Stuck with a preform mold design checklist? You are missing the real goal. A bad design costs you money every second in wasted plastic, energy, and time.

Key preform mold design factors include: 1. Quality (concentricity, gate design). 2. Efficiency (cooling, hot runner). 3. Longevity (S136 steel). 4. Maintenance. These factors directly control your final cost per preform and overall profitability.

This is not just a technical list. It is a business plan. I have seen clients focus on one factor (like a low price) and ignore another (like cooling), only to see their profits disappear. Let's break down how I approach this from a profitability angle.

Introduction: Beyond a Checklist - Designing for Profitability?

Is your mold maker just checking boxes on a spec sheet? This is a huge risk. A design that is not optimized for your factory is a design for failure.

Designing a preform mold is not about drawing a part. It is about designing for profitability. A great design lowers your cycle time, saves energy, and reduces material waste from day one. A bad design is a permanent leak in your profits.

The Mold as a "Profit Center" vs. a "Leaking Wound"

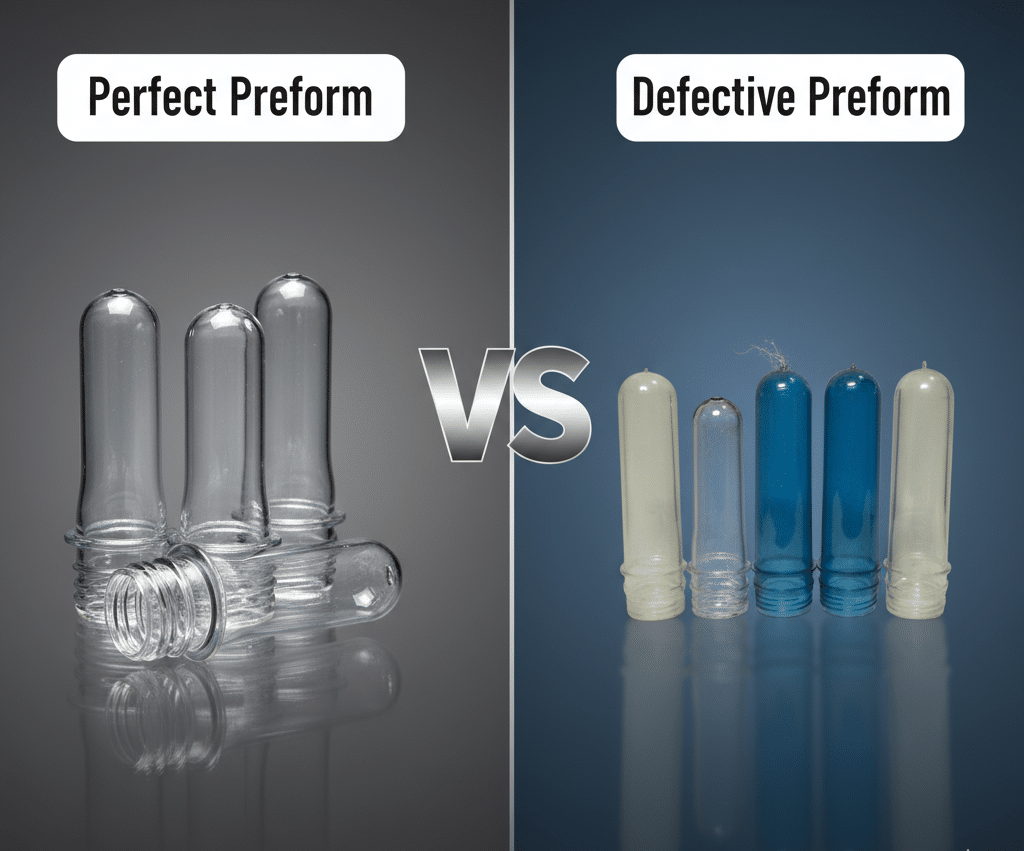

I see two types of molds in the factories I visit. The first type is a profit center. It runs 24/7, with a fast cycle, and produces perfect preforms. It just quietly makes money. The second type is a "leaking wound." It is always down. It has a slow cycle. It produces 5% scrap. This mold costs the company money every day. The difference is almost always in the initial design.

I often meet clients who come to me with a "perfect" preform drawing. They want a quote. My first step is to not give them a quote. My first step is to ask more questions.

- "What is your target cycle time?"

- "What is your exact injection molding machine model and tonnage?"

- "What is your local cost of electricity ($/kWh)?"

- "What is your annual volume target?"

They are sometimes confused by these questions. But they are the most important questions. Why?

- A high electricity cost means an efficient cooling design is not a "nice to have," it is essential for your ROI.

- Your machine specs limit the mold design. I cannot design a mold that your machine cannot run properly.

- Your annual volume tells me if a 72-cavity mold is a smart investment or a terrible waste of capital.

I must emphasize: The "best" design is always the "most suitable" design. It must match your goals, your equipment, and your costs.

| Business Goal | Design Focus (Our Recommendation) |

|---|---|

| Lowest Startup Cost | Lower cavitation (e.g., 8-16), P20 steel base, standard pin-point gate. |

| Lowest Unit Cost | High cavitation (e.g., 72-96), S136 steel, valve gate hot runner, optimized cooling. |

| High Flexibility | Medium cavitation (e.g., 32), quick-change neck inserts, balanced design. |

I remember a client in South America. He wanted a 72-cavity mold to get the "lowest cost per preform." But his factory's electricity cost was one of the highest in the region. I ran the numbers. The massive IMM and chiller needed to run that 72-cavity mold would consume so much power, it would erase all his savings. We showed him that a 48-cavity, high-efficiency mold with a special cooling design was more profitable.

A mold design is a business plan. Let's look at the first group of factors: quality.

Factor Group 1: Preform Quality - The Foundation of Everything?

Worried about your final bottles failing? The problem is not your blowing machine. The root cause is almost always a poor-quality preform.

The foundation of a good bottle is a perfect preform. The mold design must guarantee this. Key factors are concentricity (even wall thickness), gate design (no bottom defects), and venting (no burns or bubbles).

Concentricity: The Most Critical Factor

Concentricity (or a lack of it) is the #1 cause of bottle blowing defects. It refers to how perfectly the mold core is centered inside the mold cavity.

If the core is perfectly centered, the preform wall thickness is the same all the way around. But if the core is off-center by just 0.1mm, one side of the preform wall is 0.1mm thinner than the other.

This creates a "domino effect" of failure:

- The preform enters your bottle blowing machine.

- It gets heated and stretched.

- The thin spot, having less material, stretches too much. It becomes a weak spot.

- The final bottle either bursts in the machine, or it fails quality control.

This is why preform concentricity is our obsession. We guarantee concentricity within 0.05mm. How? It is not just about precision machining. It is about a robust mold design. We use a high-precision CMM (Coordinate-Measuring Machine) to check every core and cavity. But we also design the mold base with strong, tapered interlocks. These interlocks ensure the core and cavity stay perfectly aligned, even after 5 million cycles of high-pressure injection.

Gate Design: The Preform's "Belly Button"

The "gate" is the tiny hole where the molten plastic enters the cavity. Its design is critical for two reasons:

- Cosmetics: A bad gate design (like a "pin-point" gate) can leave a long plastic "tail" or "stringing." This tail can get trapped, causing defects. A valve gate system cuts the plastic flow off cleanly, leaving a smooth, flat surface on the preform bottom.

- AA Value (Acetaldehyde): This is a chemical byproduct created when PET is heated. A bad gate design (too small) creates high "shear" (friction) as the plastic is injected. This extra heat increases the AA value. This is a huge problem for bottled water, as it can give the water a slight "fruity" taste. A well-designed valve gate hot runner system preform mold minimizes shear, keeping AA levels low and the water tasting pure.

Venting: Letting the Mold "Breathe"

When molten plastic rushes into the empty cavity (in milliseconds), the air inside must escape. If it cannot escape, it gets compressed.

This compressed air gets so hot (like a diesel engine) that it burns the plastic. This shows up as black or yellow specks ("burn marks" or "diesel effect") on the preform. Trapped air can also cause "short shots," where the plastic cannot fill the space, leaving bubbles or incomplete parts.

Venting is an art. We must design micro-vents (usually 0.03mm deep, too small for plastic to flow into) in exactly the right places. We use computer flow simulations (MoldFlow) to predict where air will get trapped. This is especially important around the preform neck finish, which has complex details. This is how we ensure a crystal-clear, blemish-free preform.

Factor Group 2: Production Efficiency - Speed is Money?

Is your cycle time stuck at 20 seconds? You are losing money on every shot. A slow mold is a profit-draining machine.

In preform molding, cycle time is everything. A 1-second reduction can mean millions more preforms per year. The top three design factors for speed are: mold cooling design, the hot runner system, and the ejection system.

Mold Cooling: The #1 Factor for Cycle Time

This is the most important part of this section. Cooling accounts for 70-80% of your entire cycle time.

Your cycle time is not just injection; it is the time it takes for the 280°C molten plastic to solidify (cool below 80°C) so it can be ejected.

A mold that cools 1 second faster is a mold that makes you 5-10% more money.

I must tell this story. I had a client, a large beverage co-packer. They were stuck at an 18-second cycle on their 48-cavity mold (it was not one of ours). They were frustrated and wanted to buy a new mold. I asked to see their old mold. The mold cooling design was terrible. It was a simple, single-loop channel. The water was getting hot and slow by the end of its path.

We designed their new preform mold with a completely different philosophy.

- Multi-Zone Cooling: We designed separate, high-flow cooling circuits for the core, the cavity, and the neck ring. This lets you run colder water in the core (to cool faster) and slightly warmer water in the neck (to prevent crystallization).

- Baffled Channels: We put "baffles" inside the channels to force the water to be turbulent. Turbulent water pulls much more heat away than smooth-flowing water.

- High-Flow Design: We used larger-diameter channels with no sharp 90-degree turns. This lets their chiller pump more water, faster.

The result? We connected our new mold to their existing chiller. Their cycle time dropped from 18 seconds to 15.5 seconds. That 2.5-second saving was a 16% increase in output. They did not just buy a mold; they bought 16% more factory capacity. That is the power of design.

Hot Runner System: The Mold's "Highway"

The hot runner system preform mold is the "highway" that delivers plastic to each cavity. A bad hot runner creates traffic jams.

- Balance: A good (valve gate) system fills all 48 cavities at the exact same time. A bad (unbalanced) system fills some cavities first and some last. You have to extend your cycle time to wait for the last cavity to fill.

- Color Change: A "dead spot" in a cheap hot runner will trap old plastic. A color change (from red to clear) can take 8 hours of purging. A well-designed system has no dead spots; a color change takes 30 minutes. That is 7.5 hours of production time saved.

Ejection System: Getting the Preforms Out

This part is simple. A preform that gets "stuck" in the mold is a cycle stop. The entire multi-million dollar line must wait. A good design includes a robust stripper plate and a take-out robot that cools the preforms after ejection (called "post-mold cooling"). This allows you to eject the preforms sooner (when they are still a bit soft), cutting even more time from the cycle.

Factor Group 3: Mold Longevity & Reliability - Built to Last?

Did your mold start failing after only 1 million shots? You were sold a "sprint" mold, not a "marathon" mold. Now you face constant downtime and repair bills.

A preform mold is a 10-year investment. It must be reliable. Longevity is designed in. This comes from premium steel (S136) for core parts, the use of high-quality standard components, and a strong, robust mold structure.

Mold Steel Selection PET: The Heart of the Mold

Not all steel is the same. This is a non-negotiable for any high-quality PET preform mold specification.

PET resin is slightly corrosive. The mold runs 24/7 under high pressure and temperature. The cooling water can cause rust.

Because of this, the "wetted" components of the mold (Core, Cavity, and Lip/Neck Ring) must be made from a high-grade stainless steel.

We use S136 stainless steel (or a similar grade like H13).

- Why S136?

- High Hardness (HRC 48-52): After heat treatment, it resists wear and tear. The neck threads will stay sharp for millions of cycles.

- Superb Corrosion Resistance: It will not rust, period. This means your cooling channels stay clean, and your preform surface stays perfect.

- Excellent Polishability: It can be polished to a true mirror finish, which is what gives your preforms that crystal-clear look.

A cheap mold might use P20 steel. P20 is a good mold base steel, but it will rust. It is not hard enough. It will fail after 1-2 million shots.

This is why we give a guarantee of at least 5 million shots.

I have a customer in the Middle East. They bought a 72-cavity mold from us in 2014. It has been running almost non-stop. They called me last year for a standard refurbishment. That mold has run over 150 million preforms. That is long-term value.

Standard Components: Easy to Fix

A mold is like a car. The "engine" (the steel) should last a long time, but the "tires" and "filters" (seals, o-rings, guide bushings) will wear out.

The design must use global standard components (like DME, Hasco, or Parker).

Why? If a mold maker uses custom-made seals, you have a huge problem. When one $5 seal breaks, your entire mold is down for 6 weeks while you wait for a custom part from that maker. We only use standard parts. Your maintenance team can buy a replacement from a local supplier.

Structural Integrity

A 96-cavity mold can weigh 15 tons. It is under hundreds of tons of clamping force. The mold base (the "frame") must be incredibly strong and thick. A weak base will "flex" (bend) a tiny bit on every shot. After a million shots, this flexing causes the concentricity to fail. We design our mold bases to be "over-built" and rigid to prevent this.

The Balancing Act: Performance vs. Budget?

Do you want the "best" mold? Be careful. The "best" (most expensive) mold might be the wrong mold for your business.

A top-spec mold (96-cav, S136 steel, valve gate) is a huge investment. You must balance performance vs. budget. Over-designing is a waste of money. We help you find the "sweet spot" for your specific production volume.

My job is not to sell you the most expensive mold. My job is to sell you the most profitable mold.

I had a startup client. He wanted to make a new craft juice. He had a beautiful PET bottle design. He asked for a quote for a 32-cavity mold.

I looked at his business plan. His total annual volume was 2 million bottles.

I talked him down to an 8-cavity mold.

Why? A 32-cavity mold was a terrible investment for him.

- High CapEx: The mold and the required large IMM would have bankrupted him.

- Massive Overcapacity: He would make his entire year's supply of preforms in one month. The expensive machine would then sit idle for 11 months, still costing him money.

The 8-cavity mold was the "sweet spot." It matched a smaller, cheaper IMM. His startup cost was low. He became profitable in 6 months. Two years later, he came back and bought a 16-cavity mold. That is a successful design.

We help you balance these tradeoffs:

| Feature | Low-Cost Option | High-Performance Option | Who Needs High-Performance? |

|---|---|---|---|

| Hot Runner | Pin-point Gate | Valve Gate | Water bottlers (low AA), high-speed lines, frequent color changers. |

| Steel (Core/Cavity) | P20 Steel | S136 Stainless | Anyone running 24/7 or needing >2M shots. Non-negotiable for high volume. |

| Cavitation | 8 - 16 Cavities | 48 - 96 Cavities | Only producers with guaranteed high volume (e.g., 80M+ preforms/year). |

A 96-cavity mold for a 20-million-unit-per-year producer is a waste. We must find your perfect balance.

Don't Forget the Details: Ease of Maintenance?

Is your mold down for a full day just to change a seal? This is a design flaw. Your maintenance team is wasting time and you are losing production.

A mold is a machine that needs maintenance. A great design makes this easy. Factors include quick-change neck parts, clearly labeled water/air hookups, and easy access to wear parts like seals.

Downtime is a profit killer. A mold that is "easy to work on" saves you thousands of dollars a year in labor and lost production.

This is where our experience really shows.

Clearly Labeled Connections

It sounds simple, but it is vital. We laser-etch every single water and air connection. "Water In 1," "Water Out 1," "Air 1." We also color-code the hoses.

I have seen molds from other makers with 24 identical, unlabeled silver nozzles. The operator spends an hour with a paper diagram. He still hooks one up backward. This starves one cavity of cooling, causing defects all day. Our design makes hookup a 10-minute, error-free job.In-Machine Accessibility

Some maintenance should be done without removing the 10-ton mold from the machine.

Our neck rings and thread-splits (the preform neck finish parts) are designed to be replaceable while the mold is still in the IMM. If an operator damages a thread, the maintenance team can replace just that one part in 30 minutes. A bad design would require removing the entire mold—an 8-hour job.Maintenance-Friendly Design

We think about the person who has to clean the mold. We add lifting holes in safe, balanced spots. We add "pry slots" to make it easy to separate the mold plates. We use standard O-rings. These small details add up to big savings in time and frustration.

The Most Critical Factor? Your Mold Maker's Expertise?

Are you just comparing spec sheets and prices? You are missing the most important factor. The cheapest mold is often the most expensive one you will ever own.

You are not just buying steel. You are buying the experience of the mold maker. Their expertise in problem-solving, their understanding of your business, and their after-sales support are more valuable than any single feature.

A preform mold is not a commodity. It is a highly complex piece of engineering. A spec sheet cannot tell you the quality of the design.

What is "expertise"?

- 1. Asking the Right Questions: A good salesperson sells you what you ask for. An expert partner (like me) asks why you are asking for it. We dig deeper to find your real need. This is the difference between getting a mold and getting a solution.

- 2. Problem Prediction: Experience is knowing what will go wrong. We know that a certain preform shape is prone to air traps. We know a certain resin needs special cooling. We design the solution before it becomes your problem.

- 3. Integrated Knowledge: This is our biggest advantage. We do not just make preform molds. We also make blow bottle molds. We understand how our preform design will behave in your blowing machine. We can design the preform to solve blowing problems. We can even do 3D printed bottle samples first. Most preform-only makers cannot do this. They only see half of the picture.

| Spec Sheet Says... | The Expert Asks... |

|---|---|

| "S136 Steel" | "Is it certified S136? Is the heat treatment done correctly to HRC 50? Is it polished in the right direction?" |

| "8 Cooling Channels" | "Are the channels in the right place? Are they balanced? Is the water flow turbulent? What is the GPM?" |

| "Valve Gate" | "Is the gate size correct for the resin? Is the thermal profile balanced? Is the tip material correct?" |

When you choose iBottler, you are not just buying a mold. You are hiring my 16 years of experience. You are hiring our entire engineering team. When you have a problem, you do not send an email to a generic "support" box. You call me. We will solve it. That is the real value.

Let's Design Your Next High-Performance Preform Mold?

Ready to buy a mold? Do not just send a "request for a quote." That is a lottery. Let's have a real conversation to design the perfect tool.

A great mold is a partnership. Let's design it together. Bring us your bottle design, your production goals, and your machine specs. Our engineers will work with you to build a high-performance mold that drives your business.

This article has covered a lot. Quality, speed, longevity, cost. It is a lot to balance.

You do not have to do it alone. The next step is not to "buy." The next step is to "collaborate."

Here is what I propose:

- Bring your idea: Your bottle design concept or preform drawing.

- Bring your goals: Your annual volume, target cycle time.

- Bring your constraints: Your budget, your existing IMM.

My engineering team and I will sit down with you. We will not just give you a price. We will give you a plan.

This plan will include:

- A preliminary preform design.

- A recommended cavitation and mold layout.

- The required IMM tonnage and chiller specs.

- An estimated cycle time and annual output.

- A clear discussion of the cost/benefit tradeoffs (e.g., S136 vs. P20).

This is a collaborative process. We will tweak the design until it is the perfect "sweet spot" for your business.

Stop searching for a simple checklist. Start a conversation with an expert partner. Contact us today, and let's have that deep technical discussion.

Conclusion

A preform mold's design is a balance of quality, speed, and cost. Choosing an expert partner to navigate these factors is the most critical decision you will make.

| Factor Group | Key Design Factors | Why It Matters for Profitability |

|---|---|---|

| Preform Quality | Concentricity, Gate Design, Venting | Reduces scrap, improves final bottle quality, ensures brand standards. |

| Production Efficiency | Cooling System, Hot Runner, Ejection | Lowers cycle time, increases output, and reduces energy cost per preform. |

| Mold Longevity | Steel Selection (S136), Standard Parts | Maximizes mold life (ROI), minimizes downtime and repair costs. |

| Budget & Cost | Cavitation, Steel, Hot Runner | Balances upfront investment (CapEx) with long-term unit cost (OpEx). |

| Maintenance | Labeled ports, easy access | Reduces downtime, lowers labor costs for cleaning and repairs. |

| Mold Maker | Expertise, Support, Experience | The "X-Factor" that ensures all other factors are optimized for your specific project. |

Frequently Asked Questions (FAQ)

Q: What is the single most important factor affecting preform mold cycle time?

A: Cooling efficiency. The time it takes for the molten PET to solidify in the mold accounts for the largest portion of the cycle. An optimized cooling channel design is paramount for high-speed production.

Q: Why is S136 steel preferred for core/cavity/lip areas?

A: S136 offers an excellent combination of high hardness (resists wear, maintains precision), superb corrosion resistance (important for PET processing and preventing rust), and the ability to achieve a mirror-like polish (ensuring preform clarity).

Q. What is "concentricity" and why is it so critical for preforms?

A: Concentricity refers to how perfectly centered the mold core is within the mold cavity. Poor concentricity leads to uneven wall thickness in the preform. When this preform is blown, the thin sections stretch too much, potentially causing bottle weakness or blowouts.

Q: How much does the hot runner system contribute to the total mold cost?

A: The hot runner system is a major cost component, often accounting for 30-50% of the total mold price, especially for high-cavitation molds with valve gate systems. Choosing the right system is crucial for both quality and budget.

Q: What basic information do I need to provide to get a preliminary mold design proposal?

A: At a minimum, we need: 1) Your preform drawing (or sample), 2) Target preform weight, 3) Intended application (water, CSD, hot-fill?), 4) Your injection molding machine tonnage, and 5) Your desired cavitation.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr