Struggling with high startup costs? A used blow molding machine seems like a tempting shortcut. But this initial saving could lead to much bigger expenses down the road.

A used blow molding machine can be a smart investment if you find a well-maintained unit with available spare parts and have in-house technical expertise. However, it often becomes a costly mistake due to hidden wear, lack of warranty, energy inefficiency, and obsolete components, leading to high long-term costs.

I get it. The idea of starting or expanding your production line is exciting, but the price tag on new equipment can be daunting. You see a listing for a second-hand PET blower at a fraction of the cost, and you think, "This is my chance." It feels like a smart, resourceful move. But I've talked to too many factory owners who walked this path only to find it riddled with unexpected problems. This article is for you. We are going to walk through this decision together, looking at it from every angle. My goal isn't just to sell you a new machine; it's to arm you with the information you need to protect your investment and your factory's future.

The "Smart Investment" Argument: The Undeniable Appeal of a Lower Upfront Cost?

Facing tight budgets? The low price of a used machine looks like the perfect solution to get started now. It seems like the fastest way to get your production running.

A lower initial purchase price is the most compelling reason to consider a used machine. For startups or businesses expanding on a limited budget, this can free up critical capital for other essential areas like marketing, raw materials, or hiring skilled staff.

The appeal of a lower upfront cost is powerful, and I won't pretend it isn't. When you're looking at your business plan and the numbers need to work, seeing a bottle blowing machine for $20,000 instead of $100,000 can feel like a huge win. This immediate cash saving is the primary driver behind the used equipment market. It allows businesses to enter the market or scale up production without seeking massive loans or giving up equity. It reduces the financial barrier to entry, which is a significant hurdle for many entrepreneurs I speak with. Let's break down the scenarios where this logic holds the most weight.

When Can a Used Machine Be a Viable Option?

While I am generally cautious, there are specific situations where buying used equipment can be a calculated, and sometimes successful, risk. It's not a simple yes or no answer; it depends entirely on your specific circumstances, your team's capabilities, and your production demands.

Low-Volume, Non-Critical Production: If you are producing a small number of bottles for a niche market, or if the machine is for prototyping and not your primary production line, the risk of downtime is less catastrophic. If the machine stops, it's an inconvenience, not a complete business shutdown. You have the time to find parts and fix it without customers breathing down your neck.

You Have a "Machine Whisperer" on Staff: Some factories are blessed with a highly experienced maintenance chief or engineer who has worked on these specific types of machines for decades. This person can diagnose problems quickly, has a network for sourcing obscure parts, and can often fabricate solutions in-house. If you have this person on your team, your risk is significantly lower. They can perform a thorough pre-purchase inspection and keep the machine running long after the manufacturer has forgotten it.

The Machine is a "Modern Classic": Sometimes you can find a machine that is only a few years old from a reputable brand. The previous owner may have gone out of business or upgraded their line. In these cases, the machine might still use relatively modern technology, and the manufacturer may still offer support and spare parts. This is the "ideal" used machine scenario, but it is also rare and these machines command a higher price.

The Cash Flow Advantage

The core of the "smart investment" argument is all about cash flow. By spending less on the initial purchase, you retain more cash in the bank. This cash can be a lifeline for a new business. It can be used for:

- Purchasing Raw Materials: Buying PET preforms in bulk often leads to better pricing.

- Investing in Quality Molds: A great machine is useless without a well-made blow bottle mold. The quality of your mold directly impacts the quality of your final product.

- Marketing and Sales: You can't sell bottles if no one knows you exist. A healthy marketing budget can be the difference between success and failure.

- Covering Operational Expenses: This includes salaries, rent, and utilities for the first few crucial months before your revenue stream is stable.

Here is a simplified look at how the initial investment can impact a startup's first-year budget:

| Budget Item | Scenario A: New Machine ($100,000) | Scenario B: Used Machine ($20,000) |

|---|---|---|

| Machine Purchase | -$100,000 | -$20,000 |

| Initial Capital | $150,000 | $150,000 |

| Capital Remaining | $50,000 | $130,000 |

| Funds for Molds, Staff, etc. | $50,000 | $130,000 |

As you can see, the difference is stark. In Scenario B, the business has an extra $80,000 in working capital. On paper, this looks incredibly appealing. It suggests more flexibility, a longer runway to become profitable, and less financial stress. This is the powerful allure of the low upfront cost. However, this table only tells the very beginning of the story. It completely ignores the operational costs and risks that come after the machine is delivered to your factory floor. The real story unfolds in the months and years that follow.

The "Costly Mistake" (Part 1): The Gamble on a Machine with No Warranty and an Unknown Past?

That cheap machine has no warranty. You're buying its entire hidden history of breakdowns and poor maintenance. Are you prepared to pay for every single repair yourself?

When you buy a used machine, you inherit its complete, undocumented history. There is no warranty to protect you from a critical failure the day after you turn it on. This gamble is the single biggest risk you take.

This is where the initial savings can start to evaporate. A warranty on a new machine is not just a piece of paper; it's a promise from the manufacturer. It's an assurance that the machine is free from defects and will perform as specified. If a major component fails, they will fix it. With a used machine, you are the warranty department. Every single problem, from a faulty sensor to a cracked manifold, comes directly out of your pocket.

I saw this firsthand with a client in Portugal. He was so proud to have found a 4-cavity fully-automatic PET blower for only $10,000. It looked clean on the outside. But the moment it arrived, the nightmare began. He was essentially buying a black box. He had no idea how many hours it had run, what kind of stress it had been under, or if the previous owners had skipped crucial maintenance schedules. He was betting $10,000 that the machine's past was a good one. He lost that bet.

What Does "No Warranty" Truly Mean?

Let's break down the tangible consequences of not having a manufacturer's warranty. It's more than just the cost of parts.

Total Cost of Repairs: You are responsible for 100% of the cost of any replacement parts. A new PLC (the machine's brain) can cost thousands of dollars. A set of seals for a pneumatic system can be hundreds. These costs add up incredibly quickly. My Portuguese client thought he was done spending after the initial purchase, but he immediately had to spend another $5,000 just on missing and broken parts to get the machine to even turn on. His $10,000 machine was now a $15,000 machine before producing a single bottle.

Sourcing Your Own Technicians: With a new machine, the manufacturer sends a trained technician for installation and troubleshooting. With a used one, you're on your own. You have to find a local technician who understands that specific brand and model. This can be difficult and expensive. If they are not an expert on that machine, their trial-and-error approach to repairs can cause even more damage.

The Cost of Downtime: This is the killer. Every hour the machine is not running, you are losing money. You can't fulfill orders, your staff is idle, and your reputation with customers is on the line. A warranty repair on a new machine is prioritized by the manufacturer. A repair on your used machine happens at the speed you can find parts and a technician. A two-day wait for a part can mean thousands of dollars in lost revenue.

The Unknown Operational History

Think of it like buying a used car without an inspection or a vehicle history report. The previous owner might tell you it runs great, but you don't know the real story.

Hidden Wear and Tear: A machine can look clean cosmetically, but internally, critical components could be at the end of their life. The clamping mechanism might have hairline fractures from years of stress. Hydraulic hoses could be brittle and ready to burst. Electrical wiring could be frayed and posing a fire hazard. These are things you often can't see during a brief inspection.

Improper Maintenance: Did the previous owner use the correct type of hydraulic fluid? Did they replace filters on schedule? Did they lubricate moving parts correctly? Skipping these simple maintenance steps can cause catastrophic damage over time. You are inheriting the consequences of their neglect.

Was the Machine Pushed Too Hard? The previous owner might have run the machine faster than its designed specifications to meet a deadline. They might have used molds that were too heavy, putting extra strain on the clamping unit. This kind of abuse drastically shortens the machine's lifespan, and there's no way to know for sure if it happened. Any information you get is from a seller who is motivated to hide these facts.

Let's compare the risk profile of buying new versus used:

| Feature | New Blow Molding Machine | Used Blow Molding Machine |

|---|---|---|

| Warranty | Typically 1-2 years, covering parts and labor. | None. Sold "as-is." All repair costs are on the buyer. |

| Technical Support | Direct access to manufacturer's expert technicians. | You must find and pay for your own independent technicians. |

| History | None. You are the first owner. | Unknown. Could be well-maintained or abused and neglected. |

| Initial Failures | Covered by warranty. Quick resolution from the factory. | Your responsibility. Can lead to immediate, significant extra costs. |

| Peace of Mind | High. You can focus on production, not repairs. | Low. You are constantly waiting for the next problem to appear. |

The gamble on a machine's past is a heavy burden to bear. The money you save upfront is essentially a fund you're setting aside for future repairs. The question is, will that fund be large enough? Often, it's not.

The "Costly Mistake" (Part 2): Paying More for Power with Outdated, Inefficient Technology?

Worried about running costs? That older machine might have a cheap price tag, but its outdated technology will consume huge amounts of electricity, costing you more every single day.

A blow molding machine from 10 or 15 years ago is a completely different animal from a modern one. The biggest difference is energy efficiency. That initial saving can be quickly eroded by significantly higher monthly electricity bills.

This was a major issue for my client in Portugal. His machine from around 2010 was a pneumatic blow molding machine. This means the primary movements, like stretching the preform and clamping the blow bottle mold, were driven by compressed air. On the surface, it sounds simple. But in reality, it's incredibly inefficient. To get the force needed for these actions, you need a massive, power-hungry air compressor running constantly. The energy cost was a shock to him.

Modern machines, by contrast, use servo motors for these critical movements. Servo motors are electric motors that offer incredibly precise control over position, speed, and torque. They only use significant amounts of power when they are actually moving. The rest of the time, their energy consumption is minimal. The difference in your electricity bill is not small; it's a major operational expense that you will pay for every single month, for the entire life of the machine.

The Servo vs. Pneumatic Divide

Understanding this key technological difference is crucial. It’s the single biggest factor in the long-term running cost of a blow molding machine.

Pneumatic Systems (Older Technology):

- How they work: Use compressed air, generated by a large external compressor, to move cylinders that perform actions like clamping and stretching.

- Energy Consumption: Extremely high. The air compressor is a huge energy drain and must run constantly to maintain pressure in the system. A lot of energy is lost as heat during the compression process. Think of it like trying to fill a leaky bucket; you have to keep the tap running all the time. A powerful air compressor can easily be the most power-hungry piece of equipment in your entire factory.

- Control and Speed: Less precise. The speed and position are controlled by regulating airflow, which can be inconsistent. This can lead to lower production speeds and higher defect rates.

- Noise and Maintenance: Pneumatic systems are notoriously loud. They also have many seals and valves that can leak over time, requiring constant maintenance.

Servo-Electric Systems (Modern Technology):

- How they work: Use high-precision electric servo motors directly coupled to the mechanisms.

- Energy Consumption: Significantly lower. Power is consumed on-demand, only during movement. There is no large, constantly running compressor. Energy savings of 40-60% over pneumatic systems are common.

- Control and Speed: Extremely precise and repeatable. This allows for faster cycle times, better bottle quality, and the ability to run lighter preforms, saving on material costs. It also makes it easier to fix common PET blow molding defects.

- Noise and Maintenance: Much quieter operation. Fewer components mean less maintenance and higher reliability.

Calculating the Real Cost of Power

Let's put some real numbers to this. Imagine two machines running a single 8-hour shift, 250 days a year.

| Feature | Used Pneumatic Machine (c. 2010) | New Servo Machine (c. 2025) |

|---|---|---|

| Machine Power Consumption | 15 kW | 10 kW |

| Required Air Compressor Power | 45 kW | 22 kW (for blowing only, not motion) |

| Total Power Draw | 60 kW | 32 kW |

| Hours of Operation per Year | 2,000 hours (8 hours/day * 250 days) | 2,000 hours |

| Total kWh per Year | 120,000 kWh | 64,000 kWh |

| Cost per kWh (example) | $0.15 | $0.15 |

| Annual Electricity Cost | $18,000 | $9,600 |

| Extra Cost per Year | $8,400 | - |

In this very realistic scenario, the old machine costs you an extra $8,400 every single year just in electricity. If you keep that machine for five years, you will have paid an extra $42,000 in power costs. That's more than double what you might have "saved" on the initial purchase price. This is a classic hidden cost. It doesn't show up on the invoice, but it bleeds your business dry month after month.

This calculation doesn't even include other related energy costs. For example, all that wasted energy from the old machine and its giant compressor turns into heat. That heat has to be removed from your factory by an HVAC system or a chiller, which uses even more electricity. The financial penalty for using old technology is relentless.

The "Costly Mistake" (Part 3): The Nightmare of Sourcing Obsolete Spare Parts and Support?

Your machine has stopped. A small, critical part is broken. But the manufacturer stopped making it years ago. Now your expensive machine is just a pile of metal, and your production is dead.

This is the long-term risk that many buyers don't consider. The availability of spare parts and technical support is not a luxury; it's a necessity. For a machine that is 10, 15, or even 20 years old, finding the right parts can become a desperate, time-consuming, and often impossible task.

When a machine breaks down, the clock starts ticking. Every minute of downtime costs you money. With a new machine from a reputable supplier, you call your contact, they identify the part, and they ship it to you from their stock. The process is fast and efficient.

With an old, used machine, the process is a nightmare. First, you have to identify the exact part number, which might be worn off or from a manual that is long gone. Then, you start your search. You might try to contact the original manufacturer, only to find they went out of business five years ago. Or maybe they were acquired by a larger company that has no interest in supporting legacy products. So you turn to a network of used parts dealers, spending hours on the phone and sending emails, hoping someone has what you need sitting on a shelf somewhere. This search can take days or even weeks. And all that time, your machine is silent.

The Lifecycle of Industrial Machinery

Industrial equipment manufacturers are constantly innovating. They launch new models with better technology, improved efficiency, and new features. To do this, they have to phase out older models. This is a normal business cycle.

- Years 1-5 (Current Model): Full support. All parts are in stock and readily available. The manufacturer's best technicians are trained on this model.

- Years 6-10 (Previous Model): Good support. Most common wear parts are still stocked. Support is available, but it might not be the top priority.

- Years 11-15 (Legacy Model): Limited support. The manufacturer may have officially declared it "end of life." They will stop producing spare parts. What's left in stock is all that's available. Technical support might be limited to providing old diagrams, if they can even find them.

- Years 16+ (Obsolete): No support. You are completely on your own. The manufacturer will offer no help. Your only hope is the second-hand market or custom fabrication.

When you buy a 15-year-old machine, you are buying a machine that is already in the "limited support" or "obsolete" phase. The initial purchase price is low precisely because the risk of it becoming a useless piece of metal is so high.

The Custom Fabrication Trap

"If I can't find the part, I'll just have a local machine shop make one for me."

I hear this sometimes, and while it sounds like a clever solution, it's often a trap.

- High Cost: Custom machining a single, complex part is incredibly expensive. You are paying for the machinist's time to design the part from scratch (if you don't have the original technical drawings), set up the tooling, and produce a one-off item. The cost can easily be 5 to 10 times the price of the original OEM part.

- Incorrect Specifications: The original part was made with specific materials, heat treatments, and tolerances. A local machine shop might not be able to replicate these exactly. A part made from the wrong type of steel or with a slightly incorrect dimension can fail quickly or cause damage to other components in the machine.

- No Guarantee: If the custom-made part fails, you have no recourse. The machine shop will blame the design, and you are back to square one, having wasted both time and money.

Think about the complex electronics. If a proprietary circuit board or a specific PLC model fails, you cannot custom-fabricate that. If the original manufacturer no longer produces it, and you can't find a used one, your machine is dead. Period. This is not a hypothetical risk; it happens all the time. Your investment isn't just the machine; it's the entire ecosystem of parts and support that keeps it running. With an old machine, that ecosystem is often collapsing or already gone.

The Deciding Factor: How to Calculate the True Cost of Ownership (TCO)?

Want to make a truly smart decision? Don't just look at the price tag. You need to calculate the Total Cost of Ownership. This simple formula will reveal the hidden costs that turn a "bargain" into a financial disaster.

The purchase price is just the tip of the iceberg. To understand the real financial impact of a machine, you must calculate its Total Cost of Ownership (TCO). This includes every single cost associated with that machine over its useful life in your factory.

Making a major capital decision based only on the initial price is one of the biggest mistakes a business owner can make. It's like buying a car because it's cheap, without considering its terrible fuel economy, expensive insurance, and notorious repair costs. The TCO gives you a much more accurate picture, allowing for a true "apples-to-apples" comparison between different options. It forces you to think beyond the immediate future and consider the long-term health of your business.

The TCO Formula

At its core, the TCO formula is straightforward. It helps you quantify the potential "hidden" costs we've been discussing.

TCO = Initial Purchase Price + Installation Costs + Operating Energy Costs + Routine Maintenance + Estimated Repair Costs + Cost of Downtime

Let's break down each component of this formula:

- Initial Purchase Price: This is the obvious one. It's the number on the invoice for the machine itself.

- Installation Costs: This can be a significant hidden cost for used machines. It includes transportation, rigging to get it into your factory, and the cost of technicians to set it up. A new machine often includes installation and training in the purchase price. For a used one, you pay for all of this separately.

- Operating Energy Costs: As we discussed, this is a major factor. You need to calculate the total energy consumption (machine + compressor + chiller) and multiply it by your electricity rate over the expected life of the machine (e.g., 5 years).

- Routine Maintenance: This includes the cost of consumables like filters, lubricants, seals, and heating lamps, as well as the labor hours for your staff to perform regular maintenance tasks.

- Estimated Repair Costs: This is the hardest to predict but the most crucial for a used machine. You must make a realistic, even pessimistic, estimate. Assume you will have at least one major component failure and several minor ones per year. Research the cost of these parts.

- Cost of Downtime: How much revenue do you lose for every hour the machine is not producing bottles? Calculate your profit per hour and multiply that by the estimated number of downtime hours per year. For a used machine, downtime will almost certainly be higher due to waiting for parts and technicians.

A TCO Case Study: Used vs. New

Let's apply this formula to a realistic scenario, comparing a 10-year-old used fully-automatic machine to a new, modern semi-automatic machine over a 5-year period.

| Cost Component | 10-Year-Old Used Fully-Auto | New Semi-Automatic Machine |

|---|---|---|

| Initial Purchase Price | $25,000 | $40,000 |

| Installation & Commissioning | $8,000 (You hire your own team) | $3,000 (Often subsidized by manufacturer) |

| Annual Energy Cost | $18,000 (Inefficient pneumatic system) | $10,000 (Efficient design) |

| Annual Routine Maintenance | $2,000 (Older parts, more frequent) | $1,000 (New components, less frequent) |

| Annual Estimated Repair Costs | $7,000 (High probability of failures) | $500 (Covered by warranty in Year 1) |

| Annual Estimated Downtime Cost | $10,000 (200 hours @ $50/hr profit) | $1,250 (25 hours @ $50/hr profit) |

| Year 1 Cost | $70,000 ($25k+$8k+$18k+$2k+$7k+$10k) | $55,750 ($40k+$3k+$10k+$1k+$0.5k+$1.25k) |

| Years 2-5 Cost (per year) | $37,000 ($18k+$2k+$7k+$10k) | $13,750 ($10k+$1k+$0.5k+$1.25k) |

| Total 5-Year TCO | $218,000 ($70k + 4*$37k) | $110,750 ($55.75k + 4*$13.75k) |

The result is shocking, but it's realistic. The used machine, with its "cheap" $25,000 price tag, ends up costing nearly double the new machine over a five-year period. The initial savings are completely wiped out by higher energy use, more frequent and expensive repairs, and crippling downtime.

This calculation is the most powerful tool you have. It moves the conversation from emotion ("This price is so low!") to logic ("This investment will cost me $218,000."). It allows you to see the future and make a decision based on data, not just hope.

Beyond "Used vs. New": The High-Value Alternative for Startups?

Think your only choices are a risky used machine or an expensive new one? There is a third option. A brand-new, high-value semi-automatic machine often has a lower total cost than a used fully-automatic one.

Many entrepreneurs I work with get stuck in a false choice. They believe they must either gamble on a used fully-automatic machine or spend a fortune on a brand-new one. But there is a powerful middle ground that is perfect for startups and small to medium-sized businesses: the new semi-automatic bottle blowing machine.

This isn't about compromising; it's about being strategic. It’s about matching the equipment to the actual needs and budget of your business, not just chasing the highest possible output number on a spec sheet. A new semi-automatic machine provides the most critical benefits of a new machine—warranty, support, and modern efficiency—at a purchase price that is often comparable to, or even less than, a much older and riskier fully-automatic machine.

What is a Semi-Automatic Machine?

Let's clarify the difference. The core blowing process is the same in both types of machines. The key difference is in how the PET preforms are loaded into the machine.

- Fully-Automatic Machine: An automated system picks up preforms from a large hopper, orients them, and feeds them into the heating ovens and then the blowing station. This allows for continuous, high-speed operation with minimal labor.

- Semi-Automatic Machine: An operator manually places the preforms into the heating unit. After heating, the machine automatically transfers them to the blowing station and ejects the finished bottles. It requires one operator to be constantly feeding the machine.

For a massive beverage company producing millions of bottles a day, the labor savings of a fully-automatic machine are essential. But for a startup, is that the most important factor? Often, the answer is no. A single, dedicated operator for the machine is a very manageable labor cost, especially when weighed against the enormous financial risks of a used fully-automatic machine.

The Strategic Advantage of a New Semi-Automatic

Let's revisit the TCO comparison, this time looking specifically at why a new semi-automatic machine is such a compelling alternative for a new business.

Lower Total Cost of Ownership: As our previous TCO calculation showed, the long-term cost of a new, efficient machine is often far lower than a used, inefficient one, even if the initial purchase price is slightly higher. The savings on energy, repairs, and downtime are massive.

Full Warranty and Support: This is the single greatest advantage. You get a brand-new machine with a full manufacturer's warranty. If something goes wrong, you have a team of experts to help you. You get training, documentation, and a reliable source for any spare parts you might need in the future. This eliminates the biggest gamble of buying used.

Modern, Efficient Technology: Your new semi-automatic machine will be built with modern components. It will likely feature a servo-driven stretching system and an energy-efficient heating design. This means lower electricity bills every single month, which directly improves your profitability.

Flexibility and Simplicity: Semi-automatic machines are often simpler mechanically than their fully-automatic counterparts. This means they are easier to maintain and troubleshoot. They are also excellent for businesses that produce a variety of bottle shapes and sizes in smaller batches, as changeovers can be quicker and simpler. This flexibility is a huge asset when you are starting out and still refining your product line. You can easily adapt your production to new opportunities. A flexible PET bottle mold design guide can also help you maximize this advantage.

Predictable Performance: With a new machine, you know what you are getting. It will perform to the manufacturer's specifications from day one. You can build your business plan on a reliable production output, not on the hope that an old machine will run consistently. My Portuguese client thought he was buying a machine with a certain output, but its actual, reliable output was less than half of what he expected. This destroyed his production forecasts.

This "third option" reframes the entire decision. The question is no longer "Should I risk buying used?" It becomes "What is the smartest way to invest my capital for secure, predictable, and profitable production?" For many startups, the answer is not the cheapest machine available, but the machine that offers the best overall value and the lowest risk.

Your Final Inspection Checklist to Avoid a Costly Mistake?

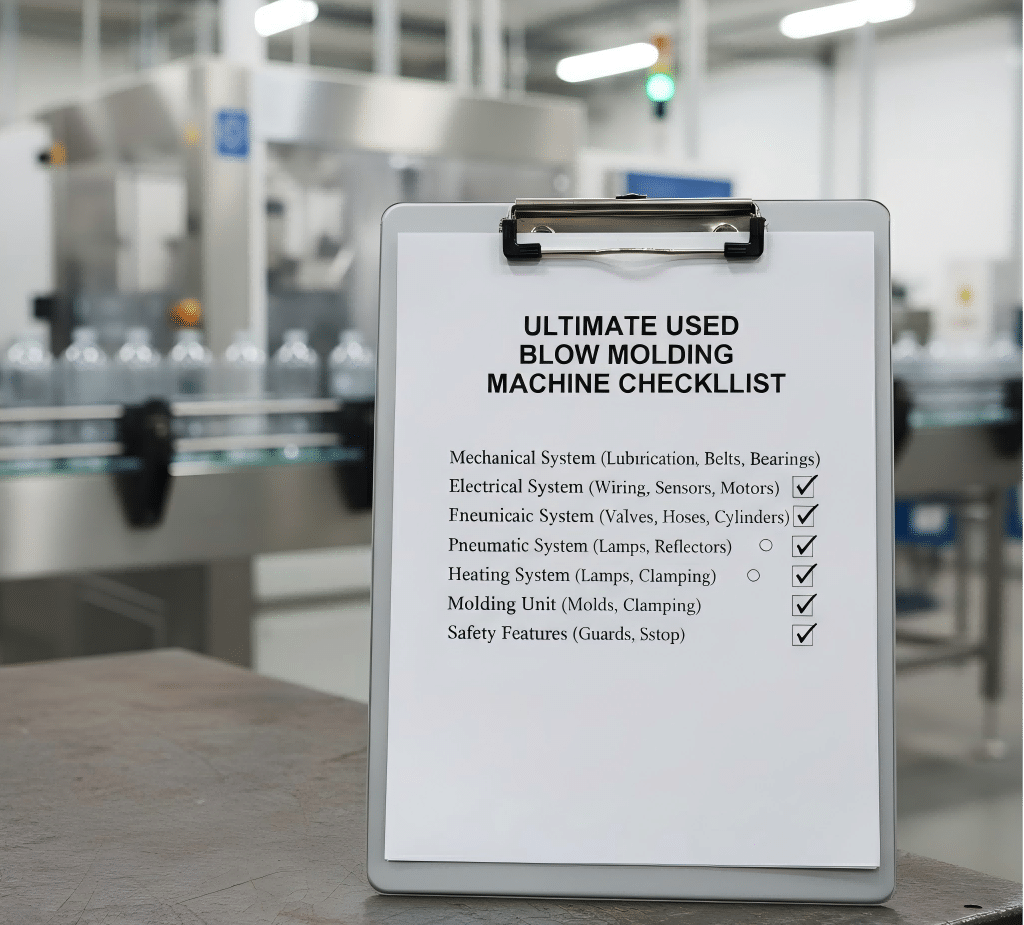

Still considering a used machine? You absolutely must perform a thorough inspection. This checklist covers the critical systems that can hide expensive problems. Don't buy anything without checking every single one of these points.

If, after considering all the risks, you still decide that a used machine is the only path forward for you, then you must approach the inspection process like a detective investigating a crime scene. Do not take the seller's word for anything. You need to see it, touch it, and test it for yourself. A few hours of rigorous inspection can save you tens of thousands of dollars and months of headaches. Take this checklist with you. If possible, bring an experienced mechanic or engineer who is not affiliated with the seller.

This is your last line of defense against making a very expensive error. If the seller refuses to let you perform any of these checks, that is a huge red flag. You should walk away immediately. A transparent seller with a well-maintained machine should have nothing to hide.

The Ultimate Used Blow Molding Machine Inspection Checklist

Print this out and take it with you. Go through it system by system.

1. Documentation and History

- [1] Request the original manual: Does it exist? Is it in a language you can read? This is vital for troubleshooting and ordering parts.

- [2] Ask for maintenance logs: A well-maintained machine will have records of oil changes, filter replacements, and repairs. No logs suggest neglect.

- [3] Check the serial number: Contact the original manufacturer with the serial number. Ask them the year of manufacture and if they still offer any support or parts for that model.

- [4] Inquire about past use: What kind of materials did it run? How many hours per day? What was the production environment like (clean or dusty)?

2. Mechanical Systems

- [1] Clamping Mechanism (The Heart of the Machine):

- Visually inspect for cracks, especially around the tie bars and platens. Use a flashlight.

- Check the tie bar bushings for excessive wear or play.

- Measure the tie bar spacing to ensure it hasn't been stretched or damaged. This is critical to know if your existing blow bottle mold will fit.

- Watch it cycle. Does it move smoothly and quietly, or does it jerk and make grinding noises?

- [2] Stretching System:

- Inspect the stretch rods. Are they straight and clean?

- Check the stretch seals. Are they dry and cracked, or in good condition?

- [3] Preform Transfer System:

- Look for worn grippers or chains.

- Ensure the movement is smooth and precise. Dropped preforms are a common source of downtime.

3. Electrical and Control Systems

- [1] Main Electrical Cabinet:

- Open the cabinet. Does it look clean and organized, or is it a "rat's nest" of messy wires and modifications? Messy wiring is a fire hazard and a troubleshooting nightmare.

- Look for signs of overheating: discolored wires, melted plastic, or a burning smell.

- [2] PLC and HMI (The Brain):

- What brand is the PLC? Is it a modern, supported brand (like Siemens, Allen-Bradley) or an obscure/obsolete one?

- Turn on the machine. Does the screen (HMI) work properly? Are there dead pixels or error messages?

- Test the buttons and controls. Do they all respond correctly?

- [3] Heating Ovens:

- Inspect the heating lamps. Are many of them burnt out? These are consumables, but a large number of dead lamps can indicate electrical issues.

- Check the reflectors behind the lamps. Are they clean and shiny, or are they dull and dirty? Dirty reflectors waste a lot of energy.

4. Pneumatic and Hydraulic Systems

- [1] Check for Leaks:

- Listen carefully for the hissing sound of air leaks. Air leaks are literally money leaking out of your factory through your compressor.

- Look for hydraulic fluid drips or puddles under the machine. Hydraulic leaks are messy, expensive to fix, and a safety hazard.

- [2] Inspect Hoses and Fittings:

- Are the hoses brittle, cracked, or bulging? A burst hydraulic hose can shut down the machine for hours.

- [3] Check the Fluid:

- Look at the hydraulic fluid level and condition. Is it clean and clear, or is it dark and milky? Milky fluid indicates water contamination, a very bad sign.

5. See It Run (The Most Important Test)

- [1] Insist on a "Dry Cycle": Watch the machine open, close, and cycle without preforms. Listen for any unusual noises.

- [2] Insist on a Production Run: This is non-negotiable. You need to see the machine running with preforms and making good bottles.

- Bring your own preforms if possible, especially if you need to know if the machine can handle a specific preform neck size.

- Let it run for at least 30 minutes to an hour to reach a stable operating temperature. Some problems only appear when the machine is hot.

- Measure the cycle time. Does it match the seller's claims?

- Inspect the bottles it produces. Are they clear and well-formed, or are there defects?

Performing this level of inspection takes time, but it is the only way to protect yourself. If you are not confident in your own ability to check these items, pay an independent expert to do it for you. The cost of their time is a tiny fraction of the potential cost of buying a lemon.

Final Comparison: Used Fully-Auto vs. New Semi-Auto?

To bring everything together, here is a direct comparison of the two most likely options for a startup or small business. This table summarizes the key trade-offs you will be making.

| Feature | Used 4-Cavity Fully-Automatic (10+ Yrs Old) | New 2-Cavity Semi-Automatic |

|---|---|---|

| Initial Purchase Price | Low ($10k - $30k) | Medium ($1k - $15k) |

| Warranty & Support | None | Full (Typically 1-2 years) |

| Theoretical Output | High (Approx. 2000-3000 BPH) | Moderate (Approx. 1000-2000 BPH) |

| Realistic Daily Production | Unpredictable due to frequent downtime | Stable and predictable |

| Installation & Commissioning | Expensive; you hire and manage your own team | Included or subsidized by the manufacturer |

| Energy Consumption | Very High (Outdated pneumatic/hydraulic systems) | Low (Modern, energy-efficient design) |

| Spare Parts Availability | Very Difficult; many parts may be obsolete | Excellent; directly from the manufacturer |

| Operator Requirement | 1 operator (supervisory) | 1 operator (to load preforms) |

| Risk of Major Failure | High to Very High | Very Low |

| Flexibility for Changeovers | Poor; complex and time-consuming | Good; designed for simpler, faster changes |

| Overall Financial Risk | Very High | Low |

| Long-Term Profitability | Compromised by high running/repair costs | Protected by low costs and high uptime |

Conclusion: Making an Informed Investment for Your Factory's Future

Choosing a machine is a long-term investment in your factory's future. The most important factor is not the initial price, but the reliable profitability it will bring you for years.

FAQs

1. What is the single most important mechanical part to inspect on a used machine before buying?

The clamping mechanism is the most critical and expensive component. You must inspect the platens and tie bars for any signs of cracks or stress fractures. Also, check the tie bar bushings for wear. A damaged clamping unit can be financially impossible to repair and can render the entire machine useless.

2. Are some brands of used machines generally a safer investment than others?

Yes. Machines from well-known, established European or Japanese brands often have a longer service life and better parts availability, even for older models. However, this is not a guarantee. The specific maintenance history of the individual machine is always more important than the brand name on the side.

3. What is the difference between "used as-is" and "refurbished," and is refurbished worth the extra cost?

"Used as-is" means you are buying the machine in its current condition with no warranty and no work done on it. "Refurbished" implies that a third-party company has inspected the machine, replaced worn parts, and tested it. A properly refurbished machine from a reputable source can be a good option as it reduces some of the risk. It is often worth the extra cost if it comes with a limited warranty (e.g., 3-6 months) on the parts they replaced.

4. How does the price of a brand-new semi-automatic machine compare to a 5-year-old used fully-automatic machine?

The initial purchase prices can be surprisingly close. A 5-year-old used fully-automatic machine from a premium brand might cost anywhere from $40,000 to $70,000. A brand-new, high-quality semi-automatic machine can range from $10,000 to $20,000. Given the benefits of a new machine (warranty, efficiency, support), the new semi-automatic often presents a much better overall value and lower Total Cost of Ownership.

5. Besides repairs, what is the biggest unexpected cost new owners of used machines face?

The biggest unexpected cost is often the extremely high initial energy bill. New owners, especially those unfamiliar with older pneumatic technology, are often shocked by how much power the machine and its required large air compressor consume. This recurring monthly cost can severely impact profitability and was not factored into their original budget.

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr