Struggling with preform molds that don’t fit your bottles? I’ve been there—wasted effort stings. Let’s nail the design basics together.

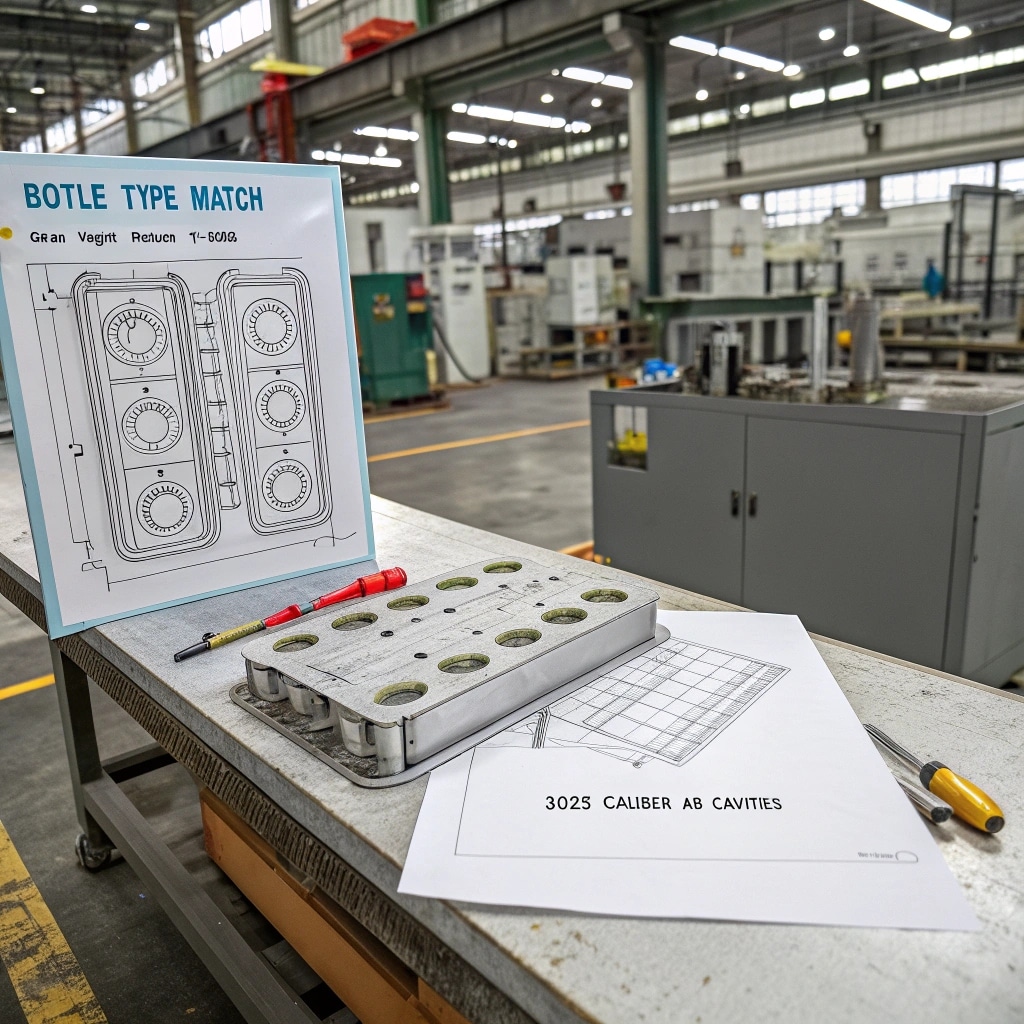

I focus on bottle type, gram weight, caliber, and cavity count. These essentials ensure my molds deliver perfect preforms every time—here’s how you can too.

I’ve spent years perfecting molds in my factory. Stick around—I’ll share what I’ve learned to boost your production.

What Are the Important Factors to Be Considered When We Design a Mould?

I’ve seen molds fail from sloppy planning—rejects pile up fast. It’s a headache I avoid now.

Match the preform to the bottle type, set gram weight, pick caliber, and choose cavities. I get these right—molds work like a charm.

Planning’s not just paperwork—it’s profit. I’ve tweaked this over time. Let’s dig into why it matters.

Breaking Down Design Factors

I start with purpose. Is the preform for a special bottle? I shape it to fit—round or square, it’s got to match. Gram weight’s next—I aim for 18 grams, tolerance at 0.2 grams max. Caliber’s key—3025 fits most, but 45 mm suits big bottles. Cavities depend on output—I run 48 for speed, but my machine limits me to 32. My first mold ignored bottle type—bottles leaked. Now, I test fits. Each choice ties to results—miss one, and you’re stuck reworking.

| Factor | Why It Matters | My Approach |

|---|---|---|

| Bottle Type | Fit and Function | Match Shape |

| Gram Weight | Consistency | Set Tight Tolerance |

| Caliber | Bottle Compatibility | Pick per Need |

| Cavities | Output Speed | Match Machine |

Nail these—you’re golden.

What Is Preform Molding?

I used to wonder how preforms turn into bottles—mystery solved. It’s simpler than it looks.

Preform molding makes plastic blanks for bottles. I inject melted PET into molds—cooled preforms get blown into final shapes later.

It’s the heart of bottle-making. I’ve run this daily—let’s explore what makes it tick.

Understanding Preform Molding

I melt PET at 280°C—it flows into my mold’s cavities. Cooling locks the shape—fast water channels help. Precision matters—0.01mm off, and blowing fails. My early molds warped—poor cooling was the culprit. Now, I control heat tight. The preform’s just step one—blow molding finishes it. Gram weight sets volume—18 grams suits 500ml bottles. It’s basic but critical—mess up, and bottles flop. I test each batch—quality’s my edge.

| Step | Key Point | My Fix |

|---|---|---|

| Melting | Even Flow | Steady 280°C |

| Cooling | Shape Lock | Fast Channels |

| Precision | Blow Success | Tight Tolerances |

Get this—bottles fly off the line.

What Are the Main Elements of Mold?

I’ve cracked open molds—lots of parts inside. Each one’s got a job.

Core, cavity, cooling channels, and gates—I build these right. They shape preforms, cool fast, and feed plastic smooth.

Parts sound boring—they’re not. I’ve learned their tricks—let’s see why they’re key.

Exploring Mold Elements

I craft the core—it forms the preform’s inside. The cavity shapes the outside—perfect fit’s a must. Cooling channels run water—close to cavities, they cut cycle time. Gates control plastic flow—small ones clog, big ones waste. My first mold had bad gates—preforms stuck. Now, I balance size. Steel matters—P20 holds up. Alignment pins keep it tight—sloppy fits ruin batches. I check wear monthly—durability’s my goal. Each piece clicks—output soars.

| Element | Role | My Tip |

|---|---|---|

| Core | Inner Shape | High Polish |

| Cavity | Outer Shape | Match Bottle |

| Cooling | Speed | Near Cavities |

| Gates | Plastic Flow | Size Right |

Build smart—molds last.

What Is the Manufacturing Process of PET Preform?

I’ve run PET preform lines for years—it’s a dance of heat and pressure. Simple, but precise.

I melt PET, inject it into molds, cool it fast, and eject preforms—ready for blowing into bottles.

It’s my bread and butter. I’ve fine-tuned it—let’s walk through how it works.

Diving Into PET Preform Manufacturing

I dry PET pellets—wet ones bubble. Heat hits 280°C—liquid flows into my 48-cavity mold. Injection pressure’s 1000 bar—fills every corner. Cooling takes 10 seconds—channels keep it even. Ejection’s smooth—pins pop preforms out. My old setup skipped drying—defects spiked. Now, I monitor temps. Gram weight’s locked—18 grams, 0.2-gram tolerance. Machine size limits cavities—I max at 144. Trials catch flaws—clients love the consistency. It’s fast, but details rule.

| Stage | Focus | My Check |

|---|---|---|

| Drying | No Bubbles | 4 Hours, 120°C |

| Injection | Full Fill | 1000 Bar |

| Cooling | Even Set | 10 Seconds |

| Ejection | Clean Release | Pin Alignment |

Master this—production hums.

Conclusion

I design molds with purpose—bottle fit, weight, caliber, and cavities drive success. Use my tips—your preforms will shine.