Struggling to find a reliable bottle blowing machine manufacturer in China? You fear hidden costs, quality issues, and poor service. This uncertainty can stall your project and risk your investment.

Finding a trustworthy partner is crucial. A great supplier provides a high-quality PET blow molding machine at a fair price, backed by solid engineering and transparent after-sales service. This ensures your production line runs smoothly and profitably for years to come.

.png)

Choosing a supplier for your PET blow molding machine is a major decision. The right partner can accelerate your growth, while the wrong one can lead to endless production headaches. My 20 years in this industry have taught me that asking the right questions upfront is the single most important step you can take. It cuts through the marketing noise and reveals the true capability and integrity of a potential supplier. I want to walk you through the essential questions that will empower you to make an informed choice and find a partner who will truly support your business's success. Let's get started.

Question 1: Are you a direct factory or a trading company?

Worried about paying extra for a middleman? You suspect some suppliers are just trading companies, adding no value but increasing your cost and communication delays. This lack of direct contact creates risk.

Dealing directly with a factory gives you better control over quality, technical details, and delivery times. A true manufacturer has deep engineering knowledge and is accountable for the final product, ensuring you get exactly what you need without communication gaps.

The Fundamental Difference: Control and Expertise

When you start your search for a PET blow molding machine, this is the very first question you must clarify. The answer fundamentally changes the nature of your business relationship, your costs, and the level of support you can expect. A trading company and a direct factory operate on entirely different models, and understanding this is key to protecting your investment.

A trading company is essentially a reseller. They source machines from various factories and sell them to international buyers. While they might offer a wide range of products and sometimes more flexible pricing, they often lack deep technical knowledge. Their primary skill is sales and logistics, not engineering. When a problem arises, they become a go-between, relaying messages back and forth between you and the actual factory. This process can be slow, inefficient, and frustrating, especially when you need a quick technical solution to get your production back online.

In contrast, a direct factory like us, iBottler, is the manufacturer. We design, engineer, assemble, and test the machines in our own facility. This gives us complete control over every aspect of the process.

Why Direct Factory Partnership Matters

Working with a direct factory provides tangible benefits that a trading company simply cannot match. Let's break down the key advantages in a more structured way.

| Feature | Direct Factory (e.g., iBottler) | Trading Company |

|---|---|---|

| Technical Expertise | In-house engineers who designed the machine are available for direct consultation. Deep knowledge of every component. | Limited technical knowledge. Relies on the factory for answers, causing delays. |

| Quality Control | Complete control over the entire production process, from raw material sourcing to final assembly and testing. | No direct control over manufacturing. Can only inspect the finished product, if at all. |

| Customization | High flexibility to modify machine specifications or design a custom bottle mold to meet your exact needs. | Very limited customization options. Dependent on what the source factory is willing to do. |

| Cost Structure | Transparent pricing. You are paying for the machine and the manufacturer's expertise directly. | Price includes a hidden margin for the trading company, increasing your overall cost. |

| After-Sales Support | Direct access to the engineers who built your machine for fast and effective troubleshooting. | Support requests are filtered through the trading company, leading to slower response times and potential miscommunication. |

| Long-Term Relationship | Invested in your success as a long-term partner. Your feedback can influence future product development. | Transaction-focused. May not have the same level of commitment to your long-term operational success. |

At iBottler, we are proud of our history and our facility. We established our business 20 years ago, making us one of the earliest PET packaging machinery factories in East China. Our 8000m² factory is not rented; it is company-owned. This is a crucial detail. Owning our factory signifies stability, a long-term commitment to the industry, and a deep investment in our infrastructure and capabilities. When you partner with us, you are not just buying a machine. You are gaining direct access to two decades of accumulated knowledge in blow molding technology, from initial bottle design to final production tuning. This is a level of service and assurance that a trading company can never offer.

Question 2: What is your core expertise: the machine, the mold, or both?

You find a supplier with a great machine, but their molds are an afterthought. Or they make fantastic molds but don't understand the machine. This mismatch can lead to endless finger-pointing when production issues arise.

A perfect bottle requires seamless integration between the blow molding machine and the mold. A supplier with expertise in both can provide a truly holistic solution, ensuring every component works in perfect harmony and taking full responsibility for the final result.

The Synergy of Machine and Mold

In the world of bottle blowing, the machine and the mold are like a lock and key. One is useless without the other, and they must be perfectly matched to function correctly. A common but costly mistake I see buyers make is sourcing their machine from one supplier and their molds from another. On the surface, this might seem like a way to get the best price on each component. However, it often creates a scenario I call the "blame game."

When a problem occurs—perhaps the bottle wall thickness is inconsistent, or there's an issue with transparency—the machine supplier will blame the mold quality. The mold supplier, in turn, will claim the machine parameters are incorrect. You, the customer, are caught in the middle with a production line that isn't working, while your suppliers argue over whose fault it is. This can lead to significant downtime and financial loss.

That's why it is critical to find a supplier whose core expertise covers both the machine and the mold. A true one-stop solution provider takes complete ownership of the entire blowing process. They understand the intricate relationship between machine movements, heating parameters, preform design, and mold engineering.

iBottler's Integrated Approach: A Case Study

Let me share a recent example that illustrates this point perfectly. Just last week, we finalized a project for a client in Thailand who was launching a new line of fruit juices. They came to us with a beautiful, but complex, bottle design. It had sharp angles and an embossed logo that would be challenging to mold perfectly.

If we were only a machine manufacturer, we would have simply sold them a machine rated for their bottle size and wished them luck. If we were only a mold maker, we would have built the mold to their specifications without considering the machine's capabilities. Instead, we took an integrated approach.

Design Optimization: Our first step was to analyze their bottle design. Using our expertise, we identified a few areas that could cause issues during the blowing process. We collaborated with their team and made minor, almost unnoticeable, adjustments to the design. This was a critical step covered in our PET Bottle Mold Design Guide. The goal was to ensure a more uniform material distribution without compromising the bottle's aesthetic appeal.

Mold Manufacturing: We then manufactured the blow bottle mold, selecting the appropriate steel and designing the cooling channels specifically for their bottle shape and target cycle time. We understood that effective cooling is crucial for clarity and stability, a topic we dive deep into when discussing the necessity of a chiller for PET blow molds.

Machine Configuration: Simultaneously, we configured one of our bottle blowing machines with the precise settings needed for their project. We pre-programmed the heating parameters, stretching speeds, and blowing pressures based on the specific preform they were using and the final bottle they wanted to achieve.

In-House Testing: Before shipping anything, we installed the new mold in the configured machine right here in our factory. We ran tests, produced sample bottles, and fine-tuned the parameters until the bottles were perfect. We sent a video of the machine in production and the sample bottles to the client for their approval.

By the time the machine and mold arrived at their factory in Thailand, it was a true plug-and-play solution. They were not just receiving a machine and a mold; they were receiving a complete, pre-tested, and optimized production system. This comprehensive, one-stop solution eliminated the risk of incompatibility and ensured they could start producing perfect bottles from day one. This is the iBottler difference.

Question 3: How do you guarantee the quality of your core components?

You're tempted by a low price, but you worry about what's inside. Cheaper machines often use inferior components that fail quickly, leading to costly downtime and repairs. This hidden compromise can turn a bargain into a disaster.

The stability and longevity of a blow molding machine are 90% determined by its core components. Reputable manufacturers use world-class brands for critical systems, ensuring reliability and performance. This transparency is the hallmark of a quality-focused supplier.

The Anatomy of a Reliable Machine

There's an old saying that "a chain is only as strong as its weakest link." This is especially true for complex industrial machinery like a PET blow molding machine. The overall performance, stability, and lifespan of the machine depend directly on the quality of its individual parts. While a low initial price might be attractive, it almost always comes at the cost of component quality. A supplier who cuts corners on these critical parts is not saving you money; they are selling you future problems.

At iBottler, we operate on a principle of radical transparency. We believe that an informed customer is our best customer. We are proud of the components we use and are always happy to show our "supplier list" to clients. We believe that by partnering with world-class component brands, we build world-class machines. This is not just a responsibility to our own brand, but a guarantee for your investment.

Let's break down the key systems of a blow molding machine and the specific, high-quality components we insist on using.

Core Component Breakdown: Our Commitment to Quality

| System | Component | Our Standard Brand | Why It Matters (The Risk of "No-Name" Alternatives) |

|---|---|---|---|

| Driving System | Servo Motor | Yaskawa (Japan) | Precision & Stability: Yaskawa servos ensure perfect positioning and smooth high-speed operation. A cheaper motor can lead to inconsistent bottle quality, higher defect rates, and premature mechanical wear due to jerky movements. |

| Control System | PLC (Programmable Logic Controller) | Omron (Japan) | Reliability & Usability: The PLC is the machine's brain. Omron PLCs have an extremely low failure rate and a user-friendly interface. An inferior PLC can cause random shutdowns, programming errors, and difficulties in troubleshooting, leading to major downtime. |

| Pneumatic System | High-Pressure Solenoid Valve | Parker (USA) | Speed & Durability: The high-pressure blowing stage is the heart of the process. Parker valves offer lightning-fast, precise response for every blow, preventing air leaks. A low-quality valve can be slow, leak high-pressure air (wasting energy), and fail quickly, halting all production. |

| Mold Material | Mold Steel | S136 (Sweden) | Longevity & Finish: For high-demand applications like cosmetics or chemicals, we use imported S136 stainless steel. It's corrosion-resistant and can be polished to a mirror finish for perfect bottle clarity. Using cheaper P20 or 45# steel will lead to rust, scratches, and a much shorter mold life. |

| Mold Material | Mold Alloy | 7075 Aviation Aluminum | Efficiency & Speed: For high-cavity water bottle molds, 7075 aluminum provides excellent strength and superior heat dissipation. This allows for faster cycle times. Using standard aluminum can result in a mold that deforms under pressure and cools too slowly, limiting your production speed. |

Our philosophy on components extends beyond just the main parts. Every sensor, every bearing, every electrical relay is carefully selected from reputable brands. We understand that a single faulty $10 sensor can stop a $100,000 production line. This is a risk we are unwilling to take, and you shouldn't have to either. When you evaluate a supplier's PET Blow Molding Machine Price, always ask for a detailed component list. A supplier who is hesitant to provide one is a supplier with something to hide.

Question 4: Can you show me case studies of machines running in a factory similar to mine?

You see polished brochures and impressive specifications, but you're skeptical. How do you know if the machine will perform in the real world, under the pressures of daily production? You need proof, not just promises.

The most reliable evidence of a supplier's capability is a video of their machine running efficiently in a real customer's factory. Seeing is believing, and this proof provides confidence that the machine can deliver on its promises.

Beyond the Brochure: The Power of Real-World Proof

A glossy brochure can make any machine look good. A list of technical specifications can be impressive, but it doesn't tell the whole story. These numbers are theoretical; they represent the machine's potential under ideal laboratory conditions. But you won't be running the machine in a lab. You'll be running it on your factory floor, day in and day out, where it needs to be a reliable workhorse that consistently produces high-quality bottles and generates profit for your company.

This is why asking for real-world case studies is a non-negotiable step in your due diligence. I always tell potential clients, "Don't just listen to what I say. Look at what our machines do." The most powerful testament to our quality is not the parameters on a spec sheet, but the sight of an iBottler machine humming along efficiently in a client's facility, sometimes years after installation. It’s the ultimate proof of performance, reliability, and customer satisfaction.

A reputable and experienced manufacturer will have a library of these cases and will be eager to share them with you. This transparency shows they have nothing to hide and are confident in their products' performance.

What to Look For in a Case Study

When a supplier provides a case study, usually in the form of a video, you should analyze it carefully. It's not just about seeing the machine move; it's about evaluating its performance in a context that is relevant to you.

Here's a checklist of what to observe:

- Product Relevance: Is the machine in the video producing bottles similar to yours? For example, if you produce 5-liter edible oil bottles, a video showing a machine making small water bottles is not very helpful. The production challenges are completely different. We make it a point to provide videos that are highly relevant to a potential client's industry, whether it's beverages, food, cosmetics, or chemicals.

- Operational Stability: Watch the machine's movements. Do they look smooth and controlled, or are they jerky and violent? A well-engineered machine operates with a steady, reliable rhythm. Pay attention to the preform loading, transfer, and bottle ejection systems. These should all function flawlessly without interruption.

- Cycle Time and Output: Can you gauge the production speed? While you might not be able to time it with a stopwatch, you can get a general sense of the machine's output. Does it seem to be running at the speed you require for your production targets?

- Bottle Quality: Look closely at the finished bottles coming out of the machine. Do they look clear and well-formed? While a video can't show everything, you can often spot obvious defects. If you see a high rate of rejected bottles, it's a major red flag. One of the most common challenges is a range of common PET blow molding defects, and a good machine minimizes these from the start.

- Factory Environment: What does the surrounding environment look like? A clean, well-organized factory is often a sign of a professional operation that values its equipment.

We understand the importance of this verification step. We can provide you with numerous videos of our machines in action at customer sites around the world, categorized by the type of product they are making. This allows you to see firsthand how an iBottler machine could perform in a factory just like yours, providing you with the confidence you need to move forward.

Question 5: What is your process for custom mold design and testing?

You have a unique bottle design, but you're not sure if it can be manufactured effectively. You worry that a supplier will just take your drawing and make a mold without considering the technical challenges, leading to a poor-quality final product.

A professional supplier doesn't just manufacture; they collaborate. They have a structured process for analyzing, optimizing, and testing your design to ensure the final mold produces a perfect bottle efficiently and reliably. This process is the soul of custom blow molding.

From Concept to Creation: The Soul of Bottle Making

The mold is, without a doubt, the soul of the final bottle. A great machine can never compensate for a poorly designed or poorly manufactured mold. This is where a supplier's true expertise is revealed. Many suppliers can "manufacture" a mold from a 3D file, but only a true partner can "design" a comprehensive molding solution. The difference is immense. "Manufacturing" is simply cutting metal. "Designing" is a holistic process that involves deep communication, engineering analysis, and a commitment to creating the best possible outcome for the client.

At iBottler, we pride ourselves on our design-centric approach to custom molds. We see ourselves as your technical consultants, not just your vendor. Our goal is to ensure that the mold we create is not just a piece of steel, but the optimal solution tailored specifically to your bottle's application, your weight requirements, and your production targets. This collaborative process minimizes risks and maximizes your chances of a successful product launch.

The iBottler Custom Mold Development Process

To give you a clear idea of what a professional process looks like, here is a step-by-step breakdown of how we handle every custom mold project:

Deep Dive Consultation:

- Application: We start by asking: What will this bottle hold? Is it for carbonated drinks, hot-fill juices, or aggressive chemicals? The application determines the required strength, barriers, and even the best choice of preform neck size.

- Gram Weight: What is your target weight? We work with you to find the perfect balance between minimizing plastic usage (to save costs) and maintaining the structural integrity required for stacking and transport.

- Production Goals: What is your target output per hour? This influences the number of cavities in the mold and the design of the cooling system, which is critical for achieving fast cycle times.

3D Design & Flow Analysis:

- Our engineers take your initial concept and translate it into a production-ready 3D model.

- We use advanced simulation software to perform a "flow analysis." This digitally simulates how the plastic will stretch and flow inside the mold cavity during the blowing process. It helps us predict and correct potential thin spots or other defects before any metal is ever cut.

Rapid Prototyping with 3D Printing:

- For complex designs, we offer a crucial validation step: 3D printed samples. We can create a physical sample of your bottle in just a few days. This allows you to hold your bottle, test the ergonomics, check the label area, and approve the final design before committing to the expensive and time-consuming process of steel mold manufacturing.

Precision Manufacturing & Testing:

- Once the design is approved, we manufacture the mold using high-precision CNC machines and the appropriate steel (e.g., S136 for durability, 7075 aluminum for speed).

- Crucially, we test the finished mold in one of our own blowing machines here at the iBottler factory. We produce actual bottle samples and fine-tune the machine parameters until we achieve a perfect result.

This structured, collaborative process ensures there are no surprises. You are involved and informed at every stage, and you get to approve the final product before it ever leaves our facility. This is how we transform a simple drawing into a high-performance production tool.

Question 6: What does your after-sales service and warranty policy truly cover?

You're concerned about what happens after you've paid. Many suppliers promise "great service," but their warranty is full of loopholes. When a problem occurs, you're left with a broken machine and no real support.

True after-sales service is not just about sending free spare parts. It's about providing rapid, expert diagnosis and practical solutions to get your production running again. Experienced suppliers can solve most issues remotely, saving you critical time and money.

The True Value of Service: Beyond Free Parts

When you are investing in a significant piece of capital equipment like a blow molding machine, the conversation about service and warranty is one of the most important you will have. A common sales tactic is to offer a long warranty period, perhaps two or even three years. While this sounds reassuring, you must dig deeper and ask what this "warranty" actually includes.

In many cases, the warranty only covers the free replacement of a part that has been proven to be defective. This sounds fair, but it omits the most challenging parts of any breakdown:

- Diagnosis: How do you figure out which part is broken?

- Urgency: How long will it take for the new part to arrive from China?

- Installation: Who will install the new part and re-calibrate the machine?

The real cost of a breakdown is not the price of a broken component; it's the cost of lost production. Every hour your machine is down, you are losing money. Therefore, a superior after-sales service policy must prioritize rapid diagnosis and recovery, not just the shipment of free parts.

The iBottler Service Commitment: Experience-Driven Support

With 20 years of experience manufacturing and servicing these machines, we've encountered nearly every possible issue that can arise. This vast knowledge base is the foundation of our service value. We know that the key to minimizing downtime is speed and accuracy in troubleshooting.

Here’s how our service model differs from the industry standard:

| Feature | Standard "Warranty" (Many Suppliers) | iBottler's Comprehensive Support |

|---|---|---|

| Focus | Replacement of broken parts. | Rapid diagnosis and production recovery. |

| Initial Response | You send an email or photo and wait for a reply, which may take days. | 24/7 technical assistance. We schedule a video call immediately to see the problem live. |

| Troubleshooting | They may guess the problem based on your description and ship a part. If the guess is wrong, you wait again. | Our experienced engineers can diagnose approximately 80% of all issues during a single video call by listening to the machine and guiding your operator through specific checks. |

| Solution Speed | Weeks. Waiting for the part to be shipped, clear customs, and then finding someone to install it. | Hours or days. If it's a setting issue, we solve it on the call. If a part is needed, we ship it via express air and provide video guidance for your team to install it. |

| Engineer Visit | Offered as a last resort, often with high travel and labor costs billed to you, even under warranty. | We only dispatch an engineer if absolutely necessary, after remote support has been exhausted. This saves you significant expense. We also provide on-site installation and training services from the start. |

Let me give you a practical example. A client in Mexico called us because their machine had stopped. A standard supplier might have asked for photos, guessed it was a faulty sensor, and shipped a new one. The client would have lost two weeks of production waiting for it.

Instead, we got on a video call. Our engineer had the operator point the camera at the PLC control screen and then at the sensor panel. Within 10 minutes, our engineer identified that a sensor had simply been knocked out of alignment by a stray preform. He guided the operator to loosen a screw, reposition the sensor, and tighten it. The machine was back online in 15 minutes. No parts were needed. No two-week wait.

This is the true value of experienced after-sales service. It’s not about the free part; it's about the invaluable expertise that gets you back to making money as quickly as possible. This is a core part of our commitment as a reliable China blow molding factory.

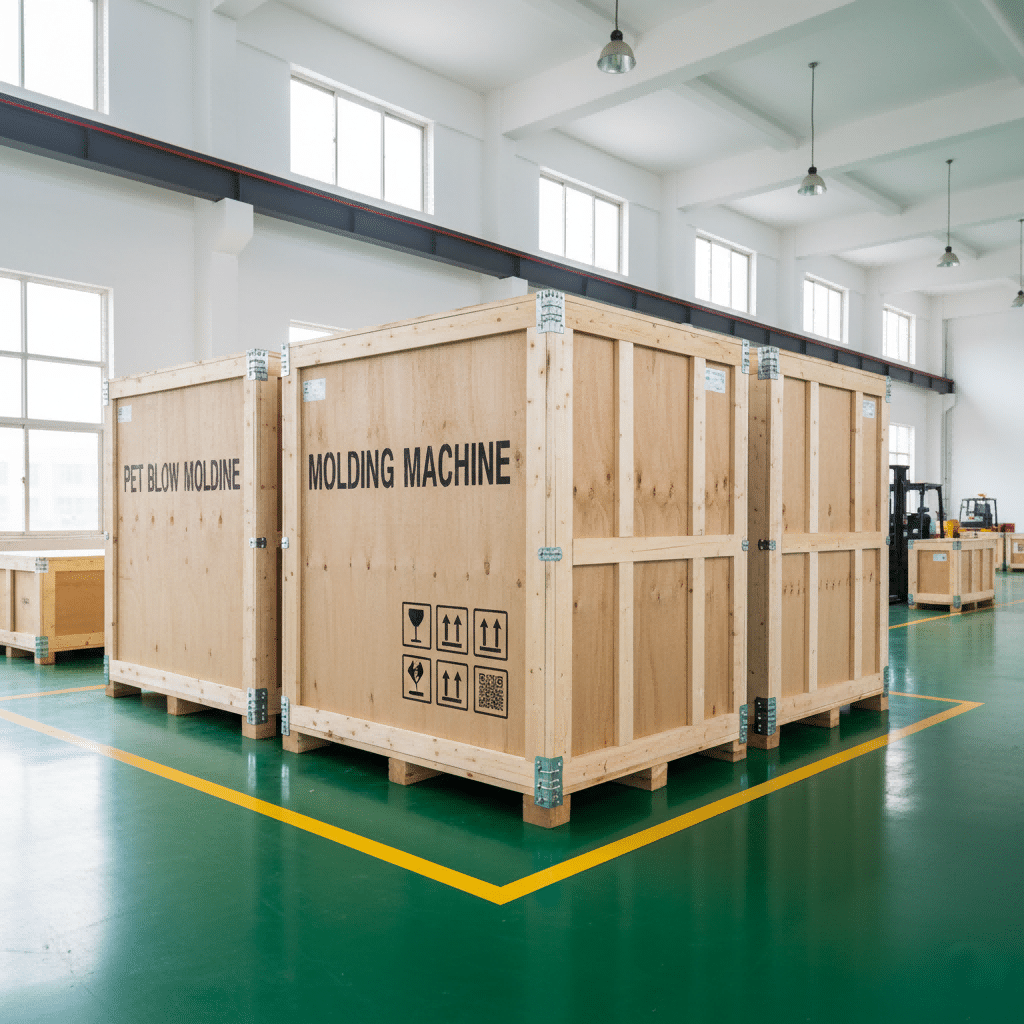

Question 7: How do you handle packaging and international shipping to ensure the machine arrives safely?

You've invested in a high-quality machine. Now you have to worry about it being damaged during a long sea journey. Improper packaging can lead to rust, broken components, and a nightmare scenario upon arrival.

A professional exporter understands the rigors of international shipping. They use robust, standardized packaging methods—like vacuum sealing and custom wooden crates—and manage the logistics to ensure your investment arrives in perfect, factory-fresh condition. This attention to detail is a mark of professionalism.

The Final, Critical Step: Protecting Your Investment

After weeks or months of discussions, design approvals, and manufacturing, the final step is getting the machine from our factory floor to yours. This journey can span thousands of miles and involve cranes, trucks, and container ships. It's a process fraught with risks—from moisture and salt in the sea air to rough handling at ports. A supplier's responsibility does not end when the machine is built; it ends when the machine is safely installed and running in your facility.

As a manufacturer with 20 years of export experience, we have refined our packaging and shipping process to a science. We understand that cutting corners here can undo all the hard work that came before. We've seen firsthand what can happen when packaging is inadequate: critical electronic components corroded by moisture, precision parts knocked out of alignment, and cosmetic damage that ruins the appearance of a brand-new machine. Our comprehensive approach is designed to prevent these issues and ensure a smooth, worry-free delivery.

Our Professional Export Packaging Protocol

To demonstrate what proper export packaging involves, here is the standard procedure we follow for every machine that leaves our factory:

Thorough Cleaning and Rust Prevention:

- The entire machine is meticulously cleaned to remove any dust, oil, or debris from the manufacturing process.

- All exposed metal surfaces, especially on the molds and clamping unit, are coated with a special anti-rust agent. This provides the first layer of defense against moisture.

Vacuum Sealing (The "Moisture Barrier"):

- The entire machine is then wrapped in a heavy-duty, plastic-lined aluminum foil bag.

- We use an industrial pump to suck all the air out of the bag, creating a vacuum seal. This is the single most effective way to protect the machine from humidity and salt corrosion during its time at sea. Desiccant packs are also placed inside to absorb any residual moisture.

Custom-Built, Reinforced Wooden Crating:

- We don't use standard-size crates. We build a custom, fumigated wooden crate for each machine.

- The machine is securely bolted to the crate's thick wooden base.

- Internal wooden braces are strategically placed to prevent any movement or shifting within the crate, even during rough seas or handling. The crate is designed to absorb external impacts.

Clear Marking and Documentation:

- Every crate is clearly marked with international shipping symbols (e.g., "This Side Up," "Fragile," "Keep Dry").

- We also label the crates with detailed information, including the contract number, crate dimensions, and gross/net weight. This makes the customs clearance and unloading process much smoother for you and your logistics team.

Comprehensive Insurance and Logistics Management:

- We provide full transit insurance for every shipment. In the unlikely event that something does happen, your investment is fully protected.

- Our logistics team handles all the documentation and coordinates with reliable shipping lines to ensure a predictable and transparent shipping schedule.

This meticulous attention to the final details is not an extra cost; it's an essential part of our service. It reflects our professionalism and our deep respect for the investment you have made with us.

Bonus: Why iBottler is Your Trusted Partner in China?

You've learned the right questions to ask, but you still need a partner you can trust. The goal is not just to buy a machine, but to build a relationship with a supplier who is transparent, capable, and committed to your long-term success.

Asking the right questions is the first step to a successful purchase. At iBottler, we don't just provide satisfactory answers; we embody the principles behind them. We are committed to being your long-term, reliable manufacturing partner in China.

Your Partner for Growth

Throughout this article, we've focused on the critical questions you need to ask any potential supplier. These questions are designed to cut through superficial sales pitches and get to the heart of what truly matters: engineering capability, quality commitment, and long-term support. Finding the right supplier is the foundation of a successful production operation.

At iBottler, our entire business model is built to be the right answer to every one of those questions.

- We are a direct factory with 20 years of history and an 8000m² owned facility, offering you direct communication and unmatched expertise.

- Our core strength is providing a one-stop solution, seamlessly integrating high-performance machines with precision-engineered custom bottle molds to eliminate compatibility issues.

- We guarantee quality by using world-class core components from brands like Yaskawa, Omron, and Parker, and we are completely transparent about our supply chain.

- We have a deep portfolio of real-world case studies and can show you our machines running in factories just like yours.

- Our custom mold design process is a collaborative partnership focused on optimizing your design for performance and efficiency.

- Our after-sales service is built on decades of experience, allowing us to provide rapid remote diagnosis that saves you invaluable production time.

- Our professional export packaging ensures your investment is protected and arrives in perfect condition, ready for work.

Choosing a partner in China can feel like a daunting task, but it doesn't have to be. We believe in transparency and building trust from the very first conversation. We welcome you to schedule a video factory tour to meet our team, see our manufacturing process, and speak directly with the engineers who would build your machine.

Asking the right questions is the key to successful sourcing. We're confident that once you have the answers, your choice will be clear.

Conclusion

Choosing the right blow molding machine supplier is about asking detailed questions. Focus on their factory status, core expertise, component quality, and after-sales support to ensure a successful, long-term investment.

Summary of Key Questions for Your Supplier

| Question Topic | Key Aspect to Verify | Why It's Critical | The iBottler Advantage |

|---|---|---|---|

| 1. Factory vs. Trader | Are they the direct manufacturer? Ask for a live video tour of their factory. | Direct control over quality, cost, and technical support. Avoids middleman delays. | 20-year-old, 8000m² owned factory. |

| 2. Core Expertise | Do they specialize in machines, molds, or both? | A one-stop solution provider prevents "blame games" between different suppliers. | Integrated expertise in both machines and molds for a seamless system. |

| 3. Component Quality | What brands are used for the PLC, servo motors, and valves? | High-quality components (Yaskawa, Omron, Parker) ensure machine stability and longevity. | We are transparent with our world-class supplier list. |

| 4. Case Studies | Can they show you videos of machines running in a similar application? | Real-world proof is more valuable than brochure specifications. | Extensive library of client videos categorized by industry. |

| 5. Mold Process | What is their design, validation, and testing process for custom molds? | A professional process ensures the mold is optimized for performance before manufacturing. | Collaborative design, flow analysis, and 3D printed samples for validation. |

| 6. After-Sales Service | What does the warranty truly cover? What is the remote diagnosis process? | Rapid troubleshooting is more valuable than just free parts. Minimizes costly downtime. | 80% of issues diagnosed via video call by experienced engineers. |

| 7. Packaging & Shipping | How do they protect the machine for international sea freight? | Professional packaging prevents damage and corrosion, ensuring the machine arrives safely. | Multi-layer process including rust-proofing, vacuum sealing, and custom crating. |

Frequently Asked Questions (FAQ)

Q: Is it cheaper to buy a bottle blowing machine from China?

A: Generally, yes, due to lower labor and supply chain costs. However, the "true cost" includes machine stability, service life, and supplier support. A reliable Chinese manufacturer like iBottler offers a high cost-performance ratio, balancing the PET blow molding machine price with long-term quality and reliability.

Q: How long does it take to manufacture and ship a machine?

A: Manufacturing typically takes 30-60 days, depending on the machine's complexity and level of customization. International sea shipping can take another 20-40 days depending on your location. A professional supplier will provide a clear and realistic timeline from the start and keep you updated throughout the entire process.

Q: Can I use my own bottle design with your machine?

A: Absolutely. We specialize in creating custom solutions. Our core strength is working with you to develop a high-performance custom bottle mold based on your unique design. Our engineering team will collaborate with you to optimize your design for the best blowing performance, material efficiency, and structural integrity.

Q: What kind of technical support do you offer for installation and training?

A: We offer comprehensive support to ensure you are successful. This includes detailed operation manuals, video tutorials for maintenance, and 24/7 remote technical assistance via video call. We can also dispatch an experienced engineer to your factory for on-site installation, commissioning, and training for your operational staff.

Q: What are the payment terms for purchasing from a Chinese factory?

A: The standard international payment terms are typically a 30-40% deposit via T/T (Telegraphic Transfer) to confirm the order and begin production. The remaining balance is paid before shipment, after you have inspected and approved the finished machine. We provide detailed photos and videos of the machine running for your final approval.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr