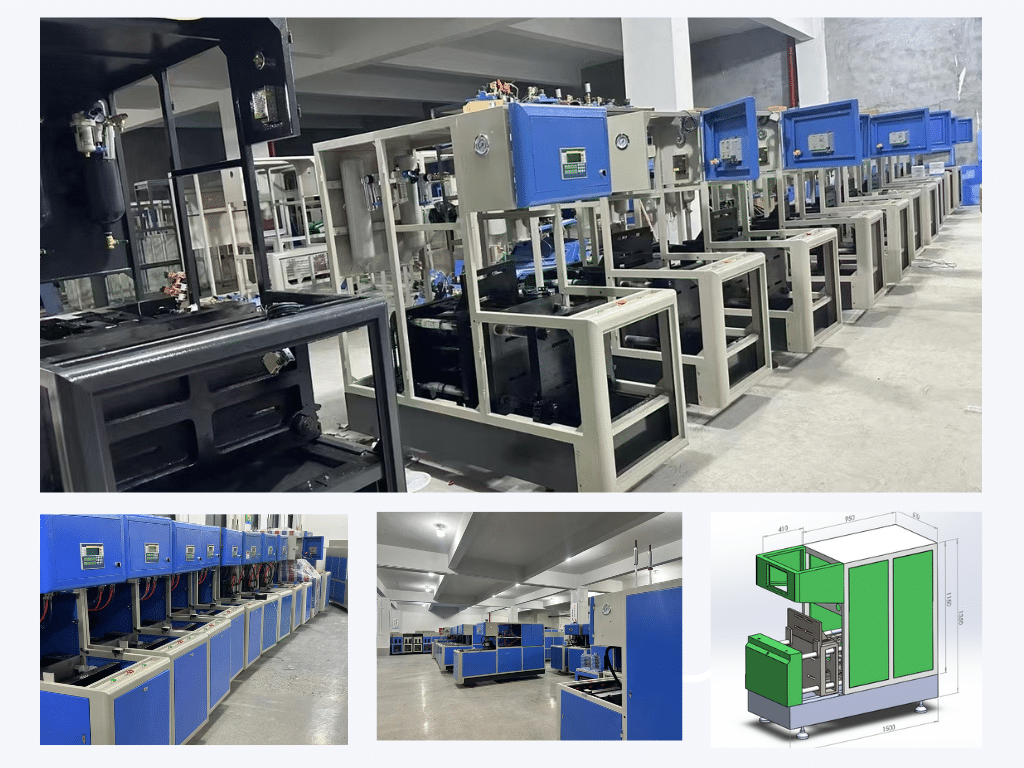

Precision Molding, Efficiency Guaranteed

Simple structure, easy operation, low cost, and high efficiency—perfect for small to medium-sized businesses!

Easy to Use, Low Cost Start

Semi-Auto Blow Molder

Simple Operation, Quick Mastery

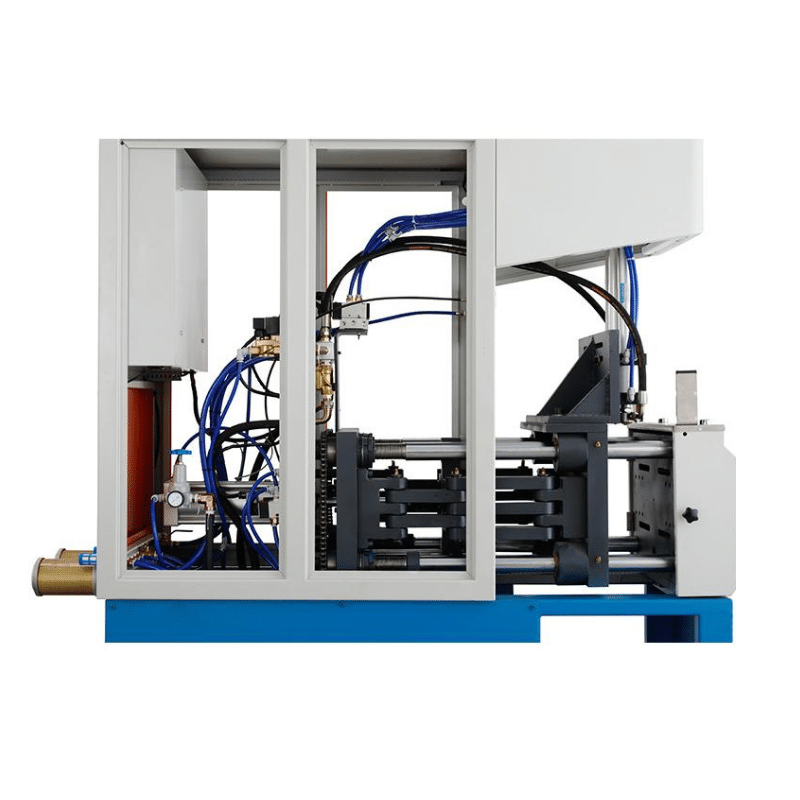

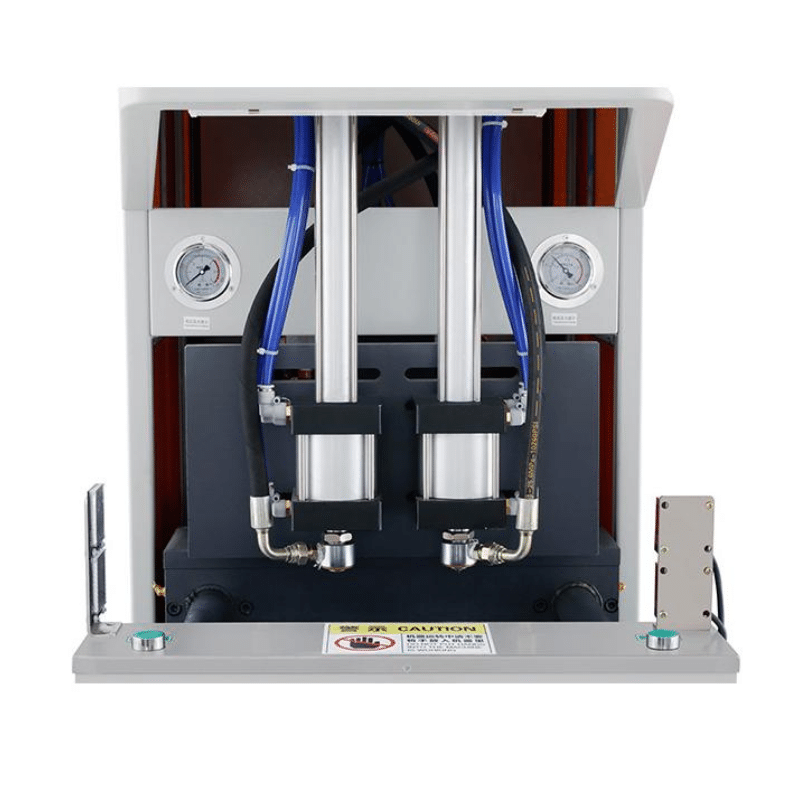

Better structure

Precise Stable Frame

Multi-Layer Safety

Intelligent Visual HMI

From Design to Delivery, Start Your Bottling Line with Ease

one-stop solution

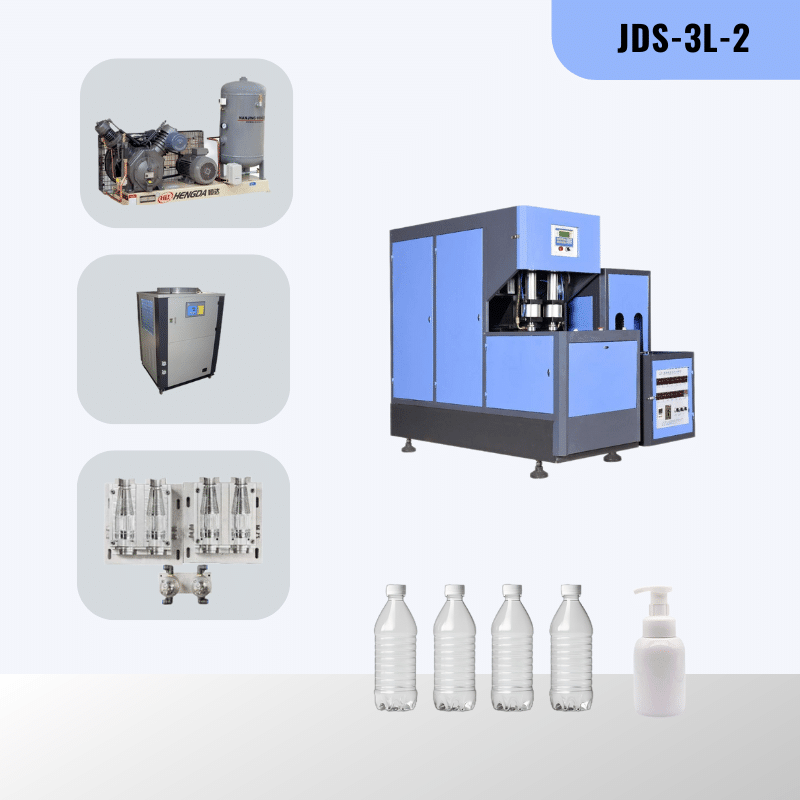

| NO. | Name | Parameters | Name | Parameters |

|---|---|---|---|---|

| 1 | Number of cavities | 2 cavities | Maximum capacity | 3L |

| 2 | Output | 1000PCS/H | Maximum bottle mouth diameter | 38MM |

| 3 | Power | 10kw | Total machine weight | 0.9T |

This 2-cavity semi-automatic bottle blowing machine has a wide range of applications. It can produce water bottles, beverage bottles, daily chemical bottles, etc. It has a favorable price and is the most popular semi-automatic bottle blowing machine.

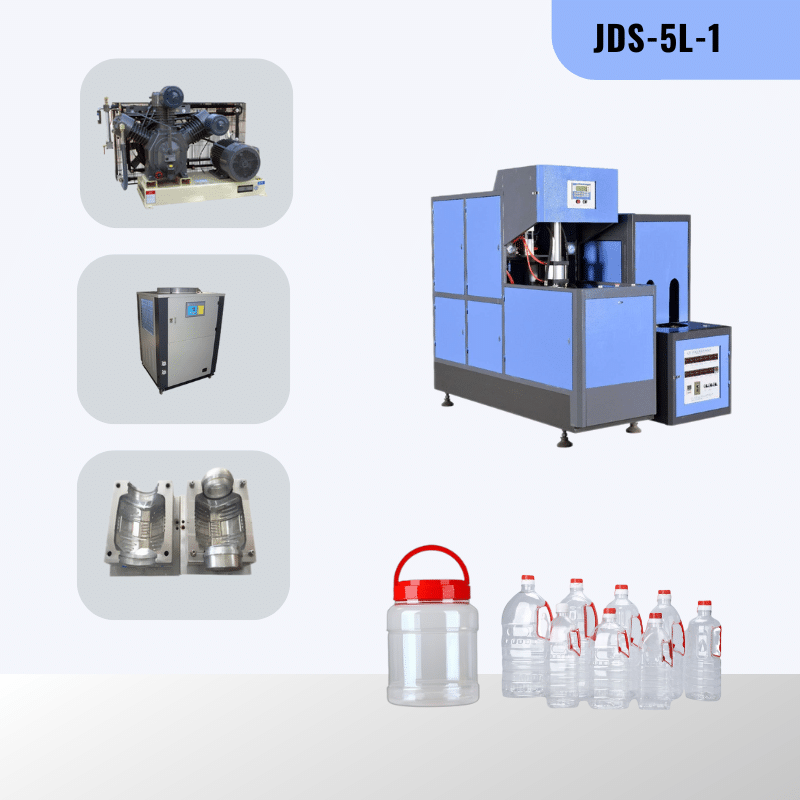

| No. | Name | Parameters | Name | Parameters |

|---|---|---|---|---|

| 1 | Number of cavities | 1 cavities | Maximum capacity | 5L |

| 2 | Output | 450PCS/H | Maximum bottle mouth diameter | 120MM |

| 3 | Power | 15kw | Total machine weight | 1.2T |

This 1-cavity semi-automatic bottle blowing machine can blow bottles below 5L, suitable for soy sauce bottles with handles, wide-mouth jars, etc. It is easy to operate and suitable for start-ups.

| No. | Name | Parameters | Name | Parameters |

|---|---|---|---|---|

| 1 | Number of cavities | 1 cavities | Maximum capacity | 10L |

| 2 | Output | 450PCS/H | Maximum bottle mouth diameter | 120MM |

| 3 | Power | 18kw | Total machine weight | 1.5T |

This bottle blowing machine is suitable for producing bottled water, oil bottles, wide-mouth jars, etc. below 10L. It is suitable for large-capacity bottles and is easy to operate, simple to install, and requires little maintenance.

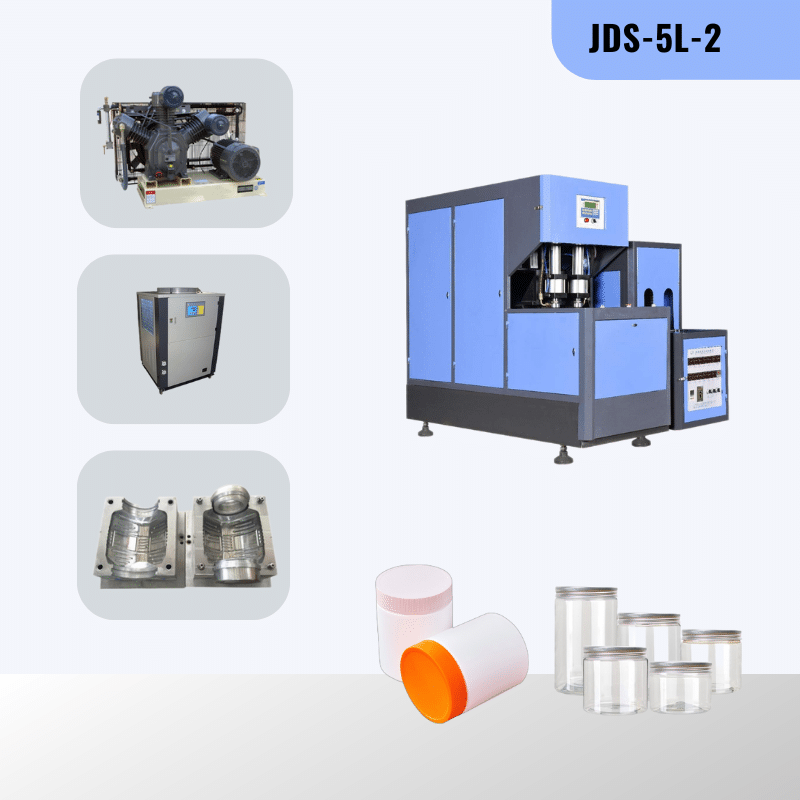

| No. | Name | Parameters | Name | Parameters |

|---|---|---|---|---|

| 1 | Number of cavities | 2 cavities | Maximum capacity | 5L |

| 2 | Output | 800PCS/H | Maximum bottle mouth diameter | 120MM |

| 3 | Power | 15kw | Total machine weight | 1.5T |

This bottle blowing machine has a higher output than the single-chamber 5L bottle blowing machine. It is suitable for factories that require slightly higher output but do not want to buy automatic machines. It is affordable and easy to operate.

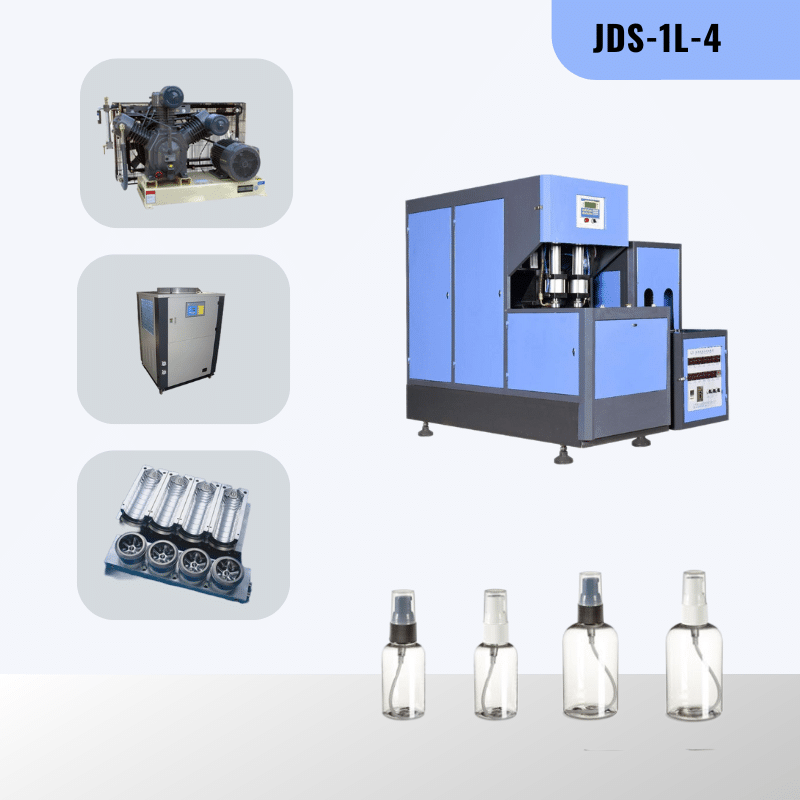

| No. | Name | Parameters | Name | Parameters |

|---|---|---|---|---|

| 1 | Number of cavities | 4 cavities | Maximum capacity | 1L |

| 2 | Output | 1800PCS/H | Maximum bottle mouth diameter | 30MM |

| 3 | Power | 15kw | Total machine weight | 1.5T |

Compared with other semi-automatic blow molding machines, this blow molding machine has the advantage of high output and is cheaper than automatic machines. It is suitable for start-up small-scale factories.

| No. | Name | Parameters | Name | Parameters |

|---|---|---|---|---|

| 1 | Number of cavities | 1 cavities | Maximum capacity | 20L |

| 2 | Output | 300PCS/H | Maximum bottle mouth diameter | 120MM |

| 3 | Power | 18kw | Total machine weight | 1.8T |

This 20L bottle blowing machine is suitable for producing five-gallon bottled water and disposable bottled water. Compared with the large investment of automatic machines, this one has the advantages of short installation time, easy operation and high output.

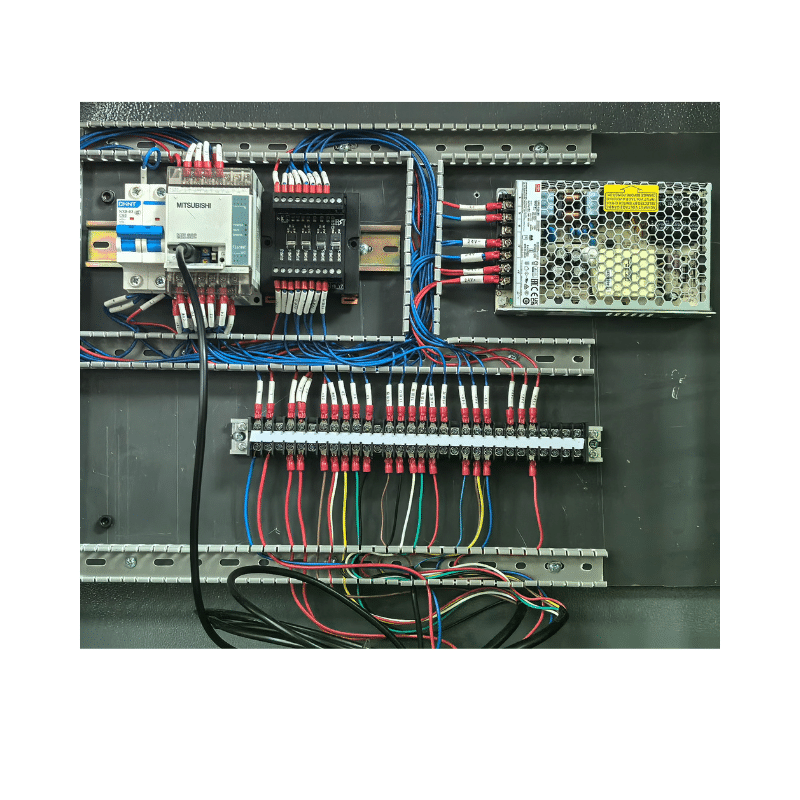

| NO. | Name | Brand | Name | Brand |

|---|---|---|---|---|

| 1 | Programmable Controller PLC | Mitsubishi | Stretch Cylinder | Yongcheng |

| 2 | High pressure air blowing combination valve | Parker | Power supply | Mean Well |

| 3 | Action valve | AirTac | AC contactor | Schneider |

There are many more semi-automatic blow molding machines that are not listed here. We provide a full range of customization. Any PET bottle has a suitable semi-automatic blow molding machine.

Why did we choose this bottle blowing machine?

Their real feedback