Do you feel that the traditional bottle market is becoming increasingly competitive, with profits getting thinner by the day? Are you struggling to find new growth opportunities? Perhaps the answer is hiding in plain sight, on the street corner you pass every day, held in the hands of young consumers.

A massive, high-profit market for PET bottles is quietly booming within the milk tea and new-style beverage industry. These shops have a soaring demand for custom, small-batch, high-value bottles, creating a brand-new blue ocean market for bottle manufacturers who can offer flexible and innovative solutions.

Over the past few years, I've witnessed the power of this revolution firsthand. I have a client who started in a small workshop with just two semi-automatic blow molding machines, supplying one or two local milk tea shops. Today, he owns over 30 fully automatic machines. He's not only a top PET bottle supplier on major Chinese e-commerce platforms like Taobao and JD.com, but his sales on Amazon are also outstanding. His secret to success was capturing this market that traditional manufacturers had overlooked. He stopped fighting price wars with large water and beverage plants and instead focused on meeting the needs of these emerging, personalized shops. This article is about sharing his blueprint for success and the enormous opportunity this market represents for you.

A Quiet Revolution: The Shift from Disposable Cups to Custom Bottles?

Walk through any bustling commercial district, and you'll notice a fascinating phenomenon. Young people are no longer just carrying standard plastic or paper cups with a logo. Instead, you'll see a variety of uniquely shaped, beautifully designed bottles—bears, ducks, miniature water jugs. This isn't just a packaging upgrade; it's a revolution in the consumer experience.

This shift from disposable cups to branded, custom bottles has already gathered into a powerful market force. A popular tea shop chain's daily bottle consumption can rival that of a small mineral water plant. Have you recognized this powerful undercurrent?

For those of us in the bottle manufacturing industry, our traditional mindset is geared towards serving massive clients—bottled water plants or large beverage companies that place orders in the hundreds of thousands or millions. We are accustomed to standardized bottle shapes, huge order volumes, and razor-thin unit profits. However, the times have changed.

Redefining the "Big Customer"

The very definition of a "big customer" is being rewritten. Let's do the math. A popular milk tea shop can easily sell 500 drinks a day. If it's a chain with 100 stores, that's a daily demand of 50,000 bottles. That's 1.5 million bottles a month. Annually, that's nearly 20 million bottles. This figure already surpasses the yearly demand of many small to medium-sized bottled water brands.

More importantly, this is just the volume of a single brand. Globally, especially in Asia and North America, thousands of such milk tea brands, juice bars, and coffee shops are emerging. Together, they form a "decentralized" but massive market. They don't have a central purchasing department like Coca-Cola; instead, they are a huge network of countless independent decision-makers.

The table below clearly illustrates the difference between the traditional and emerging markets:

| Characteristic | Traditional Beverage Bottle Market (Water/Large Beverage Plants) | Emerging Tea Drink Bottle Market (Milk Tea Shops/Juice Bars) |

|---|---|---|

| Customer Structure | Centralized, a few large clients | Decentralized, thousands of small to medium clients |

| Order Volume | Massive (Millions per order) | Flexible (Thousands to tens of thousands per order) |

| Design Needs | Standardized, unchanged for years | Highly customized, frequent updates (Quarterly/Monthly) |

| Profit Margin | Extremely low (Cents per unit) | High (Dimes per unit) |

| Core Competency | Scale of production, cost control | Creative design, rapid response, flexible manufacturing |

My successful client was one of the first to have this insight. He told me that when he started, many of his peers laughed at him for "picking up sesame seeds while ignoring the watermelon," meaning he was chasing small-time tea shops instead of big water plants. But as it turned out, these "sesame seeds," when gathered together, were not just a watermelon but an entire, fertile melon patch. He avoided the brutal price wars and built his core competency in a completely new dimension. As bottle manufacturers, we have to ask ourselves: are we, by clinging to tradition, walking right past our next, and perhaps even better, big customer?

The Power of "Social Currency": Why a Photogenic Bottle Sells Itself?

In today's business environment, the best advertising isn't bought; it's created willingly by users. Milk tea shop owners understand this better than anyone. Why would they pay more for a unique bottle instead of a standard cup? The answer is: social currency.

In the age of TikTok, Instagram, and Facebook, a uniquely designed bottle is the most powerful marketing tool in itself. It elevates a simple drink from a "thirst quencher" to "social currency," generating a continuous stream of free exposure and user growth for the brand.

"Social currency" refers to the information people share to build their desired image among their social circles. When a consumer buys a cute bear-shaped milk tea, they are purchasing more than just a beverage; they are buying an opportunity to project an image of being "fun," "cute," and "trendy" on their social feeds. Every photo they post, every short video they share, is a highly trusted, precisely targeted, and completely free advertisement for that milk tea brand.

Turning Product into Content

Traditional marketing follows a "Product → Ad → Consumer" model. The new tea drink marketing model is "Product (as Content) → Consumer → Social Sharing → More Consumers." The core of this model is to embed content attributes into the packaging itself. A photogenic bottle serves several key functions:

- Turns Consumption into an Experience: It transforms the simple act of "drinking milk tea" into a complete experience involving visual delight, tactile sensation, and the joy of sharing.

- Turns Product into a Prop: The bottle becomes a fashion accessory for selfies and styled photos, much like a handbag or a piece of jewelry.

- Turns Customers into Fans: When consumers repeatedly purchase because they love the bottle, or even start collecting different styles, they transition from ordinary customers to loyal fans of the brand.

My client understands this deeply. What he provides to his milk tea shop customers has never been just a plastic bottle. He provides the "potential for the next viral hit." He has a dedicated design team that studies social media trends daily and translates them into designs for new blow bottle molds. His clients are willing to pay a higher unit price because they know this money is not just a packaging cost but a marketing investment with an incredibly high return.

Let's look at just how high that return can be:

| Marketing Method | Cost | Reach | Trust Level | Duration |

|---|---|---|---|---|

| Traditional Flyers | High (Printing + Distribution) | Limited, passive reception | Low | Short-term |

| Paid Social Media Ads | Very High (Pay-per-click/impression) | Controllable, but users are often wary | Medium | Effective only while paying |

| Custom "Social Currency" Bottle | Medium (Mold R&D + slightly higher unit cost) | Viral potential, unlimited | Very High (Peer recommendation) | Continuous as long as the bottle is seen |

The evidence is clear: the brand exposure value generated by a successful bottle design far exceeds its incremental cost. This is precisely why a photogenic bottle sells itself—it harnesses the most powerful growth engine in the world today: social sharing.

Beyond Looks: Are There Practical Drivers of the PET Bottle Trend?

If "high visual appeal" is the external allure that attracts consumers to milk tea bottles, then their intrinsic practical functions are the fundamental reason why merchants are committed to them. This is especially true today, when food delivery has become a mainstay of the restaurant industry, where the advantages of PET bottles are overwhelming.

A securely sealed PET bottle perfectly solves the biggest pain point in the food delivery scene: spills. The resulting improvements in hygiene, safety, and perceived value are the powerful pragmatic drivers behind this trend, and they are far more important than just looks.

A few years ago, the biggest worry when ordering milk tea for delivery was that it would arrive half-spilled. The thin film seals on cups are notoriously fragile during a bumpy ride. One bad review, one messy experience, and a customer could be lost forever. The advent of the PET bottle has fundamentally solved this problem.

The Packaging Solution Born for Delivery

- Superior Sealing: A PET bottle with a screw-on cap can be 100% leak-proof. Whether it's shaken vigorously or accidentally tipped over, it ensures not a single drop is spilled. For businesses that rely on third-party delivery platforms, this is a lifeline for maintaining service quality.

- Standardization Advantage: Bottles have standardized heights and diameters, making them easy to pack for delivery and for couriers to stack, significantly improving efficiency.

- Better Insulation: Compared to thin plastic cups, the thicker walls of a PET bottle provide better insulation, helping to maintain the drink's optimal temperature for longer.

Enhancing Consumer Trust and Experience

Beyond functionality, PET bottles also play a crucial psychological role for consumers.

- Hygiene and a Sense of Security: A completely sealed, first-time-opened bottle gives consumers a strong sense of being "untouched," hygienic, and safe. In the post-pandemic era, this trust has become invaluable. Consumers are willing to pay a premium for this peace of mind.

- Increased Perceived Value: The feel and weight of a well-designed bottle in hand are far superior to a flimsy plastic cup. It significantly enhances the product's perceived value. A drink that sells for $5 in a plain cup can easily be sold for $7 when packaged in a unique bottle. The extra $2 in profit far outweighs the increased cost of the bottle itself. We have a detailed PET bottle mold design guide that can help brands create high-value bottle shapes from scratch.

My client shared a story with me. When he first convinced a regional milk tea chain to switch their packaging, he didn't focus on how cute the bottles were. Instead, he did the math for the owner: he calculated the monthly losses from bad reviews, refunds, and lost customers due to delivery spills. Then, he showed how switching to PET bottles would not only eliminate these losses but also allow for a price increase due to the upgraded image, leading to higher profits. In the end, it was this pragmatic, bottom-line calculation that made the owner commit. Visual appeal is the trigger, but practicality is the solid foundation that allows this trend to persist and proliferate.

The "Hidden Factory": How to Size Up the Milk Tea Bottle Market?

Unlike the traditional beverage market, which is dominated by a few giants, the new-style tea market is a classic "ant market." Thousands of independent brands, regional chains, and mom-and-pop shops collectively form a demand network that is seemingly fragmented but massive in total volume. For bottle manufacturers, this is both a challenge and an opportunity.

The milk tea bottle market is a decentralized network of countless small businesses whose combined demand forms a massive "hidden factory." This market requires novelty in design and flexible, smaller batch orders, creating an unprecedented opportunity for responsive, regional producers.

Large bottle manufacturers thrive on scale. Their production lines are designed to produce millions of a single bottle type at a time. Asking them to produce 5,000 bear-shaped bottles for one tea shop, then change molds to produce 8,000 duck-shaped bottles for another, is economically and operationally unfeasible. Their machinery and business model are simply not built for this market.

This leaves a huge space for small to medium-sized, more agile bottle producers to thrive. My client's rise to success is built on his deep understanding of this market structure. He positioned his factory as the "shared production workshop" for these emerging brands.

The Unique Demands of This Market

- Low MOQ, High Frequency: Tea shops typically lack large warehouses for storing packaging. They need a supply model with a low minimum order quantity (starting from a few thousand) but with the need for frequent reordering, perhaps monthly.

- Fast Design Iteration: To maintain market freshness, tea brands need to constantly introduce new bottle shapes, especially for holidays or seasonal promotions. This means their bottle supplier must have strong capabilities for rapid development and changeover of blow bottle molds.

- One-Stop Solution: Many tea shop owners lack professional expertise in packaging development. They need a supplier who can not only produce but also provide design suggestions, 3D prototypes, and even recommend partners for caps and labels. A supplier who can offer 3D printed sample services to quickly validate designs will have a significant competitive edge.

How to Serve This Market?

To succeed in this market, producers need to adjust their operational model.

| Operational Aspect | Traditional Model (Serving Giants) | Emerging Model (Serving Tea Shops) |

|---|---|---|

| Equipment Investment | Large, high-cavity, high-speed fully automatic bottle blowing machines | Flexible semi-automatic machines, small-cavity fully automatic machines |

| Core Competency | Cost control, production efficiency | Fast mold changes, design conversion, customer service |

| Sales Model | Bidding, key account sales | Online marketing, regional sales, consultative selling |

| Inventory Strategy | Make-to-order, minimal finished goods stock | May require holding some safety stock for key clients' popular designs |

My client built his "hidden factory" on this very model. He has a design and mold-making team of over 20 people who develop more than 200 new sets of molds each year. His workshop houses both semi-automatic machines for ultra-small batches and complex shapes, as well as small-cavity fully automatic lines for stable production of hit designs. He offers his clients a full service, from an idea to the final product. He told me, "I don't sell bottles. I sell solutions that help tea shop owners grow their business." This shift in mindset is the key to capturing this "hidden market."

What Are the Key Design Trends: Cuteness, Nostalgia, and Miniaturization?

In this visually-driven market, what kind of bottle designs are most effective at capturing consumers' hearts? By analyzing the viral hits on social media over the past few years, we can clearly identify several major design trends. For producers hoping to enter this space, understanding these trends is crucial.

From adorable animal shapes to miniaturized replicas of everyday objects and collaborations with pop culture icons, the core of milk tea bottle design trends is about creating an emotional connection and a sense of novelty. These designs don't just make the product stand out; they make it a story worth sharing.

My client's mold workshop is like a trend barometer. The 200+ new molds he develops each year are almost all centered around the following themes.

Trend 1: Adorable Animals

This is the most timeless and consistently successful direction. Cute animal figures can transcend cultural and age barriers to directly trigger positive emotions.

- Bearbrick-style Bears: Combining the silhouette of trendy designer toys with a bottle creates an item that is both cute and fashionable.

- Ducks: A round, charmingly simple shape that is incredibly endearing, especially to female and younger consumers.

- Cats/Paws: The "cute factor" of cats is a reliable currency on the internet. Bottles shaped like cat heads or paws are always a source of buzz.

- Other Animals: Rabbits, pigs, elephants—any animal with distinct and lovable features can be an inspiration.

Trend 2: Miniature Icons

The genius of this trend lies in leveraging people's familiarity with common objects and creating a sense of novelty and fun by "shrinking" them.

- Mini Water Cooler Jugs: This has been one of the hottest shapes in recent years. It takes the familiar office water cooler jug and scales it down, creating a delightful contrast when filled with milk tea.

- Mini Milk Cartons: Mimicking the classic gable-top milk carton evokes a sense of childhood nostalgia.

- Retro Lightbulbs/Cola Bottles: PET versions of objects with vintage appeal, like old-fashioned lightbulbs or classic glass soda bottles, cater to the current retro trend.

- Mini Gas Canisters/Fire Extinguishers: These bolder designs create strong visual impact and conversation by making industrial objects cute and small.

Trend 3: Pop Culture & Co-Branding

This is the most advanced play, leveraging the power of existing, strong intellectual properties (IP) to create a 1+1>2 effect.

- Cartoon/Anime IP Collaborations: Partnering with well-known characters (like Pokémon or SpongeBob) to launch limited-edition bottles can instantly attract the IP's fanbase, leading to frenzied buying and collecting.

- Artist/Designer Collaborations: Working with local or internet-famous artists to apply their signature style to a bottle can elevate the brand's artistic and cultural appeal.

- Holiday Exclusives: Creating bottles with festive elements for Christmas (snowmen), Halloween (pumpkins), or Valentine's Day (hearts) creates scarcity and drives short-term sales.

The table below summarizes the core strategy behind these design trends:

| Design Trend | Core Strategy | Consumer Psychology | Best Use Case |

|---|---|---|---|

| Adorable Animals | Emotional Trigger | Healing, cute, lovable | Everyday sales, targeting female market |

| Miniature Icons | Familiarity + Novelty | Nostalgia, fun, surprising contrast | Creating buzz, social media promotion |

| Pop Culture | Leverage Existing Equity | Sense of belonging, collectibility, fandom | Limited-time offers, brand collaborations |

Understanding and applying these design trends is the key for a bottle manufacturer to transform from a passive processor into a proactive partner who creates value for their clients.

What is the Investment Blueprint for Supplying This Market?

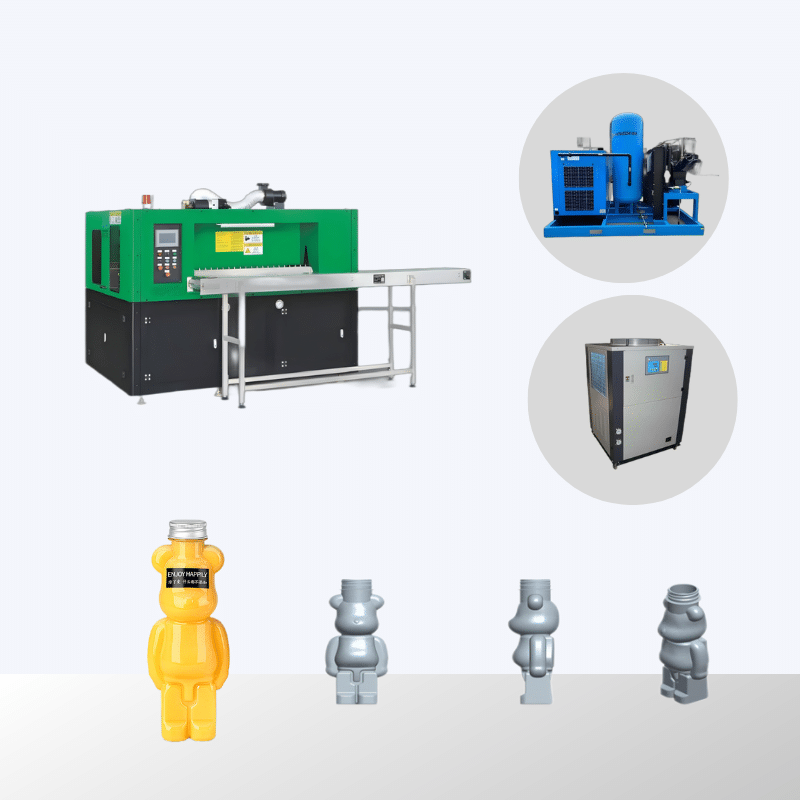

After understanding the immense potential and key trends of this market, the most practical questions arise: as a potential investor or an existing bottle manufacturer, how do you get started? What equipment is needed? What is the core competitive advantage? And what does the profit model look like?

The ideal starting point for entering the milk tea bottle market is a flexible semi-automatic or small-cavity fully automatic blow molding machine. The core competitive advantage lies in the ability to develop custom molds quickly and with high quality, while profitability comes from the significantly higher per-unit margins of high-value bottles compared to standard ones.

Based on my client's growth path from 2 to 30 machines, I will outline a practical investment blueprint for you.

Step 1: Choose the Right Machine

Your first piece of equipment will define your ability to serve this market. You don't need the biggest or fastest machine; you need the most flexible one.

- Semi-Automatic Blow Molding Machine: This is the lowest-cost entry option.

- Pros: Low initial investment, extremely fast mold changeovers (often just 30 minutes), capable of blowing complex and irregular shapes, small footprint.

- Cons: Low output, requires more manual labor, with one operator producing about 300-600 bottles per hour.

- Best for: Start-ups, serving clients with very small orders (hundreds to a couple of thousand), or for developing and testing new molds.

- Small-Cavity Fully Automatic Machine (2-4 Cavities): This is the best choice for balancing scale and flexibility.

- Pros: High level of automation, consistent product quality, moderate output (a 2-cavity machine produces about 1,500-2,000 BPH), still maintains relatively fast mold changes compared to larger machines.

- Cons: Higher initial investment than a semi-automatic.

- Best for: Growth-stage businesses with stable clients and order volumes in the thousands to tens of thousands. Most of my client's machines are 4-cavity automatics.

The choice of which bottle blowing machine to buy depends on your starting capital and target clients. A prudent strategy might be to start with a semi-automatic machine and add a fully automatic one once you secure stable, larger orders.

Step 2: Build Your Core Competency (The Mold)

In this market, the machine is just the ticket to enter; your custom mold design and manufacturing capability is your true competitive moat.

The development process typically looks like this:

- Concept & Communication: The tea shop owner comes to you with an idea—perhaps a sketch or a picture they found online.

- Professional Design: Your design team translates this into a professional 3D model, considering the feasibility of the blow molding process. Our detailed PET bottle mold design guide can serve as a reference for your team.

- Rapid Prototyping: Use 3D printing to create a 1:1 scale model. This allows the client to see and feel the bottle's shape and size and request revisions.

- Mold Manufacturing: Once the prototype is approved, use high-precision CNC machines to craft the mold.

- Testing & Optimization: Test the new mold on your own blow molding machine, fine-tuning the process parameters until you can consistently produce perfect bottles.

This process requires expertise and investment, but once established, it will be your strongest weapon against competitors.

Step 3: Understand the Profit Model

The profit model for this market is completely different from the traditional one.

| Cost/Revenue Item | Standard 500ml Water Bottle | Custom 500ml Bear Bottle |

|---|---|---|

| Preform Cost | Approx. $0.03 | Approx. $0.04 (May be heavier) |

| Production Cost (Energy/Labor) | Approx. $0.005 | Approx. $0.01 (Slower cycle) |

| Total Cost | Approx. $0.035 | Approx. $0.05 |

| Selling Price | Approx. $0.045 - $0.05 | Approx. $0.15 - $0.25 |

| Gross Profit Per Unit | $0.01 - $0.015 | $0.10 - $0.20 |

| Profit Margin | Approx. 20-30% | Approx. 200-400% |

Note: The figures above are estimates to illustrate the model difference.

It is clear that while the absolute cost of a custom bottle is higher, its selling price and profit margin are in a different league from standard bottles. You are no longer selling the PET plastic itself; you are selling design, creativity, and marketing value. This is the fundamental reason why my client was able to grow from a small, obscure workshop into an industry leader with 30 automatic machines in just a few years.

What's Next for Retail Beverage Packaging?

The explosion in popularity of milk tea bottles is just the tip of the iceberg. It reveals a much larger trend: in the retail sector, packaging is transforming from a cost center into a core part of the brand experience and a key driver of marketing. So, after seizing the current opportunity, what future directions should we be watching?

Sustainability (eco-friendly materials), expansion into more retail sectors, and deeper levels of personalization will define the future of retail beverage packaging. Producers who can strategically position themselves in these three areas will lead the next wave of competition.

Direction 1: Sustainability

As global consumer awareness of environmental issues grows, so does the demand for sustainable packaging.

- Recycled PET (rPET): This is the most viable eco-friendly option currently available. Using rPET not only reduces reliance on virgin plastics but also serves as a powerful marketing story for brands. Modern technology can produce food-grade rPET bottles with clarity and safety comparable to virgin PET.

- Bio-plastics: Although currently more expensive, plant-derived materials like PLA (Polylactic Acid) are gaining attention due to their compostable properties.

- Light-weighting: Optimizing PET bottle mold design to reduce the amount of material in each bottle without compromising performance is another important eco-friendly measure.

Being able to offer clients reliable and compliant green material options will become a significant competitive advantage.

Direction 2: Expansion to Other Sectors

The "high-value packaging" model proven by milk tea shops is being rapidly adopted by other retail beverage industries.

- Coffee Shops: A growing number of specialty coffee shops are launching bottled cold brew and ready-to-drink lattes. They often use amber-colored PET bottles that mimic beer or apothecary bottles to create a professional and vintage feel.

- Fresh Juice Bars: The vibrant colors of juice are best showcased in high-clarity PET. Simple, elegant shapes or bottles that mimic the shape of fruits are very popular.

- Bakeries/Dessert Shops: Bottled yogurts, puddings, and milkshakes are also adopting custom bottles as an extension of their takeaway and retail business.

- Cocktail Bars: The market for pre-mixed cocktails-to-go is emerging, and unique bottle designs allow consumers to enjoy a sophisticated bar experience at home.

For bottle manufacturers, this means your potential customer base extends far beyond tea shops. The design and production expertise you build today can be applied to a much broader retail market tomorrow.

Direction 3: Deep Personalization

If today's customization is "for the brand," the future trend will be "for the event and the individual."

- Event-Specific Editions: Launching exclusive, limited-edition bottle shapes for local music festivals, sporting events, or comic conventions can generate immense market excitement.

- Corporate/Wedding Customization: Providing bottles with special logos or dates for corporate events, brand launches, or private weddings as party favors or on-site beverages.

- On-Demand Production: With advancements in digital printing and more flexible manufacturing technologies, the future may even hold the possibility of on-demand customization for even smaller batches, catering to highly niche personalization needs.

The future of retail beverage packaging is filled with limitless imagination. It is evolving from an industrial, standardized field into a creative industry deeply integrated with fashion, culture, and emotion.

Conclusion: Your Next Big Customer is Waiting

We started with a quiet revolution, explored the power of social currency, analyzed the market's true demand and design trends, and outlined an investment blueprint and future outlook. Now, the conclusion is crystal clear.

The milk tea industry is just the beginning; it signals a larger shift across the entire retail landscape towards brand-driven, visually-centric packaging. Those bottle manufacturers who can offer creative design, flexible production, and high-quality products will undoubtedly win this new blue ocean market.

My client's success story is not an unrepeatable miracle but a roadmap that can be followed. He proved that by focusing on this overlooked niche, a small workshop can absolutely grow into an industry leader.

This opportunity is now in front of you. Thousands of milk tea shops, coffee shops, and juice bars are looking for a packaging partner to help them stand out. They are your next big customer, and they are waiting.

Contact us today to explore how our versatile blow molding solutions can position you as a key supplier in this exciting new blue ocean.

Frequently Asked Questions (FAQ)

1. For a startup aiming to supply various milk tea shops, what is the best type of blow molding machine to invest in?

For a startup, flexibility is king. I strongly recommend starting with a high-quality semi-automatic blow molding machine. It has the lowest initial investment, allows for extremely fast mold changes, and can handle a wide variety of complex shapes and small batch orders (from a few hundred to a few thousand). This enables you to serve multiple clients with minimal risk and respond quickly to their changing design needs. Once you have a few stable clients with order volumes in the tens of thousands, investing in a 2-cavity or 4-cavity fully automatic machine is the most robust growth path.

2. How much does a custom mold for a unique shape (like a mini water cooler) typically cost, and what is the lead time from design to production?

This is a core question. Mold cost and lead time depend on the bottle's complexity, size, and the number of cavities. A typical single-cavity blow bottle mold for a unique shape will cost roughly between $1,500 and $4,000 USD. The timeline for the entire process is as follows:

- Design & Confirmation (3-5 days): Includes 3D modeling and revisions.

- 3D Printed Sample (1-2 days): For physical approval.

- Mold Machining (15-20 days): This is the most time-consuming part.

- Mold Testing & Adjustment (1-2 days):

Overall, a realistic expectation from a confirmed design to the start of mass production is approximately 20 to 28 days.

3. What is a realistic minimum order quantity (MOQ) for custom bottles from a typical tea shop, and how should a producer plan for this?

A tea shop's MOQ is typically far lower than a traditional beverage plant's. In our experience, a realistic MOQ ranges from 3,000 to 10,000 units. For highly unique shapes, some clients might even want to test the market with as few as 1,000 units. As a producer, your planning should include:

- Tiered Pricing: Set up a pricing structure for different order volumes to encourage clients to order larger batches.

- Production Scheduling: Group orders with similar materials and weights together to reduce the time spent on raw material changes and machine adjustments.

- Inventory Management: For popular "public mold" creative shapes (like a generic bear bottle), consider keeping a small amount of stock to meet urgent client needs. For clients' private molds, produce strictly to order.

4. Are there any special food-grade certifications or material requirements for PET bottles that will contain milk, tea, and acidic fruit ingredients?

Absolutely, and this is a non-negotiable red line. All PET material used for beverage packaging must be 100% virgin food-grade PET. You must request and verify the relevant food safety certifications from your preform supplier, such as FDA or EU compliance documents. For beverages containing milk or highly acidic ingredients (like lemon), standard food-grade PET is generally sufficient and safe. However, communicating clearly with your clients and guaranteeing the use of high-quality, unadulterated raw materials is key to building long-term trust. Never compromise on material safety for a marginal cost saving.

5. With growing environmental concerns, are there viable recycled PET (rPET) or other eco-friendly options for these trendy milk tea bottles?

This is a very forward-thinking question. The answer is yes, and rPET (recycled PET) is the most mature and viable eco-friendly solution at present.

- Viability: Modern recycling and cleaning technologies can produce food-grade rPET that is nearly indistinguishable from virgin PET in terms of clarity and safety.

- Market Acceptance: A growing number of consumers are willing to pay a premium for brands that use sustainable materials. Marking a bottle with "This bottle is made from 100% rPET" is a powerful marketing point in itself.

- Challenges: The cost of rPET may currently be slightly higher than virgin PET, and it requires finding a stable, certified supplier of rPET preforms.

As a producer, proactively introducing and offering rPET options to your clients will not only meet future market trends but also position you as a socially responsible and forward-thinking supplier.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr