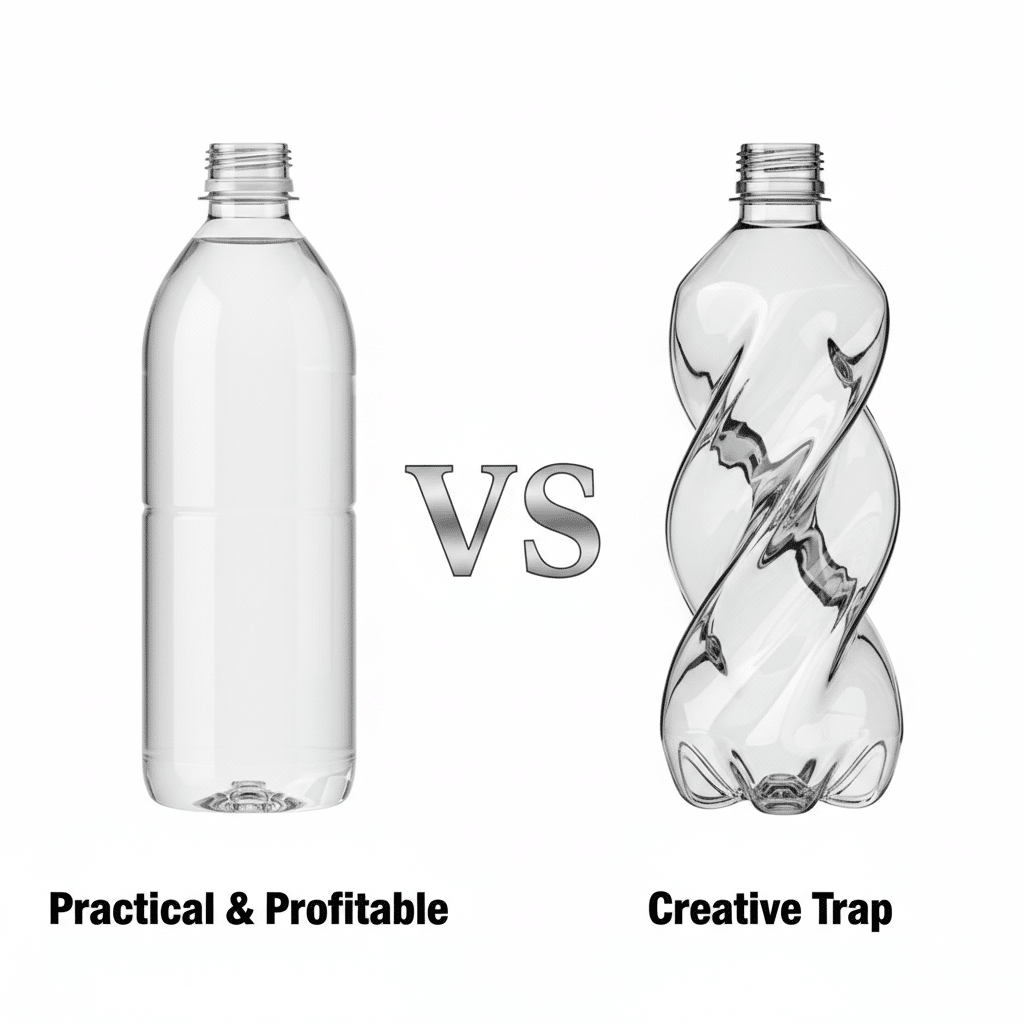

Struggling with a "unique" bottle idea? It might be costing you sales and creating production nightmares. This is the "creative trap."

A "profitable" and "practical" PET bottle mold design focuses on low weight, high strength, and manufacturing efficiency. This beats "creativity" because it lowers your total cost and ensures consumers can actually use and transport your product easily.

Key Article Takeaways

| Concept | Why It Matters for Your Business |

|---|---|

| "Creative Trap" | A "unique" bottle often has hidden costs: more material, slower production, and consumer usability problems. |

| "Practical" Design | Focuses on strength (for stacking/shipping) and low defect rates. This protects your product. |

| "Profitable" Design | Focuses on lightweighting (saving material cost) and fast cycle times (high efficiency). This protects your profit. |

| Lightweighting | The #1 way to save money. Every 1 gram saved can be worth $10,000+ per year. |

| Strength | Practical ribs and base designs prevent crushing, which is a 100% loss. |

| Machine Matching | Your mold must match your machine. Mismatch is the biggest cause of factory failure. |

| Startup Strategy | Reference "market-validated designs" and add brand modifications to launch fast and save money. |

| Vivian's Promise | I will give you an honest "profitability review," not just a blind quote. |

I've seen this happen for 20 years. Many new clients believe a unique bottle is their ticket to success. But this belief is often a costly mistake. Let's explore why this happens and what you should focus on instead.

The "Creative Trap": Why Isn't a Unique Bottle an Easy Path to Good Sales?

Want your bottle to stand out? Be careful. That "unique" shape might just be a unique way to lose money and alienate customers.

Consumers buy the product inside, not the bottle itself. A strange, "creative" bottle can be hard to hold, hard to ship, and hard to store. This creates barriers for the customer and hurts your sales.

"I'm Vivian. In my 20 years at Jindong (iBottler), I've seen too many clients fail because of 'creativity.' They paid a premium for a 'unique' bottle, only to find consumers didn't care, and their production costs were sky-high. We must understand: the bottle is a 'cost center,' not an 'art center'."

The "Art Center" vs. "Cost Center" Mistake

A bottle is a piece of packaging. Its job is to get your product from your factory to your customer's hand, safely and cheaply.

- An "Art Center" approach focuses only on the look. It tries to win a design award.

- A "Cost Center" approach focuses on the total function at the lowest possible cost.

Your bottle must survive the entire supply chain. It must be filled, capped, labeled, packed onto a pallet, shipped in a truck, unpacked by a retailer, and stocked on a shelf. At every single step, it is being handled by machines or people.

A "creative" bottle might jam the labeling machine because of its weird shape. It might not stack properly on a pallet, leading to unstable loads that collapse during transport. This is what I mean by "cost center." Every single failure in this chain is a cost that comes directly from your profit.

Hidden Cost 1: Higher Material Weight (Gram Weight)

A simple cylinder is the most efficient shape. It uses the least plastic for the most volume. Any "creative" design—like sharp angles, twists, or non-round shapes—creates structural weak points.

To fix these weak points, an engineer is forced to add more PET material. We have to make the whole bottle thicker to make sure the "creative" part doesn't break. This directly increases your cost per bottle.

Let's look at the numbers. A standard 500ml water bottle might weigh 13 grams. A "creative" design for the same 500ml might be forced to 18 grams. That's an extra 5 grams.

PET resin costs roughly $1,200 per ton (this price changes, but it's a good example).

- 5 grams per bottle...

- ...multiplied by 10 million bottles per year...

- ...is 50,000,000 grams. That is 50,000 kg, or 50 tons.

- *50 tons $1,200/ton = $60,000.**

Your "creative" design just cost you $60,000 in extra raw material. Every single year. This is a "creative tax" that many startups cannot afford.

Hidden Cost 2: Complex Molds and Slower Cycles

A strange shape requires a complex blow bottle mold. This mold is much harder to machine.

- Upfront Cost: The CNC machine has to run slower. It must use tiny, special tools. This takes many more hours of machine time. Machine time is money. Your mold cost might jump from $10,000 for a simple design to $25,000 for a complex one.

- Operating Cost (Cycle Time): This is the real killer. Complex shapes are harder to cool. The mold has water channels to remove heat. In a complex shape, we might not be able to get cooling channels close enough to the "hot spots" (like thick areas or sharp angles).

This means the bottle must stay in the mold for longer to become solid. Maybe your cycle time goes from 3 seconds to 4.5 seconds. That is a 33% reduction in your factory's output. You just lost one-third of your production capacity. This "hidden cost" can bankrupt a new company.

Hidden Cost 3: The Consumer's Practical Problems

I always ask my clients these simple questions. Most "creative" designers never do.

- Does your bottle fit in a car cup holder?

- Can a child hold it without dropping it?

- Can you stack two of them in a refrigerator?

- Can you pack 24 of them in a shipping carton without wasting space?

Most "creative" designs fail these simple tests. A bottle that tips over easily is an annoyance. A bottle that is hard to hold is an annoyance. An annoyance does not get a repeat purchase. Consumers expect packaging to be easy. If you make it hard, they will buy your competitor's "boring" bottle next time.

Table: Comparing Creative vs. Practical Design Costs (First Year)

| Feature | "Creative" Design (Example) | "Practical" Design (Example) |

|---|---|---|

| Upfront Mold Cost | $20,000 | $10,000 |

| Bottle Gram Weight | 18 grams | 13 grams |

| Material Cost (10M Bottles) | $216,000 | $156,000 |

| Production Cycle Time | 4.5 seconds | 3.0 seconds |

| Total Bottles (1 Year) | ~7 million | ~10.5 million |

| The "Creative Trap" Cost | You spent $10k more, paid $60k more for plastic, and produced 3.5M fewer bottles. |

My experience: I remember a client who wanted a bottle shaped like a "tornado." It looked amazing in the 3D rendering. We warned him. He insisted. The mold was incredibly expensive. The result? The sharp "twists" were so thin that 30% of the bottles failed the pressure test. He couldn't even fill them. He wasted his entire mold investment. We had to re-design it into a simple bottle with a logo of a tornado. That one worked. This is the reality of PET bottle mold design. It is an engineering discipline.

What Is an Engineer's Definition of a "Practical" and "Profitable" Design?

Think your 3D design is ready? A beautiful picture is not a business plan. An engineer sees risks and costs, not just art.

A "practical" design is strong, easy to make with a low defect rate, and easy for consumers to use. A "profitable" design uses the least amount of PET material (lightweight) and has the fastest production cycle.

"A 'creative' designer gives you a pretty 3D picture. A 'practical' engineer (like at iBottler) gives you a 'profitable' business plan. Our design focuses on your 'Total Cost of Ownership' (TCO) for the next 5 years, not on winning an art award."

Breaking Down "Practical" Design

"Practical" means it works in the real world. This has three parts:

- Structural Integrity: This is priority one. Can the bottle hold the product? Can it be stacked? This is "top-load" strength. Can it be gripped? This is "side-wall" rigidity. For CSD (carbonated drinks), can it hold 3-4 bars of pressure? We design this using features like ribs, not just by adding thick plastic.

- Manufacturability: This means a low defect rate. Can we blow this bottle 10 million times with less than a 0.1% failure rate? This requires a good stretch ratio, no sharp corners that cause common bottle defects, and easy demolding. If your defect rate is 5% ("creative" trap) vs 0.1% ("practical" design), you are throwing away 49,000 bottles for every 1 million you make.

- Usability: This is the consumer part. It has a stable base. It is easy to open. It is comfortable to grip. It just... works. No frustration.

Breaking Down "Profitable" Design

"Profitable" means it makes you the most money. This also has three parts:

- Lightweighting: This is the biggest factor. I will talk about this more in the next section. Every 0.1 gram we save is pure profit for you, repeated millions of times.

- Fast Cycle Time: This is speed. How many bottles per hour can your bottle blowing machine produce? This is a function of mold cooling, machine speed, and bottle design. Less plastic = less heat to remove = faster cooling = faster cycle. A faster cycle means your factory is more productive.

- Total Cost of Ownership (TCO): This is the most important concept. New clients only ask me, "How much for the mold?" This is the wrong question. The right question is, "What is my cost per bottle over 5 years?"

Your TCO includes:

- Upfront Mold Cost (e.g., preform mold and blow mold)

- Upfront Machine Cost

- Material Cost (PET resin) per year

- Energy Cost (electricity for the machine, heaters, and air compressor) per year

- Labor Cost per year

- Maintenance Cost per year

A cheap mold might save you $2,000 upfront. But it might be made of cheaper steel and wear out in 2 million cycles. Our iBottler molds are guaranteed for 5-10 million. That cheap mold might have a bad cooling design that adds 0.5 seconds to your cycle time. That 0.5-second delay over 5 years can cost you $200,000 in lost revenue. This is TCO.

Table: 5-Year TCO (Creative vs. Profitable Design)

| Cost Factor | "Creative" Design | "Profitable" Design | The "Profitable" Advantage |

|---|---|---|---|

| Upfront Mold Cost | $20,000 | $10,000 | Saves $10,000 upfront |

| Bottle Weight | 18 grams | 13 grams | 5 grams lighter |

| Material Cost (50M Bottles) | $1,080,000 | $780,000 | Saves $300,000 |

| Cycle Time | 4.5 seconds | 3.0 seconds | 33% faster production |

| Mold Lifespan | 2 million cycles (cheap steel) | 8 million cycles (good steel) | 4x longer life |

| Total 5-Year Cost | $1,100,000 + Lost Revenue | $790,000 | Massive Savings |

My Role as Your "Profitability" Engineer

When a client brings me a design, I don't just give a quote. I run a virtual analysis. I look at the stretch ratios. I estimate the minimum possible gram weight. I check the neck finish. Just choosing the right preform neck size is a huge part of profitability. A designer might pick a wide, heavy neck for a small water bottle. This wastes grams on every single bottle.

I ask, "What machine will you run this on?" If they don't know, I cannot guarantee a "profitable" design. This is why a complete PET bottle mold design guide is so important. It forces this practical thinking. A designer gives you a shape. An engineer like me gives you a manufacturing process. This process is what makes you money.

What Is the First Pillar of Profitability: Lightweighting to Save Material Costs?

Are you overpaying for every bottle you make? Your bottle's design might be forcing you to waste tons of plastic. This is a silent profit killer.

Lightweighting is how mold engineers save you money. We use structural analysis (like ribs and base design) to reduce your bottle's gram weight. This lowers your PET material cost without sacrificing strength.

"Creative" bottle shapes often need more gram weight. They need this to support their strange structures. A "practical" design is different. We use professional structural analysis. This is often called Finite Element Analysis (FEA). We build the bottle in a computer and simulate the pressure. We can see exactly where the weak points are.

Case Study 1: The 25-Gram Water Bottle

I'll give you a perfect example.

"Case Study 1: Last year, a water factory client brought us a 25-gram bottle design. His designer thought it 'looked strong.' Our engineers modified only the bottle's base ribs, reducing the weight to 21 grams. The mold cost him about $10,000, but he saves over $30,000 every year in material costs alone. That is 'profitable' design."

How did we do it?

The client's design had all the weight in the wrong place. The base was a simple, flat design. It had no strength.

Our engineers put his design into our FEA software. We showed him: the base would deform.

Our engineers modified only the bottle's base ribs. We added a "petaloid" (flower-shaped) base. This base is incredibly strong for its weight. This change allowed us to remove weight from the side walls.

The final bottle weight was 21 grams. We cut 4 grams.

The client's blow bottle mold cost him about $10,000.

Now, let's look at his savings. He produces 10 million bottles a year.

- 4 grams/bottle * 10,000,000 bottles = 40,000,000 grams.

- That is 40,000 kilograms of PET resin.

- Let's say the price of PET resin is $1.20 per kg.

- *40,000 kg $1.20/kg = $48,000.**

He saved $48,000 in his first year. He paid for his $10,000 mold almost five times over. In one year.

This, my friends, is 'profitable' design. It is not art. It is engineering. It is money.

How Do We Achieve Lightweighting?

It's a science. It's not just "making it thinner."

- FEA Simulation: We simulate stacking pressure (top-load) and internal pressure (for CSD or nitrogen-dosed water). The computer shows us high-stress areas (in red) and low-stress areas (in blue). We add tiny amounts of material (or ribs) to the red areas. We remove material from the blue areas.

- Strategic Ribs: You see those lines or grooves on water bottles? Those are not just for looks. They are "structural ribs." Like the beams in your house. They add massive rigidity to the side wall. This allows the wall itself to be incredibly thin. A "creative" smooth-wall bottle has no ribs. It must be very thick to stand up. This is a waste.

- Optimized Base Design: The base is the most complex part. For still water, we use "petaloid" or star-shaped bases. For hot-fill (juice), we use special "vacuum-panel" bases that pull inward as the liquid cools. This stops the bottle from deforming. A designer who doesn't understand this will cost you a fortune in bottle defects.

The Compounding Value of Grams

Clients often argue with me over 1 gram. "Vivian, it's just one gram. My designer likes this look."

When I hear this, I show them this table. This is the 5-year cost of "just 1 gram" of plastic.

Table: The 5-Year Cost of "Just 1 Gram" (Assuming $1.20/kg PET Price)

| Annual Production | 1-Gram Weight | PET Wasted (kg) / Year | Annual Cost | 5-Year Cost |

|---|---|---|---|---|

| 5,000,000 bottles | 1 gram | 5,000 kg | $6,000 | $30,000 |

| 10,000,000 bottles | 1 gram | 10,000 kg | $12,000 | $60,000 |

| 50,000,000 bottles | 1 gram | 50,000 kg | $60,000 | $300,000 |

| 100,000,000 bottles | 1 gram | 100,000 kg | $120,000 | $600,000 |

When I show clients this table, they suddenly stop caring about the "creative" look. They become very interested in my engineer's "profitable" design. This is the truth of the business. Every gram matters. My job is to find that gram and give it back to you as profit. We do this by focusing on smart engineering, not on "art."

What Is the First Pillar of Practicality: Designing for Strength in Transport?

Your bottles look great. But they collapse in the warehouse. They get crushed during shipping. This is a 100% loss that is killing your business.

A "practical" bottle is designed for strength. This means high "top-load" (stacking) strength and "axial-load" (gripping) strength. We use structural ribs and special base designs to achieve this.

"A 'creative' bottle that collapses in the warehouse is a 100% loss. A 'practical' iBottler design adds a few reinforcing ribs—ones you might not even notice—that can increase your bottle's rigidity by 30%. Our job is to protect your product all the way to the customer."

The Customer's Nightmare: The "Soft Bottle"

New clients often face this. They get their first shipment of product. The bottles on the bottom of the pallet are crushed, leaking everywhere. The bottle is too "soft."

This happens because the design did not consider Top-Load Strength. A pallet of water can be 6-8 layers high. The bottom bottle must support hundreds of pounds.

This is especially true for carbonated soft drinks (CSD). The internal pressure from CO2 is constantly trying to push the bottle apart. A weak design will fail.

Understanding Bottle Strength: Top-Load and More

When we talk about "strength," we mean specific, measurable things:

- Top-Load Strength (Axial Load): This is the most important. How much weight can the bottle support from the top before it buckles? This is for stacking in your warehouse and in transport.

- Side-Wall Strength (Radial Load): This is how much the bottle resists being "squeezed." This is important for high-speed filling lines that use "grippers" to move bottles. A flimsy bottle will be crushed by the machine.

- Pressure Resistance (for CSD): The bottle must contain the internal pressure (around 3-4 volumes of CO2) without deforming or bursting.

- Drop Resistance: If a customer drops the bottle, does it burst? The base design is critical for this.

How Engineers Design for Strength

"Creative" designs, especially smooth-walled bottles, are terrible at this. They have no structure. They are like a plain piece of paper. A "practical" engineer designs strength into the shape.

- Structural Ribs (Hoop Ribs): These are the horizontal or vertical lines I mentioned. Think of a simple paper tube. You can crush it easily. Now, fold that paper into an accordion shape. It becomes very strong. The ribs on a bottle work the same way. They add massive rigidity without adding weight.

- Optimized Base Design: For CSD, we must use a "petaloid" base. Those five "feet" on a soda bottle are not for looks. They are engineered to handle the massive internal pressure. The pressure is distributed to those five points. A "creative" flat base on a soda bottle would bulge out and tip over. It would fail 100% of the time.

My Experience with a CSD Client

I had a CSD (soda) client who wanted a "retro" look. He wanted a smooth bottle with a flat base, like an old glass bottle. He was very passionate. I had to be the one to tell him "No."

I explained, "This design is impossible in PET. The base will bulge, and the bottle will fall over. The side wall is too weak and will feel like a half-full balloon."

He was disappointed. But I didn't just say "no." I offered a "practical" solution.

I said, "Let's keep your retro label and silhouette. But we must add a modern 'petaloid' base. And on the side, we will add 'micro-ribs'—very thin, almost invisible lines that will give you the strength you need."

We made a 3D printed sample for him. He could hold it. He could feel the strength. He agreed.

Today, his product is on the shelf. It has the "retro" feel he wanted, but it works. It stacks. It ships. It doesn't burst. This is the job of a practical engineer: to find the balance between the client's vision and the physical laws of manufacturing.

Table: Common Strength Problems and Engineering Solutions

| Problem | "Creative" Cause | "Practical" Engineering Solution |

|---|---|---|

| Bottle collapses when stacked | Smooth side walls, weak base | Add horizontal/vertical structural ribs. Optimize base. |

| Bottle deforms or bursts (CSD) | Flat base, thin walls | Use a "Petaloid" 5-point base. |

| Bottle feels "soft" or "cheap" | No structural ribs | Add strategically placed "micro-ribs" to improve grip feel. |

| Bottle tips over easily | Small or uneven base | Widen the base diameter, use a petaloid or flat-panel base. |

| Bottle deforms after hot-filling (juice) | Standard PET bottle design | Use a hot-fill (heat-set) mold with special vacuum panels. |

We anticipate these common bottle defects before we cut the steel. A designer gives you a picture. I give you a bottle that survives the real world.

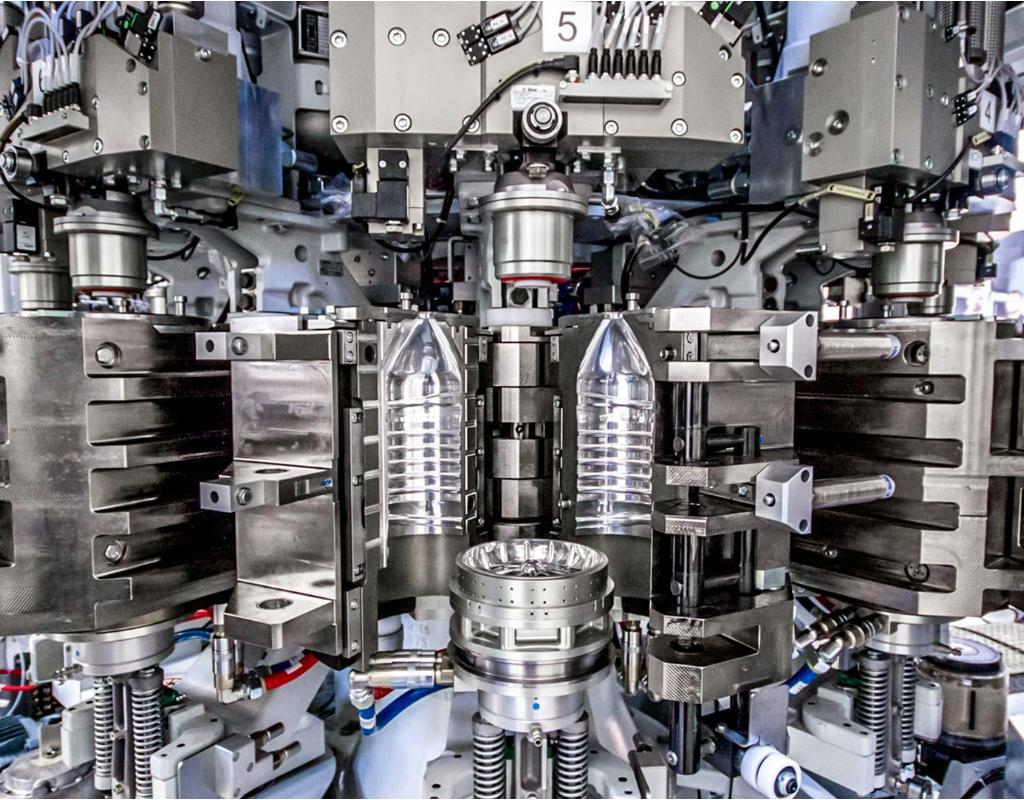

What Is the Biggest "Profitability" Trap: Mold and Machine Mismatch?

You bought a beautiful mold. You bought a blowing machine. But they don't work together. This is a disaster that stops your entire factory.

A "profitable" design requires a mold that is 100% matched to your blowing machine. A "pure mold" factory cannot guarantee this. They don't know your machine's stretch rod, heating, or air setup.

"At iBottler (Jindong Machinery), we manufacture both the bottle blowing machine and the blow mold. This is our greatest advantage. Our mold engineers and machine engineers sit in the same office. The mold we design is 100% guaranteed to run at peak efficiency on my (Vivian's) machine. This integrated 'profitable' system is something a 'pure mold' factory cannot give you."

The "Pure Mold Factory" Problem

This is the biggest "profit" trap I see. A client buys a machine from Company A. They buy a mold from Company B (a "pure mold" factory). Company B makes a beautiful mold. The client installs it.

Disaster.

- Maybe the mold doesn't physically fit the mounting plate.

- Maybe the stretch rod on the machine is too short to push the preform properly for that specific bottle design.

- Maybe the machine's heaters can't heat the preform correctly for the mold's shape.

- Maybe the mold's cooling channels don't line up with the machine's water ports.

Who is responsible? The machine factory blames the mold factory. The mold factory blames the machine factory. The client is stuck in the middle, losing thousands of dollars every day.

Key Matching Points That "Creative" Designers Miss

A mold is not just a piece of metal. It is part of a system. Here are the critical mold and machine matching points:

- Mounting Dimensions: How does the mold bolt into the machine? We have mounting dimensions for 80% of blow molding machines worldwide. A "pure mold" factory might just guess.

- Stretch Rod Stroke: The machine has a rod that stretches the hot preform. A mold for a very tall, thin bottle must be possible within that machine's maximum stretch stroke. A creative designer doesn't know this. We do.

- Heating Capability: The machine's ovens heat the preform. A thick preform (for a large bottle) needs more heating. A "creative" bottle might need uneven heating. Does the machine's oven have enough lamps and zones to do this? If not, you will get thin spots.

- High-Pressure Air System: The machine provides high-pressure air. Does the mold's design (a big bottle) need more air volume than the machine's air compressor can supply? If so, your cycle time will be slow.

- Cooling System: The mold has water channels. These connect to a chiller. An inefficient mold with "hot spots" will run slow, no matter how fast your machine is.

Table: iBottler (Integrated) vs. "Pure Mold" Factory

| Feature | iBottler (Machine + Mold) | "Pure Mold" Factory |

|---|---|---|

| Guaranteed Fit | Yes. We make both. We test it. | No. It's a risk. |

| Cycle Time | Optimized. We match mold cooling to machine speed. | Unknown. Often slow due to mismatch. |

| Process Support | Yes. We know the whole system. | No. They only know the mold. |

| Troubleshooting | One call. We are 100% responsible. | Finger-pointing. Machine vs. Mold. |

| Profitability | High. System is designed for max efficiency. | Risky. Mismatch kills efficiency. |

My "One-Stop Solution" Philosophy

This is why I believe in our system at iBottler. We provide the entire line. The bottle blowing machine, the blow bottle mold, the preform mold, the chiller, the air compressor.

When you buy from me, I am not selling you parts. I am selling you a guarantee of bottles-per-hour.

My engineers design the mold knowing which machine it will run on. They sit in the same room. The mold engineer asks the machine engineer, "What is the true cooling capacity of the chiller for this model?" The machine engineer asks the mold engineer, "Can you add ribs here to let us use a lighter preform?"

This integration is what "profitability" means. It removes 100% of the technical risk for you. That is my job.

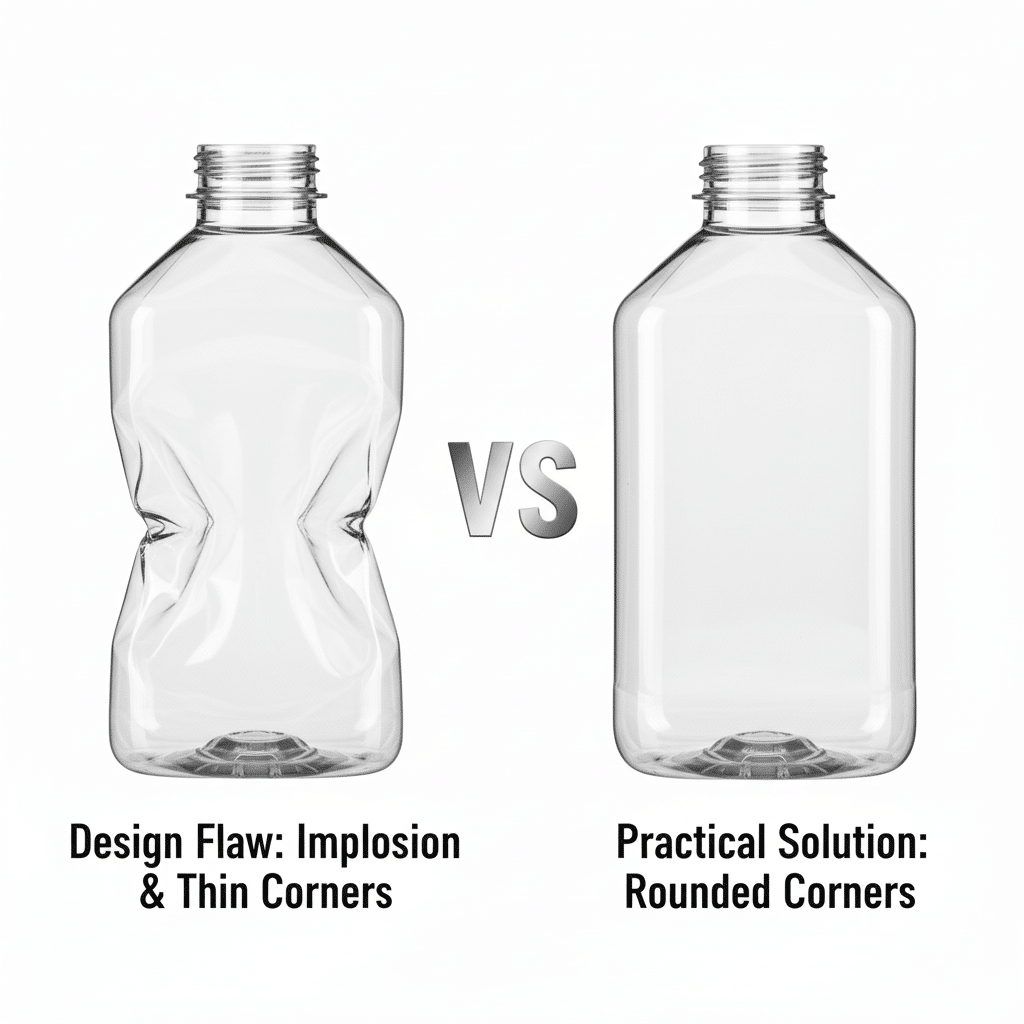

Case Study 2: Why Did We "Say No" to a Client's Square Bottle Idea (And Save Their Investment)?

You have a "brilliant" idea for a square bottle. It looks unique. But it's a manufacturing trap. It will cause defects and stop your production.

We "saved" a client by rejecting his "pure-angle" square bottle. This design causes uneven stretching, thin/weak corners, and bottle collapse (implosion) after cooling. We proposed a "practical" rounded-corner design instead.

"Square bottle" is the most common "creative" request I get. And it's the most dangerous.

A client (Case Study 2) came to us for his juice drink. He wanted a "pure straight-edge, 90-degree-angle" square bottle. His designer made a beautiful 3D model. He was very excited.

I had to be the one to tell him it was a "bad idea."

The 3 "Disasters" of a True Square Bottle

I didn't just say "no." I showed him the engineering problems.

- Uneven Stretching (Thin Corners): A PET preform is a round tube. When you blow it into a square mold, the plastic has to travel much farther to reach the corners. The plastic in the middle of the flat side barely moves. The plastic at the corner stretches like crazy. This creates paper-thin corners. They will break. They will leak. This is one of the worst bottle defects you can have.

- Cooling and Collapse (Implosion): This is the part designers never think about. After the hot bottle is blown, it cools. As it cools, the plastic shrinks. A round bottle shrinks evenly, holding its shape. A square bottle... those large, flat sides have no structural support. As the bottle cools, the plastic shrinks and the flat sides are "sucked" inward. Your beautiful, flat square bottle becomes a collapsed, imploded, "dented" mess.

- Demolding Problems: Molds have to open and release the bottle. A true 90-degree "zero-draft" angle means the bottle will get stuck. It will scrape against the mold wall as it's ejected. This creates scratches and can stop the machine.

This is even worse for hot-fill juices. When the hot liquid cools, it creates a powerful vacuum that will instantly destroy a flat-walled bottle.

My "Saying No" Insight

"Case Study 2 (Continued): The client was unhappy at first. But after he saw our simulation analysis of 'collapsing' and 'bursting,' he understood. We helped him avoid a 'disaster.' A supplier who dares to say 'No' to you is the only partner you can trust long-term. My (Vivian's) job isn't to blindly execute your 'creativity'; it's to make you 'profitable'."

We then proposed a solution. We called it a "class-A" square bottle. It looks square to the consumer. But it has large, soft "R-angles" (rounded corners). These rounded corners allow the plastic to stretch more evenly.

We also added very subtle, almost invisible curves to the "flat" sides. This "structural curve" gave the side wall strength to resist the cooling implosion.

We made him a 3D printed sample of both bottles. His "creative" one and our "practical" one. He held them. He saw the "imploded" look of his. He felt the strength of ours.

He chose our design.

This principle applies to many "creative" shapes, not just squares. Triangles, stars, any shape with sharp angles or large flat panels is a high-risk design. My team knows how to translate that "creative" idea into a bottle that can actually be manufactured profitably. This is the difference between a 3D artist and a 20-year mold engineer.

Table: "Creative" Square Bottle vs. "Practical" (Rounded) Square Bottle

| Feature | "Creative" (90° Angle) Bottle | "Practical" (Rounded) Bottle |

|---|---|---|

| Corner Strength | Very thin (High risk of bursting) | Good, even thickness (Strong) |

| Side Wall | Collapses / Implodes after cooling | Stable. Resists vacuum. |

| Demolding | Difficult. Scratches. | Easy. Clean release. |

| Production | High defect rate. Very slow cycle. | Low defect rate. Fast cycle. |

| Final Look | "Dented" and cheap. | "Premium" and strong. |

What Is the Best Choice for Startups: Reference "Market-Validated Designs" and Add Brand Modifications?

Are you a startup with a limited budget? Don't risk investing heavily to "invent" a brand-new bottle shape. There is a smarter, safer way to launch.

We recommend startups reference "market-validated designs"—those that are already proven to be efficient, practical, and accepted by consumers. Then, we help you apply "brand modifications" to make it uniquely yours.

"You don't need to reinvent the wheel. I'm Vivian. In my experience, the most successful startups 'stand on the shoulders of giants.' They reference a classic bottle shape, like the 'premium' image an Evian bottle conveys. Then, we work together to modify its shoulder, body, or base to add your brand's unique DNA. This launches you quickly while avoiding both the 'creative trap' and the 'copycat' risk. This is the most responsible way to treat your investment."

What Is a "Market-Validated Design"?

This does not mean a "public mold" that you can just go and use. That concept doesn't really exist in the PET industry, as every mold is custom-made for a client.

A "market-validated design" is a concept. It refers to a bottle design style that is already successful and widely accepted by consumers in the market.

For example:

- The classic cylindrical water bottle (like Evian): Conveys "purity," "premium." Consumers see this shape and instantly think of high-quality mineral water.

- The "grip-waist" sports drink bottle: Conveys "function," "easy to hold."

- The squared-off juice bottle: Conveys "full volume," "shelf-friendly."

These designs are successful because they have achieved a perfect balance of "practical" and "profitable." They are lightweight, strong, and easy to manufacture.

Why "Reference + Modify," Not "Invent" or "Copy"?

This is a strategic choice about risk and reward.

- The Risk of "Inventing": This is the "creative trap" we've been discussing. You might design a bottle that can't be made, is too expensive, or that consumers dislike. This is a high-risk gamble for a startup.

- The Risk of "Copying": This is a legal and brand risk. You cannot 100% copy a bottle like Evian. This leads to lawsuits and makes your brand look like a cheap knock-off, destroying its value.

- The Wisdom of "Reference + Modify": This is the smartest strategy. You come to us and say, "Vivian, I like the premium feel of the Evian bottle."

Our engineers use this as a benchmark. We keep the efficient cylinder and strong base concept. But we will design a completely new "shoulder curve" for you, or a unique set of "structural ribs," and emboss your logo on the side.

The result: The consumer's first glance associates it with "premium water," but a closer look reveals your brand. This new design is still 100% "practical and profitable." It is still lightweight, strong, and easy to produce. You get market acceptance and your own unique brand.

Table: Comparing Three Startup Strategies

| Strategy | "Creative Invention" (New Design) | "Direct Copy" (Knock-off) | "Reference + Modify" (iBottler Way) |

|---|---|---|---|

| Mold Cost | Very High | Medium (Still need a mold) | Controlled and Reasonable |

| Risk | Extremely High (Production/Market failure) | Extremely High (Legal risk, cheap brand) | Low (Based on a proven concept) |

| Performance | Unknown (Could be terrible) | Known (But it's not yours) | Guaranteed (Optimized practicality) |

| Brand Image | Unknown | Cheap knock-off | Professional and Unique |

| Time to Market | Very Slow (4-8 weeks design/test) | Slow (Still need a mold) | Fast (Shorter design process) |

My Advice to All Startups

I am very direct with my new clients. I tell them: Spend your money on what matters.

- Choose the market you want to enter (e.g., premium water).

- Find the "gold standard" bottle shape for that market (e.g., Evian).

- Work with us to "reference" and "modify" it into your own unique design.

- We will ensure this new design is lightweight, strong, and efficient.

- Spend the massive R&D and risk-cost savings on your water and your marketing.

This is how you build a "profitable" brand, not just a "creative" bottle.

Want a Free "Profitability Review" of Your Bottle Design?

You have a design. You think it's ready. But are you sure? Are there hidden costs, weight problems, or manufacturing risks you can't see?

Send me (Vivian) your design. I will give you a free "Profitability and Risk Review." I won't just give you a price. I will tell you the truth about your design's risks and potential.

"I'm Vivian. Send me your design. Your 2D drawing, your 3D file, even just a sketch on a napkin.

I won't just give you a blind quotation; I will tell you the truth.

If it's a good design, I'll help you optimize it. We can run a quick simulation and see if we can save you 1 gram.

If it's a 'bad idea'—like the square bottle—I will be the first to tell you, and then I'll offer you a more 'profitable' alternative.

That is the iBottler (Jindong Machinery) promise."

What Is a "Profitability and Risk Review"?

This is a free service I offer to potential clients. It is based on my 20 years of experience. When you send me your design, my engineering team and I will analyze it.

We are not just trying to "win the order." We are trying to build a long-term partner. I will only succeed if you succeed.

Our review will include:

- Manufacturability Risk Assessment: We look for "creative traps." Sharp corners, flat panels, bad stretch ratios. We will tell you, "This corner will be thin," or "This flat side will implode."

- Estimated Gram Weight: Based on the design and volume, I will give you an expert estimate of the minimum gram weight you can achieve. If your designer thinks it's 20 grams and I know it will need to be 25 grams to be strong, that 5-gram difference is a massive cost you need to know about.

- Strength and Practicality Check: We will ask the hard questions. Will this stack? Will it be stable? Does it fit a standard cup holder?

- Machine Matching Feedback: I will ask, "What machine are you using?" If you tell me, I can warn you, "Your machine's stretch rod might be too short for this tall design." This is the mold and machine matching expertise that saves you from disaster.

Why Do I Offer This For Free?

Because I want your business for the next 20 years.

If I sell you a "bad mold" for your "creative design," you will fail. You will blame me. You will go out of business. I will have made one small sale and lost a customer forever.

If I tell you the truth—even if it's bad news—and I help you fix your design, you will see me as a partner. You will trust me. When your design is "profitable" and you start making money, you will come back to me for your second, fifth, and tenth mold. You will buy my bottle blowing machines. You will build an entire factory with iBottler.

This is a "long-term profitable" business strategy. I am "practical," just like my molds. Other companies will see your "bad design" and just send you a high quotation. They know it has problems. But they will take your money. Their job is to sell you a piece of steel.

My job is to sell you a result. The result is millions of high-quality, low-cost bottles. This free review is my way of proving I am a partner, not just a supplier.

Table: What to Send Me (and What You Get Back)

| What You Send Us | What You Get Back (For Free) |

|---|---|

| A 3D file (.step, .iges, .x_t) | Detailed feedback on manufacturing risks. |

| A 2D drawing (.dwg, .pdf) | An expert gram weight estimation. |

| A photo, a simple sketch, or a "reference" bottle | Questions about strength, stacking, and use. |

| Your target bottle volume (e.g., 500ml) | A "Profitable Alternative" suggestion. |

| The machine you plan to use (if known) | A quotation for a "practical" iBottler mold. |

Take the First Step

Before you pay a designer thousands of dollars...

Before you spend $10,000 on a mold that might not work...

Send your idea to me. Let me give you 20 years of experience before you commit.

This is the most important step in your entire project. It's the difference between a "creative idea" and a "profitable business."

Contact me, Vivian, at iBottler. Let's review your design. Let's make sure it is not just "creative," but "practical" and "profitable." This is how you win.

Conclusion

In PET bottle mold design, 'creativity' can be a trap. A 'practical' and 'profitable' design—focused on lightweighting, strength, and machine efficiency—is the true path to success. Start smart.

Article Summary: Practical vs. Creative Design

| Feature | "Creative" Design (The Trap) | "Practical" & "Profitable" Design (The iBottler Way) |

|---|---|---|

| Main Goal | Look "unique" or "artistic." | Be low-cost, strong, and efficient. |

| Material Cost | High. Uses extra grams for structure. | Low. Optimized for lightweighting. |

| Production Speed | Slow. Complex shape cools slowly. | Fast. Simple, efficient cooling. |

| Strength | Low. Fails stacking and transport. | High. Designed with ribs and strong base. |

| Machine Matching | High Risk. A "pure mold" may not fit or run well. | Guaranteed. An integrated system (like iBottler's). |

| Startup Strategy | No. Too expensive and risky. | Yes. Reference "market-validated designs" + brand modifications. |

Frequently Asked Questions (FAQ)

1. What is the biggest mistake startups make in PET bottle design?

The biggest mistake is focusing on "creativity" instead of "profitability." They spend their limited budget on a complex, expensive custom mold. This "creative" bottle often has high material costs (high gram weight) and production problems (slow cycle time). A smarter choice is to reference a "market-validated design" and apply brand modifications.

2. How much money can PET bottle lightweighting really save me?

A lot. As I showed in the article, saving "just 1 gram" on a bottle can save you $12,000 per year (if you make 10 million bottles and PET is $1.20/kg). In our case study, we saved a client 4 grams, which was over $48,000 in material costs in the first year alone. Lightweighting is the single most important part of a "profitable" design.

3. Why is a "true square" bottle a bad idea for PET?

A "true" 90-degree angle square bottle is a manufacturing disaster. The round PET preform stretches unevenly, creating paper-thin and weak corners. Also, the large, flat sides have no structure. When the bottle cools, the plastic shrinks and the flat sides "implode" or "suck in," making the bottle look dented and cheap. A "practical" solution is a "rounded" square bottle that looks square but is strong and stable.

4. Is it better to buy my blow mold and blowing machine from the same company?

Yes, 100%. This is the "integrated solution" I talked about. When you buy the mold and machine from one company (like iBottler), you have a 100% guarantee that they work together perfectly. There is no "finger-pointing." The system is designed for maximum efficiency (fastest cycle time) from the start. This removes a huge risk for your factory.

5. How can a startup balance "unique" and "cost"? Do I have to invent a new bottle?

You do not have to invent a new bottle. The best strategy is to "reference" a design that is already proven in your target market (like the classic shape for premium water). Then, work with our engineers to "modify" it with your brand's DNA—like changing the shoulder curve, adding unique ribs, or embossing your logo. This gives you an efficient, low-cost, low-risk bottle that still has clear brand identity and avoids any legal copycat issues.

🔗 Related Pages on Our Website

PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr