Starting a bottling business but finding preform suppliers unreliable? You think making your own is the answer, but the hidden costs might sink your entire operation before it even starts.

A complete PET preform plant investment involves more than just an injection machine. You must budget for molds, auxiliary equipment, infrastructure, raw materials, and daily operational costs. A small line can easily exceed $100,000, making it a significant financial commitment for a startup.

I often get calls from enthusiastic entrepreneurs. They're running a small operation, maybe with a semi-automatic bottle blowing machine, and they want a quote for a full preform production line. My first question is always, "What's your current output?" More often than not, their production volume is quite low. When I hear this, I have to be direct. Investing in your own preform manufacturing when your output is small is often a recipe for financial strain. You end up tying capital in machinery that you can't fully utilize. This article is for them. It's for you. I want to pull back the curtain and show you every single cost you need to consider. Let's break down the real numbers so you can make a truly smart decision for your business.

Initial Capital Investment: The Core Machinery Breakdown?

You see the price of an injection molding machine and think you've got the main cost covered. But that's just the tip of the iceberg, and overlooking the other core components is a common mistake.

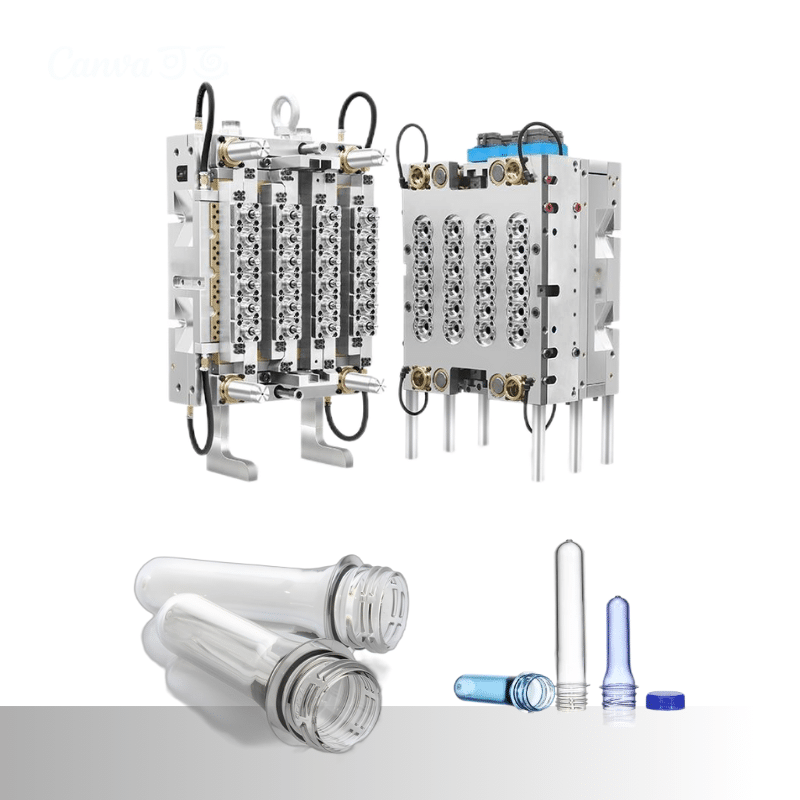

The core machinery for a preform plant includes an injection molding machine, a PET preform mold, a resin dryer, and a chiller. The total cost for these essential items can range from $80,000 to over $500,000, depending on capacity, brand, and level of technology.

Let's get straight to the point. The first thing everyone asks about is the Injection Molding Machine Price. This is the engine of your plant, but you can't just buy any model. You need a machine specifically designed for PET. These have a special screw with a higher length-to-diameter ratio to properly plasticize the PET resin. The price is mainly determined by its clamping force, measured in tons. A smaller startup might begin with a 160-ton or 200-ton machine, while a large-scale factory could use machines of 500 tons or more. The brand also plays a massive role in the cost. A machine from a top European or Japanese brand can cost several times more than one from a reputable Chinese manufacturer. You must balance your budget with the need for reliability and efficiency.

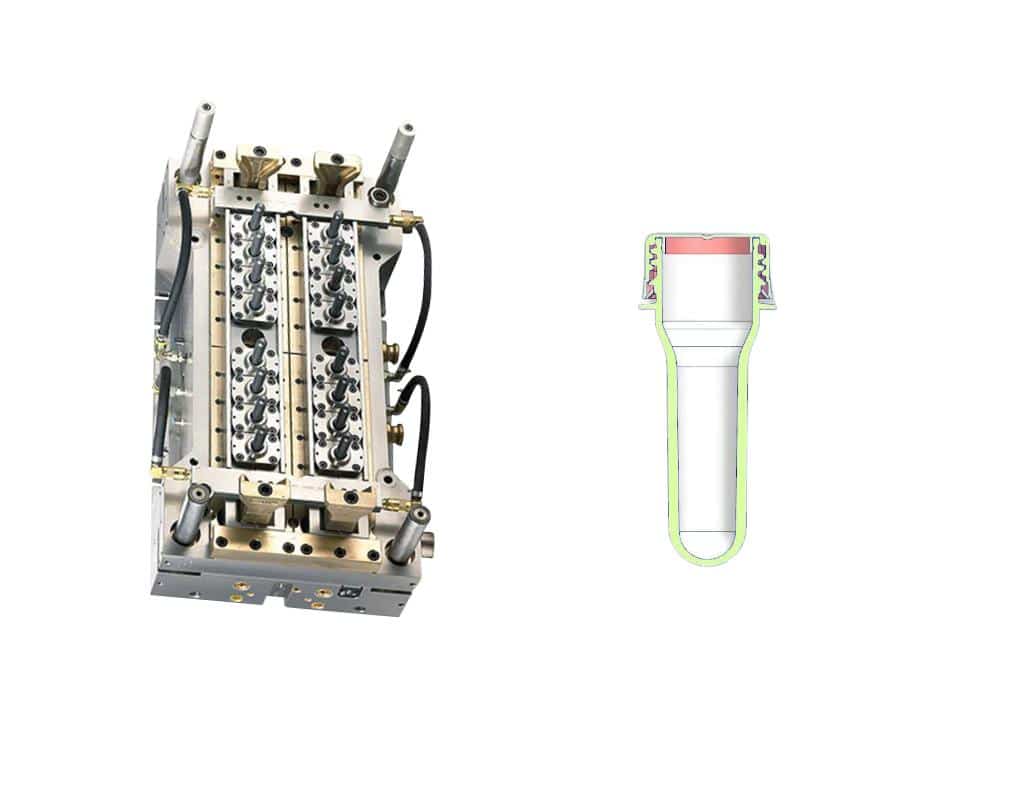

The PET Preform Mould - The Heart of Quality

Next, and equally important, is the PET preform mold. I tell my clients this is where you should not cut corners. The mold determines the quality, consistency, and weight of your final product. A poor mold will give you constant headaches and production waste. The PET Preform Mould Cost is influenced by three main factors: the number of cavities, the quality of the steel, and the brand of the hot runner system. More cavities mean higher output per cycle, but the cost increases exponentially. For steel, you should insist on a high-grade, hardened stainless steel like S136. It resists corrosion and wear, ensuring a long service life. The hot runner system is the complex network that delivers molten plastic to each cavity. A balanced system from a top brand like Yudo or Husky ensures all preforms are identical, which is critical for the subsequent blowing process. A high-quality mold is a major part of your Preform Manufacturing Investment.

Essential Support - Dryer and Chiller

Finally, you have two critical support machines. PET resin is hygroscopic, meaning it absorbs moisture from the air. If you try to mold wet resin, it will degrade, resulting in brittle, hazy preforms. You absolutely need a dehumidifying dryer to reduce the resin's moisture content to below 50 parts per million (PPM) before it enters the injection machine. The other machine is the industrial chiller. Injection molding is a game of temperature control. A powerful chiller circulates cold water through the mold to cool the plastic rapidly. A faster cooling time means a shorter cycle time, which translates directly to higher output and lower cost per preform. As I've explained before, understanding why PET blow molds need a chiller is fundamental to both molding and blowing operations.

To give you a clearer picture, here is a breakdown of what a starter set of core machinery might cost.

| Equipment | Specification Example | Estimated Cost Range (USD) | Notes |

|---|---|---|---|

| PET Injection Molding Machine | 160 Ton Clamping Force | $40,000 - $90,000 | Price depends heavily on brand and features. |

| PET Preform Mould | 16-Cavity, S136 Steel | $25,000 - $60,000 | Hot runner brand is a major cost factor. |

| Dehumidifying Dryer | 200kg/hr capacity | $8,000 - $20,000 | Essential for processing PET resin properly. |

| Industrial Chiller | 20 HP Cooling Capacity | $7,000 - $15,000 | Critical for mould cooling and fast cycles. |

| Total Core Investment | $80,000 - $185,000+ | This is for the core production machinery ONLY. |

Beyond the Machine: Essential Auxiliary Equipment Costs?

You've budgeted for the main machines, feeling confident. But then you realize they can't run without a complex support system. Suddenly, your budget is stretched thin and production is at a standstill.

Crucial auxiliary equipment includes an air compressor system, a water cooling tower, material handling systems (loaders), and quality control lab devices. These items can add another $20,000 to $60,000 or more to your initial PET Preform Plant Cost, and they are absolutely non-negotiable for stable production.

The big machines I described above are useless by themselves. They are like the engine of a car, but you still need the wheels, transmission, and electronics to actually go anywhere. This is a part of the Preform Manufacturing Investment that startups frequently underestimate.

The Power of Air and Water

First, you need compressed air. Many high-quality preform molds use valve-gated hot runner systems, which require high-pressure air to actuate the pins that control plastic flow. You also need low-pressure air for other functions, like robotic arms that might remove the preforms from the mold. This often means investing in a complete air compressor system with dryers and tanks. It's similar to how a blowing operation needs a cost-efficient air system. Then there's the water system. Your chiller generates a lot of heat, and that heat needs to go somewhere. The chiller itself is cooled by water from a separate water cooling tower, which is usually installed outside your factory. This involves more equipment, plumbing, and installation costs.

Moving Materials and Ensuring Quality

How does the resin get from the bag into the dryer and then into the machine? You could do it by hand, but that introduces contamination and is inefficient. The standard solution is an automated vacuum loader system. These loaders automatically suck the resin from a central bin or bag and feed it into the dryer hopper as needed. After the preforms are molded, you'll need a conveyor belt to move them from the machine to a collection bin. Some advanced setups use a robot arm for this, which adds to the cost but protects the preforms from damage.

Most importantly, you need a quality control lab. You cannot manage what you do not measure. Selling inconsistent or defective preforms will destroy your reputation. A basic lab for a preform plant must include a precision gram scale to check for weight consistency, a polariscope to check for internal stress in the preforms, and a preform eccentricity tester to ensure the wall thickness is uniform. If your preforms are bad, they will cause major issues down the line, leading to the kinds of problems we outline in our guide to common PET blow molding defects.

Here's a look at the potential costs for these essential support systems.

| Item | Purpose | Estimated Cost (USD) |

|---|---|---|

| Air Compressor System (Low/High Pressure) | Powering auxiliaries, valve gates | $5,000 - $15,000 |

| Water Cooling Tower | Cooling the industrial chiller | $4,000 - $10,000 |

| Auto-Loader & Hopper System | Feeding resin automatically | $2,000 - $5,000 |

| Quality Control Lab Equipment | Polariscope, Scale, Eccentricity Gauge | $5,000 - $20,000 |

| Conveyor Belt / Robot Arm | Post-molding handling | $4,000 - $15,000+ |

| Total Additional Cost | $20,000 - $65,000+ |

Factory Infrastructure: Rent, Renovation, and Utilities Setup?

You found a cheap factory space and signed the lease. But the floor can't handle the machinery, the power is insufficient, and there's no proper water access. The "cheap" space now needs expensive upgrades.

Factory infrastructure costs include rent or purchase, floor reinforcement and epoxy coating, electrical system upgrades for heavy machinery, and plumbing for cooling systems. These foundational expenses can easily add $15,000 to $100,000+ to your startup costs before a single machine is installed.

This is where the "paper" costs turn into very real, physical expenses. A factory is not just four walls and a roof. It's a specialized environment that you have to build.

Choosing Your Space and Preparing the Foundation

The first decision is whether to rent or buy your factory space. For a startup, renting is usually the less capital-intensive choice. You need a building with high ceilings to accommodate the machinery and potentially a small crane for mold changes. Most importantly, the concrete floor must be thick and strong enough to support the immense weight and vibrations of an injection molding machine. I've seen startups have to pour a whole new concrete slab, which is a huge unexpected cost. Once the floor is solid, you need to treat it. The industry standard is an epoxy floor coating. It creates a smooth, durable, and dust-free surface that is easy to clean and safe for workers.

Powering Your Plant and Running the Pipes

A PET preform plant is extremely power-hungry. Your main injection machine, the dryer, the chiller, and the air compressor all consume massive amounts of electricity. You cannot simply plug them into a standard wall outlet. You will need a heavy-duty, three-phase industrial power supply. In many cases, the existing power supply to a building is not sufficient. You may have to pay the utility company a very large sum to run a new, higher-capacity line to your facility. This cost alone can be a deal-breaker for some. Beyond electricity, you have to install a network of pipes. Pipes for chilled water need to run from the chiller to every mold. Pipes for compressed air need to be run throughout the production area. All of this custom installation work adds up quickly in both labor and material costs.

Planning the Layout for Efficiency

A good factory layout is crucial for a smooth workflow. You can't just place machines randomly. You need to designate specific areas for different functions. This includes a raw material warehouse where you store your PET resin, a dedicated production area around the machines, a quality control lab that is clean and well-lit, and a finished goods warehouse to store the preforms before they are shipped. The flow should be logical: raw materials come in one end, move through production, and finished goods go out the other. A logical layout starts with a great design concept, just as a successful bottle project begins with a comprehensive PET bottle mold design guide. Taking the time to plan this on paper will save you a lot of time and money later.

Raw Material Sourcing: Understanding PET Resin Price Fluctuations?

You've set your preform price based on today's resin cost. But next month, oil prices spike, and your raw material cost jumps 20%. Suddenly, you're producing at a loss, and your business model collapses.

PET resin is a petroleum derivative, so its price is directly tied to volatile oil markets and seasonal demand. A startup must budget for an initial stockpile of several tons, which can represent an upfront cost of $10,000 to $50,000+ just for raw materials.

Your machinery is a one-time cost, but your raw material, PET resin, is a constant expense that you will be paying for as long as you are in business. Understanding this market is critical to your survival.

.png)

The Unbreakable Link to Crude Oil

Polyethylene terephthalate (PET) is a plastic made from crude oil. It's that simple. When the global price of a barrel of oil goes up, the price of PET resin follows. It is not a matter of "if," but "when." This volatility means you cannot have a fixed price for your raw materials. You have to watch the market constantly. A sudden geopolitical event on the other side of the world can directly impact your profitability in a matter of weeks. When you create your business plan, you must account for this. I advise my clients to run scenarios: what happens to my cost per preform if resin goes up 10%? What about 25%? If you don't know these numbers, you are vulnerable.

Seasonality and Supply Chain Headaches

The demand for PET bottles is not flat year-round. It peaks during the hot summer months when people drink more beverages. This increased demand can also put upward pressure on resin prices. Beyond seasonal cycles, you have to consider the global supply chain. Most PET resin is produced in large chemical plants, and if one of these plants has a scheduled maintenance shutdown or an unexpected problem, it can tighten the supply and increase prices. In recent years, we have all seen how shipping costs and port delays can add unexpected costs and lead times. You can't assume you can get resin delivered next week. You need to plan ahead.

Budgeting for Your First Batch

When you start your plant, you can't just buy one bag of resin. You need a significant initial stockpile to ensure continuous production while you establish a reliable supply chain. A standard full truckload of resin is typically 20 to 25 metric tons. Let's say the market price for virgin PET is $1,200 per ton. Your initial raw material purchase would be $24,000 to $30,000. This is pure working capital that will be tied up in inventory. This significant outlay is a key component of planning for a Turnkey Preform Production Line; you must fund not just the machines but also the materials to feed them.

Operational Expenses (OPEX): The Hidden Costs of Daily Production?

Your machines are running, and preforms are coming out. You feel successful. But when the first utility bill arrives, your heart sinks. The cost of electricity alone is eating up all your profit.

Daily operational expenses (OPEX) are the relentless costs of running your plant. The biggest three are electricity for machinery, labor for operation and quality control, and ongoing equipment maintenance. These costs determine your actual production cost per preform and your long-term profitability.

This is the part that I find startups are often least prepared for. The initial investment is a mountain, but OPEX is a tide that comes in every single day. If you don't manage it, it will drown you.

The Unseen Giant: Electricity Costs

I cannot overstate this: an injection molding plant is an energy-intensive operation. Let's break down where the electricity goes. The injection molding machine itself has powerful heaters to melt the PET resin and a large motor to run the hydraulics or electric drives. The dehumidifying dryer runs large heaters and blowers 24/7. The chiller and the air compressor are also running constantly. When you add it all up, the monthly electricity bill can be shocking, often amounting to thousands or even tens of thousands of dollars. This is why investing in modern, energy-efficient machines during your initial Preform Manufacturing Investment phase is so important. A cheaper, less efficient machine might save you money upfront, but it will cost you far more in the long run through higher utility bills.

The Human Element: Labor Costs

Machines don't run themselves. For a professional operation, you need skilled staff. This includes trained machine operators who can set up the machine, troubleshoot problems, and ensure smooth production. You need dedicated quality control technicians who are constantly checking the preforms to ensure they meet specifications. You also need maintenance personnel to service the machines and molds. If you plan to run 24 hours a day to maximize your investment, you will need to hire enough staff for three separate shifts. Labor is a significant and recurring monthly expense that depends heavily on the wage rates in your specific location.

Keeping the Wheels Turning: Maintenance and Spares

Your machines and molds are valuable assets, and they need to be cared for. This means a budget for regular maintenance. Hydraulic oil and filters in the injection machine need to be changed. The chiller and compressor need periodic servicing. The PET preform mold requires regular cleaning to prevent vent blockages and residue buildup. Over time, parts will wear out. Heating elements, thermocouples, seals, and nozzles on the hot runner system are all consumable items. You must have a budget for these spare parts and ideally keep some critical ones in stock. A machine sitting idle because of a small, broken part is losing you money every single hour. Ignoring maintenance is as risky as not knowing if your blow mold will fit your machine, a small oversight that can halt your entire operation.

| Expense Category | Estimated Monthly Cost (USD) | Notes |

|---|---|---|

| Electricity | $5,000 - $15,000 | The largest utility cost, varies by machine efficiency and usage. |

| Labor (3 shifts, 4-5 staff) | $8,000 - $20,000 | Depends heavily on local wage rates. |

| Maintenance & Spares | $1,000 - $3,000 | Averages out over the year; can be lumpy. |

| Factory Rent | $2,000 - $8,000 | Varies greatly by location. |

| Total Estimated OPEX | $16,000 - $46,000+ | This is before you even buy the raw materials for the month. |

Mould Investment: Balancing Cost, Quality, and Longevity?

You find a cheap preform mold online that promises high output. But after a few months, it starts flashing, the preforms are inconsistent, and maintenance becomes a nightmare. Your "savings" have turned into a production disaster.

A PET preform mold is a long-term investment where quality pays dividends. The cost is driven by the number of cavities, the type of steel (S136 is ideal), and the hot runner system. A cheaper mold often leads to higher maintenance and lower preform quality.

I spend a lot of time discussing molds with my clients because it is one of the most critical decisions they will make. The mold is not just a tool; it is the birthplace of your product. Its quality is paramount.

Cavitation: Scaling Your Output

The number of cavities in your mold directly determines your production capacity. A mold can have as few as 2 cavities or as many as 144. A startup might consider a 16- or 32-cavity mold. The more cavities, the more preforms you produce with each cycle of the machine. However, the complexity and cost of the mold increase significantly with each cavity you add. It requires a more powerful machine to run, a larger chiller to cool, and a more sophisticated hot runner system. My advice is always to match the cavitation to your real, proven market demand, not your optimistic projections.

The Soul of the Mould: Steel and Hot Runners

The material of the mold itself is crucial. For PET preforms, you need high-quality, hardened stainless steel, with S136 being a common industry standard. It's expensive, but it offers excellent corrosion resistance (PET can be slightly corrosive at high temperatures) and can be polished to a mirror finish, which is essential for clear preforms. Some cheaper molds use P20 steel, which is fine for many other plastics but will not last as long with PET and is more prone to rust.

The hot runner system is the mold's circulatory system. A good hot runner from a reputable brand ensures that every single cavity fills with plastic at the same time, at the same pressure, and at the same temperature. This balance is key to producing preforms that are consistent in weight and dimensions. An imbalance will lead to some preforms being overweight and others being underweight, causing major problems in the blowing stage. This is why a high PET Preform Mould Cost is often justified by the reliability and precision of its hot runner system.

Making the Right Choice for Your Stage

This brings me back to my conversations with startup owners. It is tempting to want the biggest and best mold right away. But this is often a mistake. Don't invest in a 48-cavity mold when your market is still unproven. It is far smarter to start with a high-quality 16-cavity mold. Running a smaller mold at full capacity is much more efficient and profitable than running a large mold for only a few days a month. This approach also gives you more flexibility. You can validate your preform and bottle designs, perhaps even using services that offer 3D printed samples to validate designs, before you commit to a very expensive, high-cavitation production mold. You need to choose the right tool for the job you have today, not the job you hope to have in five years. And it all starts with understanding your needs, right down to how to choose the right preform neck size.

Calculating Your ROI: A Sample Cost-Benefit Analysis?

You've spent hundreds of thousands of dollars and are finally in production. But are you actually making money on each preform? Without a clear financial model, you're flying blind, unable to price correctly or plan for the future.

Calculating your Return on Investment (ROI) requires a full accounting of your total investment and your true cost per preform. By creating a financial model, you can forecast your break-even point and make informed decisions about pricing and future expansion.

This is where we put everything together. The numbers can be intimidating, but facing them is the only way to build a sustainable business.

Tallying the Total Investment

First, you need to calculate your total upfront investment, often called CAPEX (Capital Expenditure). This isn't just the machine price. It's the sum of everything we've discussed so far.

- Total Initial Investment = (Core Machinery Cost) + (Auxiliary Equipment Cost) + (Factory Infrastructure & Setup Cost) + (Initial Raw Material Stockpile) + (Working Capital for ~3 months of OPEX)

For a small but serious startup, this number will almost certainly be in the range of $200,000 to $500,000. It is a substantial amount of money and a significant financial risk.

Finding Your True Cost Per Preform

Next, you need to know exactly how much it costs you to make one single preform. This is critical for setting your prices and understanding your profitability. The formula is conceptually simple:

- Cost Per Preform = (Total Monthly Costs) / (Total Good Preforms Produced in a Month)

Total monthly costs include your variable costs (PET resin, electricity) and your fixed costs (labor, rent, maintenance, depreciation of your machinery). It's vital to only count the good preforms. Any scrap or defective products are a loss and increase the cost of your good ones.

Let's look at a hypothetical example to make this real.

| Metric | Value (USD) | Calculation / Notes |

|---|---|---|

| Total Initial Investment | $250,000 | (Machines, Aux, Setup, 3 mo. OPEX) |

| Monthly Production | 2,000,000 preforms | (16-cavity mold, ~9s cycle, 24/5 operation) |

| Monthly OPEX | $25,000 | (Power, Labor, Rent, Maintenance) |

| Monthly Material Cost | $30,000 | (Assuming 25 tons of PET at $1200/ton for 2M 12.5g preforms) |

| Total Monthly Cost | $55,000 | ($25,000 + $30,000) |

| Cost Per Preform | $0.0275 | ($55,000 / 2,000,000) |

| Market Price Per Preform | $0.0325 | (Hypothetical selling price to others or value to your own blowing operation) |

| Profit Per Preform | $0.005 | |

| Monthly Gross Profit | $10,000 | ($0.005 * 2,000,000) |

| Payback Period (Simple) | 25 months | ($250,000 / $10,000 per month). This simple calculation does not account for taxes, interest, or major repairs. |

As you can clearly see from this sample analysis, even with a solid operation and a profitable margin, the time it takes to recoup your initial investment is over two years. This is the financial reality you must be prepared for. There are no quick profits in manufacturing.

Smart Startup Strategies: Tips for Cost Optimization and Phased Investment?

The sheer scale of investment seems overwhelming, making you question your dream. But what if there was a smarter, more cautious way to enter the market? A path that minimizes risk and grows with your success.

A smart startup strategy focuses on minimizing initial risk. This can involve starting with a lower-cavity mold, purchasing energy-efficient machinery to reduce long-term OPEX, or even postponing preform production entirely until your blowing business achieves a significant, stable scale.

After laying out all the daunting costs, I want to end with practical advice. The goal is not to discourage you, but to empower you to make a smart, strategic decision. A successful business is not about spending the most money; it's about spending it wisely.

Start Small, but Start with Quality

I've said it before, but it bears repeating: do not over-invest in capacity you don't need. It is far better to buy a high-quality 16-cavity mold and run it 24/7 than to buy a cheaper 48-cavity mold and run it one week a month. When a machine is idle, it is not making you money, but you are still paying for the space it occupies and its depreciation. Start with a production scale that matches your current, proven demand. You can always add a second production line later as your business grows.

Prioritize Efficiency Over Upfront Cost

When you compare quotes for machinery, it is tempting to choose the cheapest option. This is often a short-sighted mistake. A slightly more expensive injection molding machine with modern servo-electric drives might consume 30-40% less electricity than an older hydraulic design. That difference in your monthly electricity bill can add up to tens of thousands of dollars per year. The more efficient machine will pay back its initial price premium surprisingly quickly and then continue to save you money for years. This is the core of a smart Preform Manufacturing Investment. Look at the total cost of ownership, not just the purchase price.

The Smartest Move: When NOT to Invest

Now, I want to be very direct. This is the advice I give to the entrepreneurs who call me about setting up a preform line when they are only running one or two semi-automatic bottle blowing machines. My advice is simple: Don't do it.

The math simply does not work. The production volume from a small-scale blowing operation is far too low to justify the massive capital expenditure and operational costs of an in-house preform plant. You would be producing preforms at a much higher cost than what you can buy them for on the open market. You will have tied up hundreds of thousands of dollars in equipment that will sit idle most of the time.

For a small or medium-sized bottling company, buying high-quality preforms from a large, dedicated manufacturer is almost always the cheaper, lower-risk, and smarter business decision. Focus your capital and your energy on what you do best: blowing bottles, filling them, and selling your final product. Perfect your process, grow your brand, and expand your distribution. Once you have a factory full of high-speed automatic machines and a massive, consistent demand for millions of preforms every month, then we can have a serious and productive conversation about investing in a Turnkey Preform Production Line. Until then, let the specialists handle the preforms while you focus on growth.

Conclusion

Starting a PET preform plant is a major industrial undertaking, not a small workshop upgrade. Analyze every cost, understand your true scale, and never be afraid to grow wisely.

Frequently Asked Questions

Q: What is the minimum initial investment to start a small-scale PET preform plant?

A: The minimum investment varies greatly based on location, equipment choice, and initial capacity. A basic startup with a single production line (one injection machine and one mould) could range from $100,000 to $300,000 USD, covering essential machinery. This figure excludes factory infrastructure and operational working capital.

Q: How much does a good quality PET preform mould cost?

A: Mould cost is a significant part of the investment, heavily influenced by the number of cavities, the quality of steel (like S136), and the hot runner system brand. A high-quality 32-cavity mould, for example, can cost anywhere from $30,000 to $80,000 USD or more, depending on the manufacturer and specifications.

Q: What are the main factors affecting the daily operational cost?

A: The top three operational costs are electricity (for machines, dryers, and chillers), raw material (PET resin), and labor. Efficient, modern machinery can significantly reduce electricity consumption, making it a key factor in long-term profitability.

Q: Is it more cost-effective to buy new or used equipment?

A: While used equipment offers a lower initial purchase price, it often comes with risks like lower efficiency, higher maintenance costs, and no warranty. For a "smarter startup," investing in new, energy-efficient machinery with full manufacturer support is generally recommended for stable production and predictable operational costs.

Q: How do I calculate the production cost per preform?

A: To calculate the cost per preform, you need to sum up your variable costs (raw material, electricity) and fixed costs (labor, rent, machine depreciation) over a period, and then divide by the total number of qualified preforms produced in that same period. A simplified formula is: (Material Cost + Energy Cost + (Labor & Overheads / Production hours)) / Preforms produced per hour.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr