Your new bottle mold project is delayed. The samples are off-spec, and trust in your supplier is fading. The cause is a simple, overlooked detail that could be costing you thousands.

The biggest mistake is measuring your bottle's volume by weighing it with water and assuming 1 gram equals 1 milliliter. This is only true for water. For sugary drinks like juice or tea, the density is higher, leading to significant measurement errors, project delays, and financial loss.

I get calls like this all the time. A production manager is frustrated, convinced the brand new mold we delivered is wrong. They've measured the volume, and it doesn't match the technical drawing. The pressure is on, deadlines are looming, and a costly dispute seems inevitable. But after 16 years in this business, I know that over 90% of the time, the problem isn't with the mold. It's with how the volume was measured. Let's walk through this common pitfall so you can avoid it completely.

The All-Too-Common Scenario: Your New Mold's Volume Seems Wrong?

Your new mold finally arrived, but the tests show a major volume deviation from the specs. Your project timeline, budget, and supplier relationship are suddenly at risk.

The initial QC report is clear: the bottle's volume is off. This single piece of data triggers a chain reaction of urgent emails and phone calls. It's a scenario that causes immediate stress for any beverage brand manager, and one I've seen play out countless times.

As a blow bottle mold manufacturer, this is a familiar story. The phone rings, and the voice on the other end is always urgent. "The volume is wrong," they say. "It's much larger than the drawing specifies." I've been in the PET blow mold industry for 16 years, and I can tell you with confidence that in the vast majority of these cases, the issue isn't a manufacturing error. It's a fundamental misunderstanding of physics that is surprisingly common. Before you blame the tool, we need to look at the liquid. The problem usually starts with a simple assumption made during testing, an assumption that water is a perfect stand-in for every other liquid. This is where the error begins, and it's an error that can have significant consequences for your entire production line.

Understanding the Initial Panic

When a new mold arrives, excitement is high. This tool represents a new product launch, a packaging update, or an expansion of production capacity. It's the culmination of weeks or even months of design, engineering, and investment. The Quality Control (QC) team has a critical job: verify that the mold produces bottles that meet every single specification on the technical drawing. One of the most important specs is, of course, the net volume.

The standard QC procedure is straightforward:

- Produce a set of sample bottles.

- Wait for them to cool to room temperature.

- Place an empty bottle on a high-precision scale and tare it (set it to zero).

- Fill the bottle to the specified fill level with a liquid.

- Weigh the filled bottle.

- Record the weight of the liquid.

The problem arises in step 4. What liquid is used? In most facilities, the most convenient, cheapest, and readily available liquid is purified water. Here, the critical mistake is made. The QC technician reads the weight in grams and records it directly as volume in milliliters. A weight of "262g" is written down as a volume of "262ml". When the technical drawing calls for a 250ml bottle, a 12ml discrepancy looks like a disaster. It's a 4.8% deviation, far outside any acceptable tolerance. The immediate conclusion is that the mold is wrong.

The Mistake Itself: Assuming All Liquids Weigh the Same?

You're in a hurry and grab the most convenient liquid for testing: water. You assume its weight in grams equals its volume in milliliters. This is the costly mistake.

This habit of equating grams to milliliters is the core of the problem. It works perfectly for water, but for almost any other commercial beverage, especially hot-fill juices and teas, this assumption is incorrect and misleading. The convenience of this method is its greatest danger.

It’s an industry habit born from the massive bottled water market. The density of pure water is almost exactly 1 g/ml. This makes the math easy. A 500-gram weight means a 500-ml volume. It's simple, fast, and for water bottlers, it's accurate. But this convenience becomes a costly error the moment you fill that bottle with juice, iced tea, or any beverage containing sugars, minerals, or other solids. I always tell my clients, "Convenience can be the start of an expensive mistake." For hot-filled beverages, this "convenient" assumption will give you a completely wrong understanding of your own product's volume.

Why This Assumption is Flawed

The relationship between mass (weight) and volume is defined by a property called density. The formula is simple:

Density = Mass / Volume

Or, rearranged to find the true volume:

Volume = Mass / Density

For pure water, the density is 1 g/ml. So, the calculation becomes:

Volume (ml) = Mass (g) / 1 (g/ml)

This is why the numbers for mass and volume are identical for water. But what about a typical fruit juice? A 12 Brix orange juice (a measure of sugar content) has a density of approximately 1.048 g/ml. It's heavier than water for the same volume.

Let's see what happens when we use this correct density in our calculation. If your QC team fills a bottle with juice and it weighs 262 grams, the actual volume is:

Volume = 262 g / 1.048 g/ml = 250.0 ml

Suddenly, the "error" disappears. The bottle that seemed to be 4.8% too large is, in fact, perfectly sized for the actual product it's designed to hold. This isn't a trick; it's just physics. Assuming all liquids behave like water is like assuming all vehicles run on the same type of fuel. It's a flawed starting point that guarantees a wrong conclusion.

A Real-World Case Study: The Bangladesh Juice Bottle Dilemma?

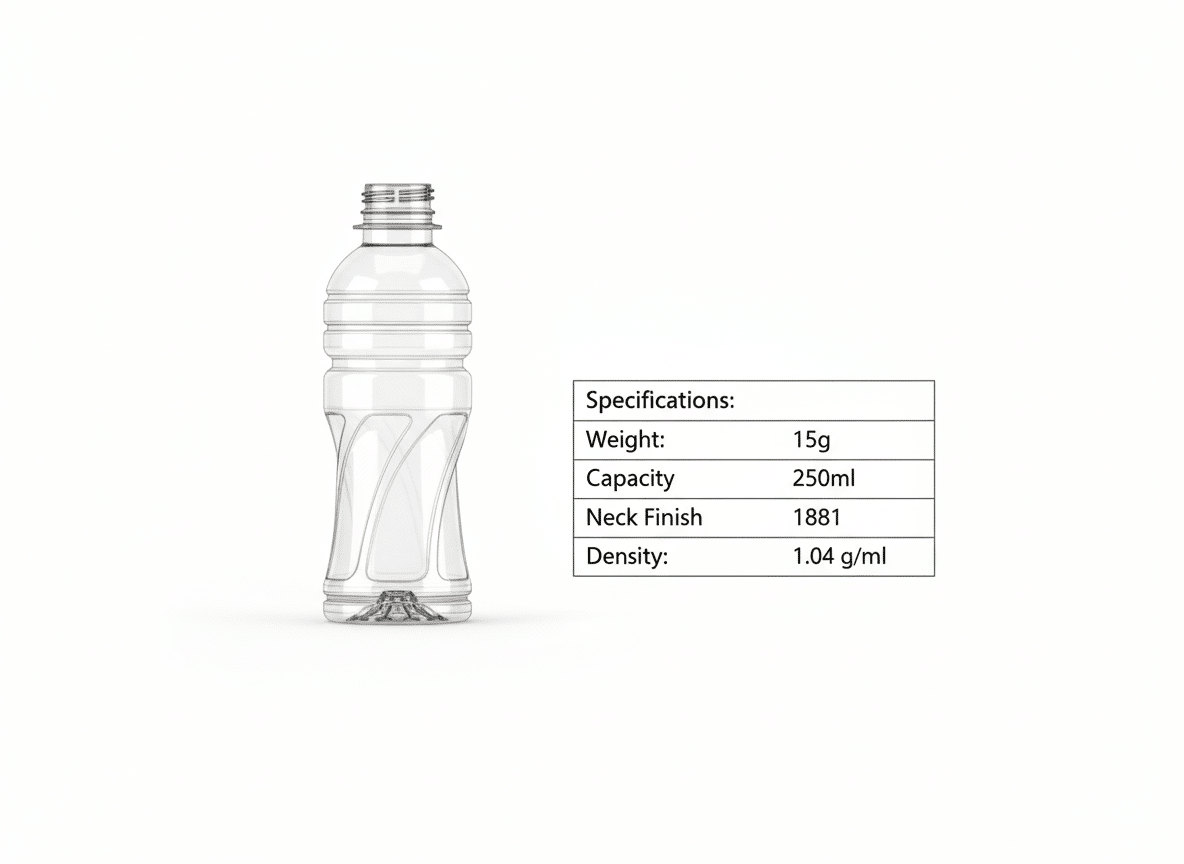

A client called, confused. The 250ml hot-fill mold we made produced bottles with a 262ml capacity. I asked one simple question that solved the entire "problem" instantly.

"Vivian, this 250ml mold is making 262ml bottles. That's almost 5% oversized!" My client in Bangladesh was puzzled. I asked, "What did you use for testing?" His answer: "Purified water. We filled it and it weighed 262 grams." This was the key.

This exact situation happened just last week. An established client in Bangladesh, for whom we had just designed and manufactured a new 250ml hot-fill juice blow bottle mold, called me. He was respectful but concerned. He explained that his team had tested the initial samples from the new tool and found the volume to be 262ml. I immediately knew what was happening. I asked him to pull up the Technical Specification Sheet we had confirmed together at the start of the project. This document is the foundation of our PET bottle mold design guide. On that sheet, we had clearly recorded that his juice product has a specific gravity, or density, of 1.04 g/ml.

The Math that Solved the Dispute

On the phone, I walked him through the simple calculation. "Let's do the math together," I said. "You have the weight of the water, which is 262 grams. Now, let's calculate the real volume this bottle is designed to hold for your specific juice."

I explained the formula: True Volume = Weight of Water / Product Density

He punched the numbers into his calculator as we spoke:

262 grams / 1.04 g/ml = 251.92 ml

There was a moment of silence on the line, followed by a laugh. The mystery was solved. The bottle's volume was perfect. In fact, it was slightly over 250ml by design, which I'll explain later, to account for cooling shrinkage. A situation that could have turned into a formal complaint or a costly mold modification was resolved with a two-minute phone call and a simple division problem. This wasn't a business dispute; it became a quick technical education session. It highlights why understanding these details isn't just for engineers; it's crucial for anyone managing a beverage packaging project.

The Science of Sweetness: Why Density is a Critical, Non-Negotiable Parameter?

Your juice contains sugar, fruit fibers, and minerals. These ingredients make it heavier than water. This difference, its density, is a vital number in mold design.

Ignoring density is like building a house without knowing the soil conditions. It's a critical, non-negotiable parameter. The density of your product dictates the precise volume of the mold cavity required to hold the correct amount of your product.

We have to approach this with scientific precision. In mold design, a tiny error can lead to huge problems down the line. We aren't just creating a generic 'container'; we are engineering a precise 'measuring tool' that will be replicated millions of times. Knowing the exact density of the product you are filling is the absolute starting point for our work. It’s the first question we ask, because the entire design hinges on that number. Without it, we are just guessing.

A Look at Different Liquid Densities

The reason your juice or tea is denser than water is simple: it has things dissolved in it. Sugar is the primary contributor, but minerals, flavor compounds, and fruit pulp also add to the mass. Think of it like adding sand to a bucket of water; the total volume doesn't change much, but the bucket gets noticeably heavier.

Let's look at some typical density values for common beverages. This shows why a one-size-fits-all approach based on water is bound to fail.

| Liquid Type | Typical Sugar Content (Brix) | Approximate Density (g/ml) at 20°C |

|---|---|---|

| Purified Water | 0° | 1.00 |

| Iced Tea with Lemon | 8-10° | 1.030 - 1.040 |

| Orange Juice | 11-12° | 1.045 - 1.050 |

| Apple Juice | 11.5° | 1.047 |

| Grape Juice | 14-16° | 1.055 - 1.065 |

| Whole Milk | N/A (contains fats, proteins) | ~1.03 |

As you can see, even a lightly sweetened iced tea is 3-4% denser than water. A sweet grape juice can be over 6% denser. If you use water to test a mold designed for that grape juice, you will get a volume reading that is 6% off. This isn't a small error; it's a massive discrepancy that would, quite rightly, cause alarm if you didn't understand the science behind it. This is why providing the correct product density is a mandatory step in our project kickoff process.

How This "Simple" Mistake Costs You Real Money?

You think a small volume error is no big deal? It leads to giving away free product, failing legal standards, and wasting weeks in delays. This "simple" mistake has real financial consequences.

This measurement error directly impacts your bottom line. The title of this article promises to explain how it costs you money, and the financial implications are very real, touching everything from raw materials to regulatory compliance.

In manufacturing, every gram of product and every minute of production time has a cost attached. Any uncertainty or error introduces financial risk. Our primary goal in the design phase is to eliminate these uncertainties through rigorous technical alignment. Let's break down the specific ways this seemingly small mistake can drain your resources.

The High Cost of Inaccuracy

The financial damage from this error can be broken down into three main categories:

Product Giveaway (Over-filling): Let's imagine the opposite scenario. You insist the mold is too big based on your water-weight test. The mold maker, against their better judgment, remakes the tool to be smaller. Now, when you fill it with your denser juice, it holds less than the label states. To meet the declared volume of 250ml, you have to over-fill it, pushing the liquid level dangerously high up the neck. More likely, you originally designed the bottle to be slightly larger to look more substantial on the shelf. If you use a mold designed for water, every single bottle you fill with juice will contain extra product that you're not getting paid for.

- Example Calculation:

- Target fill: 250ml of juice (density 1.04 g/ml)

- You use a bottle with a true volume of 255ml (designed using water).

- Each bottle contains 5ml of extra juice.

- Over a production run of 1,000,000 bottles, you give away: 1,000,000 * 5 ml = 5,000,000 ml = 5,000 liters of free product.

- If your juice costs $0.50 per liter, that's a $2,500 loss on that single production run.

- Example Calculation:

Compliance and Legal Risks (Under-filling): This is even more dangerous. Suppose you convince your supplier to reduce the mold volume based on the incorrect water test. The new, smaller mold arrives. You fill it with your 1.04 density juice. The bottle that held 250g of water now only holds about 240ml of your juice (250g / 1.04 g/ml = 240.4ml). Your label says "250ml." You are now under-filling every bottle by almost 4%. This puts you at serious risk of failing regulatory inspections, leading to hefty fines, product recalls, and immense damage to your brand's reputation.

Time and Opportunity Costs: The back-and-forth communication, the arguments, the shipping of samples, and the re-testing all consume valuable time. A product launch delayed by four weeks because of a measurement dispute is four weeks of lost sales. While your team is busy trying to solve a problem that doesn't actually exist, your competitors are on the market. This opportunity cost can often be far greater than the direct costs of product giveaway or rework. This is also why having a clear process for validating blow mold designs is so important.

Our Solution: Designing for Density from Day One?

You're worried about getting the volume right. We eliminate that worry entirely. Our process starts with your product's specific density, making precision the foundation of your mold design.

We proactively prevent this entire problem from ever occurring. Our design process doesn't just allow for product density; it requires it. It is a mandatory field in our project initiation forms, right alongside filling temperature and target volume.

Our 3D design software doesn't just calculate a generic volume. The calculations are directly linked to the material density parameter we input. We don't give the software a simple command like "create a 250ml cavity." Instead, the instruction is far more precise: "Design a mold cavity that, after accounting for thermal shrinkage, will hold a 250ml volume of a liquid with a density of 1.04 g/ml." This is the difference between an amateur approach and professional engineering.

Our Process for Precision

To ensure accuracy from the very beginning, we follow a strict protocol that places the responsibility for precision on us, the mold designer.

Mandatory Technical Specification Sheet: Before any design work begins, we work with the client to complete a comprehensive checklist. This sheet covers every critical parameter, including:

- Product Name and Type

- Product Density / Specific Gravity (g/ml)

- Target Fill Volume (ml)

- Maximum Filling Temperature (°C / °F)

- Target Bottle Weight (g)

- Preform Neck Finish and Weight

- Labeling Type and Area

- Capping Method

Cross-Verification: We don't just take the number and plug it in. We cross-verify it. For a 12 Brix juice, we expect a density around 1.04-1.05. If a client gives us a number that seems unusual, we will ask for clarification or a sample of the product to test ourselves. This diligence prevents errors before they happen.

Density-Adjusted CAD Modeling: As mentioned, our engineers input the density directly into the CAD software. The software then calculates the exact cavity volume needed. This removes any guesswork or manual calculation errors. The volume you see on our final design drawing is the effective volume for your product, not for water.

Clear Communication: We make sure the client understands why we need this information. We explain the science, just as I have in this article. An educated client is the best partner. When they understand that we are designing for their specific product, it builds trust and ensures a smoother project. This is a core part of ensuring our blow mold will fit not just their machine, but their product perfectly.

Don't Forget About Thermal Shrinkage!?

You've accounted for density, but there's one more crucial factor. Hot-filled bottles shrink as they cool. A professional mold designer builds this shrinkage into the mold from the start.

This is another layer of expertise that separates professional mold makers. A hot-fill bottle is filled at a high temperature, typically 85-92°C (185-198°F), and then cools to room temperature. This cooling process causes the PET material itself to contract, resulting in a small but significant reduction in the bottle's internal volume.

A 250ml hot-fill bottle mold is therefore never designed to have a cold-state volume of exactly 250ml. It is intentionally designed to be slightly larger. We call this calculated "extra" volume the shrinkage allowance. We don't just consider the bottle's state in the mold; we engineer for its final state on the retail shelf.

The Science of Shrinkage

The typical volume shrinkage rate for a hot-fill PET bottle is between 0.5% and 1.2%. The exact percentage depends on several factors:

- Bottle Design: Bottles with large, flat panels or complex shapes may shrink differently than simple, round bottles. The presence of vacuum panels is critical.

- Wall Thickness: Thicker walls generally lead to slightly less shrinkage.

- PET Resin Grade: Different heat-set PET resins have slightly different thermal properties and shrinkage characteristics.

- Filling Temperature: The higher the fill temperature, the greater the temperature drop, and thus the more shrinkage will occur.

A skilled mold designer takes all these factors into account. We use a combination of experience and software simulation to predict the precise shrinkage rate for a specific bottle design.

Calculating the Target Mold Volume:

The formula is straightforward:

Target Mold Volume = Final Target Volume / (1 - Shrinkage Rate)

Let's use our 250ml juice bottle as an example. If we predict a shrinkage rate of 1.0% (or 0.01), the calculation would be:

Target Mold Volume = 250 ml / (1 - 0.01) = 250 ml / 0.99 = 252.52 ml

So, we would design the mold cavity to have a volume of 252.5ml when cold. This is not an error. It is a precisely calculated allowance to ensure that after filling and cooling, the final bottle has a perfect 250ml capacity for your product. It's this attention to detail that prevents post-production issues, such as those listed in guides to common PET blow molding defects.

Before Your Next Hot-Fill Project, Ask the Right Questions?

Starting a new project can be daunting. Ensure success by asking potential suppliers one critical question about density and temperature. Their answer will reveal their level of expertise.

A successful project begins with asking the right questions. Before you commit to a mold supplier, you need to be confident they understand the specific challenges of hot-fill packaging. Don't assume they know; make them prove it.

When you evaluate a potential mold manufacturer, please, ask them this directly: "How do you account for my product's density and my specific filling temperature in your mold design process?" If they give you a vague answer, hesitate, or say "we just make it to the volume on the drawing," you should be very cautious. A true expert will welcome this question and provide a confident, detailed answer similar to what I've outlined here. Feel free to contact us to receive a copy of our internal Hot-Fill Project Technical Specification Checklist. It will ensure your next project starts on a foundation of precision and avoids costly mistakes from day one.

Your Pre-Project Checklist

To arm you for your next project, here is a list of essential questions to ask your team internally before you even approach a supplier. Having these answers ready will streamline the entire process.

Internal Project Kick-Off Questions:

- What is the exact specific gravity (density) of our product?

- Who is the contact person in our R&D or Quality department who can confirm this number?

- What is our maximum filling temperature?

- Has our production line been tested to confirm this temperature is stable?

- What is our target net volume to be declared on the label?

- What is the acceptable tolerance (+/- ml or %)?

- What preform are we using?

- Have we confirmed the neck finish and weight are suitable for hot-fill applications? Our guide on choosing neck sizes can help here.

- What are the full specifications of the bottle blowing machine the mold will be used on?

- This includes the brand, model, and number of cavities.

Being prepared with this information transforms your first conversation with a supplier from a vague inquiry into a productive technical discussion. It shows that you are a knowledgeable client and sets a professional tone for the entire project. It ensures that you and your partner are speaking the same language—the language of precision manufacturing.

Conclusion

The most expensive mistake in measuring hot-fill bottle volume is using water as a universal standard. Always use your product's actual density for accurate, cost-effective, and successful production runs.

Article Summary

| Key Concept | The Common Mistake | The Correct Method | Financial Impact of Mistake | Our Professional Solution |

|---|---|---|---|---|

| Volume Measurement | Assuming 1g of water = 1ml for all liquids. | Volume = Mass / Density. Test using the actual product or a liquid of identical density. | Product giveaway, compliance risks (fines, recalls), project delays. | Mandatory inclusion of product density in all design specifications. |

| Density (Specific Gravity) | Ignoring that dissolved solids (sugar) increase liquid density. | Obtaining the exact density from the client's R&D department and using it in all calculations. | Incorrect mold volume, leading to over-filling or under-filling. | Density is a non-negotiable parameter in our CAD software and project checklists. |

| Thermal Shrinkage | Not accounting for the bottle's volume reduction after cooling from a hot-fill temperature. | Calculating the expected shrinkage (0.5%-1.2%) and making the mold cavity slightly larger to compensate. | Final bottle volume is smaller than required, leading to under-filling. | We design the "cold mold" volume to be larger based on a precise shrinkage rate calculation. |

| Project Management | Blaming the mold manufacturer for volume discrepancies found during water-based testing. | Asking the right questions about density and temperature before starting the project. | Wasted time, damaged supplier relationships, and significant opportunity costs. | Proactive communication and educating clients to build a partnership based on technical accuracy. |

Frequently Asked Questions (FAQ)

Q: Where can I find the exact density (specific gravity) of my product?

A: The best source is your product's food technologist or R&D department. They should have this data on file. If that's not available, you can measure it yourself using a lab-grade hydrometer or by carefully weighing a precise volume (e.g., using a 100ml graduated cylinder and a high-precision scale) and then calculating density (Mass/Volume).

Q: How much does a hot-filled PET bottle shrink after cooling?

A: The typical volume shrinkage rate for a PET hot-fill bottle is between 0.5% and 1.2%. The exact rate depends on the bottle's design (especially the vacuum panels), wall thickness, and the specific grade of heat-set PET resin used. A professional mold designer will calculate this for your specific project.

Q: Is there a standard volume tolerance for hot-fill bottles?

A: Yes, a well-designed mould and a stable, controlled blowing process should be able to keep the final bottle volume to within a tolerance of +/- 1% of the target volume. For a 250ml bottle, this would be +/- 2.5ml.

Q: Does this density issue also apply to edible oil bottles?

A: Yes, absolutely. In fact, it's the reverse situation. Edible oils are less dense than water (typically 0.91-0.93 g/ml). If you use water to test an oil bottle mould, the measured volume will be significantly lower than the true volume. The principle is exactly the same: always test with your actual product or a liquid with the same density.

Q: What is the most critical piece of information I need to provide for a new hot-fill mould project?

A: There are two equally critical pieces of information that form the foundation of the entire design: 1) Your product's exact density (specific gravity), and 2) Your maximum filling temperature. Without these two parameters, any design is just a guess.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr