Your bottle label says 500ml, but the bottle holds more. This confusion can lead to costly production errors. How do you master these different volumes to ensure a perfect product run every time?

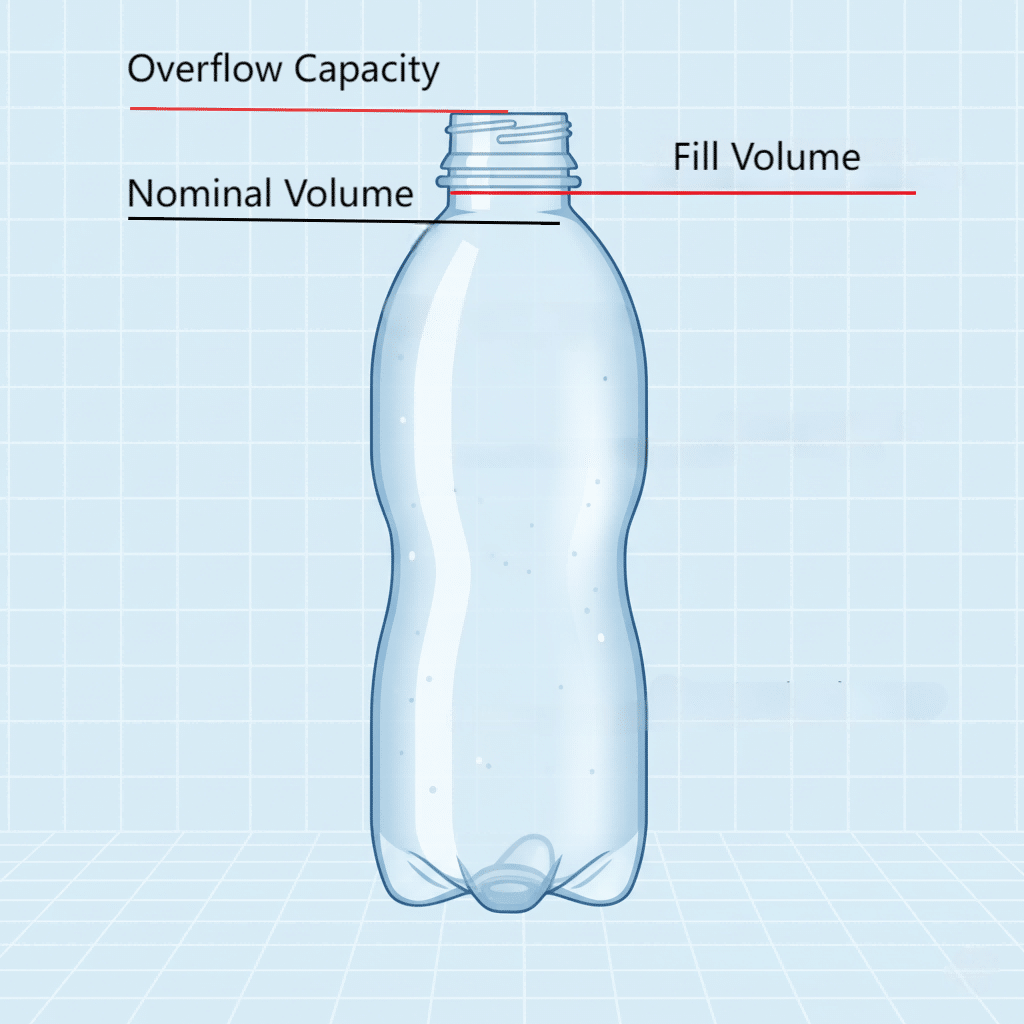

The key is understanding three distinct capacities: Nominal Volume (the label claim, e.g., 500ml), Fill Volume (the actual liquid amount set by your filler), and Overflow Capacity (the bottle's absolute maximum volume). Mastering the relationship between these three prevents costly production errors and ensures consistency.

Getting these volumes wrong isn't just a small mistake. It can lead to product recalls, legal issues, and massive financial loss. I've seen it happen. But once you understand the role each capacity plays, you can turn a potential problem into a streamlined, efficient, and profitable production line. Let’s dive deep into what each of these terms means for your business.

The Three Core Capacities Every Producer Must Know?

You have a bottle design, but do you truly understand its volume? Many producers focus only on the number on the label. This oversight can cause major headaches on the filling line later.

Each PET bottle has three critical capacities: Nominal, Fill, and Overflow. They are not the same. Each one serves a vital purpose, from making a promise to the consumer, to defining the reality on your production line, to verifying the quality of your manufacturing process itself.

Understanding these three capacities is the first step toward total process control. Nominal Volume is your legal declaration to the customer. Fill Volume is the practical target for your filling machine. Overflow Capacity is the ultimate test of your blow bottle mold and process stability. Think of them as three legs of a stool. If one is off, the entire operation becomes unstable. In my years of experience, I've seen that the clients who grasp this concept from the start are the ones who avoid the most expensive mistakes. They understand that a bottle isn't just a container; it's a precisely engineered tool. This guide will break down each capacity, showing you how they connect and why controlling all three is essential for success. We'll look at why the space you don't fill is just as important as the space you do, and how a simple measurement can tell you everything you need to know about the health of your production.

A Deeper Look at the Trio

The journey from a plastic preform to a filled bottle on a store shelf is a story told in volumes. Let's break down why each one matters so much.

Nominal Capacity: This is the most straightforward. It's the volume you print on the label. If your bottle says "500ml," that is its nominal capacity. It is a commercial agreement and a legal requirement. It's the promise you make to your customer about how much product they are buying. This volume is governed by weights and measures regulations, and failing to meet it can result in serious penalties. It's the number that marketing, legal, and sales departments care about the most.

Fill Volume (or Fill Level): This is where engineering takes over. The fill volume is the actual amount of liquid your filling machine dispenses into the bottle. It must, at a minimum, be the nominal capacity. However, it is almost always slightly more to ensure you're compliant. But it can't be the same as the overflow capacity. You need to leave some empty space at the top. This empty space is called headspace, and it's critically important for reasons we'll discuss soon. Setting the correct fill volume is a balancing act between legal compliance, product stability, and profitability.

Overflow Capacity (or Brimful Capacity): This is the true, total internal volume of the bottle if you were to fill it right to the very top, with no headspace. This number is invisible to the consumer, but it is the most important metric for you, the producer, and for me, the mold maker. Why? Because the overflow capacity is a direct reflection of the physical cavity of the blow bottle mold. If this volume is consistent from bottle to bottle, it means your blowing process is stable. If it varies, it's the first sign of trouble.

Here's a simple table to clarify the roles of each capacity:

| Capacity Type | Primary Role | Who Cares Most? | Key Consideration |

|---|---|---|---|

| Nominal Capacity | Commercial & Legal | Marketing, Legal, Sales, Consumer | The "promise" on the label (e.g., 500ml). |

| Fill Volume | Production & Product Safety | Production Manager, Quality Control | The actual liquid amount, allowing for headspace. |

| Overflow Capacity | Process & Quality Control | Mold Maker, QC, Plant Manager | The total possible volume; a measure of consistency. |

Mastering the interplay between these three is fundamental. You design for a specific overflow capacity to achieve a target fill volume that safely delivers the promised nominal capacity. It's a chain of dependencies where one weak link can break the entire process.

Nominal Capacity: The Promise to Your Customer?

You see a bottle on the shelf labeled "1 Liter." You buy it expecting 1 liter of product. This is the power and responsibility of nominal capacity. It’s not just a number; it’s a binding promise.

Nominal capacity is the legally declared volume on the bottle's label. This is a commercial and legal standard that the final filled product must meet or exceed. It is the single most important number from the consumer's perspective and is heavily regulated by trade and safety standards.

This number dictates everything. It influences the price, the nutritional information, and the consumer's trust in your brand. Getting it wrong can lead to fines, forced recalls, and lasting damage to your reputation. If you promise 500ml, you must deliver at least 500ml in every single bottle. To ensure this, your actual fill volume will need to be slightly higher, creating a buffer. But this promise starts long before the filling line; it starts with a proper PET bottle mold design guide. The entire bottle, from its shape to its overflow capacity, must be engineered to reliably deliver on this nominal promise.

Beyond the Label: Legal and Brand Implications

The nominal capacity is where your product meets the law. Almost every country has a government body responsible for ensuring that consumers get what they pay for. In the U.S., it's the Fair Packaging and Labeling Act. In the EU, it's the e-mark system. These regulations are strict. They specify not just that the average volume in a batch must meet the label, but also how many individual bottles are allowed to fall below that amount, and by how much. This is known as the "Tolerable Negative Error" or TNE.

Let's break down the consequences of failing to meet the nominal capacity:

- Legal Penalties: If an inspection finds your products are consistently under-filled, you can face significant fines. Regulators can also order you to stop selling the product immediately, leading to massive disruptions in your supply chain.

- Reputational Damage: Word travels fast. An accusation of short-changing customers, whether intentional or not, can destroy consumer trust that took years to build. This can have a far greater financial impact than any fine. Your brand's integrity is on the line.

- Retailer Relationships: Major retailers have their own quality standards. If your product is found to be non-compliant, they may refuse to stock it, delist your brand, and even charge you back for the costs associated with the recall.

This is why the nominal capacity cannot be an afterthought. It must be the starting point of your entire project. It defines the minimum performance requirement for your entire production line, from the bottle blowing machine that forms the container to the filler that dispenses the liquid. I always tell my clients to think of the nominal capacity as the foundation of a house. If the foundation is weak or poorly defined, everything you build on top of it is at risk of collapse. You must design the bottle and process with enough margin to guarantee that, even with slight variations in filling, every single bottle honors the promise made on its label.

Fill Volume & Headspace: The Reality on the Production Line?

You've promised the customer 500ml. But you can't just fill the bottle with 500ml of liquid. The reality of production is more complex, involving product safety, stability, and the laws of physics.

Fill volume is the actual amount of liquid you put into the bottle, set on your filling machine. To ensure you meet the 500ml nominal promise, you might set the filler to 503ml. The empty space left above this liquid is the "headspace," and it's essential for product integrity.

Headspace is not wasted space. It is a crucial design feature. It allows for thermal expansion if the product heats up, preventing leaks. For carbonated drinks, it provides the room needed for the gas to exist without creating excessive pressure. Ignoring headspace is a recipe for disaster on the production line and on the store shelf. Therefore, the bottle's total volume—its overflow capacity—must be large enough to accommodate both the fill volume and this vital headspace.

The Science and Safety of Headspace

Headspace might look like empty space, but it's performing several critical jobs. The amount of headspace required is not arbitrary; it's calculated based on the specific properties of your product and its life cycle.

Let's look at why it's so important for different product types:

Non-Carbonated Beverages (e.g., Water, Juice): The primary role of headspace here is to accommodate thermal expansion. A bottle filled in a cool factory might be transported in a hot truck. The liquid will expand as its temperature rises. Without enough headspace, the pressure inside the bottle could force the cap to leak or even cause the bottle base to deform, making it unstable. A typical headspace for these products is 3-5% of the nominal volume.

Carbonated Soft Drinks (CSDs): For CSDs, headspace is even more critical. It's needed to manage the equilibrium pressure of the dissolved carbon dioxide ($CO_2$). When a CSD bottle is filled, it is often pressurized with $CO_2$ to keep the gas in solution. The headspace provides a buffer zone, ensuring the internal pressure remains within safe limits during transport and storage, preventing the bottle from becoming dangerously rigid or bursting. This often requires a headspace of 5-7% or more.

Hot-Fill Products (e.g., Teas, Sports Drinks): In hot-filling, the product is filled at a high temperature (around 85°C or 185°F), and the bottle is capped immediately. As the product cools, it contracts significantly. This contraction creates a vacuum inside the bottle. The headspace is essential for this vacuum to form properly. This vacuum pulls in the bottle's side panels (designed as "vacuum panels"), adding rigidity to a lightweight bottle and acting as a tamper-evident feature.

Here is a table detailing typical headspace requirements:

| Product Type | Key Function of Headspace | Typical Headspace Volume | Potential Problem if Incorrect |

|---|---|---|---|

| Still Water | Thermal Expansion | 3-5% | Leaking, Base Deformation |

| Carbonated Drinks | Pressure Management | 5-7% | Over-pressurization, Bottle Bursting |

| Hot-Fill Juices/Teas | Vacuum Formation | 6-10% | Panel collapse failure, Lost rigidity |

The fill volume you set on your machine is therefore a precise calculation: it must be equal to or greater than the nominal volume, but low enough to leave the required headspace. This is why a precise and consistent overflow capacity is non-negotiable. You need a reliable container to execute this delicate balancing act millions of time over. This is also where things like the preform neck size come into play, as it must be compatible with your filling heads for a clean, accurate fill.

Overflow Capacity: The True Measure of Your Mold and Process?

Consumers never see it, and marketers don't talk about it. So why is overflow capacity the most important volume of all? Because it tells you the truth about the health of your manufacturing process.

Overflow capacity is the absolute maximum volume the bottle can hold when filled to the very brim. This is a critical Quality Control (QC) parameter used to verify the consistency of your blow molding process. It is a direct measurement of the internal volume of your mold's cavity.

If you produce 1,000 bottles and each one has an identical overflow capacity, it means your process is perfectly stable. The preform heating is even, the blowing pressure is consistent, and the mold is performing flawlessly. It's the ultimate indicator of stability. Any variation in this number is a warning sign that something in your process is drifting, which can lead to a cascade of problems downstream.

The Foundation of Quality Control

In manufacturing, you can't control what you don't measure. Overflow capacity is the single most important measurement for a PET bottle because it's a direct proxy for process stability. A stable process produces bottles with consistent wall thickness, weight, and performance characteristics. An unstable process does not.

Here’s how we use overflow capacity as a QC benchmark:

Establishing a Baseline: When a new blow bottle mold is commissioned, the first thing we do is run a series of tests to establish the target overflow capacity and its acceptable tolerance range (e.g., 525ml ± 2ml). This becomes the "golden standard" for all future production runs.

Routine Production Checks: During production, operators will pull bottles from the line at regular intervals (e.g., every 30 minutes) and measure the overflow capacity. This is a quick and simple test. If the measurement falls within the specified tolerance, the process is considered stable.

Troubleshooting and Diagnosis: If the overflow capacity starts to drift high or low, or if the variation between bottles increases, it's an immediate signal to investigate. It tells the technicians exactly where to look. Is the preform temperature fluctuating? Is the high-pressure air from the air compressor unsteady? Is the mold cooling, which relies on the chiller connection, not working correctly? The overflow capacity measurement points them in the right direction.

I once had a client whose filling line was experiencing random low-fills. Their first instinct was to blame the filler, but the machine checked out fine. I asked them to start measuring the overflow capacity of their bottles. They discovered that about 5% of their bottles had a significantly larger overflow capacity. This meant the bottle walls were too thin in some areas, causing the bottle to expand more during blowing. The extra volume was the culprit. The filler was dispensing the correct amount of liquid, but in these larger bottles, it resulted in a lower fill height, triggering the rejection sensor. The problem wasn't the filler; it was an unstable blowing process. By focusing on overflow capacity, they found the root cause in the preform oven, saving them weeks of frustrating and expensive guesswork. This is why I always say: trust the overflow capacity. It never lies.

Why Inconsistent Overflow Capacity Is a Major Red Flag?

You notice your fill levels are bouncing up and down, causing rejects and slowing your line. You blame the filling machine, but the real problem might be starting much earlier. An inconsistent overflow capacity is a serious warning.

Variable overflow capacity indicates deep problems in your process. It could mean uneven wall thickness, inconsistent preform heating, or a worn-out mold. This directly leads to unstable fill levels, potential line stoppages, and a product that looks unprofessional and inconsistent on the shelf.

This is not a small issue you can ignore. It’s a sign that you are losing control of your process. I had a client in Denmark who learned this the hard way. They started with a mold designed to have a 550ml overflow capacity. They mistakenly had 100,000 labels printed that read "550ml," assuming this was their fill volume. But their filling machine couldn't fill to the brim; it was set to leave a headspace, resulting in a fill volume of only 540ml. They were faced with a terrible choice: either throw away all the labels or pay for an expensive mold modification to increase the overflow capacity, so that a 550ml fill volume would still leave a safe headspace. An inconsistent process just makes this guessing game impossible and far more costly.

Diagnosing the Root Causes

When I see inconsistent overflow capacity, I know it's a symptom of a deeper issue. It's like a fever in the human body—it tells you something is wrong, and you need to find the cause. Let's break down the most common culprits.

Uneven Preform Heating: This is the number one cause. The preform must be heated to a precise and uniform temperature profile before it enters the mold. If some parts of the preform are too hot, the plastic will stretch too easily, creating thin spots and increasing the bottle's volume. If parts are too cold, the plastic won't stretch enough, resulting in thick spots and a smaller volume. This can be caused by faulty oven lamps, poor ventilation, or incorrect settings.

Fluctuating Blowing Pressure: The bottle is formed by high-pressure air that forces the hot preform against the mold walls. If this pressure is not consistent from cycle to cycle, the material distribution will vary. A sudden drop in pressure can result in an under-formed bottle with a smaller capacity. This points to issues with the air compressor or air delivery system.

Inconsistent Mold Temperature: The mold is actively cooled by a chiller. If the cooling is inefficient or uneven, some parts of the mold will be warmer than others. This affects how quickly the PET "freezes" into its final shape, altering the final internal volume. Blocked cooling channels are a common cause.

Worn-Out Mold or Components: Molds are precision tools, but they do wear out over time. The parting lines can wear down, or the cavity surface can become damaged. This can change the internal dimensions of the mold, directly impacting the overflow capacity. Regular maintenance is crucial.

Here's a troubleshooting table that connects the symptom to the likely cause:

| Symptom | Possible Root Cause | Where to Look First | Related Defect Link |

|---|---|---|---|

| Overflow capacity is consistently high | Preform is too hot; Material is too thin | Check oven lamp settings and temperatures | Common PET Blow Molding Defects |

| Overflow capacity is consistently low | Preform is too cold; Insufficient blow pressure | Check preform temperature profile and air pressure | Common PET Blow Molding Defects |

| High variation in overflow capacity | Unstable heating; Fluctuating air pressure | Monitor oven stability and compressor output | Common PET Blow Molding Defects |

| Gradual increase in overflow capacity | Mold wear, especially on the base | Inspect the mold cavity and parting line for wear | Common PET Blow Molding Defects |

Ignoring these warning signs doesn't just risk inconsistent fill levels. It risks catastrophic bottle failures, such as stress cracking or bursting under pressure, because the underlying cause is almost always poor material distribution.

How to Measure Bottle Capacities Accurately?

You can't control what you don't measure. Talking about capacities is one thing, but how do you get a reliable number? Thankfully, measuring overflow capacity is simple, fast, and requires minimal equipment.

The most accurate way to measure overflow capacity is the gravimetric method, which uses weight. You weigh an empty bottle, fill it to the brim with water, weigh it again, and then calculate the volume based on the water's known density. It's a highly precise method.

This practical skill is essential for any quality control team. It’s the first step in diagnosing production issues and validating that a new mold meets specification. This simple test, which takes only a minute, can save you thousands of dollars by catching process deviations before they result in a large batch of rejected products. Let’s walk through the exact steps.

A Step-by-Step Guide to the Gravimetric Method

This method is the industry standard for a reason: it's accurate, cheap, and easy to perform right on the factory floor. All you need is a calibrated digital scale with good precision (at least 0.01 grams), water at a known temperature, and a syringe or pipette for precise filling.

Step 1: Prepare the Bottle and Equipment

Ensure the sample bottle is clean, dry, and at room temperature. Let the bottle sit for at least an hour after molding to allow the PET to stabilize. Also, let your water sit out so it reaches a stable room temperature. You'll need to know this temperature to get the correct density value.

Step 2: Weigh the Empty Bottle

Place the empty, uncapped bottle on the digital scale. Tare the scale (set it to zero) with nothing on it first. Then, place the bottle on the scale and record its weight. Let's call this W_empty.

Example: W_empty = 20.50 grams

Step 3: Fill the Bottle with Water

Carefully fill the bottle with water. As you approach the top, use a syringe or pipette to add the last few drops. You want to create a slightly convex meniscus—where the water surface bulges slightly above the rim of the bottle opening—without any spillage down the side. This ensures it is truly at its maximum overflow capacity.

Step 4: Weigh the Filled Bottle

Carefully place the water-filled bottle back on the scale. Be sure not to spill any water. Record the total weight of the filled bottle. Let's call this W_full.

Example: W_full = 545.75 grams

Step 5: Calculate the Weight of the Water

Subtract the empty bottle's weight from the full bottle's weight. This gives you the net weight of the water inside.

W_water = W_full - W_empty

Example: W_water = 545.75g - 20.50g = 525.25 grams

Step 6: Calculate the Volume

The final step is to convert the weight of the water to volume. The volume of water is its weight divided by its density. The density of water changes slightly with temperature. At a typical room temperature of 20°C (68°F), the density of water is approximately 0.9982 g/ml.

Volume = W_water / Density_water

Example: Volume = 525.25 g / 0.9982 g/ml = 526.19 ml

The overflow capacity of your bottle is 526.19 ml. By performing this test on multiple bottles from a production run, you can quickly determine if your process is stable and within the required specification.

The Ideal Relationship: Connecting All Three Capacities for Optimal Production?

You know the three capacities, but how do they work together? A successful production run depends on them having a specific, stable relationship. Getting this balance wrong leads to chaos on the filling line.

The ideal relationship can be summarized in a simple formula: Nominal Volume < Fill Volume < Overflow Capacity. A well-designed bottle and a stable process will have a consistent and adequate gap between these values. This ensures a smooth and reliable production run every time.

This "gap" is your safety margin. It ensures you always meet the legal requirement (Fill > Nominal) while preventing spills and managing product stability (Fill < Overflow). A poorly designed bottle might have an overflow capacity that is too close to the nominal volume, leaving no room for error or headspace. This is a recipe for disaster. This is a conversation I have with every single client at the start of a project. Just yesterday, I was explaining this to a client from the UK. He sent me a drawing for a 600ml bottle and had marked the fill line at exactly 600ml, right at the top. I had to explain that this was the overflow capacity, not a realistic fill level. We needed to design the bottle's total overflow volume to be larger—say, 630ml—so his filling machine could safely target a fill volume of 605ml, guaranteeing he met his 600ml promise while still leaving 25ml of crucial headspace. It's this deep understanding of the entire process that's central to a successful PET bottle mold design.

Engineering the Perfect Balance

Achieving the ideal relationship isn't an accident. It's the result of careful engineering and process control. The goal is to create a "process window" where your production can run efficiently without constant adjustments.

Let's use our 500ml water bottle example to illustrate the ideal balance:

- Nominal Capacity: 500ml. This is the non-negotiable promise on the label.

- Target Fill Volume: 503ml. This gives a 3ml safety buffer to ensure that even with minor filler variations, the volume never drops below 500ml. This protects you legally.

- Required Headspace: For still water, let's say we need 4% headspace for thermal expansion. 4% of 503ml is about 20ml.

- Target Overflow Capacity: To accommodate the fill volume and the headspace, the minimum overflow capacity must be 503ml + 20ml = 523ml.

- Final Mold Design: To add a manufacturing safety margin, we would design the mold to have a target overflow capacity of 525ml. This gives us a comfortable window to work within.

This creates clear targets for everyone in the production chain.

| Parameter | Target Value | Purpose | Tolerance |

|---|---|---|---|

| Nominal Capacity | 500 ml | Legal & Commercial Promise | None (Must be met or exceeded) |

| Fill Volume | 503 ml | Production Target | ± 1.5 ml |

| Overflow Capacity | 525 ml | QC & Process Stability Target | ± 2.0 ml |

With this structure, you have a robust process. Your filling machine targets 503ml. The QC team checks for an overflow capacity of 525ml. As long as both are within their tolerances, you know that every bottle will be legally compliant, safe for the consumer, and efficient to produce. This clarity prevents the kind of costly mistake my Danish client made. By understanding this relationship from the start, they could have matched their labels, their fill volume, and their mold design perfectly, saving them a fortune. This is the level of detail that turns a simple container into a high-performance product.

Partner with a Manufacturer Who Understands Capacity Control?

You can have the best filling machine in the world, but it's useless if your bottles are inconsistent. True production efficiency starts with the mold. You need a partner who understands the entire process, not just how to cut metal.

As an experienced manufacturer, we design and build molds with precise overflow capacity control as a top priority. We know that our success is measured by how perfectly your bottles perform on your filling lines. That is our ultimate goal.

We obsess over the details that guarantee consistency. We use advanced simulations to predict material flow, ensuring uniform wall thickness. We engineer optimized cooling channels to maintain stable mold temperatures. We understand that a difference of just one milliliter in overflow capacity can be the difference between a smooth run and a costly shutdown. That is why we work to ensure our molds will be a perfect fit for your blowing machine, minimizing the variables from the very start.

Our Commitment to Your Success

Our job isn't finished when the mold is shipped. We see ourselves as your partner in production. Our design philosophy is built around ensuring your success on the factory floor.

Here’s how we turn our expertise into your advantage:

Design for Manufacturing (DFM): Before we cut any steel, we analyze your bottle design through the lens of the complete production line. We consider your nominal capacity, your product type, your required headspace, and your filling line's capabilities. We use this information to engineer a bottle and mold with the ideal overflow capacity and a wide, stable process window. This collaborative approach is central to our PET bottle mold design guide.

Rapid Prototyping and Validation: We don't believe in guesswork. We provide 3D printed samples and functional prototypes early in the process. This allows you to hold the bottle, test it on your equipment, and perform your own capacity measurements. You can validate the design and feel confident long before the final production mold is made. This critical step de-risks the entire project.

Precision Engineering and Materials: We use only the highest-grade materials and state-of-the-art CNC machining to build our molds. Our quality control is relentless. Every mold cavity is scanned and measured to ensure its volume is exactly to specification. This guarantees that the overflow capacity of your bottles will be consistent from the first shot to the millionth.

Comprehensive Support: We understand that the mold is part of a larger system. We provide guidance on everything from selecting the right preform mold to optimizing your blowing process parameters. We know how variables like preform temperature and air pressure affect the final bottle capacity, and we share that knowledge with you.

Ultimately, you are not just buying a mold; you are investing in consistency, reliability, and peace of mind. Partnering with a manufacturer who understands the critical relationship between overflow, fill, and nominal capacity is the smartest investment you can make for your production line.

Conclusion

Mastering PET bottle capacity is not optional. Understanding the distinct roles of nominal, fill, and overflow volume is essential for legal compliance, product safety, and production efficiency. Get this right, and you ensure a stable and profitable operation.

Frequently Asked Questions

Q: What are the main causes of inconsistent overflow capacity in PET bottles?

A: Inconsistent overflow capacity is a direct sign of an unstable blow molding process. The most common causes are uneven preform heating, fluctuating blowing pressure, or a poorly maintained mold. These issues lead to variable wall thickness, which changes the bottle's internal volume.

Q: How much headspace is typically required in a PET bottle?

A: The ideal headspace depends on the product. For non-carbonated water, 3-5% of the nominal volume is common. For carbonated soft drinks (CSDs), you might need 5-7% or more to handle internal pressure. For hot-fill products, the headspace is critical for creating the vacuum that gives the bottle rigidity.

Q: Can I change a bottle's overflow capacity without making a new mold?

A: No. The overflow capacity is a direct function of the mold's internal cavity volume, which is a fixed physical dimension. To change the overflow capacity, you must create a new mold or modify the existing one (which is often not feasible or cost-effective).

Q: Is there an industry standard for overflow capacity tolerance?

A: While there isn't one single universal standard, a good manufacturing practice (GMP) is to keep the overflow capacity tolerance within a very tight range, often ±0.5% to ±1.0% of the target volume. This level of consistency is crucial for high-speed, automated filling lines.

Q: How does the bottle's gram weight relate to its overflow capacity?

A: They are two different but related QC parameters. Overflow capacity measures the volume, while gram weight measures the mass of PET used. A bottle can have the correct overflow capacity (correct shape) but the wrong gram weight, leading to thin spots and performance failures. Both must be controlled simultaneously for a quality bottle.

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr