Are you tired of blow molding machine breakdowns and inconsistent bottle quality? This common headache often stems from a hidden factor: the manufacturing base.

Guangdong leads China's PET blow molding machine industry because of its unwavering commitment to "in-house core component manufacturing," which guarantees high precision and long-term stability, contrasting sharply with the "outsourced assembly" model prevalent in other regions like Taizhou.

When I first started in this industry, I quickly realized that not all machines—even those with similar price tags—were created equal. The difference between a high-performing industrial asset and a continuous repair project often comes down to where and how it was built. Stick with me, and I will break down the essential differences that make Guangdong PET blow molding machine manufacturers the top choice for serious packaging companies.

The Core Difference: In-House Precision vs. Distributed Assembly?

Do you know why some new machines start breaking down right after installation? The root cause is usually a fundamental difference in how they are built.

The core difference between Guangdong and Taizhou PET machine bases lies in manufacturing philosophy: Guangdong factories, represented by giants like Tech-Long and Ribo, insist on self-manufacturing critical parts for maximum precision, while the Taizhou model excels at cost efficiency through a vast, external supply chain for rapid assembly.

I often compare the two main manufacturing models to buying a custom-built computer versus buying a mass-produced, off-the-shelf brand. The Taizhou model—which I often refer to as the "assembly speed" model—thrives on an incredibly mature ecosystem of specialized suppliers. They have distinct, dedicated factories for machine frames, sheet metal enclosures, and preform feeding systems. This distributed assembly approach makes them super-fast and cost-effective. A Taizhou main plant acts like a system integrator, purchasing these standard components and bolting them together. This is great for new market entrants or projects where the budget is the absolute priority.

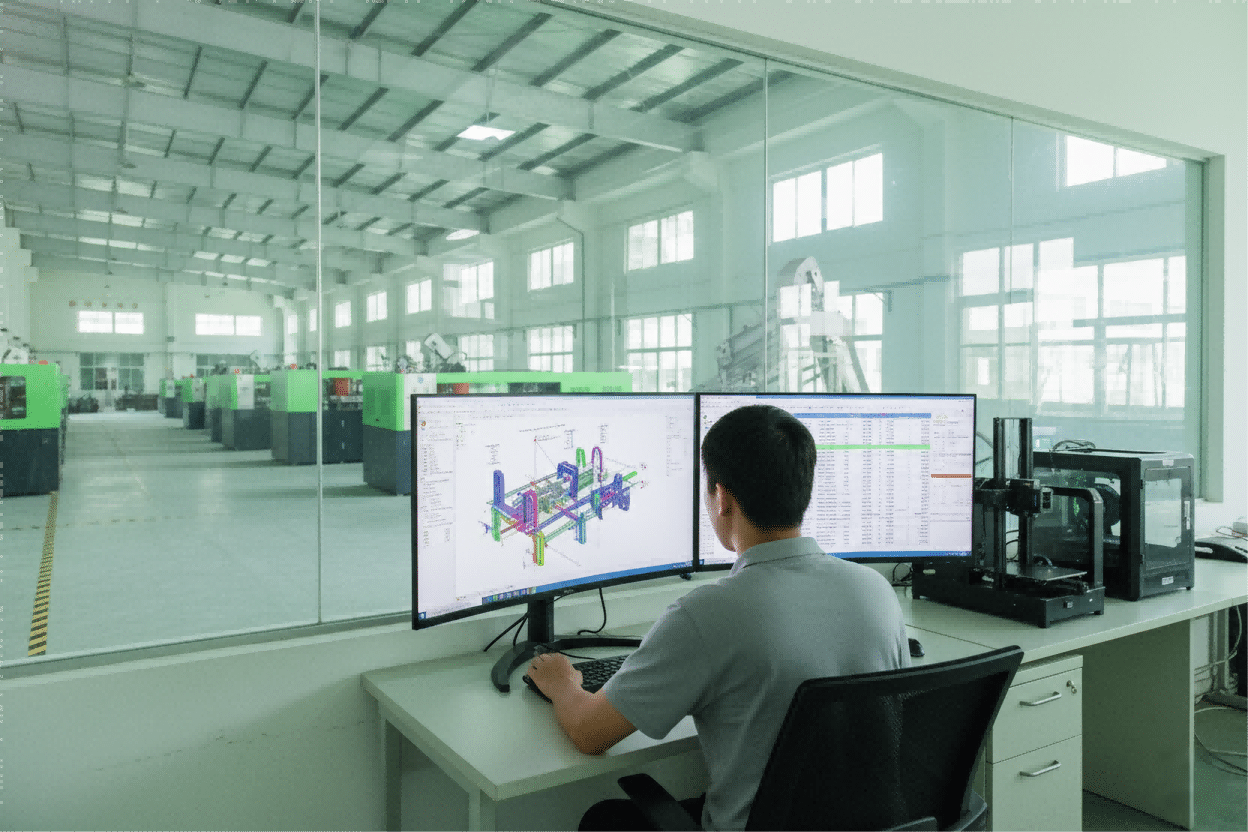

However, the Guangdong philosophy, which we strictly follow at iBottler, is fundamentally different. Our approach is the "core components self-made" model. I realized early on that if you want to control quality, you have to control the source. When we talk about precision in a high-speed blow molding machine, we are talking about tolerances measured in single microns. When the frame is outsourced to one vendor, the clamping unit to another, and the heating oven to a third, the cumulative margin of error—what engineers call "Tolerance Stack-up"—becomes almost impossible to manage. My factory in Zhongshan, part of the heart of the Guangdong manufacturing zone, invests heavily in our own CNC machining centers. This is not about saving money; it is about controlling every micro-movement of the machine. When my team designs a new blow molding machine, we are not just drawing a bolt-on assembly; we are designing the machine and the parts it uses as a single, integrated system. This internal control allows us to hold much tighter tolerances than any external supplier ever could, directly contributing to the machine's speed, stability, and the high quality of the final product.

For instance, consider the clamping system. The tremendous pressure exerted during the blowing process creates massive stress and vibration. A machine frame we weld and stress-relieve in-house, designed specifically for that force, will maintain its rigidity much longer than a standard, off-the-shelf frame that might have been built to a lower, general-purpose specification. An outsourced frame may not perfectly match the specific machine's stress points, leading to deformation over time. We also find that the electronic controls and the mechanical movements—the "mechatronics"—achieve a much deeper, more seamless integration when developed side-by-side by the same engineering team. This is a level of sophistication that an assembly-focused plant just cannot replicate. This distinction is the bedrock of the Guangdong PET blow molding machine reputation for high precision PET machine products.

| Feature | Guangdong Advantage | Taizhou/Assembly Focus |

|---|---|---|

| Manufacturing Model | Core Components Self-Made (Vertical Integration) | Distributed/Outsourced Assembly (Horizontal Specialization) |

| Precision Control | Excellent (Tolerances controlled in-house) | Difficult (Prone to Tolerance Stack-up from multiple vendors) |

| Frame Rigidity | High (Custom welding, stress-relieved, specific to machine stress points) | Moderate (Often standard, general-purpose frames) |

| Innovation Speed | High (Design changes go directly to the factory floor) | Slow (Limited by the standardization of external suppliers) |

| Cost Focus | Quality and Long-Term Stability | Low Initial Acquisition Cost |

The "Assembly Trap": Risks of Outsourced Components (Frames & Sheet Metal)?

Many buyers focus only on the speed rating, but the machine's true reliability hides in the parts you cannot easily see.

The "Assembly Trap" involves risks like poor component matching and low structural rigidity, stemming from outsourcing critical parts like the machine frame and sheet metal. This practice, while lowering the initial cost, leads to long-term issues like machine deformation and increased maintenance needs.

I have seen too many companies fall into the trap of focusing only on the price tag. I learned very quickly that the foundation of any long-lasting machine is the physical structure—the machine frame and the enclosures. In the typical assembly-centric model outside of Guangdong, the machine frame is often sourced from an external structural steel company. This company works on volume, producing generic, low-cost frames. When the main supplier gets the frame, they bolt their own components onto it. My experience is that this system has inherent flaws. The outsourced frames are often built to a general standard, not one specifically optimized for the extreme dynamic loading of a high-speed blow molding cycle.

A PET blow molding machine is subject to immense forces, especially during the high-pressure locking of the mold. The machine frame must act like an immovable anchor. When we manufacture our own frames at iBottler, we specify the steel grade and the exact welding and stress-relieving procedures required. Stress-relieving, or annealing, is a critical step that removes internal stresses from the welding process, preventing the machine from slowly deforming or twisting over its lifespan. A generic, outsourced frame often skips or rushes this step, meaning after a year or two of high-cycle operation, the frame might subtly warp. A warp of even a few hundredths of a millimeter can throw the mold alignment off, causing flashing or unstable bottle bases, leading to high rejection rates.

The same principle applies to the seemingly minor details, such as the sheet metal and electrical enclosures. I have personally visited factories where the gaps in the protective sheet metal were uneven, leading to excessive noise and dust ingress. This is not just an aesthetic flaw; it indicates a lack of precision in the assembly process. The sheet metal supplier works independently and is focused only on delivering a product that meets their drawing, not one that fits perfectly with the final machine structure. In contrast, when we control the fabrication of the enclosures, the goal is a perfect, hermetic fit that minimizes vibration and noise, and maximizes cleanliness. At iBottler, we treat the sheet metal as a functional part of the machine's sound and safety damping, not just a cover. This attention to detail is a hallmark of the Guangdong PET blow molding machine build quality and is a huge factor in the machine's long-term operational costs and safety standards. If you are serious about low maintenance and high consistency for a decade or more, controlling the source of every structural component is a non-negotiable requirement.

| Outsourced Frame Risk Factor | Description | Long-Term Impact |

|---|---|---|

| Low Rigidity | Frame not custom-engineered for specific clamping/blowing forces. | Premature wear on moving parts, mold misalignment, increased downtime. |

| No Stress Relief | Internal stresses from welding not removed by annealing process. | Frame deformation over time, leading to inconsistent product quality. |

| Poor Fitment | Components bought from different external vendors often do not match perfectly. | Excessive vibration, noise, and increased energy loss during operation. |

| Difficult Repair | If a structural part fails, finding a perfect, matching replacement from a generic supplier is hard. | Long and expensive repair cycle, potential for permanent machine retirement. |

R&D Leadership: Where New Technology is Born (Not Just Copied)?

Are you interested in the newest energy-saving features or high-speed innovations? You need to look to the source of the breakthrough, not the copycat.

Guangdong is the undisputed leader in PET machine R&D because it possesses the deepest talent pool of automation engineers and large-scale industry giants like Tech-Long, meaning new technologies like full-servo drives and specialized low-pressure clamping are invented here, not just reverse-engineered.

This is where the distinction between a manufacturer and an innovator becomes crystal clear. Guangdong has always been the technological heartland of liquid packaging in China. Industry giants based here, like Tech-Long and Ribo PET machine, do not just build machines; they define the future of the industry. The sheer concentration of top-tier mechanical and electrical engineering talent in the Pearl River Delta is unmatched. I know this from personal experience, as my own senior R&D team members often come from the engineering departments of these larger, standard-setting firms. They bring with them a DNA of genuine innovation.

For example, the widespread adoption of the full-servo electric blow molding machine in China—a technology that vastly improves energy efficiency and precision—was spearheaded by Guangdong companies. They were the ones who perfected the complex control algorithms needed to coordinate multiple servo motors in milliseconds. While other regions might then take these concepts and simplify them to hit a lower price point, the fundamental knowledge of "why" the machine moves the way it does—the deep-seated understanding of mechanical dynamics and control logic—remains rooted in Guangdong.

I recall a project where a customer needed to produce ultra-lightweight bottles with an unusual, wide-mouth finish. This required a very specific low-pressure clamping technology to prevent stress marks on the neck. This kind of custom requirement is not a simple assembly job. It requires intense simulation and calculation of fluid dynamics and mechanical forces. The design and implementation of such a novel clamping sequence and the corresponding software to manage it can only be done by a manufacturer that fully owns its mechanical and electrical IP. An assembly-focused factory relies on standardized components and standardized programming from their outside vendors. They cannot fundamentally alter the machine's core operation because they do not hold the "source code" or the original mechanical blueprints. My team, at iBottler, because we control our design from the ground up, was able to iterate on the clamping mechanism and write a custom control sequence in under two months, something an assembly plant could never have achieved. This capacity for first-principles innovation, rather than just feature replication, is the real Guangdong PET blow molding machine advantage. It ensures that the machines coming from this region are not only high quality today but are also ready for the technological demands of tomorrow.

| Technology Originator | Technology Focus Area | Innovation Depth in Guangdong |

|---|---|---|

| Full-Servo Control | Energy Efficiency, High-Speed Precision | Developed core control algorithms for coordinated, simultaneous axis movements. |

| Lightweighting | Bottle Material Reduction, Stability | Advanced flow dynamics and cooling calculations to ensure structural integrity of thin-walled PET bottle mold design guide from concept to production bottles. |

| Low-Pressure Clamping | Neck Finish Protection, Mold Wear Reduction | Custom mechanical design and software to apply minimal yet sufficient force for specific applications. |

Customization Capability: The Power of Controlling the Drawings?

Do you have a unique bottle shape or a special line requirement that standard machines cannot meet? Your ability to customize relies entirely on your supplier's engineering control.

Guangdong factories offer superior customization capability because they control the core mechanical and electrical CAD drawings, enabling them to quickly modify parameters like clamping stroke or accommodate specific voltages without relying on external suppliers' restrictive standard components.

The power of controlling the drawings cannot be overstated. Because we at iBottler design our own machine architecture, if a customer needs an extra 50mm of opening stroke to accommodate a massive blow molding mold, our engineers simply modify the original CAD file for the opening/closing mechanism. We then issue this revised drawing directly to our internal or closely managed machining center. The entire process of non-standard modification is contained and controlled.

Now, imagine an assembly-focused factory. They purchase their opening/closing unit as a standard, modular component from a separate vendor. That vendor has invested in tooling to produce thousands of that standard component efficiently. To ask them to change the opening stroke just for one machine is economically unviable for them. The assembly factory's hands are tied, and the customer is told, "That's not possible with our machine." This is a significant limitation for any ambitious packaging company.

Furthermore, consider the international compliance aspect. We frequently export our bottle blowing machine products to markets like Europe and North America, which have rigorous electrical standards, such as UL certification for the electrical cabinet. Because we design and build our own electrical cabinets, we can ensure compliance from the earliest design phase—specifying UL-certified components and wire routing that meets all safety codes. A factory that buys a pre-made, generic electrical cabinet from a third-party vendor can only apply last-minute patches or modifications to an already finished product, which often compromises both the integrity and the compliance. Controlling the core drawings—both mechanical and electrical—is the key to offering true, responsive customization, a fundamental reason why the Guangdong PET blow molding machine sector is preferred by global brands.

| Customization Requirement | Guangdong Approach (Controlling Drawings) | Assembly Factory Limitation (Standard Parts) |

|---|---|---|

| Increased Mold Height | Engineers modify the frame/clamping drawings in-house; self-made components are adjusted. | Limited by the fixed dimensions of the external supplier's standard frame and clamping unit. |

| Non-Standard Voltage | Electrical cabinet designed from scratch using the required specific components and safety standards. | Forced to buy a standard cabinet and apply risky, last-minute modifications or external transformers. |

| Specialized Motion | Software and mechanical parts adjusted in unison for unique functions (e.g., asymmetrical stretching). | Only standard operational programs are available; core motion cannot be fundamentally changed. |

The Electrical Cabinet & Programming: The Brain of the Machine?

Do you worry about slow technical support when your machine is down? The speed of the fix often depends on who wrote the machine's software.

The electrical cabinet and programming are the machine's brain, and Guangdong factories gain an advantage by developing the source code in-house, ensuring deeper mechatronic integration, faster remote diagnostics, and better synchronization of millisecond-level machine movements compared to systems that rely on outsourced, third-party code.

I have often heard the machine described as having a body and a brain. The frame is the body, but the electrical cabinet and the PLC program inside it are the brain. The quality of this brain determines everything: cycle speed, bottle consistency, and, critically, how quickly the machine can be fixed when something goes wrong. In many assembly-focused environments, the electrical cabinet, the wiring, and the PLC program are all outsourced to a specialist electrical control company. This means the machine builder is selling you a machine whose deepest operating logic they do not fully understand.

This creates a massive bottleneck in after-sales service. If a subtle bug appears in the code—say, a millisecond delay in the synchronization between the stretch rod and the pre-blow air—the machine supplier has to call the third-party programmer. The programmer has to schedule a visit or remote session. The main factory does not have the "source code." I have seen this lead to downtime measured in weeks, not days.

At iBottler, and this is a common trait among high-quality Guangdong PET blow molding machine manufacturers, we view the PLC program as part of our core intellectual property. Our mechanical and electrical engineers work together, often in the same room, writing and debugging the software while the machine is physically being assembled. This close, iterative process is what we call deep mechatronic integration. It allows us to achieve precise synchronization—the exact moment the high-pressure air hits, the exact speed the stretch rod is moving, and the exact position of the mold lock. This is critical to avoiding common PET blow molding defects common PET blow molding defects and how to fix them quickly and achieving the maximum cycle speed without compromising bottle quality.

When a machine we built experiences an issue, our in-house programmer can remotely connect, review the code, and often push an updated parameter set immediately. This difference between calling a third party and directly modifying the source code is the difference between a quick, professional fix and a prolonged, frustrating outage. Moreover, we can continuously optimize the logic. We constantly look for ways to shave milliseconds off the cycle by fine-tuning the sequencing of the valves and motors, a continuous improvement process that is simply impossible if you do not own the software. The brain must be owned by the body's designer.

| Electrical Component | Guangdong In-House Control | Assembly Factory Outsourced Control |

|---|---|---|

| Program Source Code | Owned and maintained internally; allows for immediate, precise modification and optimization. | Owned by a third-party vendor; requires coordinating with the vendor for every change or fix. |

| Mechatronic Integration | Deep; Mechanical and Electrical teams co-develop for perfect motion synchronization. | Shallow; Integration is limited to standardized communication protocols, less nuanced movement control. |

| After-Sales Support | Fast remote diagnostics and code updates possible. | Slow; Dependent on the third-party's availability to troubleshoot. |

The Role of Industry Giants (Tech-Long, Ribo, Guozhu)?

Do you understand how a region maintains consistently high quality? It comes down to the influence of industry leaders who set the standard for everyone else.

Guangdong's high standards are driven by industry giants like Tech-Long, Ribo, and Guozhu, who set a globally competitive benchmark for high-speed, high-precision manufacturing, creating a demanding local supply chain and a deep talent pool that raises the quality floor for every factory in the region.

The presence of major, established industry players like Tech-Long and Guozhu blow molding acts as a powerful quality anchor for the entire Guangdong PET blow molding machine ecosystem. These companies are not just local businesses; they are international competitors whose technical standards are aimed at rivals like Krones and Sidel. This high bar trickles down to every level of the Guangdong supply chain.

When I started iBottler, I understood that to survive in this environment, you must adhere to world-class standards. A small or medium-sized factory in Guangdong benefits immensely from this "competitive overflow." For example, the smaller, specialized suppliers in the region—for components like specialized bearings, pneumatic valves, or sensors—know that if they want to sell to Tech-Long, their components must meet extremely strict performance and longevity criteria. This forces them to maintain a much higher quality standard than a generic supplier operating in a low-cost region. As a result, when we source a component, even a non-core part, we are indirectly benefiting from the high standards these industry giants have established.

Furthermore, the talent flow is crucial. These large firms train hundreds of high-quality engineers, technicians, and specialized CNC operators. When these individuals move to smaller, more flexible companies like ours, they bring that culture of precision and rigor with them. My own factory's backbone is built on individuals who have decades of experience under these leading brands. They do not tolerate sloppy assembly or cutting corners because they have been trained on the best practices in the world. This is the "Guangdong DNA" of manufacturing—a refusal to accept "good enough."

This competitive pressure and high-standard ecosystem is why, even if you are not buying the most expensive machine from the largest manufacturer, a Guangdong PET blow molding machine product will generally have a much higher quality floor. The whole regional ecosystem is designed to deliver reliability. It is a fundamental economic driver: the big players demand the best, and the smaller players must deliver near the best to stay in the game. This focus creates a virtuous cycle of quality and expertise that other regions simply cannot match, as they often lack this historical foundation of global-facing industry leadership.

| Industry Giant's Influence | Mechanism of Quality Improvement | Direct Benefit to iBottler/Customer |

|---|---|---|

| Standard Setting | Demanding standards for component precision (e.g., tolerance, lifetime) from all regional suppliers. | Guaranteed access to high-quality, reliable, pre-vetted components from the local supply chain. |

| Talent Cultivation | Training a large pool of world-class mechanical, electrical, and automation engineers. | Ability to hire experienced staff who carry a culture of precision and advanced technical knowledge. |

| Technological Pace | Continuous investment in R&D for the next generation of full-servo and high-speed machines. | Ensures that the regional machine designs are always modern and leverage the latest efficiency technologies. |

Long-Term Maintenance: Why Owning Core Tech Matters?

Do you think about what happens five years down the line when a critical part fails? Your machine's longevity depends on whether the supplier can reproduce the component.

Owning the core technology is vital for long-term maintenance because Guangdong manufacturers, who control their component drawings, can accurately reproduce parts years later, guaranteeing future spare parts availability, while assembly-based machines risk obsolescence as their external component suppliers change or go out of business.

This is the hidden cost of the low-price assembly machine: long-term maintainability. When you buy a machine, you are not just buying a piece of hardware; you are buying a promise of production for the next ten to fifteen years. The difference in this long-term promise is stark.

In the assembly model, the machine is a collection of parts bought from whoever was cheapest at the time of manufacture. A factory might use Supplier A for a specific type of pneumatic cylinder this year, but if Supplier B is 10% cheaper next year, they switch. Three years later, when you, the customer, need a replacement for that pneumatic cylinder, Supplier A might be out of business or might have changed the component's specification or mounting dimensions. The original supplier is now relying on a component that they do not have the drawing for and cannot perfectly source or reproduce. I have personally witnessed companies struggling to keep older machines running because they cannot find an exact match for a critical, non-standard component, often leading to a premature machine retirement.

This scenario is drastically different for a Guangdong PET blow molding machine from a vertically integrated factory like iBottler. Because we manufacture or specifically design the core mechanical components—including the custom parts of the clamping unit or the specific dimensions of the blow molding mold interface—we possess the complete, archived CAD drawings. If you need a replacement part seven years from now, our team can pull up the original drawing, manufacture the component to the exact, original specification, and ship it to you. This guarantees component continuity and compatibility.

Moreover, owning the core technology makes troubleshooting much more efficient. When a complex failure occurs, an assembly factory often resorts to a simple "swap and test" strategy—replacing component after component until the machine works. This is expensive and time-consuming. Because we understand the deep relationship between the mechanical movement and the electrical code, we can use the machine’s sensor data and error logs to pinpoint the exact root cause—be it a subtle mechanical wear, a calibration drift, or a specific pneumatic failure. This diagnostic precision reduces downtime and ensures a permanent fix, not just a temporary patch. Investing in a machine from a manufacturer that controls its core technology is an investment in guaranteed, decade-long operational life. I always tell my customers: "Do not buy a machine; buy a commitment to your long-term production."

| Maintenance Aspect | Guangdong Advantage (Core Tech Ownership) | Assembly Factory Risk (Outsourced Parts) |

|---|---|---|

| Spare Parts Availability (5+ Yrs) | Guaranteed; parts can be manufactured on demand from archived, complete drawings. | High risk of obsolescence; dependent on the continued existence and consistency of external, generic suppliers. |

| Fault Diagnosis | Precise; deep knowledge of mechatronics allows for root cause analysis via data logging and code review. | Trial-and-error; limited to component swapping as the deep mechanical/electrical relationship is not understood by the assembler. |

| Part Consistency | All replacement parts manufactured to the exact original tolerance. | New parts may have slight tolerance variations from different suppliers, potentially leading to fitment issues. |

Conclusion: Choosing Precision and Innovation (The iBottler Approach)?

Are you ready to decide between initial cost savings and long-term industrial stability? The answer defines your business future.

The choice is clear: while Taizhou offers excellent entry-level value, the Guangdong PET blow molding machine sector, through its insistence on precision, in-house core manufacturing, and R&D leadership, is the superior option for any company seeking long-term stability, customization, and guaranteed technical support.

We have established throughout this discussion that the distinction between the two major Chinese manufacturing hubs is one of fundamental philosophy. The Taizhou model offers immediate and undeniable value: a fast, cost-effective machine that is perfect for simple bottle shapes and initial, budget-sensitive projects. It is a great starting point for many.

However, if you are planning for the long haul—if your focus is on high-speed production, complex bottle designs, minimal defect rates, and a machine that remains a reliable industrial asset for over a decade—the Guangdong model is the only answer. You must honestly evaluate your needs: Are you purchasing a “usable tool to make money now” (the assembly approach), or are you investing in a “long-term, stable industrial asset with guaranteed future support” (the Guangdong approach)?

At iBottler, located in Zhongshan, we are a true product of this Guangdong PET blow molding machine heritage. We do not chase the title of "the cheapest factory in China" because we know what that requires: compromise on core component quality. We adhere to the fundamental principles we have discussed: we own and refine our core mechanical designs, we design and build our own electrical systems, and we are constantly iterating on our PLC program for minute improvements in cycle time and energy use. We maintain the highest standards in our mold manufacturing, an essential link in the quality chain, ensuring that every blow bottle mold we deliver meets the precision of our machines. Our commitment is to control the quality of the machine from the first CAD line to the final assembly bolt. When you choose an iBottler machine, you are not just getting hardware; you are gaining a manufacturing partner who has 100% control over the core technology of your investment, which is the only way to ensure your production line's stability and success.

| Manufacturing Base | Primary Focus | Best Use Case | Long-Term Service Risk |

|---|---|---|---|

| Guangdong (Precision Model) | Core IP Ownership, Stability, R&D | High-speed lines, complex bottle designs, long-term asset investment. | Low (Parts guaranteed from archived drawings) |

| Taizhou (Assembly Model) | Low Cost, Production Speed | Budget-sensitive projects, simple bottle shapes, market entry phase. | High (Parts dependent on external supplier stability) |

Conclusion

The Guangdong sector leads China's PET machine industry through its commitment to in-house component precision, R&D innovation, and deep technical control, making it the essential choice for buyers prioritizing long-term stability and high-quality customized production.

| Factor | Guangdong Advantage Summary |

|---|---|

| Precision Source | In-house manufacturing of core components (frames, clamping units). |

| Technological Edge | R&D leader; innovator of full-servo and advanced control technologies. |

| Customization | Full control of CAD drawings allows for rapid, non-standard machine modifications. |

| Long-Term Value | Guaranteed spare part availability and faster, precise diagnostics via in-house technical control. |

FAQ Section

Q1: How does the "in-house core component" model affect the price of a Guangdong PET machine?

A: The commitment to in-house manufacturing, which includes maintaining high-end CNC centers and a large R&D team, means that the initial acquisition cost of a Guangdong PET blow molding machine is generally higher than an assembly-based machine. This higher price reflects the superior quality of the steel structure, the precision of the mechanical interfaces, and the guarantee of long-term parts availability. The investment is justified by lower long-term operating costs, reduced downtime, and higher average bottle quality over the machine's lifespan. We encourage customers to look at the Total Cost of Ownership (TCO) over five years, not just the purchase price.

Q2: Is the speed of an assembly-based machine from Taizhou comparable to a Guangdong machine?

A: On paper, the stated cycle speed—for example, 2,000 bottles per hour per cavity—can often be the same. However, the critical difference is sustainable speed and consistent quality at speed. Because the Guangdong machine controls the mechanical and electrical synchronization more precisely, it can run at its maximum rated speed with a lower defect rate and for longer periods without the cumulative wear-and-tear issues caused by poor tolerance stacking. An assembly machine might hit the speed briefly, but running it consistently at that maximum speed often leads to rapid mechanical wear and an unacceptable rate of bottle defects.

Q3: Why is owning the electrical program "source code" so important for machine uptime?

A: Owning the source code is vital for rapid troubleshooting and maintenance. When a complex issue arises, an in-house engineer from a Guangdong factory can instantly access the program's logic. This allows for immediate remote diagnosis, identifying whether the issue is a sensor failure, a faulty timing sequence, or a simple parameter drift. An outsourced program means the machine builder is reliant on an external party, resulting in slow, complicated, and potentially costly service calls. My team at iBottler has fixed issues in minutes remotely that would take an outsourced-program factory days to even begin to diagnose.

Q4: Does the Guangdong advantage apply to all types of machines, including preform mold manufacturing?

A: Yes, the principle extends throughout the entire PET production ecosystem. The same precision engineering ethos—in-house CNC machining, tight tolerance control, and deep material science expertise—is applied to preform mold manufacturing. This is crucial because the blow molding process begins with a perfectly formed preform. The precision and consistent cooling channels in a Guangdong PET blow molding machine preform mold directly translate to better preform consistency, which is the foundation for a defect-free final bottle.

Q5: If I purchase a Guangdong machine, do I still need to worry about peripheral equipment like chiller and air compressor?

A: Yes, absolutely. The best machine in the world still requires the correct inputs. A high-precision blow molding machine demands a constant supply of clean, dry, high-pressure air and perfectly temperature-controlled water for mold cooling. We always advise customers to select their air compressor and chiller based on the machine's actual peak demands, not just the minimum specs. Inadequate peripherals will undermine the performance of even the most precise Guangdong machine, leading to issues like long cycle times and stress whitening in the bottle.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr