Your production line has stopped, a blow mold is damaged, and every second of downtime costs money. The choice between a quick repair and a new mold is daunting.

Deciding whether to repair or replace a damaged blow mold is a critical financial and operational choice. A successful repair can quickly restore production at a low cost, while a new mold offers long-term stability, higher efficiency, and the latest technology, representing a strategic investment in your future output.

I’ve been in the PET industry for 16 years, and the question of mold repair is one of the most common concerns I hear from clients. "How long is the warranty? If my mold breaks, can you fix it?" These are questions I get all the time. The decision isn't always straightforward. It involves carefully weighing the immediate costs against the long-term benefits. This guide is built from those years of experience to help you navigate this complex choice, ensuring you control your costs and make the best decision for your business.

The Starting Point: How to Accurately Assess Your Blow Mold's Damage?

A machine is down, and the culprit is a damaged mold. The pressure is on to get it running, but a hasty decision now could cost you dearly later.

A proper assessment is your first, most crucial step. You must differentiate between minor cosmetic flaws and severe structural damage. A professional diagnosis provides a clear roadmap, preventing you from investing in a repair that is doomed to fail or prematurely scrapping a salvageable mold.

Differentiating Surface Scratches from Structural Flaws

The first thing I tell my clients is that not all damage is created equal. You need to become a detective and understand the nature of the wound to your mold. We can break down the damage into two main categories: surface damage and structural damage.

Surface Damage: This is the kind of damage that is immediately visible but primarily affects the aesthetics of the final bottle.

- Scratches and Dings: These are often caused by mishandling, using the wrong tools for cleaning, or a foreign object accidentally entering the mold. The result is a corresponding mark on the bottle's surface. While it might make the bottle look imperfect, it usually doesn't stop production unless you are making high-end products for a very demanding client.

- Pitting or Corrosion: This can happen over time, especially if the mold is not stored correctly or if the cooling water quality is poor. Small pits on the mold surface create dull spots or tiny bumps on the bottle. Again, this is an aesthetic issue more than a functional one.

Structural Damage: This is far more serious because it impacts the mold's core function, its ability to seal properly, and its overall integrity. This type of damage almost always leads to defective products and can even pose a safety risk.

- Parting Line Wear: The parting line is where the two halves of the mold meet. After thousands and thousands of cycles under high clamping pressure, this edge can start to wear down. This results in a more prominent, sometimes sharp, seam on the bottle. In severe cases, it can cause material to leak out, a phenomenon known as "flash," which is a major quality defect. Effective parting line repair is a common topic of discussion.

- Damage to the Neck or Base Inserts: These areas define the critical dimensions of your bottle's opening and bottom. Any damage here, even if small, can mean the bottle won't seal properly with a cap or won't be stable when standing. This is a critical failure.

- Cracks in the Mold Body: This is the worst-case scenario. A crack in the aluminum or steel body of the mold, often caused by extreme stress or a catastrophic failure, compromises the entire structure. This is almost always a situation where replacement is the only safe option.

Understanding this difference is the foundation of your decision. A surface scratch might be fixed with simple polishing, while a worn parting line requires precise welding and CNC machining.

A Practical Checklist for Self-Assessment

Before you even pick up the phone to call a mold specialist like me, you can perform a preliminary check. This will help you have a more informed conversation and understand the scope of the problem. Here’s a simple checklist you can use.

| Mold Area | What to Check For | Potential Impact on Bottle / Production |

|---|---|---|

| Mold Cavity | Scratches, dents, corrosion, pitting, any imperfections on the main body surface. | Cosmetic flaws on the bottle body, dull spots, non-uniform appearance. |

| Parting Line | Wear, rounding of the edges, nicks, or gaps when the mold is closed. | Visible seam line on the bottle, potential for flash (plastic leakage), inconsistent bottle weight. |

| Neck Finish Area | Dents or wear on the threads, damage to the sealing surface. | Improper cap fit, leakage, failure in quality control checks. A good neck is key; see our preform neck size guide. |

| Base Area | Wear on the push-up (the indent on the bottom), damage to the standing ring. | Unstable bottles that wobble or fall over, stress cracking originating from the base. |

| Venting Slots | Clogged or damaged vents. These are tiny channels that let air escape. | Incomplete bottle formation, burnt spots on the plastic, thin patches in the bottle wall. |

| Guide Pins/Bushings | Visible wear, scoring, or looseness. | Misalignment of mold halves, leading to uneven wall thickness and excessive wear on the parting line. |

| Cooling Channels | Leaks, blockages (diagnosed by uneven mold temperature). | Increased cycle times, inconsistent bottle quality due to poor cooling. This is why a proper chiller is non-negotiable. |

Use a good light source and, if possible, a magnifying glass. Take clear photos of any areas of concern. This documentation will be invaluable when you seek professional help.

When to Call in the Professionals

While your self-assessment is a great start, it has its limits. You can see the surface, but you can't measure microscopic wear or detect internal stresses. For anything beyond a simple surface scratch, you need a professional diagnosis.

I had a client once who thought they had a simple wear issue on one cavity. They sent it to a local machine shop for a quick polish. The problem persisted. When they finally sent the mold to us, our CMM (Coordinate Measuring Machine) inspection revealed that the entire mold block had slightly warped due to overheating. The "simple wear" was just a symptom of a much larger problem. Their initial "fix" was a waste of time and money.

A professional mold manufacturer will use precision tools to give you an authoritative damage report:

- CMM Inspection: This machine uses a probe to measure the geometry of your mold down to the micron level. It can compare the mold's current dimensions to the original CAD design, revealing any deviation, warping, or wear that is invisible to the naked eye.

- Hardness Testing: We can test the hardness of the mold steel or aluminum. A repair that involved welding might have softened the metal in the heat-affected zone, making it prone to faster wear in the future.

- Non-Destructive Testing (NDT): For suspected cracks, methods like dye penetrant testing or magnetic particle inspection can reveal hairline fractures that could lead to catastrophic failure under pressure.

This professional report isn't an expense; it's an investment. It tells you exactly what's wrong, what it will take to fix it properly, and whether a repair is even a viable long-term solution. It's the only way to move from guessing to knowing.

The Iceberg Model: Calculating the Full "Visible Costs" of Repairing a Blow Mold?

You've received a quote for the repair, and it seems reasonable. But is that the full picture? The initial quote is often just the tip of the iceberg.

The true visible cost of a repair includes direct fees, outsourced services, and unexpected spare parts. Neglecting to account for all these elements can lead to budget overruns and turn a seemingly cheap fix into an expensive headache.

Breaking Down Direct Repair Fees

When you send a blow bottle mold for repair, the primary quote you receive will cover the direct labor and materials. It's essential to understand what these entail, as the complexity of the job can cause these costs to vary significantly. I always provide my clients with a detailed breakdown so there are no surprises.

Let's look at a typical repair scenario, like fixing a damaged parting line on a single cavity mold made from Aluminum 7075.

Materials Cost: This is the cost of the physical "stuff" needed for the repair.

- Welding Rods: For aluminum, we'd use a specific TIG welding rod that is compatible with the 7075 alloy. This is not just any rod; it needs to have similar properties after cooling. The cost might seem small, perhaps $50-$100, but using the wrong one will cause the repair to fail.

- Steel Inserts: If the damage is too severe to be welded, like in a threaded neck area, we might machine out the damaged section and insert a new piece of steel (like P20 or S136). The cost here includes the raw block of steel, which could be anywhere from $100 to $500 depending on the size and grade.

Labor / Machine Time Cost: This is almost always the largest part of the bill. It's calculated based on the hours a skilled technician and expensive machinery are dedicated to your mold.

- Assessment & Disassembly: Before any work begins, the mold must be carefully taken apart. This can take 1-2 hours.

- Welding: This is a highly skilled job. A welder has to carefully build up the worn parting line, layer by layer. For a single cavity, this could take 2-4 hours of meticulous work.

- CNC Machining: After welding, the excess material must be machined back to the original design specifications. The mold half is set up in a 3-axis or 5-axis CNC mill. This is the most time-consuming part, potentially taking 8-12 hours of machine time.

- Polishing and Hand Finishing: A machine can only get so close. The final surface finish, especially on the parting line and inside the cavity, is achieved by hand. A skilled mold polisher might spend another 4-6 hours using progressively finer stones and polishing compounds to achieve a mirror finish.

- Reassembly & Quality Check: Finally, the mold is put back together, and we check that everything aligns perfectly. This takes another 1-2 hours.

Let's make a hypothetical table of these direct costs, assuming a labor rate of $80/hour:

| Service | Estimated Hours | Estimated Cost | Notes |

|---|---|---|---|

| Disassembly & Assessment | 2 | $160 | Standard procedure for all repairs. |

| TIG Welding | 3 | $240 | Requires a highly skilled welder. |

| CNC Machining | 10 | $800 | Resurfacing the welded area to original specs. |

| Hand Polishing & Finishing | 5 | $400 | Crucial for product quality and mold sealing. |

| Reassembly & Final QC | 2 | $160 | Ensuring the repair was successful. |

| Subtotal Labor | 22 | $1,760 | |

| Materials (Welding Rods) | N/A | $75 | |

| Total Direct Repair Fee | $1,835 |

This gives you a much clearer picture than a single lump-sum quote. It shows that over 95% of the cost is in skilled labor and machine time.

The Hidden Costs of Outsourcing

Sometimes, a repair requires a process that we, or any standard mold shop, don't do in-house. These are specialized services that need to be outsourced to a third-party vendor. It's a "hidden" cost because it might not be in the initial estimate if the need isn't identified until after the mold is taken apart.

- Heat Treatment: This is primarily for steel molds. After welding, the steel's internal structure is disturbed. It needs to be heat-treated (quenched and tempered) again to restore its original hardness and durability. If this step is skipped, the repaired area will be soft and wear out extremely quickly. This process can cost several hundred dollars and add a few days to the repair timeline.

- Surface Coating: Many high-wear molds have special coatings to increase their lifespan.

- Chrome Plating: Often used on neck rings and other high-friction areas to provide a hard, smooth surface. If this area is repaired, it will need to be stripped and re-plated.

- Nitriding: A process that hardens the surface of steel molds, making them more resistant to wear and corrosion.

- Nickel-Teflon Coatings: Provides lubricity, helping the finished bottle release from the mold more easily.

These coating services are highly specialized and add another layer of cost and time. You have to ship the mold part to the coater, wait for them to process it, and then get it back. This can easily add a week and $500-$1,500 to the project.

Don't Forget Spare Parts

This is the final piece of the "visible cost" puzzle. During the repair, we often discover that standard components, which weren't part of the original problem, are at the end of their life and need to be replaced. It makes no sense to complete an expensive repair and then put worn-out components back in.

Here are common spare parts we often recommend replacing during a major repair:

- Guide Pins and Bushings: These ensure the two halves of the mold align perfectly. Worn pins can lead to parting line damage.

- O-rings and Seals: These prevent water leaks from the cooling channels. They are cheap and should always be replaced when a mold is disassembled.

- Wear Plates: Sacrificial plates placed in high-friction areas. They are designed to wear out so the main mold body doesn't.

- Fasteners: The bolts holding the mold together can stretch and fatigue over time. It's good practice to replace them.

The cost of these parts can range from a few dollars for O-rings to several hundred for custom-made wear plates. I always tell my clients to budget an extra 10-15% of the repair cost for these "while-you're-in-there" replacements. It's preventative maintenance that saves you from another shutdown in the near future.

The Impact of Hidden Costs: How Much is Downtime Truly Costing You?

The repair bill is one thing, but the real pain comes from the silence. A stationary production line isn't just resting; it's actively losing you money, every single hour.

This hidden cost of downtime is often far greater than the repair itself. It includes lost production, potential damage to customer relationships, and the wages of an idle workforce. Understanding this impact is key to making an urgent and wise decision.

Calculating Production Loss

Most factory managers have a gut feeling that downtime is expensive, but they often underestimate the actual amount. I encourage my clients to stop thinking in terms of "days" of downtime and start thinking in "hours." The number becomes much more alarming and motivating. Here is a simple but powerful formula to put a real number on your loss:

Downtime Cost per Hour = (Bottles Produced per Hour × Profit per Bottle)

Let's walk through a realistic example. Imagine you have a production line with one of our bottle blowing machines running a 4-cavity mold.

- Cycle Time: 6 seconds (a fairly standard time)

- Bottles per Cycle: 4

- Cycles per Minute: 60 seconds / 6 seconds = 10 cycles

- Bottles per Minute: 10 cycles × 4 bottles/cycle = 40 bottles

- Bottles per Hour: 40 bottles/minute × 60 minutes = 2,400 bottles

Now, let's talk profit. This is the sale price of the bottle minus the cost of resin, electricity, labor, and overhead. Let's say your net profit is a modest $0.015 per bottle.

- Profit per Hour: 2,400 bottles/hour × $0.015/bottle = $36 per hour

This $36 per hour might not sound catastrophic. But a mold repair can easily take a week. Let's assume you run two 8-hour shifts per day, 5 days a week.

- Downtime: 5 days × 16 hours/day = 80 hours

- Total Lost Profit: 80 hours × $36/hour = $2,880

Suddenly, that "small" downtime has cost you nearly $3,000 in lost profit alone. This is often more than the cost of a simple repair. If the mold needs to be shipped for repair, the downtime could be two or three weeks. The number gets very big, very fast. When you present the decision to your finance department, showing them this calculation makes the choice much clearer. The cost of not acting is now a quantifiable number.

Order Delays & Customer Churn Risk

The financial loss from a silent production line is only the beginning. The ripple effects can damage your business in ways that are harder to measure but potentially more devastating.

Contract Penalties: Many large customers, especially in the beverage and consumer goods industries, have strict delivery schedules. Their own production lines depend on your bottles arriving on time. Your supply contract likely includes penalties for late delivery, which can be a percentage of the order value. A week of downtime could not only wipe out the profit from that order but also cost you extra in penalties.

Loss of Customer Trust: This is the intangible cost. When you call a client to tell them their order will be late, you are damaging the trust they have in you as a reliable supplier. The first time, they might be understanding. The second time, they will be concerned. If it becomes a pattern, they will start looking for a second supplier. I’ve seen it happen. A good customer is hard to win and easy to lose. Once they have found a reliable alternative, it is incredibly difficult to win them back.

Permanent Customer Churn: This is the ultimate risk. If a major client faces shutdowns on their own filling lines because you couldn't deliver bottles, they will not just be angry; they will be forced to find another supplier to protect their own business. Losing a key account over a preventable mold issue can be a blow that takes years to recover from. This is why having a proactive blow mold maintenance strategy is so critical.

I always think of my UK client. They had a 20-cavity rotary mold that had been running for five years. They were smart; they contacted me before it failed. They saw some wear and were worried about potential downtime. The risk of shutting down their high-speed line and failing to supply their customers was a much bigger fear than the cost of the repair itself.

Idle Labor Costs

The third component of hidden costs is the money you spend on a workforce that has nothing to do. Your machines might be silent, but your payroll is still running.

Think about everyone associated with that production line:

- Machine Operators: The people who run the blow molder, the labeler, the packer.

- Quality Control Technicians: The people who check the bottles for defects.

- Maintenance Staff: They might be busy trying to fix the mold, but if not, they are also waiting.

- Supervisors: The line supervisor is still on the clock, managing a non-existent output.

- Forklift Drivers: No pallets of bottles to move.

You can try to reassign these employees to other tasks like cleaning or inventory, but often, you are simply paying them to wait. Let's create a simple table to visualize this cost.

| Employee Role | Number of Employees | Hourly Wage | Cost per Hour | Cost per 80-hour Week |

|---|---|---|---|---|

| Machine Operator | 2 | $20 | $40 | $3,200 |

| QC Technician | 1 | $22 | $22 | $1,760 |

| Supervisor | 1 | $30 | $30 | $2,400 |

| Total Idle Labor Cost | $92 | $7,360 |

Now, let's add it all up for that one week of downtime:

- Lost Profit: $2,880

- Idle Labor: $7,360

- Total Hidden Cost (1 Week): $10,240

This $10,240 is before any potential late fees and before any long-term damage to customer relationships. It's a staggering number that completely changes the financial equation. It shows that the fastest solution, whether it's a repair or ordering a new mold with expedited shipping, is often the cheapest one in the long run.

The Post-Repair Mold: Realistic Expectations for Performance, Lifespan, and Quality?

The repair is complete, and your mold is back. But will it be the same? It's easy to assume it will perform just like it did before, but that's rarely the case.

A repaired mold is a compromise. While it can get you back into production, you must have realistic expectations about its performance, lifespan, and the quality of the bottles it produces. Knowing these limitations is key to managing your production process effectively after the repair.

Performance Recovery Level

One of the first questions my clients ask is, "Will it run as fast as before?" My honest answer is, "Probably not, at least not without some adjustments." While a professional repair from a company like mine aims to restore the mold's primary functions, you can't always get back to 100% of the original manufactured standard.

The most common area of compromise is in thermal performance. PET blow bottle molds are typically made from aircraft-grade aluminum because of its excellent thermal conductivity. It pulls heat out of the just-blown bottle very quickly, which is what allows for short cycle times.

When we have to perform a weld repair, for example on a worn parting line, we are introducing a new material (the welding rod) and applying intense heat to a localized area. This has consequences:

- Changes in Material Properties: The repaired area, even after cooling, will not have the exact same crystalline structure as the original parent aluminum. This can create a "hot spot" or a "cold spot" because the thermal conductivity in that specific area is now different from the rest of the mold.

- Impact on Cooling: This difference in heat transfer can mean that one part of the bottle cools slightly slower than the rest. To produce a consistent, stable bottle, you may need to increase the overall cooling time in your machine's settings. Increasing the cooling time by just half a second on a 6-second cycle is an 8% increase in cycle time, which means an 8% reduction in your production output.

- Potential for Defects: These hot spots can also lead to quality issues that require troubleshooting. You might see issues like hazy spots or areas with higher-than-normal shrinkage. Resolving these might require adjustments to preform temperature or blowing pressure, further complicating your process. Our guide on common PET blow molding defects can be a valuable resource here.

So, while the mold is "functional," you may have to trade away some of your hard-won efficiency to accommodate the reality of the repair. It's a trade-off: you're back in business, but perhaps at a slightly slower pace.

Expected Use Lifespan

A new mold has a predictable lifespan. You know that, under normal operating conditions, you can expect to get, for example, 10 to 15 million cycles out of it. A repaired mold, however, comes with a much shorter and less certain warranty on its future.

The lifespan of the repair depends entirely on two factors: the root cause of the original damage and the quality of the repair itself.

- Addressing the Symptom vs. the Cause: If the parting line wore out simply because of high cycle count after years of service, a good repair might last a reasonably long time. But if the wear was caused by a machine issue, like the clamping platens being out of alignment, the repaired mold will fail again very quickly unless the root cause on the bottle blowing machine is also fixed.

- The "Weakest Link" Principle: The repaired area is now, and will always be, a potential point of failure. The welding process, as mentioned, changes the metal's properties. This area may be more susceptible to fatigue or wear than the original mold material. I often tell clients to think of a repaired mold as a solution to get them through the next 1-2 million cycles, which might be enough to meet short-term demand or to bridge the gap while a new mold is being manufactured.

- The Risk of Recurring Issues: It's not uncommon for a repaired mold to require further touch-ups or fixes down the line. It becomes part of a cycle of reactive maintenance rather than the "set it and forget it" reliability of a new tool.

A repaired mold can be a fantastic short-term solution. But if you are planning your production for the next five years, relying on a heavily repaired mold is a risky strategy.

Product Quality Consistency

This is a particularly important point for companies running multi-cavity molds. If you have an 8-cavity mold and one cavity is damaged and repaired, that one cavity is now physically different from the other seven.

Even with the most precise CNC machining and hand polishing, it is nearly impossible to make a repaired cavity 100% identical to the others. These microscopic differences can translate into measurable variations in the final product.

Here’s what you might encounter:

- Weight Variation: The repaired cavity might produce a bottle that is slightly heavier or lighter than the bottles from the other cavities. While a difference of 0.1 grams might not sound like much, for a lightweight bottle, this could be a significant percentage and cause issues with your quality control parameters.

- Wall Thickness Distribution: The way the material flows and cools in the repaired cavity can be different. This might lead to a bottle where the wall is slightly thinner in one area and thicker in another compared to its siblings from the other cavities. This can affect the bottle's top-load strength and overall performance.

- Visual Differences: You might even see subtle differences in clarity or surface finish between the bottle from the repaired cavity and the others. For a premium product where appearance is everything, this lack of consistency can be a major problem.

To manage this, you will need to implement a more rigorous quality control process. You may have to check bottles from each cavity individually rather than just taking a random sample from the conveyor belt. This adds labor and complexity to your operation.

The bottom line is that a repaired mold can be a valuable asset, but it comes with compromises. You trade a lower upfront cost for potential reductions in performance, a shorter lifespan, and the added challenge of maintaining product consistency.

Investing in a New Mold: What Do You Get Besides the High Price Tag?

The sticker shock of a new mold is real. It's a significant capital investment, and it's easy to focus solely on that number. But looking only at the price is like judging a book by its cover.

A new mold isn't just a replacement; it's an upgrade. You're investing in the latest technology, full warranty protection, and long-term operational stability. These benefits often provide a return that far outweighs the initial cost.

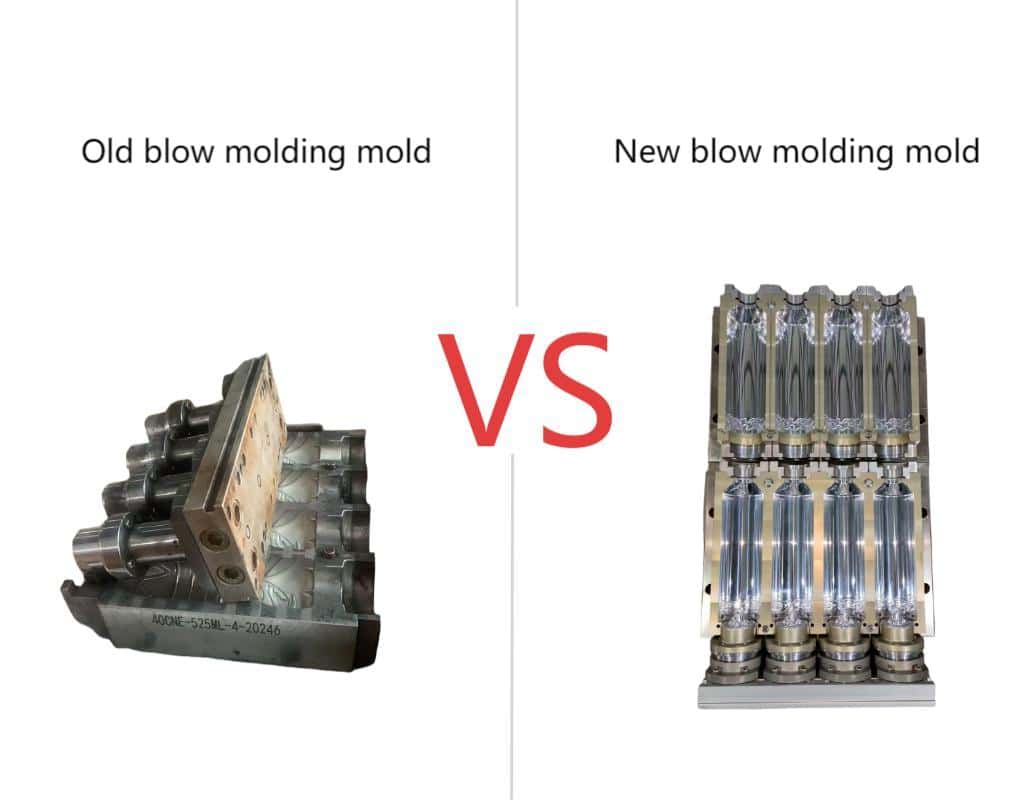

Latest Technology & Design

The world of mold manufacturing doesn't stand still. The new mold you buy today is a much more sophisticated piece of engineering than one made even five or ten years ago. When you invest in a new blow bottle mold, you are buying years of innovation.

Optimized Cooling Channels: This is one of the biggest advancements. In the past, cooling channels were just straight lines drilled through the aluminum block. Today, we use advanced fluid dynamics simulation to design complex, contoured cooling channels that follow the shape of the bottle. This "conformal cooling" pulls heat out of the plastic more evenly and much more quickly. A reduction in cooling time of just one second can translate to a 15-20% increase in output. This is a massive gain in efficiency that a repaired old mold can never match. Better cooling is also essential for quality, which is why a properly sized chiller is so critical to the system.

More Durable Materials and Coatings: We have access to better materials now. While 7075 aluminum is still a workhorse, we can use newer, tougher alloys for the main body. More importantly, we can build molds with replaceable inserts made from hardened steel (like S136 or Stavax) in high-wear areas like the neck and base. These inserts can take the brunt of the mechanical stress and can be replaced easily and cheaply when they wear out, dramatically extending the life of the main mold body. We also use advanced coatings that reduce friction and prevent corrosion, further enhancing durability.

Advanced Lightweighting Design: The cost of PET resin is one of your biggest variable expenses. Modern mold design, guided by Finite Element Analysis (FEA), allows us to create bottles that are significantly lighter but just as strong as older, heavier designs. A new mold can be specifically designed to optimize material distribution, putting plastic only where it's structurally needed. Shaving just one gram off a bottle might save you tens or even hundreds of thousands of dollars in material costs over the life of the mold. This is a strategic advantage that is almost impossible to achieve by repairing an old, heavy-design mold. Our PET Bottle Mold Design Guide delves deep into these modern techniques.

Full Quality Assurance & Warranty

This is a simple but incredibly important benefit. When you buy a new mold from a reputable manufacturer, you get peace of mind.

- Manufacturer's Warranty: A new mold comes with a warranty. This is our promise to you that the mold is free from defects in materials and workmanship. If something goes wrong in the initial period of operation—say, a water leak develops or an insert fails prematurely—we will fix it at no cost to you. This protects your investment and eliminates risk. A repair job, on the other hand, is usually offered "as-is" or with a very limited guarantee that only covers the specific work that was done.

- Guaranteed Performance: We don't just guarantee the mold won't break; we guarantee it will perform. The mold is warrantied to produce a specific number of cycles (e.g., 10 million) and to produce bottles that meet the agreed-upon quality specifications. We validate this before we even ship the mold, often by running tests and sending you bottle samples. You can even validate designs rapidly with our 3D printed sample service before cutting any metal.

This assurance allows you to start production confidently, knowing that the tool at the heart of your operation is fully supported. There are no hidden surprises or finger-pointing if an issue arises.

Long-Term Stability & Predictability

For a business, predictability is gold. The ability to forecast your production output, your costs, and your maintenance schedule allows for effective long-term planning. A new mold is the cornerstone of this stability.

Predictable Production Efficiency: With a new mold featuring optimized cooling and design, you can lock in a consistent, fast cycle time. You know exactly how many bottles you can produce per shift. This makes it easy to schedule production, promise delivery dates to customers, and manage inventory. A repaired mold, with its potential for slightly longer cycle times and inconsistencies, introduces variables that make planning more difficult.

Consistent, High-Quality Output: A new multi-cavity mold is manufactured with incredible precision. All cavities are virtually identical. This means every bottle you produce will be the same in weight, dimensions, and performance. You don't have to worry about variations between cavities. This simplifies your quality control process and ensures your customers receive a consistent product every time. This consistency is also crucial for ensuring a perfect fit with your bottle blowing machine, minimizing setup time and scrap.

Predictable Maintenance: New molds come with a recommended maintenance schedule from the manufacturer. You know when to inspect wear parts, when to perform cleaning, and what to look for. This allows you to practice proactive, planned maintenance instead of the reactive, emergency-based maintenance that often accompanies an aging, repaired mold. This stability reduces stress on your team and prevents unexpected, costly downtime.

Investing in a new mold is not just buying a piece of metal. It's an investment in efficiency, quality, and predictability that pays dividends for years to come.

The Financial Perspective: Comparing ROI and Payback Period?

Ultimately, the decision to repair or replace comes down to the numbers. Which option gives you a better return on your money? To answer this, we need to look beyond the initial price tag.

By calculating the Return on Investment (ROI) and Payback Period for both options, you can make a data-driven decision. This financial analysis separates short-term tactical fixes from long-term strategic investments, giving you a clear path forward.

ROI of a Repair: The Short-Term View

The Return on Investment for a repair is typically very high and very fast, which is why it's such an attractive option. It's a tactical move designed to solve an immediate problem and get production running again as quickly as possible. The calculation is focused on cost avoidance and immediate gains.

The formula looks like this:

Repair ROI = (Avoided Downtime Costs + Profit from Urgent Orders) / Total Repair Cost

Let's use the numbers we've developed in previous sections to create a clear example.

- Total Repair Cost: We estimated a direct repair fee of $1,835. Let's add a bit for shipping and internal labor, rounding it to a $2,500 total.

- Avoided Downtime Costs: Let's say the repair takes one week. A new mold might take 8 weeks to manufacture and deliver. The repair allows you to avoid 7 weeks of downtime. Using our previous calculation of $10,240 in hidden costs (lost profit + idle labor) per week, the avoided cost is 7 weeks × $10,240/week = $71,680.

- Profit from Urgent Orders: During those 7 weeks, you are able to fulfill orders. Let's say you generate a total profit of $20,000 during this time that you would have otherwise lost.

Now, let's calculate the ROI:

Repair ROI = ($71,680 + $20,000) / $2,500 = $91,680 / $2,500 = 36.7

To express this as a percentage, you multiply by 100. The ROI is 3,670%.

This number is huge, and it shows why repairs are so critical in the short term. For a small investment of $2,500, you unlocked over $90,000 in value by keeping the factory running. This is a powerful, tactical return. However, it doesn't account for the potential for lower efficiency or the risk of another failure in the near future. It's a snapshot, not the full movie.

ROI of a New Mold: The Strategic View

Calculating the ROI for a new mold is more complex because it's a long-term, strategic investment. We need to consider not just the cost, but the value it generates over its entire life cycle. The initial cost is higher, but the returns come from efficiency gains and cost savings year after year.

The formula is more comprehensive:

New Mold ROI = (Total Lifetime Value - Total Lifetime Costs) / Total Lifetime Costs

Let's build a comparison table for an old, repaired mold versus a new, high-efficiency mold over a 5-year period.

Assumptions:

- New Mold Cost: $25,000 (a realistic price for a quality multi-cavity mold)

- Old Mold Annual Repair Cost: $1,500/year (for minor touch-ups and issues)

- New Mold Efficiency Gain: The new mold is 15% faster due to better cooling. This translates to more output and thus more profit. Let's say this equals $10,000 in extra profit per year.

- New Mold Material Savings: The new lightweight design saves 0.5 grams per bottle. Over millions of bottles, this adds up to a resin cost saving of $8,000 per year.

Here's how the numbers stack up over 5 years:

| Financial Metric | Old Repaired Mold | New High-Efficiency Mold | Notes |

|---|---|---|---|

| Initial Cost | $2,500 (repair) | $25,000 (purchase) | The major difference in upfront cash. |

| Annual Maintenance/Repair | $1,500 | $200 (preventative) | Repaired molds need more attention. |

| Total Maintenance (5 Yrs) | $7,500 | $1,000 | |

| Total Cost (5 Yrs) | $10,000 | $26,000 | |

| Annual Efficiency Gain | $0 | $10,000 | New mold produces more bottles per hour. |

| Annual Material Savings | $0 | $8,000 | From lightweighting design. |

| Total Value Generated (5 Yrs) | $0 (baseline) | $90,000 ($18,000/yr × 5) | The new mold creates new value. |

| Net Financial Outcome (5 Yrs) | -$10,000 (cost) | +$64,000 (gain) | Value Generated - Total Cost |

From this table, the strategic advantage is crystal clear. The repaired mold has a total cost of ownership of $10,000 over five years. The new mold, despite its high initial price, actually generates a net positive financial outcome of $64,000.

The ROI calculation would be:

New Mold ROI = ($90,000 - $26,000) / $26,000 = $64,000 / $26,000 = 2.46 or 246%

While 246% is much lower than the repair's 3,670%, it's a return on a much larger, longer-term investment. It represents sustainable, strategic growth for the company.

Payback Period: When Do You Break Even?

The final piece of the financial puzzle is the payback period. This answers the question, "How long until I get my money back?"

Repair Payback Period: This is almost instantaneous. Based on our downtime cost of over $10,000 per week, the $2,500 repair pays for itself in less than two days of operation.

New Mold Payback Period: We need to look at the annual savings and gains the new mold generates.

- Annual Value Creation: $10,000 (efficiency) + $8,000 (materials) = $18,000 per year.

- Payback Period = Initial Investment / Annual Value Creation

- Payback Period = $25,000 / $18,000 per year = 1.39 years

This means it will take approximately 1 year and 5 months for the new mold to "pay for itself" through the extra value it creates. After that, for the rest of its 10+ year lifespan, it is a pure profit-generating machine for your company.

This financial analysis shows that repair is an essential tactic to stop the bleeding, but investing in new technology is the strategy that leads to long-term health and profitability.

A Window for Tech Upgrades: Should Your Repair Decision Consider Future Products?

Your mold is damaged, and the focus is on getting today's product running again. But this moment of crisis is also a moment of opportunity. It forces you to ask a critical question: should this decision be based on my past, or my future?

Before you default to a simple repair, take a step back. This decision point is a rare chance to align your manufacturing hardware with your company's future strategy. Considering your product pipeline, market trends, and new materials can turn a simple repair job into a strategic upgrade.

Current Product Lifecycle

Not all bottles are created equal in the eyes of the market. The first question you should ask is, "How much longer are we even going to be making this specific bottle?" The answer will heavily influence your decision.

End-of-Life Products: I once had a client in the juice industry. They had a mold for a uniquely shaped 500ml bottle that was being phased out in six months in favor of a new, standardized design for their entire product line. When the old mold suffered significant wear, the decision was easy. A full replacement costing $30,000 for just six months of production made no sense. A quick and cheap $2,000 weld repair to just keep it limping along until the deadline was the obvious and correct choice. In this case, the goal is not perfection; it's survival for a limited time.

Flagship Products: On the other hand, if the damaged mold is for your best-selling water bottle that accounts for 40% of your revenue, the calculation is completely different. This product is your company's workhorse. Relying on a repaired mold with its potential for lower efficiency and higher risk is a dangerous game to play with your most important asset. For a flagship product, investing in a brand new, high-performance mold is not just a good idea; it's a critical investment in securing your primary revenue stream for the future. You might even consider ordering a new mold and repairing the old one to keep as a backup.

Analyzing where the product is in its lifecycle—introduction, growth, maturity, or decline—provides a powerful strategic filter for the repair vs. replace decision.

Future Design Trends (e.g., Lightweighting)

The beverage and consumer goods markets are intensely competitive and constantly evolving. What your customers demand today might not be what they want tomorrow. Your mold decision should reflect these trends. The most significant trend of the last decade has been lightweighting.

- The Push for Sustainability and Cost Savings: Everyone wants lighter bottles. Lighter means less PET plastic, which is better for the environment and, more importantly for your bottom line, reduces your resin cost. It also reduces the weight of the final product, which can lead to savings in shipping and logistics.

- The Strategic Opportunity: Your old mold was likely designed 5 or 10 years ago, before modern lightweighting analysis was common. Repairing it means you are locking yourself into that old, heavy design. Investing in a new mold gives you the opportunity to completely redesign the bottle. We can use advanced computer simulations to remove material from non-critical areas while maintaining or even improving the bottle's strength. As I often explain in my PET Bottle Mold Design Guide, a redesign can often reduce bottle weight by 10-15% without any perceptible difference to the consumer.

Let's imagine you produce 20 million bottles a year with this mold. The old bottle weighs 15 grams. A new, lightweighted design weighs 13.5 grams—a 1.5-gram saving.

- Total Weight Savings: 20,000,000 bottles × 1.5 g/bottle = 30,000,000 grams = 30,000 kg.

- Cost Savings: Assuming a PET resin cost of $1.50/kg, that's a $45,000 saving per year.

Suddenly, the $25,000 cost of a new mold doesn't just look like an expense; it looks like an incredible investment with a payback period of just over six months from material savings alone. This is a strategic move that makes your company more competitive and more profitable. Choosing to just repair the old mold would mean leaving that $45,000 on the table, year after year.

Potential for Material Changes

The final piece of future-proofing is considering the materials you will use. The industry is seeing a massive push towards using more recycled content.

- The Rise of rPET: Using recycled PET (rPET) is becoming a requirement for many major brands who have made public sustainability pledges. Many governments are also mandating minimum recycled content levels.

- rPET is Different: Running 100% virgin PET is easy. Running a high percentage of rPET (like 50% or 100%) is more challenging. rPET has a different melt viscosity, can have slight color variations, and often requires different processing parameters. It can be more prone to certain defects.

- Designing for rPET: When we design a new mold today, we can optimize it specifically for rPET. This might mean designing different venting paths to allow gases to escape, adjusting the gate design for better material flow, or using specific steel inserts and coatings that are more resistant to the potential impurities in rPET.

If you know that in the next 1-2 years you will need to move to a 50% rPET blend, repairing your old mold that was designed for virgin PET might be setting yourself up for future headaches. You could face a constant battle with processing issues and quality defects. Investing in a new mold designed for the material of the future ensures a smooth transition and maintains high efficiency and quality. This foresight can save you countless hours of blow molding troubleshooting down the road.

This moment of decision is a chance to pause and think strategically. Are you just fixing a problem, or are you building a foundation for your future success?

The Final Decision Checklist: 10 Questions to Help You Make a Smart Choice

We've covered a lot of ground, from technical assessments to financial calculations. Now it's time to bring it all together to make a final, confident decision.

To simplify the process, I've created a practical checklist and a risk matrix. These tools will help you consolidate your thoughts and visually compare your options. They are designed to cut through the complexity and lead you to the most logical choice for your specific situation.

The 10 Questions to Guide Your Choice

Run through these ten questions. The pattern of your answers will often point clearly toward either repair or replacement. Be honest with your answers.

- Is the damage structural? (e.g., on the parting line, neck finish, or a crack in the mold body) (Yes/No)

- Is the mold relatively old? (e.g., more than 5 years or 8 million cycles) (Yes/No)

- Is this mold for a critical, high-volume, flagship product? (Yes/No)

- Have you had to repair this mold before for a similar issue? (Yes/No)

- Is there an opportunity to significantly lightweight the bottle with a new design? (Yes/No)

- Do you plan to switch to new materials like high-percentage rPET in the near future? (Yes/No)

- Is the estimated repair cost more than 30% of the cost of a new mold? (Yes/No)

- Is the downtime required for a proper repair almost as long as the lead time for a new mold? (Yes/No)

- Would a 5-10% reduction in cycle efficiency after repair significantly impact your profitability? (Yes/No)

- Do you have the capital budget available for a new mold investment? (Yes/No)

Scoring your answers:

- 0-3 "Yes" answers: A repair is very likely the most sensible and cost-effective option.

- 4-6 "Yes" answers: You are in the grey area. You need to look very closely at the financial analysis (ROI and payback) and the risk matrix. A major overhaul or refurbishment might be an option, or it might be time to invest.

- 7-10 "Yes" answers: The signs are strongly pointing toward replacement. Repairing the mold is likely to be a poor long-term investment. You should be actively seeking quotes for a new mold.

Visualizing Your Options with a Risk Assessment Matrix

Sometimes a picture is worth a thousand words. This simple matrix helps you plot your two main options—repair and replace—based on their associated cost and risk. Risk, in this context, means the risk of future failure, quality problems, and lost efficiency.

| Low Risk | High Risk | |

|---|---|---|

| High Cost | Quadrant 3: New Mold High upfront cost, but low risk of failure, quality issues, or inefficiency. A strategic, long-term investment. | Quadrant 4: Major Overhaul on Old Mold High cost for a complex repair, with a high risk that it won't perform as expected or will fail again. (DANGER ZONE) |

| Low Cost | Quadrant 1: Simple Repair Low cost, low risk. Ideal for cosmetic damage or minor wear. The clear choice when applicable. | Quadrant 2: Cheap Fix on Critical Damage Low initial cost, but high risk of imminent failure, poor quality, and extended downtime. A short-sighted gamble. |

How to use the matrix:

- Simple Repair: If your damage is minor (e.g., a scratch in the cavity), your repair option lands squarely in Quadrant 1. It's a low-cost, low-risk fix. This is an easy decision.

- Replacement: A new mold always lands in Quadrant 3. The cost is high, but the risk is very low. It's a safe, predictable choice.

- The Tough Choices: The difficulty lies with major damage.

- Trying to do a "quick and cheap" fix on a worn-out parting line puts you in Quadrant 2. You save money upfront, but you are taking a huge risk. This is often a poor decision.

- Paying for a complex, expensive repair (e.g., welding multiple cavities and resurfacing) on a very old mold puts you in Quadrant 4. You are spending a lot of money on an option that still carries a high risk of failure. This is the most dangerous quadrant and should generally be avoided.

If your repair scenario falls into Quadrant 2 or 4, you should strongly lean towards replacement (Quadrant 3).

The Bottom Line—When Replacement is a Must

After all the analysis, there are a few situations where the decision is made for you. In these cases, repair is not a viable or safe option, and you must replace the mold.

- Irreparable Cracks in the Mold Base: If there is a crack in the main body (the aluminum or steel block) of the mold, the structural integrity is compromised. Welding this is extremely risky, as it could fail catastrophically under the high clamping pressure of the machine. This is a safety hazard. The mold must be replaced.

- Critical Dimensions Cannot Be Restored: If the mold has been so severely damaged or warped (for example, by a major crash or overheating event) that a CMM inspection shows the core dimensions are beyond recovery, it's time for a new one. You can't produce good bottles from a bad mold.

- The Cost of Repair Exceeds 60-70% of a New Mold: If a comprehensive quote for a full refurbishment comes in at a price that is a significant majority of a new mold's cost, the repair simply doesn't make financial sense. For a little more money, you can get all the benefits of new technology, a full warranty, and zero risk.

I want to close with the story of my UK client with the 20-cavity rotary mold. The shipping cost to send the entire huge mold to China for repair was prohibitive. Their local shops couldn't handle the specialized work. They faced a dilemma. After seeing photos and discussing the issue, I realized the main mold bodies were fine; only the base inserts were worn.

This allowed for a creative, hybrid solution. It wasn't a simple repair, but it also wasn't a full, expensive replacement. We manufactured 20 brand new, identical base inserts in our factory. We then air-freighted these small, lightweight parts to the UK. Their local maintenance team could easily swap out the old bases for the new ones.

This was the perfect solution. They avoided massive shipping costs and weeks of downtime. They got a high-quality, brand-new critical component at a fraction of the cost of a new mold. This is the kind of problem-solving that comes from a deep partnership between a client and a mold manufacturer. Sometimes the best choice isn't just "repair" or "replace," but a smarter, targeted solution in between.

Conclusion

The choice between repairing and replacing a blow mold is a balance. It weighs immediate cost savings and uptime against long-term efficiency, quality, and strategic advantage. Use this analysis to make a confident, data-driven decision for your factory's future.

Frequently Asked Questions (FAQ)

1. What is the average lifespan of a new PET blow mold?

A well-maintained PET blow mold made from high-quality materials like aircraft-grade aluminum or S136 steel can typically last for 10 to 15 million cycles. The exact lifespan depends on factors like cycle time, clamping pressure, the complexity of the bottle design, and the quality of your maintenance program.

2. Can minor scratches on the mold cavity wall really affect the final bottle?

Yes, absolutely. Even a small scratch on the polished surface of the mold cavity will be transferred to every bottle produced, appearing as a fine line or a scuff mark. While this may not affect the bottle's structural integrity, it is a cosmetic defect that can be unacceptable for many products, especially in the food, beverage, and cosmetics industries where brand appearance is critical.

3. Is it possible to repair parting line wear, and how effective is it?

Yes, parting line wear is one of the most common repairs. The process typically involves TIG welding to add material back to the worn edge, followed by precise CNC machining and hand polishing to restore the original sharp profile. A high-quality repair can be very effective in the short to medium term, eliminating flash and improving bottle quality. However, the repaired area may be slightly softer than the original material and could wear more quickly, making it a good solution for 1-3 million additional cycles, but not a permanent one.

4. How much faster can a new mold with optimized cooling be?

A new mold with modern, conformal cooling channels can be significantly faster than an old mold with simple drilled-line cooling. Depending on the bottle size and weight, it's realistic to see a reduction in the required cooling time of 0.5 to 1.5 seconds. On a typical 7-second cycle, a 1-second reduction represents a 14% increase in production output, which is a massive gain in efficiency.

5. If I repair one cavity in a multi-cavity mold, do I need to do anything to the others?

This is a great question. While you only need to repair the damaged cavity, you must be aware that this cavity will now be slightly different from the others. It's crucial to implement a stricter quality control procedure to check the bottles from the repaired cavity for any variations in weight, wall thickness, or dimensions compared to the bottles from the original cavities. If consistency is absolutely critical, some companies choose to perform the same refurbishment on all cavities to maintain uniformity, though this increases the cost.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

📞 Contact: Vivian

🏭 Zhongshan Jindong Machinery Co., Ltd.

🌍 www.ibottler.com

📧 Vivian@ibottler.com | 💬 WhatsApp: +86-13106288777

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr