, and heated back up to operating temperature.

- Testing and Adjustment: The first few bottles are carefully inspected to ensure the repair was successful. Adjustments to clamping pressure or other settings may be needed.

This entire process can take anywhere from a few hours for a simple polish to an entire day or more for a weld-and-machine repair. And the worst part? Because the base is still aluminum, the clock starts ticking immediately, and you know you'll be doing it all over again in a few months.

The Uptime Advantage of a Hybrid Mold

Now, contrast that with the maintenance schedule for a Jindong (iBottler) hybrid mold. The stainless steel insert simply does not wear in the same way. It requires no polishing, no welding, and no re-machining. The "maintenance" for the mold base consists of wiping it clean with a cloth during routine preventative maintenance checks.

This reliability transforms your production planning.

| Aspect of Production | With All-Aluminum Molds | With Jindong (iBottler) Hybrid Molds |

|---|---|---|

| Production Scheduling | Unpredictable. Must budget for unplanned downtime for mold repairs. | Highly predictable. Production runs are consistent and uninterrupted by base wear issues. |

| Maintenance Labor | High. Technicians spend significant time on reactive, repetitive repairs. | Low. Technicians can focus on proactive, value-added tasks instead of fighting fires. |

| Spare Parts Inventory | May need to keep spare mold sets or base components on hand. | Reduced need for spare mold inventory, freeing up capital. |

| Overall Equipment Effectiveness (OEE) | OEE is lowered by frequent, unplanned stops, reducing availability. | OEE is maximized through high availability and consistent performance. |

I once visited a customer who was running a highly efficient, lean manufacturing operation. Everything was optimized, except for one bottleneck: their blow molder. The plant manager showed me his data. His OEE was consistently dragged down by the "Availability" component, and the primary reason for that was "unplanned mold maintenance." They were treating it as a normal part of the process. We installed a set of our hybrid molds for a trial. Six months later, he sent me an email with a new OEE chart. The availability of his blow molder had jumped by over 15%. He calculated that this increase in uptime alone paid for the entire cost of the molds in less than a year. He wrote, "Your molds didn't just make our bottles; they fixed our production schedule." This is the real-world impact of designing for reliability. It's not just about saving a few hours of a technician's time; it's about making your entire operation more stable, predictable, and profitable.

Benefit #3: how do you get consistent and superior bottle quality over time?

You've worked hard to perfect your product. The last thing you want is for a packaging defect like a leaky bottle to damage your brand's reputation. But as your all-aluminum molds age, you start to see more and more quality control issues.

A pristine, unworn mold base is the foundation of a perfect bottle. Any degradation in the sealing surface directly impacts the quality and consistency of every single bottle you produce.

Our hybrid mold's stainless steel insert does not wear down over time. This ensures a perfect seal and a consistently formed bottle base for millions of cycles. This stability protects your product quality and your brand, preventing issues like leaks, wobbly bases, or inconsistent wall thickness that plague aging all-aluminum molds.

Let's explore the direct causal link between the condition of the mold base and the final quality of the PET bottle. It’s a chain reaction where a small imperfection at the start leads to a major failure at the end. The base of the mold is arguably the most critical surface for the structural integrity of the final product.

The Foundation of a Good Bottle: The Sealing and Stretching Process

When the blow molding cycle begins, the mold closes around the hot, pliable PET preform. The bottom of the mold has two jobs that happen almost simultaneously:

- Create a Perfect Air Seal: The mold base must form an airtight seal with the bottom edge of the preform. This is crucial to contain the high-pressure air (up to 40 bar) that is about to be injected.

- Form the Bottle Base: The shape of the mold base cavity dictates the final shape of the bottle's base, which is critical for its stability (so it doesn't fall over) and strength (so it can withstand internal pressure and stacking).

If the mold base is worn, both of these critical functions are compromised. A groove or a dent on the sealing surface, even one that is fractions of a millimeter deep, allows high-pressure air to escape. This leak prevents the preform from being stretched correctly and the bottle from being fully formed.

How a Worn Base Leads to Common Bottle Defects

A compromised seal creates a cascade of problems. Here is a table detailing the cause-and-effect relationship between base wear and common defects, many of which are detailed in our guide to fixing common PET blow molding defects:

| Mold Base Condition | Resulting Physical Effect | Final Bottle Defect | Consequence for Your Business |

|---|---|---|---|

| Worn Sealing Surface | Air leak during high-pressure blowing. | Under-blown Bottle: The bottle is not fully formed, appearing soft and malformed. | Increased scrap rate, wasted material and energy. |

| Uneven Wear / Dents | Inconsistent seal pressure around the preform. | Uneven Base Thickness: Creates thin, weak spots in the bottle's base. | Bottles may burst during filling or shipping. Product recalls. |

| Scratches or Grooves | PET material is forced into the imperfections. | Base Flashing / "Angel Hair": Creates sharp, thin strands of plastic on the base. | Safety hazard for consumers, aesthetic failure. |

| Deformed Base Cavity | The shape of the base is no longer to spec. | Unstable or "Wobbly" Bottle: The bottle does not stand flat and can easily tip over. | Problems on the filling line, poor consumer experience. |

I was once called in to help a customer in the juice industry who was experiencing a sudden spike in customer complaints about leaking bottles. Their QC team was overwhelmed. They checked everything: their cappers, their filling heads, their preform neck size, but they couldn't find the source. I asked to see their blow molds. They were using all-aluminum molds that were about 18 months old. When we inspected the mold bases, the problem was obvious. A distinct, worn groove had formed on the sealing surface of every single cavity. Under high pressure, this groove allowed a tiny, almost invisible stress fracture to form in the base of the bottles. The bottles looked fine coming off the line, but the fracture would open up later during shipping or when a consumer squeezed the bottle. By replacing their worn-out molds with our hybrid molds, the problem vanished overnight. It was a powerful lesson for them: bottle quality starts with mold quality. Investing in a durable mold is a direct investment in brand protection.

The consistency offered by the stainless steel base means that the 8 millionth bottle you produce will have the exact same base integrity and dimensional accuracy as the first one. This is the definition of process stability and quality control.

Conclusion: why does this single detail define a smarter investment?

Making a decision on a new blow mold is about more than just the initial price. It's about the future of your production line.

The choice to use a hybrid mold with a stainless steel base is a strategic decision. It is an investment in long-term production stability, quality, and profitability, not just a simple tool purchase. This choice reflects a deep commitment to operational excellence.

At our company, Jindong, our 20 years of experience have taught us that a durable, reliable mold is the true heart of any bottling operation. The hybrid design is the result of decades of listening to customers and refining our engineering to solve their biggest problems. We offer this superior design because we believe in building partnerships, not just selling parts. By providing a mold that runs longer, requires less maintenance, and produces consistently higher quality bottles, we help ensure your long-term success. And because we include this feature as a standard, we make this smart investment an easy choice.

Frequently Asked Questions

How much more does a hybrid aluminum/steel mold cost compared to a standard all-aluminum mold?

This is the most common question we get, and the answer surprises many of our clients. At Jindong (iBottler), we do not charge a premium for our hybrid design. A hybrid aluminum/stainless steel mold from us is priced competitively with a standard 7075 all-aluminum mold from other suppliers. It's a core philosophy at our company, Zhongshan Jindong Machinery Co., Ltd., that durability and longevity are not luxury features; they are essential requirements for modern, high-volume production. We made a strategic decision years ago to standardize this technology in our blow bottle mold offerings. We were able to do this by optimizing our manufacturing processes and accepting a slightly lower margin on each mold, betting that the superior performance and customer satisfaction would lead to stronger long-term relationships and repeat business. So, you get a vastly superior, longer-lasting product for a similar initial investment.

Can you provide a real-world comparison of the expected lifespan (in cycles) between a hybrid mold and an all-aluminum mold?

Absolutely. Based on decades of data and direct feedback from our customers across various industries (water, CSD, juice, etc.), we can provide a very clear comparison.

| Mold Type | Typical Production Environment | Expected Lifespan (Cycles) | Key Failure Point |

|---|---|---|---|

| Standard All-Aluminum Mold | High-speed, 24/7 operation | 1,500,000 - 3,000,000 | Wear and deformation of the aluminum mold base. |

| Jindong (iBottler) Hybrid Mold | High-speed, 24/7 operation | 5,000,000 - 8,000,000+ | Usually not the base; potential wear on other components like the neck finish area after very long service. |

For example, a major bottled water client running our molds 24/6 reported replacing their previous all-aluminum molds every 18 months, which corresponded to roughly 2.5 to 3 million cycles. The first set of our hybrid molds they installed ran for over 5 years, achieving well over 8 million cycles before they were retired when the bottle design was changed. The stainless steel bases on those retired molds were still in excellent condition.

Does the stainless steel insert negatively affect the cooling time of the bottle base?

This is an excellent technical question. While it's true that stainless steel has lower thermal conductivity than aluminum, our design mitigates any negative impact on cooling time. We achieve this in two ways:

- Optimized Geometry: The steel insert is engineered to be as thin as possible while still providing the necessary strength and rigidity. This minimizes the distance that heat needs to travel through the less conductive material.

- Maximum Surface Contact: The insert is precision-machined for a perfect, tight fit against the aluminum body. This ensures there are no air gaps and creates maximum surface area for conductive heat transfer from the steel to the aluminum. The large aluminum body acts as a massive heat sink, rapidly pulling the heat away from the steel insert and transferring it to the circulating chilled water.

In practice, our tests and customer feedback confirm that there is no measurable increase in the base cooling time or overall cycle time compared to an all-aluminum mold. You get the full cooling speed advantage of the aluminum body where it matters most—along the walls of the bottle—without creating a thermal bottleneck at the base.

Is it possible to replace only the stainless steel insert if it eventually wears out?

Yes, it is. This is another key benefit of our modular design philosophy. While it is extremely rare for one of our hardened steel inserts to wear out under normal operating conditions within the mold's expected 8-million-cycle lifespan, the design allows for it. The inserts are mechanically fastened, not permanently bonded, to the aluminum body. If an insert were to be accidentally damaged by a foreign object or after an extremely long service life, it can be unbolted and a new, pre-machined replacement can be installed. This is a much faster and more cost-effective repair than attempting to re-weld and re-machine an entire solid aluminum mold base, let alone replacing the entire mold half. This replaceability adds another layer of long-term value and serviceability to your investment.

Is this hybrid design recommended for all types of bottle production, or are there specific applications where it is most effective?

The hybrid design is beneficial for almost all PET blow molding applications, but it provides the most significant and fastest return on investment in high-volume, continuous production environments. This is where the sheer number of cycles amplifies the effects of wear and tear. Specifically, it is most effective for:

- Bottled Water & CSD: These are typically the highest-speed lines with the highest annual cycle counts. The longevity of the hybrid mold provides a massive TCO advantage.

- 24/7 Operations: For factories that run around the clock, minimizing any and all downtime is the top priority. The reliability of the hybrid mold is a huge asset.

- Hot-Fill Bottles: The higher preform temperatures and pressures in hot-fill applications can accelerate wear on aluminum molds, making the durability of a steel base even more valuable.

While a lower-volume producer might not see the financial benefits as quickly, they will still appreciate the consistent quality and peace of mind that comes from knowing their mold's critical surfaces are not degrading over time. Essentially, if you are concerned about mold longevity and consistent bottle quality, our hybrid design is the superior solution.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

📞 Contact: Vivian

🏭 Zhongshan Jindong Machinery Co., Ltd.

🌍 www.ibottler.com

📧 Vivian@ibottler.com | 💬 WhatsApp: +86-13106288777

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr