Thinking of entering the large-format bottled water market, but feeling overwhelmed by complex designs, endless raw material specifications, and expensive equipment? A single wrong decision can lead to cost overruns and market failure, wasting your investment.

This guide provides a complete A-to-Z roadmap. We'll dive deep into the design principles for 10L bottles, how to precisely select preforms (weight, neck, color) and caps, and the correct specifications for a supporting production line, complete with a cost calculation tool to help you launch successfully in this rapidly growing market.

In recent years, as living standards have improved, so have demands for the quality and convenience of drinking water. This trend is unmistakable; this year alone, my team has produced and delivered around 20 complete production lines for 10L to 15L water bottles. Just last month, we successfully completed the installation and commissioning of another 10-liter water bottle line in Thailand. From the initial bottle design to the selection of the blow molding machine and auxiliary equipment, and the final confirmation of preform and cap specifications, we worked hand-in-hand with the client, ensuring every detail was perfectly executed.

I know from experience that for entrepreneurs or companies looking to expand their product lines, the key design points of a 10L bottle and the complex specifications of its preforms are often blind spots. Today, I want to share our experience through this article, providing a comprehensive, clear, and actionable guide for anyone looking to enter this field.

The Market Shift: Why Consumers are Choosing 10L Single-Use PET Kegs?

Have you noticed a new type of 10L large-format water bottle quietly appearing on supermarket shelves and in household corners? This is no accident. Compared to traditional, returnable PC water coolers, consumers are increasingly favoring single-use PET kegs. This reflects a profound shift in consumer psychology leading into 2025.

This shift isn't caused by a single factor but is the result of three key driving forces: hygiene, convenience, and aesthetics. For an entrepreneur, understanding these underlying reasons is the first step to seizing the market opportunity and the foundation of your product positioning and marketing strategy.

Hygiene Assurance: The Core Advantage of Single-Use Packaging

"Cleanliness" is the number one requirement for drinking water. Traditional PC kegs require collection, cleaning, and disinfection. Any oversight in this process can lead to secondary contamination, a persistent doubt in the consumer's mind. In contrast, a single-use PET keg is sealed at the factory and is brand new every time it's opened. This "single-use" nature directly translates to "hygiene assurance." In the wake of global public health events, consumer focus on health and safety has reached an unprecedented high. If your product can directly address this need for security, you've already won a significant measure of consumer trust.

Convenience: A Perfect Fit for the Modern Lifestyle

Urban living spaces are becoming more compact. For small families, single residents, or modern offices, a traditional 18.9L keg is not only heavy and cumbersome but often leads to the water inside becoming stale before it's finished. The 10L capacity is the perfect compromise. It's easier to carry, requires less storage space, and can be consumed within an ideal timeframe of about a week, ensuring freshness. This "just right" convenience precisely fills the market gap between large, bulky kegs and small, individual bottles, meeting the specific needs of modern life.

Aesthetic Perception: The Visual Revolution of PET Material

Never underestimate the power of "shelf appeal." High-quality PET material has a crystal-clear, brilliant appearance that far surpasses the often-scuffed and dated look of PC kegs. When pure water is housed in a highly transparent bottle, the light shining through enhances the psychological perception of "purity, safety, and high quality." A well-designed PET bottle shape is a silent advertisement in itself, capable of capturing a consumer's attention on the shelf instantly. A transparent light-blue tint can further give the water a cooler, more refreshing visual feel, boosting its appeal.

| Driving Force | Core Consumer Pain Point | The 10L PET Keg Solution |

|---|---|---|

| Hygiene Assurance | Worry that recycled kegs are not cleaned thoroughly, posing a risk of contamination. | Single-use eliminates cross-contamination, offering the highest level of sanitary confidence. |

| Convenience | Traditional large kegs are too heavy; water isn't consumed quickly enough in smaller households. | A manageable size that is easy to carry and store, ensuring water is consumed while fresh. |

| Aesthetic Perception | PC kegs look dated and fail to convey the high quality of the water inside. | Crystal-clear PET material and modern bottle designs enhance the perception of "purity" and product value. |

Part 1: Bottle Design – Balancing Aesthetics, Strength, and Lightweighting

A successful 10L bottle design is not just a scaled-up version of a small bottle. It is a precise engineering compromise between aesthetics, structural mechanics, and cost control. The thought you put into the design phase will directly determine your product's shelf appeal, its damage rate during shipping, and most importantly, your production cost per bottle.

We break the design process down into three core pillars: strength, ergonomics, and lightweighting. These three elements are interconnected and form the foundation of an excellent bottle.

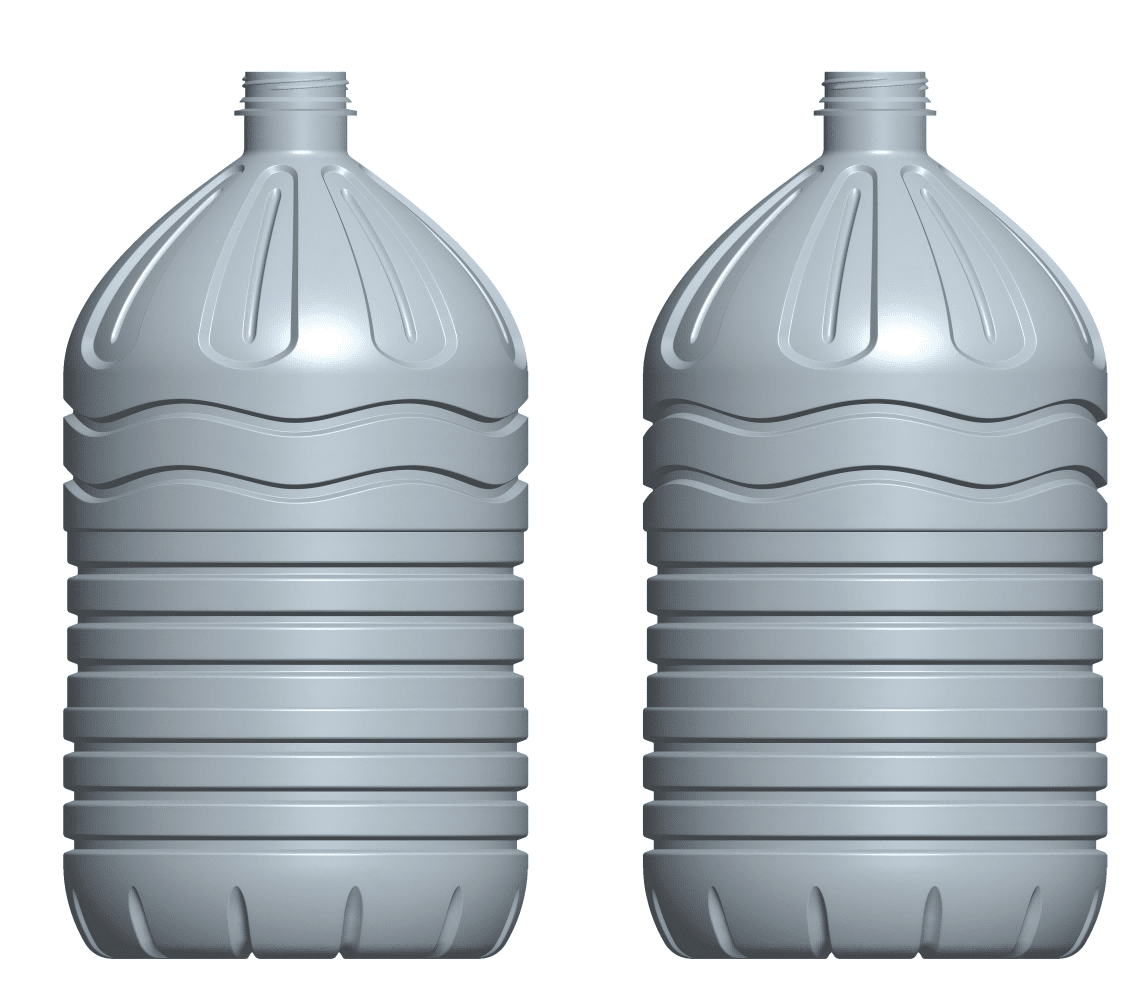

Strength and Stability: The Key to Stacking and Shipping

A 10L bottle, when full, weighs 10 kilograms (22 lbs). During warehousing and transport, it's common to stack them 3 to 4 layers high. This means the bottom bottle must withstand over 30 kg (66 lbs) of vertical pressure, or top-load. If the bottle's structure is not strong enough, it will deform or even burst, leading to significant financial loss.

- Reinforcing Ribs: The ring-shaped or vertical ribs on the bottle's body are a critical design feature. They act like the load-bearing beams of a building, dramatically increasing the bottle's structural integrity and top-load strength. The shape, number, and distribution of these ribs must be precisely calculated to achieve maximum support with minimal material.

- Stable Base: The design of the base is equally important. A flat or specially grooved base (like a petaloid base) increases the bottle's standing stability, preventing it from wobbling or tipping over easily on conveyor belts or shelves. An unstable bottle is a disaster on an automated filling line.

Ergonomics: The Science of the Handle

The handle is the part of your product that consumers will physically interact with most frequently. Its user experience directly impacts brand loyalty. A poorly designed handle—too thin, too hard, with sharp edges from the molding process—will make carrying the bottle uncomfortable, or even painful.

- Integrated Handle: For 10L kegs, an integrated handle that is part of the bottle body is the best choice. This means the handle is formed along with the bottle during the blow molding process. The challenge lies in precisely designing the handle's shape within the blow bottle mold to ensure a comfortable grip while being robust enough to withstand the 10kg weight repeatedly without failing.

- Comfort Testing: Before finalizing the design, creating 1:1 physical models via 3D printed samples for real-world user testing is an absolutely essential step.

Lightweighting: The Core of Cost Control

The preform is the main component of a bottle's cost. Even saving a few grams per preform translates into astonishing cost savings when production runs into the millions. However, lightweighting is not about cutting corners; it's a science.

- Finite Element Analysis (FEA): Modern bottle design relies heavily on FEA software. Engineers create a 3D model of the bottle and simulate the stress distribution when it is subjected to top-load pressure, drops, and internal pressure. This analysis precisely identifies high-stress areas (which need more material) and low-stress areas (where material can be thinned out).

- Intelligent Material Distribution: This intelligent distribution allows us to create a bottle with a lighter preform (e.g., 120g) that has the same strength as one made from a heavier 140g preform. This not only reduces raw material costs but also lowers energy consumption during production. Please note that PET resin prices fluctuate with global oil prices; the table below is for cost analysis illustration only.

| Preform Weight | Example Preform Cost Range | Example Savings per 1 Million Bottles |

|---|---|---|

| 130 grams | $0.16 - $0.21 | Baseline |

| 120 grams | $0.15 - $0.18 | $20,000 - $30,000 |

Part 2: Preform Selection – Choosing the Right Weight, Neck, and Color

If the bottle design is the "blueprint," the preform is the "DNA." Every parameter of the preform directly dictates the performance and appearance of the final blown bottle. Choosing the wrong preform will yield poor results, even with the best blow molding machine and mold. When you communicate with your preform supplier, you must clearly and accurately provide the following four key specifications.

These four parameters—weight, neck finish, color, and material grade—collectively define a preform. There is no absolute "best," only what is most suitable for your specific product and equipment.

1. Weight

The weight of the preform, or grammage, directly correlates to the thickness and strength of the bottle. For a 10L container, the preform weight typically ranges from 120 grams to 150 grams.

- 120-130g: This is a relatively lightweight option. The advantage is lower raw material cost, but it places extremely high demands on the bottle design and blowing process. The lack of weight must be compensated for with a superior structural design (as mentioned with reinforcing ribs and FEA), otherwise, strength issues are likely.

- 140-150g: This is a safer, more common choice. A heavier preform means thicker walls, providing better top-load strength and impact resistance. The blowing process is also more forgiving. For startups, I usually recommend starting with a slightly heavier preform to ensure stable product quality.

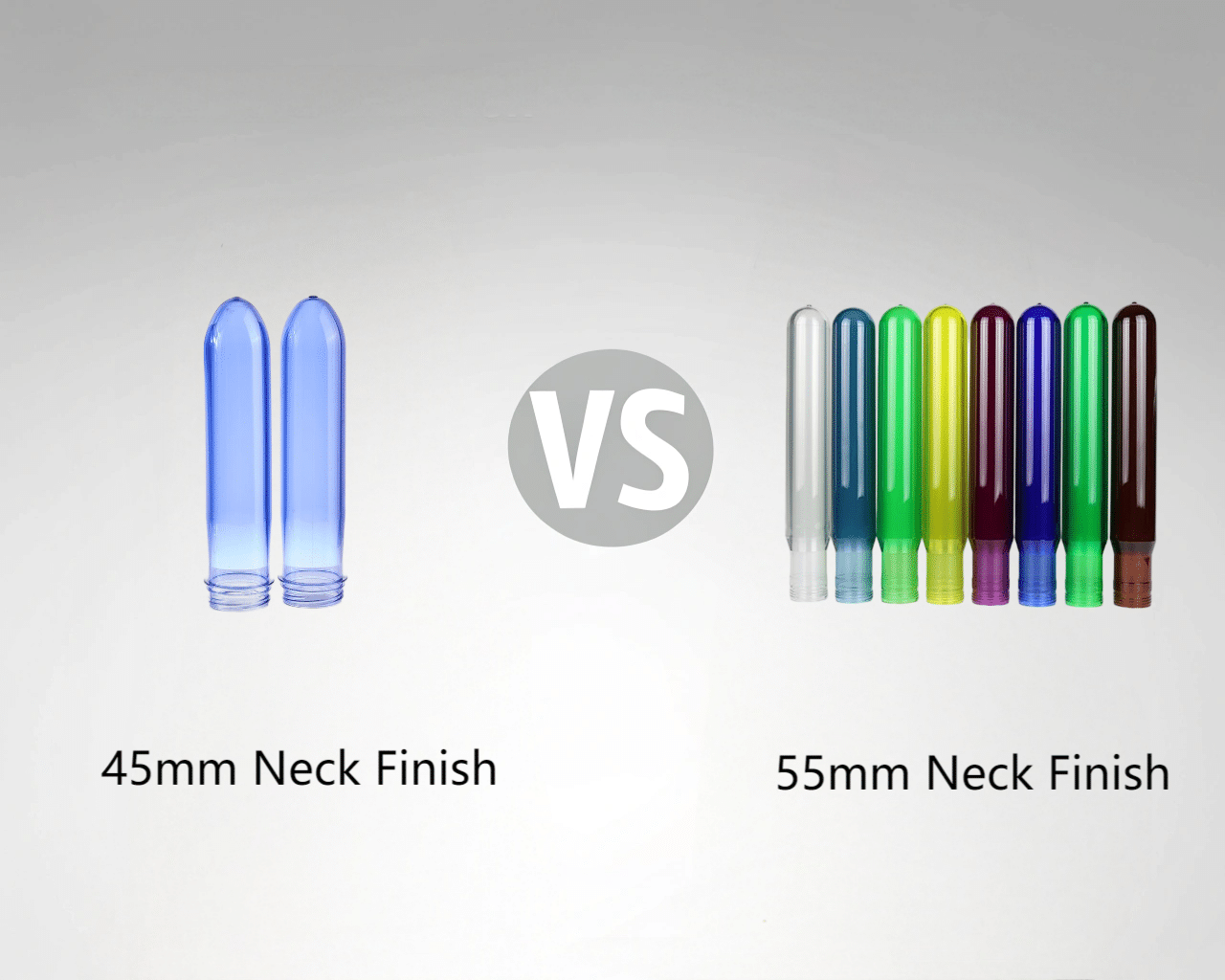

2. Neck Finish

The neck finish of the bottle determines which caps it can be paired with and also affects the ease of pouring. For 10L kegs, the most mainstream neck finishes are 45mm and 55mm.

- 45mm: A fairly common choice with a wide variety of compatible caps available at a competitive cost.

- 55mm: A larger opening makes filling and pouring faster and easier, improving the consumer experience. The larger contact area also provides a stronger seal and better support for the cap. When making a choice, be sure to consult our guide on choosing the right preform neck size and consider the dominant water cooler interfaces or cap types in your target market.

3. Color

Color is a direct factor in a consumer's purchasing decision.

- Clear: The purest choice, showcasing the clarity of the water and conveying a sense of "additive-free, safe" confidence.

- Transparent Blue: One of the most popular colors on the market. A light blue tint gives the water a purer, cooler, more refreshing visual feel, which is especially popular in hot climates.

4. Material Grade

This point is critical but often overlooked. The PET resin used to make preforms comes in different grades, and a key indicator is Intrinsic Viscosity (IV). A higher IV value means the PET's molecular chains are longer, resulting in better material toughness and strength. For blowing large containers like a 10L bottle, you must use a high IV PET resin (typically between 0.80-0.84 dL/g). Using a low IV resin designed for small bottles will likely cause the preform to tear during the stretching and blowing process, failing to form properly.

| Specification | Options & Considerations | Impact on Final Product |

|---|---|---|

| Weight | 120g - 150g | Directly determines bottle strength, cost, and blowing difficulty. |

| Neck Finish | 45mm, 55mm | Determines compatible cap types, seal integrity, and user experience. |

| Color | Clear, Transparent Blue | Influences aesthetic perception and market positioning. |

| Material Grade (IV) | 0.80 - 0.84 dL/g | Determines if the bottle can be blown successfully and its final physical properties. |

Part 3: Cap Selection – More Than a Seal, It’s About User Experience

The cap is the primary point of interaction between the consumer and your product. Its function goes far beyond simply sealing the bottle; a well-designed cap can significantly enhance the user experience and even become a key differentiator for your product. For 10L kegs, you have three mainstream choices, each corresponding to a different cost and market position.

Your choice of cap should depend on your brand positioning, cost budget, and target customer base.

1. Standard Screw Cap

This is the most basic and cost-effective solution. It consists of a simple screw-on cap and a tamper-evident ring. Its job is to seal.

- Pros: Very low cost, mature technology, stable supply.

- Cons: Single-function, mediocre user experience. The consumer must completely unscrew the cap to pour, which can be awkward with a heavy 10kg keg.

- Best For: Entry-level or economy-focused products where cost control is the absolute priority.

2. Cap with Integrated Handle

This cap integrates a sturdy handle onto a standard screw cap. It solves the handling problem for bottles that do not have a built-in handle or have a poorly designed one.

- Pros: Significantly improves carrying convenience, a very practical upgrade that consumers immediately appreciate.

- Cons: Higher cost than a standard cap, more complex structure.

- Best For: Mid-market products looking to add value through enhanced convenience.

3. Non-spill "Smart" Cap

This is a high-value-added cap, often featuring an internal valve system. When the keg is placed upside down on a water cooler, a probe on the cooler opens the valve, allowing water to flow out without splashing.

- Pros: Offers unmatched convenience and a clean user experience, a key feature for premium positioning.

- Cons: The highest cost, requires compatibility with standard water coolers.

- Best For: High-end market positioning or products specifically targeting the office and home water cooler market.

| Cap Type | Cost Level | Core Advantage | Market Position |

|---|---|---|---|

| Standard Screw Cap | ★☆☆ | Lowest cost | Economy / Entry-Level |

| Cap with Integrated Handle | ★★☆ | Improves carrying convenience | Mid-Range / Mainstream |

| Non-spill "Smart" Cap | ★★★ | Water cooler compatible, spill-proof | Premium / Office Channel |

The Production Line: What Equipment Do You Need to Blow 10L Bottles?

Not just any blow molding machine can produce a 10L bottle. This task has strict requirements for the equipment's technical specifications. Choosing the right combination of machinery for your factory is a prerequisite for ensuring production efficiency and product quality. A complete line typically consists of the core blow molder and two vital pieces of auxiliary equipment.

The production line we configured for our client in Thailand was based on this "best value" principle, ensuring he could start high-quality production quickly with a reasonable initial investment.

Core Equipment: Semi-Automatic Blow Molder

For startups or businesses with a production demand of a few hundred bottles per hour, a semi-automatic blow molder specifically designed for large-capacity bottles is the most cost-effective entry choice.

- Large Platen Area: The mold for a 10L bottle is very large. The machine's platens (the platforms that hold the mold) must have enough space to accommodate it.

- Sufficient Clamping Force: During the instant of high-pressure air blowing (often up to 30-35 bar), the mold experiences immense opening forces. The machine must have a powerful clamping force to hold the mold halves tightly shut, otherwise, air will escape at the parting line, causing defects.

- Extended Heating Oven: 10L preforms are long and require a longer heating oven with more heating lamps to ensure the preform is heated evenly and thoroughly to the optimal stretching temperature before entering the mold.

Key Auxiliary #1: High-Pressure Air Compressor

The air compressor is the "heart" of the blow molding line, supplying the essential high-pressure air for the blowing process. Large bottles are particularly "air-hungry."

- Pressure: You must choose a compressor that can reliably provide at least 30 bar (435 PSI) of pressure. Insufficient pressure will result in under-blown bottles with sunken panels or poorly defined details.

- Flow (Capacity): The compressor's output volume (measured in m³/min or CFM) must be sufficient to supply the blow molder and any other pneumatic components. Underestimating compressor capacity is one of the most common mistakes startups make, leading to poor efficiency. Our article discusses in detail how a single high-pressure air compressor can efficiently run an entire line.

Key Auxiliary #2: Industrial Water Chiller

Blow molding is a process of heating and then cooling. The cooling efficiency directly determines the production speed and the clarity of the bottle.

- Cooling Capacity: A 10L blow bottle mold is large and heavy, accumulating a great deal of heat during production. You must equip your line with a sufficiently powerful industrial water chiller to continuously circulate cold water (typically 8-12°C or 46-54°F) through the mold, dissipating heat.

- Impact on Quality: Inadequate cooling will cause the bottle to shrink or warp after ejection because it's too hot. The bottle walls will also appear hazy, losing the crystal-clear quality of PET. Efficient cooling shortens the cycle time and increases output.

A Critical Calculation: The True Production Cost Per 10L Bottle

"What is my actual cost per bottle?" This is the most pressing question for every entrepreneur. Accurate cost accounting is the foundation for your pricing strategy and profitability assessment. A common mistake is to only calculate the direct costs of the preform and cap while ignoring equally important variable and fixed production costs.

Below, I will provide a sample cost breakdown and a simple calculator to help you estimate your own unit bottle cost. Please note that preform costs fluctuate significantly with oil prices; the values in the calculator below are only current market estimates for demonstration.

Cost Component Breakdown

The true cost of a bottle is composed of several parts:

- Direct Material Costs: These are the most obvious costs.

- Preform Cost: Based on your chosen grammage and purchase price.

- Cap Cost: Based on your chosen type and purchase price.

- Label and Packaging Cost: The cost of the label for each bottle and the plastic bag or carton used for shipping.

- Variable Production Costs: These costs vary with production volume.

- Electricity Consumption: The blow molder, air compressor, and chiller are all significant power consumers. You need to estimate the total hourly power consumption of the entire line.

- Labor Cost: The hourly wages of the workers needed to operate the equipment, pack, and handle materials.

- Fixed Cost Allocation: These costs do not change with production volume and must be allocated to each product.

- Equipment Depreciation: The total investment in equipment allocated over its useful life (e.g., 5 or 10 years) and then broken down per month or hour.

- Factory Rent & Overheads: The monthly rent and other administrative expenses allocated to the hourly production cost.

Cost Per Bottle Calculator

Please enter your estimated data below to calculate the approximate production cost of your 10L water bottle.

10L Bottle Unit Cost Calculator

Common Pitfalls to Avoid in Your 10L Bottle Project

Theoretical knowledge and perfect plans are the foundation, but during actual project implementation, unexpected problems always arise. Based on our experience helping numerous clients set up their production lines, I've summarized the three most common "pitfalls" for startups. Knowing about them in advance can save you a great deal of time and money.

These may seem like small issues, but any one of them can severely impact your product quality, production efficiency, and brand reputation.

Pitfall #1: Being Overly Frugal on Preform Weight, Leading to Insufficient Strength

Under cost pressure, choosing the lightest possible preform seems like a tempting option. But it's a huge gamble. I've seen too many clients opt for a 120g or even lighter preform to save a few cents, but without a fully optimized bottle design to match. The result? The bottles deform when stacked in the warehouse, they burst during bumpy transportation, and it all leads to a flood of customer complaints and returns. The resulting losses far outweigh the initial savings on raw materials.

- How to Avoid: In the initial phase of your project, choose a relatively safe preform weight (e.g., 130-140g). Only after you have accumulated sufficient production experience and can continuously optimize your bottle design through tools like FEA should you gradually attempt lightweighting. Remember, many common blow molding defects can be related to preform weight and uneven wall thickness distribution.

Pitfall #2: Underestimating the Required Air Compressor Capacity, Leading to Slow Production

"My blow molder's theoretical output is 400 bottles per hour, so why can I only produce 250?" This is a question I'm often asked. Nine times out of ten, the answer lies with the air compressor. Blowing a 10L bottle is an extremely air-intensive process. The compressor must provide not only high enough pressure but also a large enough volume of air. If the compressor's output can't keep up with the molder's consumption, the pressure in the air tank will drop. When the pressure falls below the minimum required for blowing, the machine has to "wait" for the pressure to recover, which extends the cycle time and causes the actual output to be far lower than the theoretical maximum.

- How to Avoid: When purchasing equipment, strictly follow the supplier's recommendations and build in a buffer of at least 20% for your air compressor's capacity. Don't just look at the pressure (bar); pay even more attention to the flow rate (m³/min). A properly matched compressor is a prerequisite for unlocking your blow molder's full potential.

Pitfall #3: Designing an Uncomfortable or Flimsy Handle, Leading to a Poor Consumer Experience

We are emphasizing the handle again because it is so easily overlooked. The consumer interacts with this handle every day. If it's too thin, it digs into their hand. If it has sharp flashing from the parting line, it can cut them. If it's not structurally sound and breaks while being carried, it's a disaster—not only does water spill everywhere, but it could also injure the consumer's foot. This one bad experience is enough to make a customer never buy your product again.

- How to Avoid: Pay high attention to the handle's ergonomics during the mold design phase. Conduct thorough physical sample testing by having people with different hand sizes try it out. At the same time, use FEA to simulate the stress points on the handle under load to ensure its structure is robust. A small handle reflects your attention to detail and care for the consumer.

Conclusion: Your Checklist for a Successful Launch

We've traveled from macro market trends deep into bottle design, material selection, equipment configuration, cost calculation, and finally, pointed out the common pitfalls. Now, it's time to condense all these key points into a simple, actionable checklist. You can use it at each critical stage of your project to review your progress and ensure nothing is missed.

This checklist is your roadmap from idea to successful production. By taking it one step at a time, you can establish a firm foothold in this market full of opportunity.

[A] Finalize Market & Design

- [1] Confirm target market (home/office) and brand positioning (economy/premium).

- [2] Complete bottle design, optimized for strength and weight via FEA.

- [3] Create 3D printed samples to physically evaluate handle comfort and overall aesthetics.

[B] Confirm Raw Material Specifications

- [1] Finalize preform weight (recommend 130g+ for starters).

- [2] Finalize preform neck finish (45mm or 55mm).

- [3] Finalize preform color (clear or transparent blue).

- [4] Explicitly require suppliers to use water-grade PET resin with an IV of 0.80 dL/g or higher.

- [5] Select cap type (standard/handle/smart) based on brand positioning.

[C] Specify Production Equipment

- [1] Select a semi-automatic blow molder with sufficient platen area and clamping force for a 10L mold.

- [2] Confirm high-pressure air compressor specs (Pressure ≥ 30 bar, with ample flow rate).

- [3] Confirm industrial chiller specs (cooling capacity must match the heat load of the large mold).

[D] Review Costs & Suppliers

- [1] Use a cost calculator to determine your comprehensive cost per bottle.

- [2] Develop a preliminary pricing strategy and profitability model.

- [3] Communicate with and compare at least 2-3 suppliers (preform, cap, equipment).

- [4] Request samples from suppliers for testing and evaluate their technical support and after-sales service.

Your Startup Quick Launch Roadmap

To give you a more strategic overview of the entire process, I've consolidated the core steps, tasks, and recommendations into a clear roadmap. I hope this helps you navigate your entrepreneurial journey more steadily.

| Step | Core Task | My Advice & Solution |

|---|---|---|

| Step 1: Market Positioning & Product Definition | Decide who you are serving and what makes your product special. | Solution: Focus on the "hygiene and convenience" selling points. Target small households and modern offices with a demand for quality, avoiding the red ocean of price wars. |

| Step 2: Bottle Engineering & Design | Find the optimal balance between aesthetics, function, and cost. | Solution: You must invest in FEA. Start with a safe preform weight (130-140g) to prioritize product strength and stability. The handle design must be tested by real users. |

| Step 3: Raw Material Selection | Precisely define the technical specifications for preforms and caps. | Solution: For preforms, insist on water-grade PET with an IV of 0.80+. I recommend a 55mm neck for a better user experience. Choose a cap that matches your brand's premium level. |

| Step 4: Production Line Configuration | Choose the equipment combination with the best return on investment. | Solution: Start with a semi-automatic blow molder. When selecting the air compressor and chiller, ensure they have at least 20% surplus capacity beyond the minimum requirements. This is key to stable production. |

| Step 5: Costing & Supplier Evaluation | Understand your true costs and find reliable partners. | Solution: Your cost calculation must include electricity, labor, and depreciation—not just materials. Get and rigorously test samples from at least three suppliers before making a commitment. |

Conclusion

Launching a 10L water bottle project is a systematic undertaking, but it is far from impossible. From precise market insights to scientific engineering design and rational equipment investment, every step is crucial. I hope this detailed guide has cleared the fog and given you the confidence to take that first step.

Frequently Asked Questions (FAQs)

1. What is a realistic starting investment for a small-scale 10L single-use water bottle production line?

This is a common question, but the answer varies widely based on equipment brand, level of automation, and country of origin. A realistic estimate for a small-scale line centered on a semi-automatic blow molder—including the machine, one 10L mold, a high-pressure air compressor, a water chiller, and air tanks—typically falls in the range of $35,000 to $70,000 USD. This does not include costs for the factory building, filling equipment, or the initial purchase of raw materials.

2. What are the main technical challenges in blow molding a large 10L bottle compared to a standard 500ml bottle?

There are three main challenges:

- Heating Uniformity: A 10L preform is long and thick. Achieving a uniform and ideal stretching temperature from the inside out and top to bottom in the heating oven is much more difficult than with a small preform.

- Stretching and Blowing Control: The stretching stroke for a large bottle is much longer, and it requires a greater volume of air over a longer time. This demands more precise control over the stretch rod speed and the timing and pressure of the pre-blow and high-blow stages.

- Cooling Efficiency: A large bottle uses more plastic and thus accumulates more heat. A powerful cooling system is essential to solidify the bottle quickly. Otherwise, the cycle time will be long, and the bottle may warp.

3. Are preforms for 10L bottles a standard, readily available item, or do they usually need to be custom-ordered?

Unlike highly standardized preforms for 500ml bottles (like a 30/25 neck), preforms for 10L bottles (especially 120g+ with a 45/55mm neck) are "less standard." While many large preform manufacturers will have these items in their product line, they may not keep a large stock and often require a high Minimum Order Quantity (MOQ). In some cases, if your design is very unique, you may need a custom preform mold to be made. Therefore, confirming the lead time and MOQ with suppliers well in advance is crucial.

4. How do you ensure a 10L bottle is strong enough for stacking and transportation without being too heavy?

The answer lies in scientific bottle design. It's not achieved by simply adding more weight, but through structural optimization. Using Finite Element Analysis (FEA) software, designers can simulate stress distribution under load. They can then add reinforcing ribs or fine-tune curvatures in high-stress areas (like the shoulder and base) while thinning out material in low-stress areas. A superior bottle design can achieve the top-load strength of a 140g preform with only 125g of material—that is the value of engineering.

5. For bottles with an integrated handle, is the handle part of the blow mold, or is it attached separately?

For PET water kegs, the integrated handle is absolutely part of the blow mold and is formed in one piece with the bottle during the blow molding process. The advantages of this design are structural integrity and low cost (no extra assembly steps). Post-molding, separately attached handles are more common on other types of plastic containers (like HDPE drums), but for PET blow molding, the one-piece, integrated design is the mainstream and optimal solution.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr