Perfect Preforms, Premium Quality

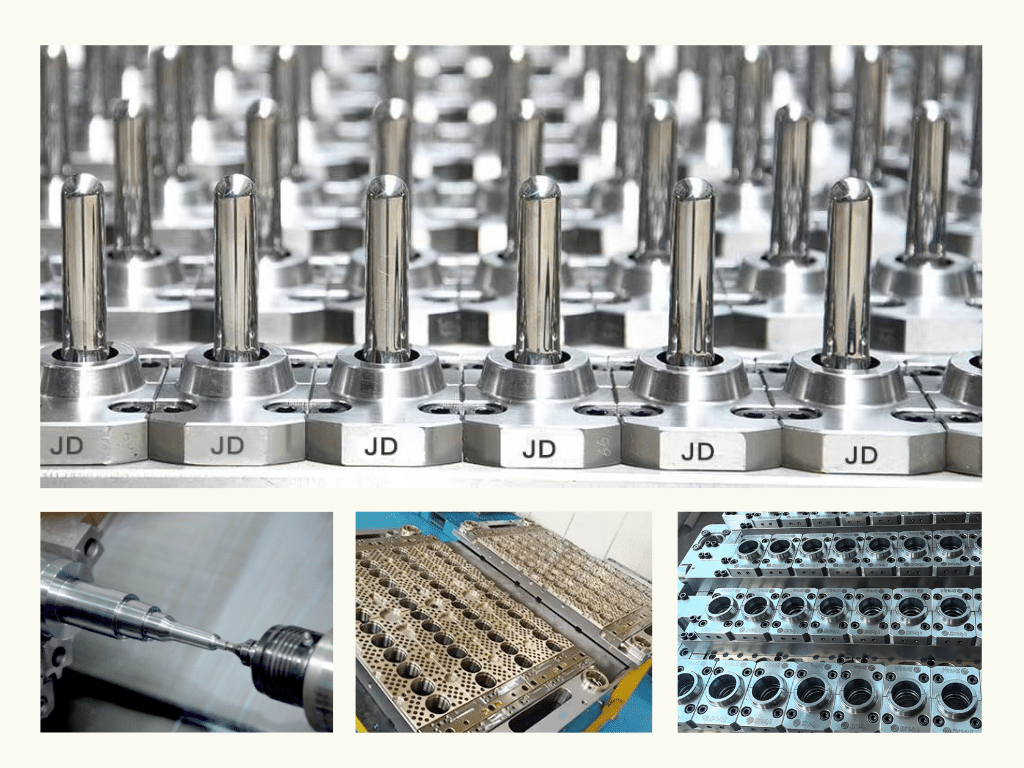

Made with top-grade steel and precision machining, customizable cavities ensure high clarity and accuracy for flawless preforms!

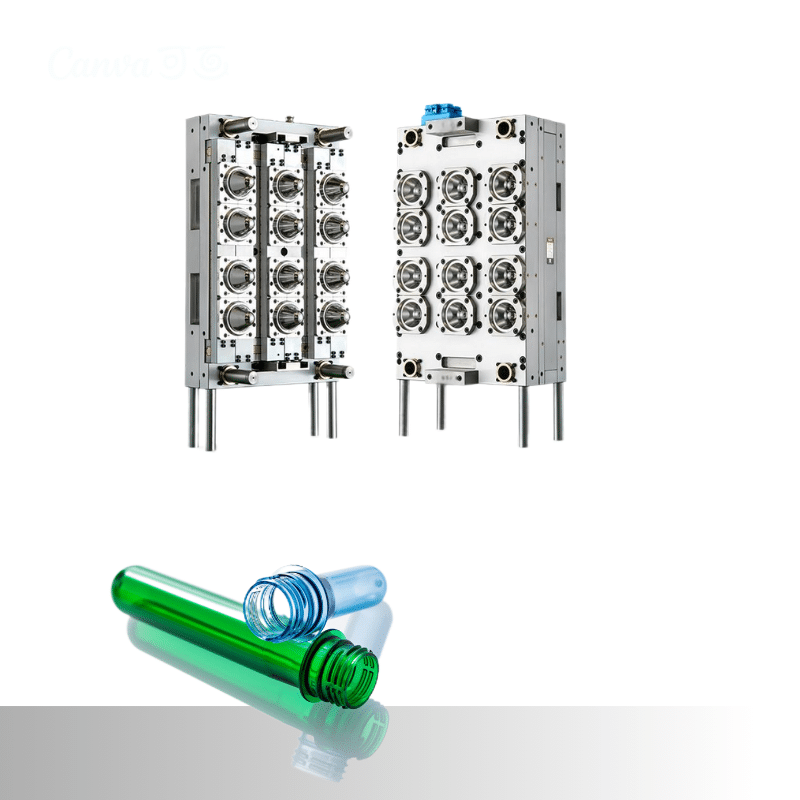

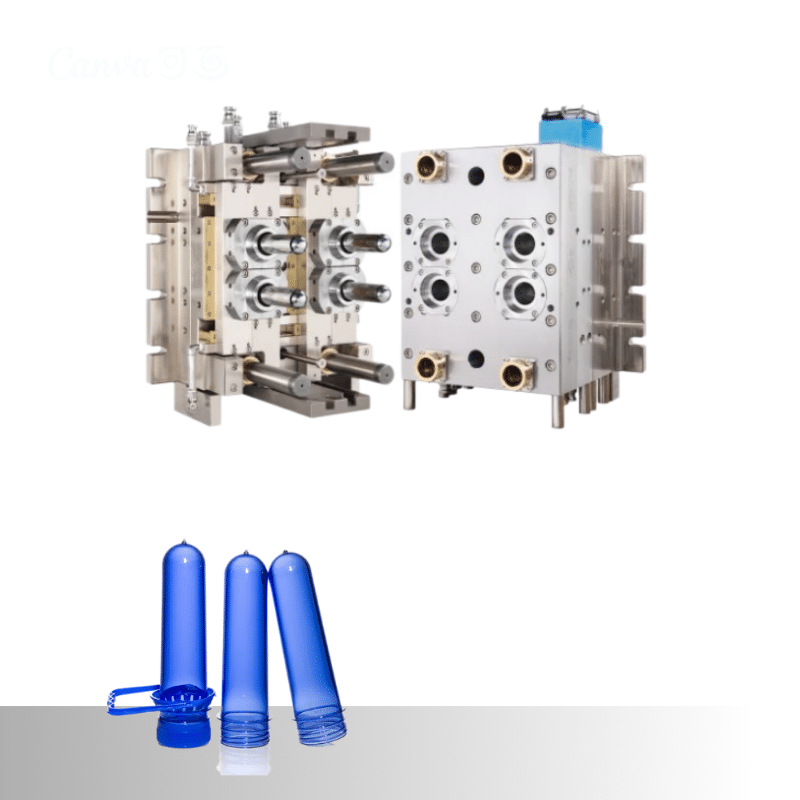

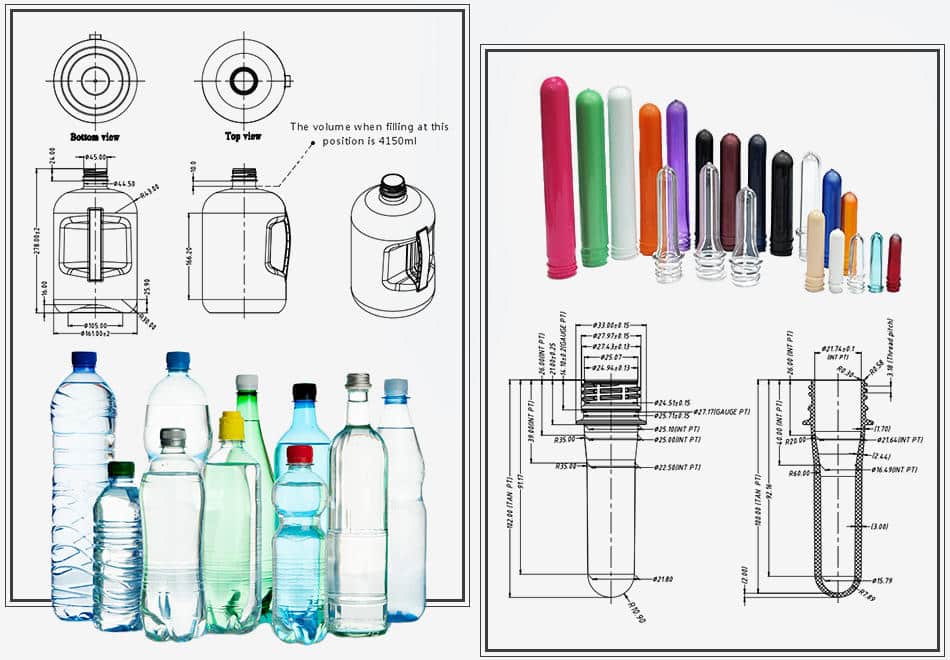

Customized PET preform mold

One-stop solution

Soda bottle preform mold

- Neck Diameter: 28mm (Standard PCO1810, PCO1881), 30mm, etc.

- Weight Range: 10g – 50g, commonly used for 500mL, 1.5L, and 5L water and carbonated beverage bottles.

Water Bottle Preform mold

- Neck Diameter: 28mm (Standard PCO1810, PCO1881), 30mm, etc.

- Weight Range: 8g – 50g, commonly used for 500mL, 1.5L, and 5L water bottles and beverage bottles.

Daily chemical bottle mould

- Neck Diameter: 20mm, 24mm, 28mm, 38mm, customizable for pump or spray heads.

- Weight Range: 6g – 80g, applicable for 10mL – 2L packaging of detergents and cosmetics.

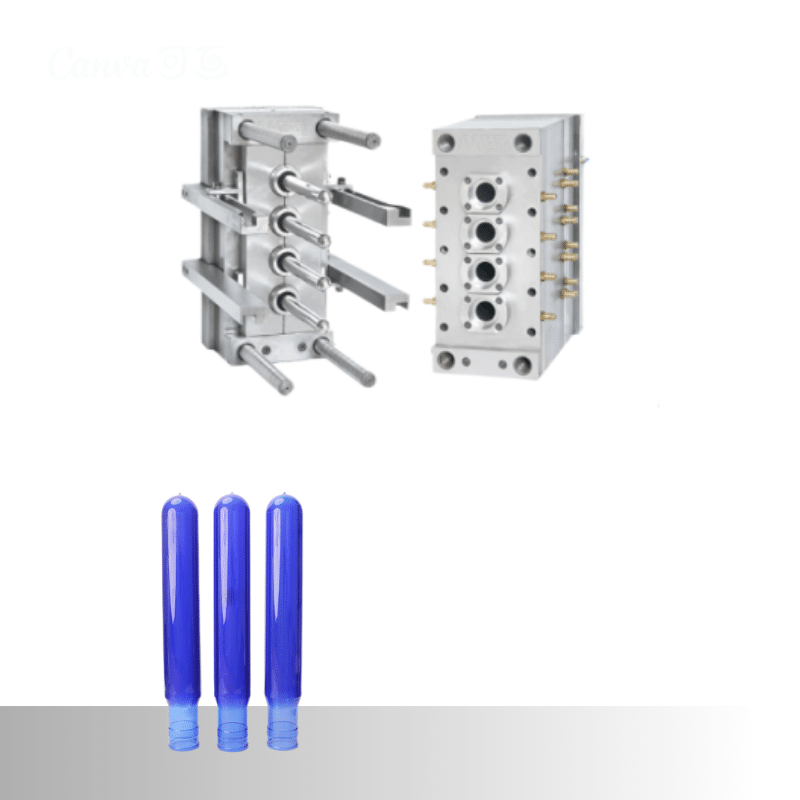

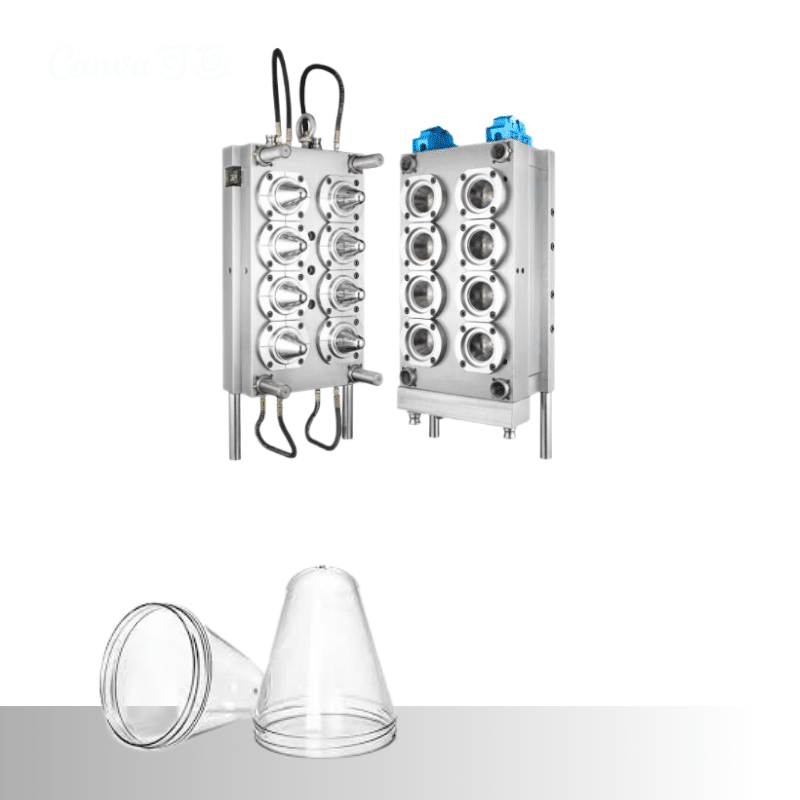

Five-gallon barrel mold

- Neck Diameter: 55mm (Standard 3-5 gallon neck size)

- Weight Range: 500g – 750g, suitable for 18.9L and 11.3L,large-capacity water bottles.

Oil bottle preform mold

- Neck Diameter: 32mm, 45mm, 55mm, designed for oil product filling standards.

- Weight Range: 50g – 200g, suitable for 1L – 20L edible oil and lubricant containers.

Wide Mouth Jar Mould

- Neck Diameter: 38mm, 45mm, 63mm, 83mm, suitable for large-diameter storage.

- Weight Range: 20g – 150g, compatible with 500mL – 5L large-volume containers.

Our Solutions

STEP.1

Requirement Analysis

STEP.2

Design & Development

STEP.3

Precision Manufacturing

STEP.4

Testing & Optimization

| Cavities | Preform weight(g) | Neck diameter(mm) | Mould height(mm) | Width (mm) | Thickness(mm) | Mould weight(Kg)) | Cycle time(sec) |

|---|---|---|---|---|---|---|---|

| 2(1*2) | 720 | 55 | 470 | 300 | 608 | 330 | 105 |

| 4(2*2) | 720 | 55 | 490 | 480 | 730 | 440 | 105 |

| 8(2*4) | 16 | 28 | 45 | 350 | 410 | 475 | 18 |

| 12(2*6) | 16 | 28 | 600 | 350 | 415 | 690 | 20 |

| 16(2*8) | 21 | 28 | 730 | 380 | 445 | 690 | 22 |

| 24(3*8) | 28 | 28 | 770 | 460 | 457 | 1070 | 25 |

| 32(4*8) | 36 | 28 | 810 | 590 | 515 | 1590 | 25 |

| 48(4*12) | 36 | 28 | 1070 | 590 | 535 | 2286 | 26 |

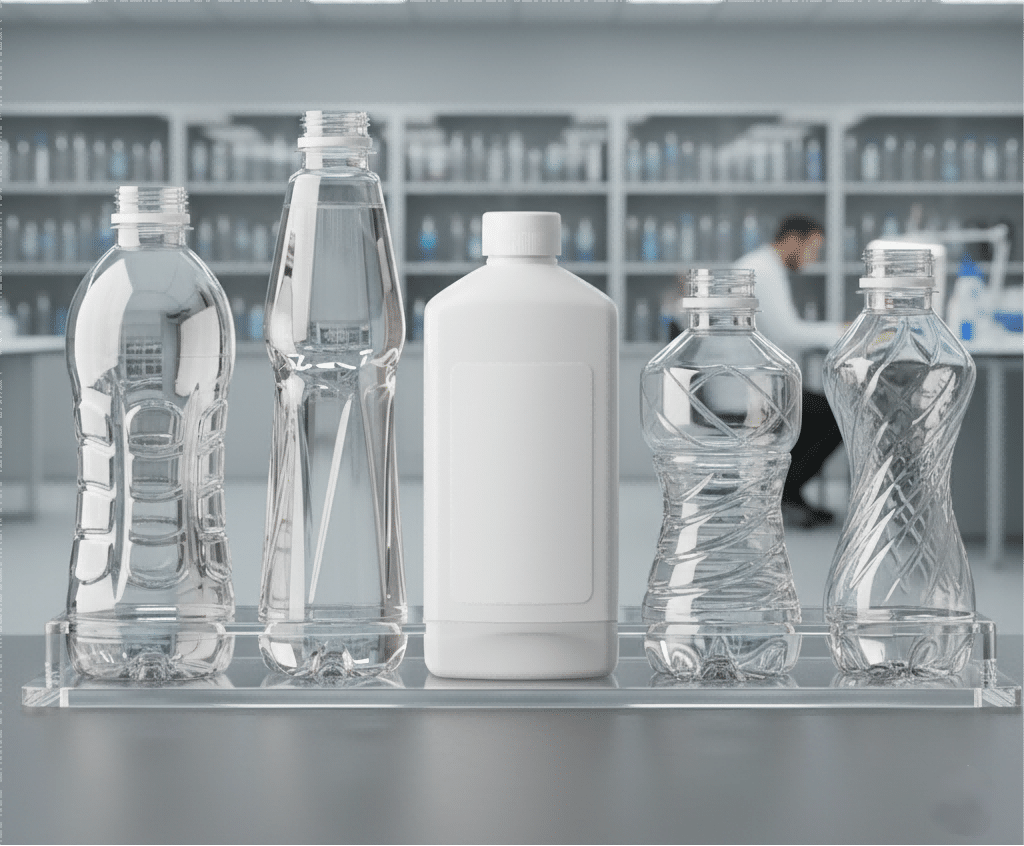

We offer a wide range of customized PET preform mold solutions, covering the entire process from preform design and injection molding to final shaping. By optimizing preform structures to meet specific product needs, we enable the production of lighter, more refined bottle shapes with reduced material usage. This helps our clients lower manufacturing costs and enhance product competitiveness.

Delivering High-Quality Preform Molds

Durable and high precision

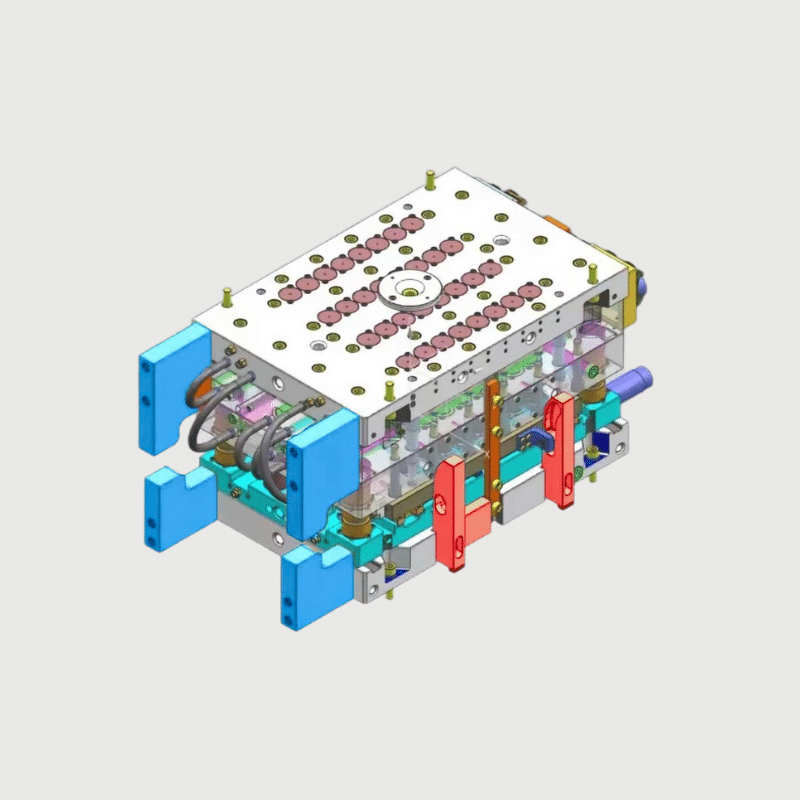

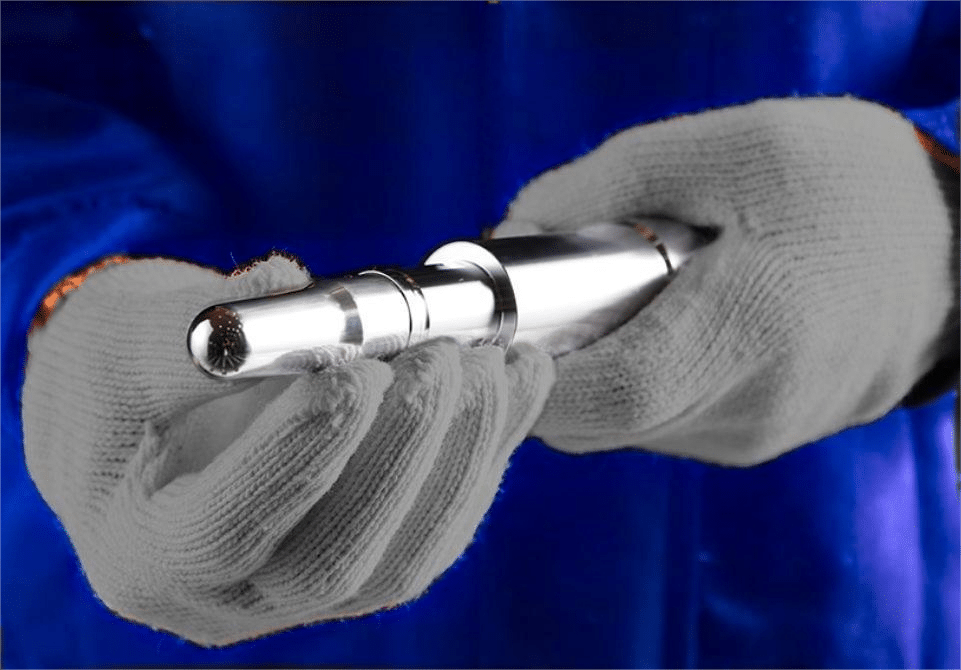

The preform mold ensures the coaxiality of the molded parts, the eccentricity is ≤0.1mm, the preform weight tolerance is ±0.2g, and the cavity and core are interchangeable. It has an efficient cooling system, the water circuit is sealed reliably without leakage, and the water and oil spacers are made of corrosion-resistant materials to ensure stable and durable mold performance.

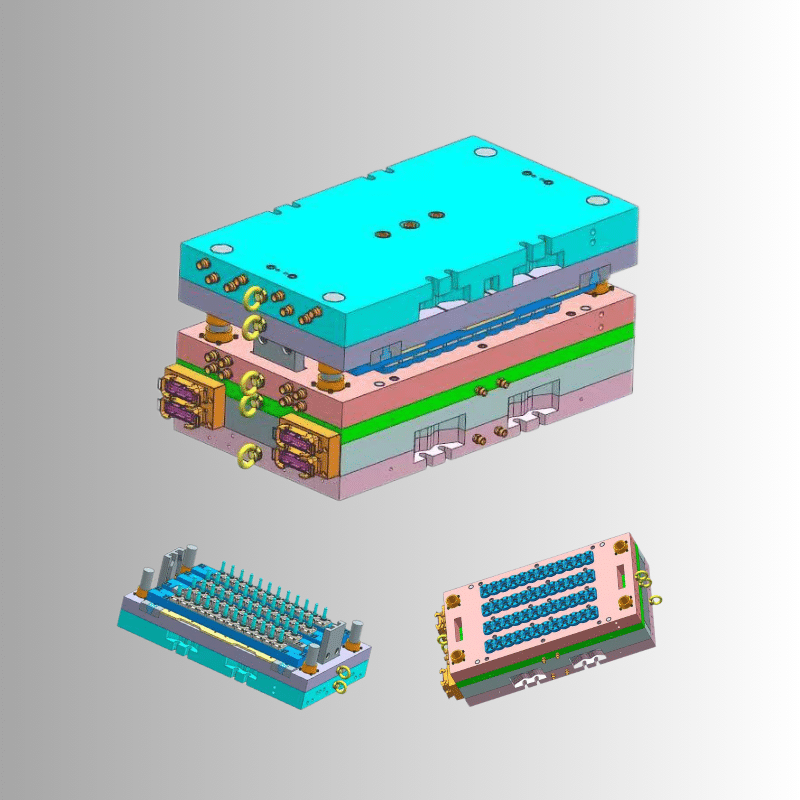

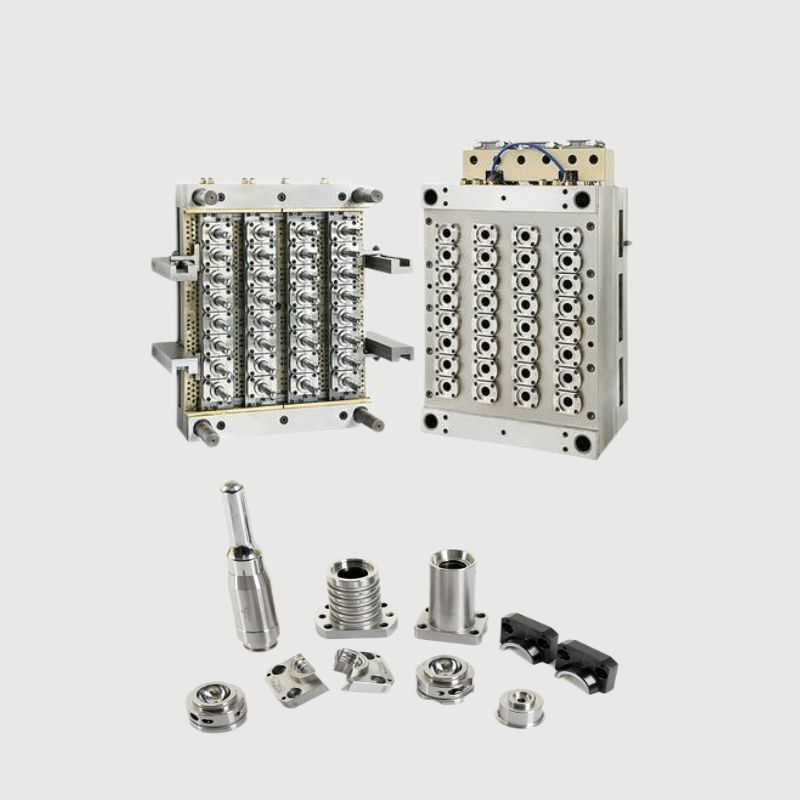

Main Structure of Preform Mold

Better structure

Mold material

The molding parts (mold core, mold base, mold cavity, screw nozzle) are all made of FS136 high-strength anti-corrosion steel, the part hardness HRC is greater than 45°, the contact surface of the sliding parts (sliders, push plates, ejectors) is self-lubricating alloy copper material, DuPont insulation cap and Ambrox beryllium copper nozzle.

Hot runner

The hot runner is reasonably designed to ensure uniform flow of glue at each injection point. The embedded heating tube is used to heat the injection point to ensure that the temperature of each injection point is balanced and consistent. The material is filled into each cavity at the same time to form a more balanced runner.

Cold mold design

Optimized cooling system ensures fast cooling.Shorten cycle time and improve efficiency.Optimized exhaust system and stable demoulding structure,It can effectively remove gas during the injection molding process, prevent defects such as bubbles and shrinkage marks, and improve the surface finish and molding accuracy of the bottle embryo.

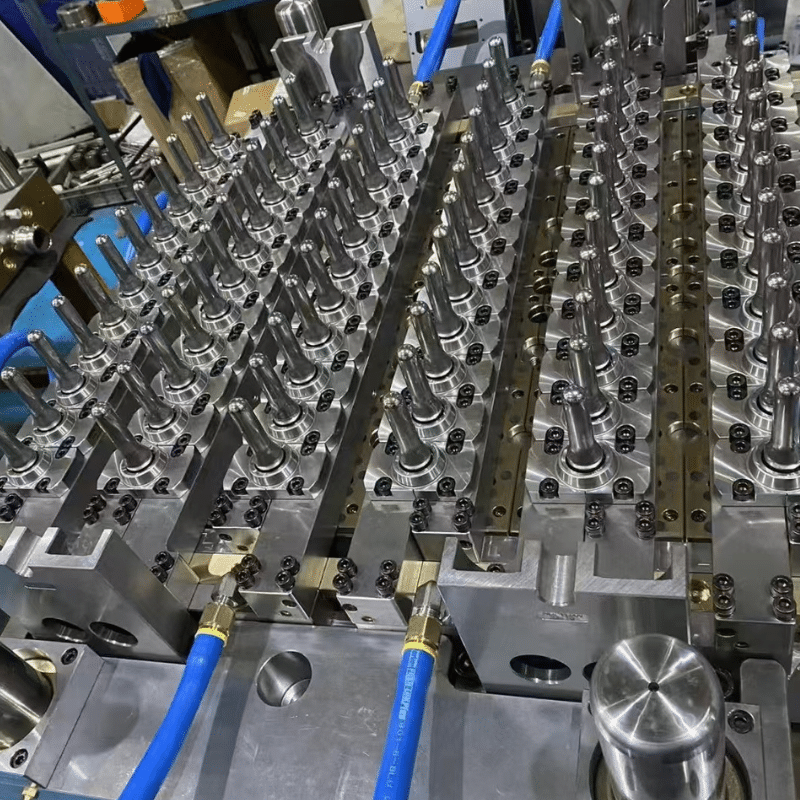

Advanced processing equipment

Our mold workshop covers an area of 4,000 square meters, with 5 Hardinge lathes, 10 CNC machines and a 500 square meter testing room.

High precision matching

Advanced processing technology ensures high-precision matching and interchangeability between mold components.

Free preform design

Our designers have more than 10 years of experience in preform injection molding industry to provide you with free design services

Free proofing

After the preform mold is completed, we will provide 500-1500 preform samples according to your needs.

Strict quality inspection

20 years of mold factory

Your mold expert

Jindong founded in 2004, it is one of the earliest preform mold factories in China. We focus on the R&D and manufacturing of PET preform molds. With 20 years of experience, we provide high-precision, one-stop injection molding solutions. The factory is equipped with advanced CNC processing equipment to ensure durability and production efficiency. The experienced R&D team supports customized needs, helping you improve production efficiency and reduce costs.

Real feedback from our customers

They have something to say

Why we choose Jindong mold?

"Professional Team"

"Good after-sales service"

"High quality"

Solve your problems effectively

FAQ

Yes, our preform molds are highly adaptable and can be customized to fit major injection machine brands, such as Haitian, Engel, and Sumitomo. We precisely adjust the mold to match your equipment parameters, ensuring seamless compatibility and enhanced production efficiency.

Our preform molds are made from high-quality imported mold steel with precise machining and heat treatment to ensure hardness and wear resistance. With proper use and regular maintenance, the mold can last for over 3,000,000 cycles. We also provide detailed maintenance guidelines and professional technical support to help extend the mold’s lifespan and reduce production costs.

We offer comprehensive after-sales services, including mold installation guidance, operator training, regular maintenance advice, and remote technical support. For international clients, our engineers are available for on-site service, ensuring mold stability, rapid troubleshooting, and sustained high-efficiency production.