Your old PET blow molding machine feels like a problem. You know an upgrade is cheaper upfront. But you worry if it's the right long-term choice for your factory.

A new machine is a big investment, but it often provides far greater long-term value. It brings higher efficiency, better reliability, and prepares your business for the future. An upgrade is usually just a short-term fix that can come with many hidden risks and costs down the line.

This decision is one of the biggest you'll make for your beverage factory. It's not just about the machine; it's about your production, your profits, and your brand's future. I've spent 16 years in the PET packaging industry, and I've seen many factory owners face this exact problem. Let's break down this million-dollar decision together, step by step, so you can see the full picture and make the right choice for your business.

True Cost of Ownership (TCO): Initial Savings of an Upgrade vs. Long-Term Efficiency of a New Machine?

You see the lower price tag of an upgrade and think you're saving money. But is that initial saving hiding much larger costs? The real financial story isn't just about the purchase price.

The true cost of ownership reveals that a new machine's efficiency often leads to significant long-term savings that outweigh the higher initial price. An upgrade might seem cheap now, but it can cost you more in energy, maintenance, and lost production over the years.

Deeper Dive: Unpacking the Real Numbers

When you are looking at a big investment, it's easy to focus on the number on the invoice. But the true cost goes far beyond that. I always tell my clients to think about the Total Cost of Ownership (TCO). This includes the initial price, but also all the money you will spend to run and maintain the equipment over its entire life. Let's break this down into three key areas.

Upfront Investment vs. Long-Term Operational Costs

First, let's compare the immediate costs. An upgrade seems straightforward. You buy a few new parts, maybe a modernization kit, pay for labor, and account for the downtime needed to install everything. It looks like the cheaper option on paper. A new machine has a higher purchase price, no question about it. This is where many decision-makers stop their analysis.

But the real story begins after the machine is running. This is where operational costs come in, and the differences are huge.

- Energy Consumption: This is the biggest factor. Most older machines use hydraulic systems. These systems run constantly, consuming a massive amount of electricity even when the machine is idle between cycles. A new, all-electric machine with servo motors uses power only when it's moving. This change alone can cut your energy consumption by 30% to 50%. We'll talk more about this later, but for TCO, this means lower electricity bills every single month for the next 10-15 years.

- Maintenance and Spares: An upgraded machine is still an old machine. The core components—the frame, the main mechanics—are still aged. Upgrading one part can put more stress on another old part, leading to unexpected failures. The costs for spare parts on old machines, if you can even find them, can be very high. With a new machine, you get a full warranty. You have a clear maintenance schedule and easy access to standard spare parts at predictable prices.

- Scrap Rate: New machines have incredibly precise controls. Advanced heating and closed-loop systems mean every bottle is nearly identical. This results in a very low scrap rate, often less than 0.5%. An upgraded older machine will likely never achieve this level of precision. Even a 2-3% scrap rate, which sounds small, adds up to a huge amount of wasted material, preforms, and energy over a year.

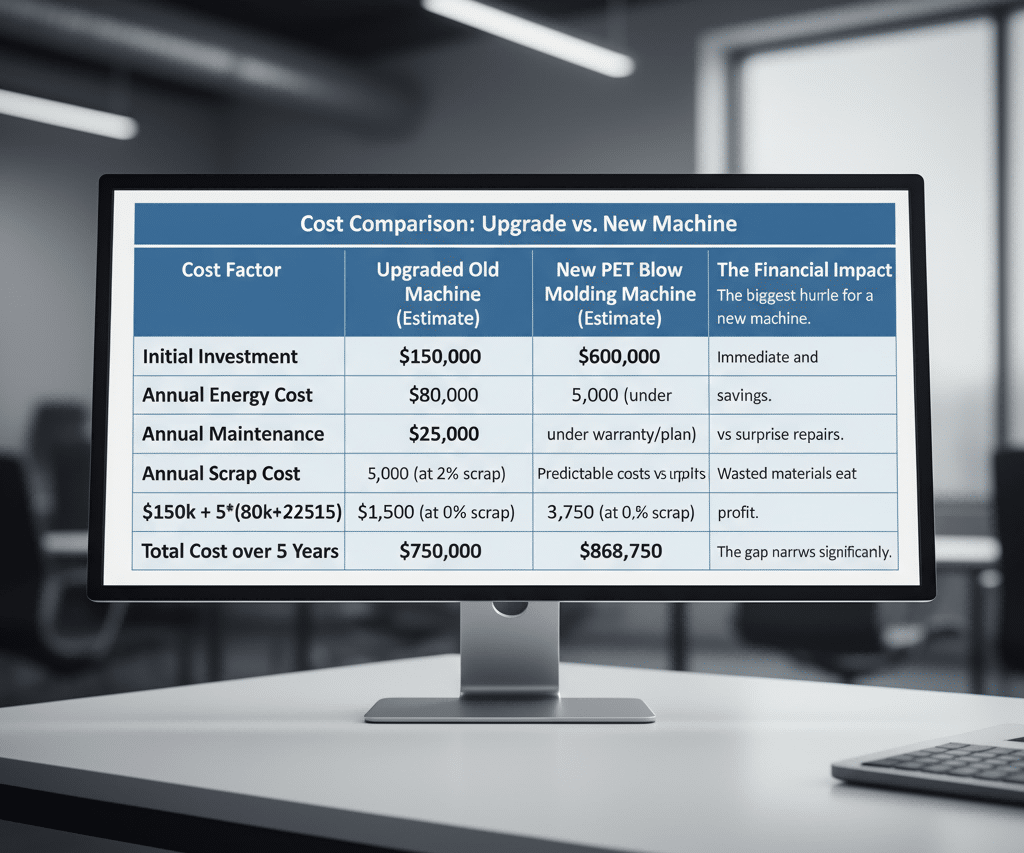

Here is a simple table to illustrate the TCO concept over 5 years.

| Cost Factor | Upgraded Old Machine (Estimate) | New PET Blow Molding Machine (Estimate) | The Financial Impact |

|---|---|---|---|

| Initial Investment | $150,000 | $600,000 | The biggest hurdle for a new machine. |

| Annual Energy Cost | $80,000 | $45,000 | Immediate and continuous savings. |

| Annual Maintenance | $25,000 | $5,000 (under warranty/plan) | Predictable costs vs. surprise repairs. |

| Annual Scrap Cost | $15,000 (at 2% scrap) | $3,750 (at 0.5% scrap) | Wasted materials eat into profit. |

| Total Cost over 5 Years | $150k + 5*($80k+$25k+$15k) = $750,000 | $600k + 5*($45k+$5k+$3.75k) = $868,750 | The gap narrows significantly. |

Note: These are illustrative figures. The actual gap can be smaller or larger depending on production hours, electricity costs, and the condition of the old machine. When we look at a 10-year lifespan, the new machine often becomes the cheaper option.

The "Invisible" Costs of Sticking with Old Tech

The costs you see on a spreadsheet are only part of the story. There are "invisible" costs to upgrading that can be even more damaging.

I had a client in Canada who bought a well-known Chinese brand of blow molder about eight years ago. It was a good machine at the time, an 8-cavity machine running at 12,000 bottles per hour (BPH). But recently, it started having problems. They contacted the original manufacturer for a major overhaul and to get some key replacement parts. The manufacturer's response was a nightmare for them: the machine was an old model, and they no longer produced the necessary parts.

This is an invisible cost. My client now has a massive machine that is a ticking time bomb. If a critical, non-standard part fails, their entire production line stops. They can't just buy a new part. Their choices are to pay a fortune for a custom-machined part or shut down production. The time spent searching for solutions, the stress, the risk to customer orders—these don't show up on an invoice, but they are very real costs.

Upgrades can also lead to compatibility issues. You install a new controller, but it doesn't communicate perfectly with the old sensors. You spend weeks troubleshooting and paying engineers. A new machine is designed to work perfectly from day one. Everything is integrated and tested. This reliability is a form of value that is hard to quantify but essential for peace of mind and stable production. The investment in a new machine is an investment in predictability. The cost of running an upgraded old machine is the cost of uncertainty.

Production Speed & Bottle Quality: Can an Upgrade Truly Meet Tomorrow's Demanding Market?

You need to produce more bottles, faster. But you also face pressure from your customers for lighter, fancier, and more perfect bottles. You wonder if a simple upgrade can really deliver on both speed and quality.

An upgrade might give you a small speed boost, but it often can't match the superior quality and consistency of a new machine. New technology is designed for modern demands like lightweighting and complex designs, which old machine frames struggle with.

Deeper Dive: The Gap Between 'Good Enough' and 'Excellent'

In today's competitive beverage market, "good enough" is no longer good enough. Your packaging is your brand's first impression on the shelf. A flawed bottle can make a customer choose your competitor. At the same time, operational efficiency demands that you produce these perfect bottles at the highest possible speed. An upgrade seems like a path to improvement, but it often falls short of what the market truly demands.

The Hard Metric of Speed (BPH)

Bottles Per Hour (BPH) is a critical number for any beverage factory. It directly impacts your capacity and your ability to meet large orders. An upgrade might involve changing some pneumatic valves to electric ones or optimizing the heating process, which could increase your BPH by 10% or maybe 15%. This sounds good. If your 8,000 BPH machine now runs at 9,000 BPH, that's an extra 24,000 bottles in a single shift.

However, a new generation of bottle blowing machine is built differently from the ground up. The servo motors, the cam linkages, the transfer systems—they are all designed to work in perfect, high-speed harmony. A new machine of a similar size might offer 12,000 or 14,000 BPH as its standard speed. That’s a 50-75% increase in output, not just 10-15%. This is a fundamental difference in capability.

Furthermore, this speed advantage becomes even more critical with modern bottle trends. Lightweight bottles use less plastic, which saves money, but they are much harder to blow correctly. The plastic has to be heated and stretched with extreme precision. The same goes for complex, fancy shapes that brands use to stand out. An older, upgraded machine might have to be slowed down significantly to produce these bottles without a high defect rate. A new machine is designed to handle these challenges at full speed. So, while an upgrade might give you a higher top speed in theory, you may not be able to use it for the very bottles that are most important for your future business.

The Uncompromising Consistency of Quality

Bottle quality is not just about looks; it's about performance and safety. A consistent wall thickness ensures the bottle won't break during filling, capping, or shipping. This is one of the biggest challenges for older machines.

New machines use advanced closed-loop control systems. Sensors constantly monitor the heating of the preforms and the stretching process. The machine's computer makes micro-adjustments in real-time to ensure every single bottle meets the exact specifications. This is how they achieve incredible consistency in wall thickness. An upgrade might add a better heating lamp or a new sensor, but it cannot replicate this integrated, intelligent system. You will still have variations, which means you either accept a higher defect rate or you have to use more plastic in your preforms to be safe—negating the potential savings from lightweighting.

Other quality factors are also at play:

- Clarity and Haze: New machines with precise temperature control in the oven and mold produce bottles with superior clarity. Old systems often have hot or cold spots, leading to a hazy appearance.

- Neck Finish: The precision of a new machine's clamping and blowing process creates a perfectly smooth and flat bottle neck. This is critical for getting a perfect seal from the cap, preventing leaks and preserving the carbonation or freshness of your beverage. An upgraded machine with an older clamping unit might struggle to achieve this level of perfection.

If you are seeing issues like uneven walls or hazy plastic, it's worth reviewing some common solutions. You can often trace these back to the machine's capabilities. A great resource is this guide on common PET blow molding defects and how to fix them quickly. But often, the permanent fix is a machine that has the technology to prevent them in the first place.

The Limitations of an Old Foundation

Finally, you have to consider the physical limitations of the old machine's frame and mechanics. It's like trying to put a sports car engine in a 30-year-old family car. The engine might be powerful, but the chassis, suspension, and brakes were never designed to handle that power.

The same is true for blow molders. Modern production requires new processes that old hardware simply cannot support.

- Hot-Fill Bottles: For juices or teas, you might need bottles that can be filled at high temperatures. This requires a special two-stage blowing and heat-setting process to crystallize the PET. An old machine's oven and mechanics are typically not designed for this.

- High rPET Content: Using recycled PET (rPET) is great for sustainability, but rPET behaves differently than virgin PET. It needs more careful and precise heating. New machines have heating profiles and process controls specifically designed to handle high percentages of rPET, while old machines struggle, leading to poor quality.

The fundamental structure of your old machine limits its potential. No matter how many new parts you add, you are still bound by that original design. Investing in a new machine gives you a foundation that is ready for the next decade of packaging innovation.

Energy Consumption: How Your Old Machine is Quietly Burning Your Profits?

Your electricity bill keeps going up, and you suspect your old machinery is a major reason why. You know it's inefficient, but you're not sure just how much it's costing you.

Your old hydraulic blow molder is a major energy drain, often consuming 30-50% more power than a modern all-electric machine. This hidden cost directly eats into your profit margin on every bottle you produce, silently burning away tens of thousands of dollars each year.

Deeper Dive: The Single Biggest Operational Saving

For most beverage factories, energy is one of the top three operating expenses, right after raw materials and labor. While you can negotiate prices for preforms and manage your workforce, the energy consumption of your main production machine is a fixed reality—or is it? The technological leap from old hydraulic systems to new all-electric servo systems is the single most significant opportunity for cost reduction in your entire bottling line. Let's look at why the difference is so dramatic and how you can quantify it for your own factory.

The Technology Gap: Hydraulic vs. All-Electric Servo

To understand the energy savings, you have to understand the fundamental difference between these two technologies.

Old Hydraulic Systems: Think of a hydraulic machine as a car with its engine always running at full throttle. A large electric motor runs continuously to power a hydraulic pump. This pump keeps a large volume of oil under high pressure. When the machine needs to move—to clamp the mold, to stretch the bottle, to transfer preforms—it opens a valve to let the pressurized oil do the work. The problem is that the motor and pump are running and consuming a huge amount of power all the time, even during the heating and cooling phases when no movement is happening. A lot of this energy is wasted, converted into heat in the hydraulic oil, which then requires even more energy for a cooling system, often involving a chiller, to dissipate. It's a very inefficient cycle.

New All-Electric Servo Systems: An all-electric machine is like a modern electric car. It's silent when it's stopped. It uses high-precision servo motors for each movement. These motors only draw power at the exact moment they need to perform an action. When the mold is clamping, the clamp motor uses power. When it's holding the clamp shut, it uses almost no power. There is no large central motor running all the time. There is no hydraulic pump, no large tank of oil to keep pressurized, and much lower cooling requirements. The energy is used on demand, which is dramatically more efficient.

The difference isn't small. I have seen clients who replaced an old hydraulic machine with a new all-electric one and saw their machine's electricity consumption drop by 40%. For some applications, the savings can be even higher. This isn't an upgrade; it's a complete change in philosophy.

Quantifying Your Annual Savings

You don't have to guess how much you could save. You can estimate it with a simple calculation.

Step 1: Find your machine's power consumption. Look at the technical plate on your old hydraulic machine. It will list a total installed power in kilowatts (kW). Let's say it's 150 kW.

Step 2: Estimate its actual average consumption. A hydraulic machine doesn't run at 100% power all the time, but it's high. A good estimate is that it averages about 60-70% of its installed power.

- 150 kW 0.65 = 97.5 kW* (average hourly consumption)

Step 3: Calculate your annual operating hours. Let's say you run two 8-hour shifts, 5 days a week, for 50 weeks a year.

- 2 shifts 8 hours/shift 5 days/week 50 weeks/year = 4,000 hours/year*

Step 4: Calculate your total annual consumption.

- 97.5 kW 4,000 hours = 390,000 kWh per year*

Step 5: Calculate your annual electricity cost. Find your cost per kilowatt-hour (kWh) from your utility bill. Let's say it's $0.15/kWh.

- 390,000 kWh $0.15/kWh = $58,500 per year*

Now, let's do the same for a new all-electric machine that produces the same output. Its total installed power might be lower, say 120 kW, but the real difference is its average consumption is much lower, maybe 35-40%.

- 120 kW 0.40 = 48 kW* (average hourly consumption)

- 48 kW 4,000 hours = 192,000 kWh per year*

- 192,000 kWh $0.15/kWh = $28,800 per year*

Annual Savings = $58,500 - $28,800 = $29,700

In this example, you would save nearly $30,000 every single year, just on electricity for that one machine. Over the 10-15 year life of the machine, that's $300,000 to $450,000 in savings—which could be a huge portion of the initial purchase price.

Beyond Electricity: The Ripple Effect of Efficiency

The savings don't stop with the electricity bill for the machine itself.

- Reduced Cooling Load: Since the new machine doesn't generate as much waste heat in hydraulic oil, your factory's overall cooling and ventilation costs will also decrease.

- No Hydraulic Oil: A large hydraulic machine can hold hundreds of gallons of expensive hydraulic oil. This oil needs to be filtered and eventually replaced, which is a significant cost and an environmental disposal issue. An all-electric machine has zero hydraulic oil.

- Optimized Air System: While the machine still needs high-pressure air for blowing, the overall system is more efficient. Paired with a modern, cost-efficient air system, the savings can be amplified.

When you add up all these factors, the decision to invest in a new, energy-efficient machine starts to look less like an expense and more like a very smart financial strategy. It's a direct investment in lowering your cost per bottle and increasing your profitability for years to come.

The Maintenance Nightmare & Downtime Risk: Is an Upgrade a Cure or Just Life Support?

You're constantly worried about your old machine breaking down. Finding spare parts is getting harder and more expensive, and any unexpected downtime throws your entire production schedule into chaos.

Upgrading an old machine is often like putting a patch on a bigger problem. It doesn't solve the core issue of aging components. This can lead to a "domino effect" of failures and makes finding critical spare parts a nightmare, creating constant uncertainty and risk.

Deeper Dive: The Choice Between Predictability and Uncertainty

Every factory manager knows that unplanned downtime is the ultimate enemy. It's not just the cost of the repair; it's the cost of idle workers, missed deadlines, and potentially lost customers. When you're deciding between an upgrade and a new machine, you are fundamentally choosing between a future of uncertainty and one of predictability. An upgrade might seem like a fix, but often it's just prolonging the anxiety.

The Spare Parts Dilemma

This is where my Canadian client's story becomes a powerful warning. He had a machine from a major brand, not some obscure manufacturer. Yet, after only eight years, the company had moved on. They had new models, new technology, and they had stopped producing and stocking the specific PLCs, valve blocks, and custom seals for his machine. This is the single biggest risk of owning aging equipment.

The industry is moving incredibly fast. The technology inside a bottle blowing machine today is as different from one from 2015 as a new smartphone is from the first iPhone. Manufacturers simply cannot afford to keep producing parts for every old model. They discontinue them.

When this happens, you are left in a terrible position:

- The Desperate Search: Your maintenance team spends days, sometimes weeks, trying to find a compatible part from a third-party supplier or a used equipment dealer. Every hour they spend searching is an hour your production line is down.

- The Exorbitant Cost: If you do find the part, the supplier knows you're desperate. The price will be hugely inflated. What might have been a $500 part becomes a $5,000 part. Or worse, you have to pay a specialized shop to custom-fabricate the component, which is incredibly expensive and time-consuming.

- The Risky Gamble: You might find a "similar" part and try to make it fit. This rarely works well and can cause even more damage to the machine.

A new machine completely eliminates this problem. You get a full warranty, typically for 1-2 years. You have a direct line to the manufacturer who has a full stock of every single component. You have a parts list with clear prices. This is predictability. You know what a part will cost and how quickly you can get it.

The "Domino Effect" of Failure

Think of your old machine as an ecosystem of aging parts. They have all worn down together over years of operation. When you perform an upgrade, you introduce a brand new, high-performance component into this fragile system.

For example, you replace an old, slow PLC with a fast, modern one. This new brain sends signals faster and more precisely. But can the old pneumatic valves, the aging wiring, and the worn-out sensors keep up? Often, the answer is no. The new, powerful component puts additional stress on all the other old parts connected to it. The valve that was working "well enough" might fail under the faster cycle rate. The old motor might burn out trying to keep up with the new commands.

This creates a "domino effect" of failures. You fix one thing, and a week later something else breaks. Then something else. Your maintenance team is constantly chasing problems instead of performing preventative maintenance. This is what I mean when I say an upgrade is often just "life support." You're not curing the machine's underlying condition—its age—you're just treating the latest symptom. This reactive, chaotic approach to maintenance is incredibly stressful and costly.

Certainty vs. Chaos: The Value of a Warranty

With a new machine, you get a clear, predictable maintenance schedule. The manufacturer tells you: "Check this at 500 hours. Replace this seal at 2,000 hours. Lubricate this bearing every month." Your team can follow a simple plan to keep the machine in perfect condition. This is proactive maintenance. It prevents problems before they happen.

An old machine exists in a state of chaos. You have no idea what will fail next. You can't plan for it. Every day you walk into the factory, you're hoping it will run without a problem. That uncertainty is a huge mental and financial burden.

The warranty and service plan that come with a new machine are more than just a promise to fix things if they break. They are a guarantee of predictability. They allow you to budget accurately for maintenance and, most importantly, to have confidence that your production line will be running when you need it to. You are trading the constant anxiety of unpredictable breakdowns for the calm confidence of a reliable, supported asset. That peace of mind is one of the most valuable things you can buy.

Market Agility: Is Your Old Equipment Holding Your Beverage Brand Hostage?

The market is changing faster than ever. New flavors, new bottle sizes, and new eco-friendly demands pop up constantly. You worry your old, inflexible machine is preventing you from seizing these new opportunities.

Your old equipment is absolutely holding your brand hostage. Its slow changeover times and inability to handle modern bottle designs and materials, like rPET, mean you can't respond quickly to market trends. A new machine gives you the agility to innovate and compete effectively.

Deeper Dive: Winning in a Fast-Moving Market

In the past, a beverage company could succeed by producing millions of the same bottle for years. That era is over. Today's market is all about choice, personalization, and sustainability. Your ability to quickly launch a new product, test a new design, or switch to a more environmentally friendly package is what will set you apart from your competitors. Your production equipment is either your greatest asset in this race or your heaviest anchor. An old, upgraded machine is almost always an anchor.

The Critical Ability for Quick Mold Changes

The trend is moving away from massive production runs and towards "small-batch, multi-category" production. One week you might be running 500ml water bottles, the next you need to produce a 300ml uniquely shaped juice bottle for a new client. Your ability to switch between these products quickly and efficiently is paramount.

On an old machine, changing a blow bottle mold can be a nightmare. It can be a heavy, manual process that takes half a day or more. It requires a highly skilled technician. You have to shut down the line, let things cool, unbolt the heavy mold, hoist it out, bring in the new one, bolt it in, and then spend hours dialing in the process parameters to get the new bottle right. This downtime is a killer for profitability. Because it's so difficult, you avoid it. You turn down smaller, more creative jobs because the changeover is just too much of a hassle.

Modern PET blow molding machines are designed for this new reality. They feature quick-change systems. Molds are often lighter and standardized. Alignment is semi-automated. A trained operator can often swap a mold in under 30 minutes, not 4-6 hours. Furthermore, the machine's control system allows you to save the exact processing parameters for every single mold. When you load the "300ml juice bottle" mold, you also load the "300ml juice bottle" recipe from the HMI. The machine automatically sets the heating profile, blowing pressures, and timings. You can be producing perfect bottles within minutes of the changeover. This is a game-changer. It gives you the agility to say "yes" to new opportunities.

A great way to start this process is by exploring your options. A comprehensive PET bottle mold design guide can show you what's possible, and you can even validate designs quickly with 3D printed samples before committing to a final mold.

Embracing New Designs and Materials

Your marketing team comes to you with a brilliant idea: a new bottle with an intricate, embossed logo and a unique, non-round shape. It looks fantastic. But can your machine make it? With an old, upgraded machine, the answer is often no. The clamp tonnage might not be sufficient for complex shapes, or the heating oven might not be able to create the precise temperature profile needed for the design. You are forced to tell your marketing team, "We can't do that." Your equipment is literally dictating your brand strategy.

A new machine opens up a world of possibilities. They are built with the rigidity, power, and precision needed to handle these creative challenges. They let you, the factory manager, say "yes" to innovation.

The same is true for materials. The biggest trend in packaging is sustainability, and that means using recycled PET (rPET). Consumers demand it, and governments are starting to legislate it. But rPET is more challenging to work with than virgin PET. Its melting and processing characteristics are different. A new machine is designed with the flexibility to handle a high percentage of rPET. Its advanced oven can be finely tuned to the specific needs of the material, ensuring you can produce high-quality, eco-friendly bottles. An old machine, even with an upgrade, will likely struggle, forcing you to use less rPET or suffer from a high defect rate, undermining your sustainability goals. You can't be a green brand if your factory can't run green materials.

This also applies to preforms. The choice of a preform, especially the preform neck size, is critical for bottle performance and cost. A modern machine gives you the flexibility to test and use a wider variety of preform molds to optimize each bottle you produce.

Meeting Regulations and Future-Proofing Your Business

The world of packaging is constantly being shaped by new rules and regulations. Governments are mandating lightweighting to reduce plastic use. They are requiring tethered caps to reduce litter. They are setting targets for recycled content.

These regulations have a direct impact on bottle design and, therefore, on the machine technology required. Lightweighting requires incredible blowing precision. New cap standards might require changes to the neck finish. A new machine from a reputable manufacturer is designed with these current and upcoming trends in mind. Buying a new machine is a way of future-proofing your operations. You are investing in a platform that will be able to meet the regulatory demands of the next 5-10 years.

An upgrade, on the other hand, is a bet on the past. You are spending money to make an old machine slightly better at doing things the old way. You risk finding yourself unable to comply with a new regulation in just a few years, forcing you to make another huge investment then. It's often smarter to make the right investment now and be prepared for the future.

Ease of Use & Automation: A Highly-Paid Technician or an Easy-to-Train Operator?

Finding and keeping skilled, experienced machine technicians is one of your biggest headaches. Training new people on your old, complex machine takes forever, and you rely too much on one or two senior people.

A modern PET blow molder is designed to be operated, not programmed. Its intuitive touchscreen interface and intelligent self-diagnostics mean a new hire can be trained in days, not months. This reduces your reliance on a few key experts and makes your operation more resilient.

Deeper Dive: Solving the Human Factor in Manufacturing

In all the talk about machines, speeds, and costs, we sometimes forget one of the most critical and challenging parts of any factory: the people. The "skills gap" is a real problem. Experienced, old-school technicians who know how to tweak a machine "by feel" are retiring, and it's incredibly difficult to find and afford replacements. The success of your factory can't depend on the intuition of one or two people. The goal of modern automation is to capture that expertise and build it directly into the machine, making it easier for everyone to achieve great results.

The Revolution of the Human-Machine Interface (HMI)

Think about the control panel on your old machine. It's likely a confusing wall of buttons, switches, dials, and small text displays. To a new operator, it's intimidating and completely meaningless. To make an adjustment, you need to know which of the 50 identical buttons to press in the right sequence. Writing down a "recipe" for a bottle is a long list of cryptic numbers. This is why it takes months to train someone to be proficient.

Now, look at the HMI on a new machine. It's a large, full-color touchscreen, just like a tablet.

- Graphical Interface: Instead of abstract numbers, you see a picture of the machine. Want to adjust the temperature in a specific heating zone? You touch that zone on the screen and a simple slider pops up. It's intuitive.

- Recipe Management: All the parameters for a specific bottle are saved under a name you can understand, like "500ml Water Bottle v2". To switch production, you just select it from a list. The machine does the rest. My Canadian client mentioned that on his old machine, a new shift operator would sometimes tweak settings based on his "gut feeling," leading to inconsistent quality. With a recipe system, you get perfect consistency across all shifts.

- Multi-Level Access: You can give a basic operator access only to start/stop the machine and load recipes. A shift supervisor might have access to make small adjustments. Only the plant engineer gets access to change core machine settings. This prevents accidental, costly mistakes.

- Language Support: With a diverse workforce, you can switch the entire interface to different languages with a single touch.

This modern HMI dramatically reduces the training curve. You are no longer training a technician; you are training an operator. A smart, capable person can learn to run a modern machine safely and efficiently in a matter of days. This widens your pool of potential employees and makes your operation less fragile.

Intelligent Diagnostics: The Machine as the Expert

What happens when your old machine stops? An alarm light might flash. Your operator calls the senior technician. The technician comes over, listens to the machine, looks at the pressure gauges, and uses his 20 years of experience to guess what might be wrong. This process is slow, and it only works if that one expert is on site.

A new machine has intelligent self-diagnostics built in. When there's a problem, the HMI doesn't just show a generic "Fault" alarm. It tells you exactly what is wrong, in plain language.

- "Sensor for transfer arm #3 is not responding. Check connection or sensor."

- "Air pressure for pre-blow is below minimum setpoint. Check for leaks in line 2."

- "Heating lamp in Zone 5 has reached end of life. Please schedule replacement."

The machine tells the operator where the problem is and often suggests a solution. An operator with a checklist can often resolve many simple issues without needing to call an engineer. This means less downtime and frees up your high-level technicians to focus on genuine, complex problems and preventative maintenance, rather than running around putting out small fires. This diagnostic system essentially acts as a built-in expert, available 24/7.

Reducing Manual Intervention for Ultimate Consistency

The ultimate goal of automation is to take human variability out of the process. Even the best operator can have a bad day. They might make a small adjustment that they forget to log, leading to a batch of low-quality bottles.

A new, fully automated machine with a closed-loop system aims to run for hours or even days with zero manual intervention. It measures its own output and adjusts itself. For example, if a sensor detects the bottle wall is becoming slightly too thin, the system can automatically increase the heating just a fraction of a degree to compensate. It maintains perfect quality without anyone touching the controls.

This creates a level of production stability that an old, manually-adjusted machine can never hope to achieve. You get the same high-quality bottle at the end of the shift as you did at the beginning, regardless of who is standing at the control panel. This consistency is a hallmark of a modern, world-class manufacturing operation. It’s what allows you to confidently guarantee quality to your customers.

The Future of Asset Value: An Appreciating Investment or a Depreciating Expense?

You need to justify this huge cost to your boss or your partners. You need to frame it not just as a necessary expense, but as a smart financial move for the company's future.

A new PET blow molding machine is a valuable asset that holds its value and can even be sold on the second-hand market later. An upgrade is a sunk cost. You're spending money on a rapidly depreciating asset that has almost no resale value, making it a pure expense.

Deeper Dive: Thinking Like an Investor, Not Just a Manager

When your company spends a million dollars, it's either an expense or an investment. An expense is money that is gone forever, like an electricity bill. An investment is the purchase of an asset that has value and can generate a return. How you categorize the decision to buy a new machine versus upgrading an old one has a huge impact on the long-term financial health of your business. As a factory manager, you need to present this decision in terms of asset value.

The Harsh Reality of the Depreciation Curve

Everything depreciates, but not everything depreciates at the same rate. Let's compare the two paths:

Path A: The Upgrade. You have a machine that is 10 years old. Its book value is probably close to zero. On the open market, it might be worth a small amount for scrap metal. You spend $150,000 to upgrade it. You have now spent $150,000 on an asset that is still fundamentally a 10-year-old machine with a book value of zero. That $150,000 is a sunk cost. It's an expense. You will never get it back. In five years, the machine will be a 15-year-old upgraded machine, and it will still be worth virtually nothing.

Path B: The New Machine. You spend $600,000 on a brand new, state-of-the-art bottle blowing machine. This is a capital asset. It goes on your company's balance sheet. Yes, it will depreciate. But after five years, that machine is still a modern, energy-efficient, well-maintained piece of equipment. It has a real, tangible value on the second-hand market. It might be worth $250,000 or $300,000. So while it has depreciated, it has retained a significant portion of its value.

This is a critical distinction. The money spent on the upgrade vanishes. The money spent on the new machine converts into a tangible asset that your company owns.

| Feature | Upgraded Old Machine | New Machine | Long-Term Financial Impact |

|---|---|---|---|

| Initial Outlay | $150,000 (Expense) | $600,000 (Investment) | Different accounting treatment. |

| Asset Value (Year 0) | ~$0 (base machine) | $600,000 | New machine is a valuable capital asset. |

| Asset Value (Year 5) | ~$0 | ~$300,000 (Estimate) | The new machine retains significant value. |

| Net Cost after 5 Yrs | $150,000 | $600,000 - $300,000 = $300,000 | The true "cost" of the new machine is much lower than the price. |

Demand in the Second-Hand Market

Now, let's think about who buys used equipment. It's often smaller companies, startups, or businesses in developing markets. What are they looking for? They are looking for value. They want a machine that is reliable, efficient, and easy to get parts for.

Which machine would they rather buy in five years?

- A 15-year-old machine with a mix of old and new parts, a discontinued PLC, known for being energy-hungry, with no manufacturer support.

- A 5-year-old, all-electric servo machine from a known brand, with a modern HMI, known for its energy efficiency, and for which parts are still readily available.

The answer is obvious. There is a healthy market for well-maintained, modern used equipment. There is almost no market for old, patched-together machines. My Canadian client with the 8-year-old machine is discovering this harsh reality. He can't sell his machine for much because any potential buyer knows they will face the same spare parts nightmare he is facing. The asset's value has collapsed because its operational future is uncertain. An important part of ensuring future value is making sure your machine and molds are compatible with industry standards. We've seen so many issues with this that we now maintain a database to ensure proper blow mold fit for 80% of machines worldwide, which is a key consideration for future buyers.

The True Nature of Return on Investment (ROI)

When you calculate the ROI for an upgrade, you're mostly looking at cost avoidance—the cost of not having a catastrophic failure. It's a defensive, low-return calculation.

When you calculate the ROI for a new machine, you are looking at multiple streams of positive returns:

- Return from Energy Savings: Tens of thousands of dollars per year.

- Return from Reduced Scrap: Thousands of dollars in saved material costs.

- Return from Increased Output: Higher BPH means more revenue-generating capacity.

- Return from Labor Flexibility: Reduced reliance on expensive technicians.

- Return from Market Agility: The ability to win new, high-margin business.

- Return from Retained Asset Value: The residual value of the machine after 5, 7, or 10 years.

Investing in a new machine is an offensive move. It's an investment in building a more profitable, more agile, and more valuable business for the future. The upgrade is just an expense to keep the past running for a little while longer. When you present the numbers this way, the "million-dollar decision" starts to look much clearer.

The Final Decision Checklist: A Simple Table to Help You Make the Smartest Choice?

You've processed a lot of information. Costs, quality, energy, maintenance. Now you need a clear way to see which path is right for your specific situation.

This final checklist will help you make a clear-eyed decision. By honestly assessing your budget, market position, and operational priorities, you can move forward with confidence, whether you choose a limited upgrade or invest in a powerful new machine for your future.

Deeper Dive: Your Personalized Decision Matrix

There is no single answer that is right for every factory in the world. The correct choice depends entirely on your unique circumstances. I've designed this checklist based on the hundreds of conversations I've had with factory owners over the past 16 years. This is not about what I want to sell you; it's about helping you find the right path for your business. Be honest with yourself as you go through these points.

The core of the decision comes down to this: Are you playing defense or offense? Are you trying to survive for another two years, or are you building a business to thrive for the next ten?

When You Should Seriously Consider an Upgrade

An upgrade can be a valid strategic choice under a very specific set of circumstances. It is essentially a short-term, defensive move. You should only consider it if you can check most of the boxes in this table:

| Checklist Item | If You Can Say YES, an Upgrade Might Be Feasible... |

|---|---|

| Budget Constraints | "Our capital expenditure budget is extremely limited for the next 1-2 years. We absolutely cannot get approval for a new machine right now." |

| Product Roadmap | "We have no plans to launch new bottle shapes, sizes, or use new materials like rPET in the next 3-5 years. Our product line is very stable." |

| Market Position | "We compete primarily on cost for a few high-volume, standard products. We are not trying to be a market innovator." |

| Current Profitability | "Our existing products are highly profitable, and our energy costs are a relatively small percentage of our total cost per bottle." |

| Machine Condition | "The core mechanics of our machine—the frame, the main platens—are in excellent condition. The problems are mostly with outdated controls or pneumatics." |

| Parts & Support | "We have a confirmed, reliable source for all major spare parts for our current machine, and the original manufacturer still offers support." |

| Technical Team | "We have a highly skilled, in-house technical team that is very experienced with this specific machine and capable of performing the upgrade and ongoing maintenance." |

If you look at this list and can't confidently say "yes" to at least five of these points, an upgrade is likely to be a poor investment that will cause more problems than it solves.

When You Absolutely Must Buy a New Machine

A new machine is an offensive move. It's an investment in growth, efficiency, and future competitiveness. If your goals are aligned with the points in this table, then investing in new technology is not just an option, it's a necessity.

| Checklist Item | If You Can Say YES, a New Machine is Essential... |

|---|---|

| Strategic Goals | "We plan to grow our business by launching innovative, lightweight, or uniquely shaped bottles to capture new market segments." |

| Sustainability Targets | "Our brand is committed to sustainability, and we need the capability to use high percentages of rPET and lightweight our bottles." |

| Operational Costs | "Energy and maintenance costs are too high and are significantly impacting our profitability. We need to lower our cost-per-bottle." |

| Quality & Downtime | "Our current scrap rate is unacceptable, and unplanned downtime is hurting our ability to meet customer orders reliably." |

| Labor Challenges | "We are struggling to find or retain skilled technicians, and we need machines that are easier to operate and maintain." |

| Brand Image | "We want to be seen as a modern, high-quality, and reliable supplier. Our production technology needs to reflect our brand promise." |

| Long-Term Vision | "We are investing for the next 10-15 years. We need an asset that will retain its value and keep us competitive for the long term." |

If you checked even three or four of the boxes in this second list, the business case for a new machine is incredibly strong. The risks of sticking with old technology are simply too high.

Your Next Step: Get a Customized ROI Analysis

These checklists give you a clear direction. But to get final approval for a major investment, you need hard numbers. You need a detailed Return on Investment (ROI) analysis that is based on your factory's real data—your electricity costs, your labor rates, your scrap rates, and your production hours.

This is something I can help with.

As a part of my service, I work with factory owners like you to build a personalized ROI report. We will plug in your numbers and compare the 5-year and 10-year Total Cost of Ownership for an upgrade versus a new machine from my company, iBottler. The report will clearly show you the payback period for your investment and the total savings you can expect.

This isn't a sales pitch; it's a strategic planning tool. It will give you the data you need to make this million-dollar decision with complete confidence. Contact my team at iBottler, and let's schedule a call to start building your customized analysis today.

Conclusion

Choosing between an upgrade and a new machine is a major decision. While an upgrade seems cheaper initially, a new machine is a smarter investment in long-term efficiency, quality, and market agility.

Frequently Asked Questions (FAQ)

1. How much energy can I really save with a new machine?

You can realistically expect to save between 30% and 50% on the machine's electricity consumption. This is because new all-electric servo machines only use power on demand, unlike older hydraulic systems that run a power-hungry pump continuously. For a typical factory, this can translate to tens of thousands of dollars in savings every year.

2. What if my budget only allows for an upgrade right now?

If your budget is truly fixed, an upgrade might feel like your only option. However, first perform a detailed Total Cost of Ownership (TCO) analysis. When you factor in the high energy and maintenance costs of the old machine, plus the risk of downtime, you may find that financing a new machine is actually cheaper in the long run. Many equipment manufacturers offer financing options that can make the initial investment more manageable.

3. How long does it take to get a return on investment (ROI) for a new PET blow molding machine?

The ROI period varies depending on your production volume, energy costs, and labor savings, but many factories see a full return on their investment within 3 to 5 years. This is driven by lower energy bills, reduced material waste (lower scrap rate), higher output (BPH), and lower maintenance costs.

4. My old machine still works, why should I replace it?

A machine "working" is not the same as it being profitable or competitive. Your old machine is likely costing you a fortune in hidden costs—excess energy use, higher scrap rates, slow changeovers, and the huge risk of a breakdown due to obsolete parts. A new machine isn't just a replacement; it's a tool to make your entire operation faster, leaner, and more agile.

5. Can an upgraded machine handle recycled PET (rPET) as well as a new one?

No, it generally cannot. Processing high percentages of rPET requires very precise heating and process control that old machines were not designed for. New machines have advanced ovens and intelligent controls specifically developed to handle the unique properties of rPET, allowing you to produce high-quality sustainable packaging without the high defect rates you would likely experience on an older, upgraded machine.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr