Struggling to meet high production demands for bottles? Wondering if there's a more efficient solution than your current setup? A 4-cavity blow moulding machine might be the answer.

A 4-cavity blow moulding machine is an automated system that produces four plastic bottles simultaneously during each molding cycle. This significantly boosts output compared to machines with fewer cavities, making it ideal for businesses needing high-volume production.

You might be thinking that upgrading your production line sounds complex and expensive. I understand that feeling. Many of my clients face this dilemma. They want to grow, but they're unsure about the next steps in machinery. This article will break down what a 4-cavity machine is, how it works, and if it’s the right choice for you. We’ll explore everything you need to know to make an informed decision.

4-Cavity Blow Moulding Machine: Semi-Auto vs. Fully Automatic – Which One Should You Choose?

Are you weighing options for a new blow moulding machine? Confused about whether semi-automatic or fully automatic is better for your needs? Making the right choice is key.

A fully automatic 4-cavity machine offers higher output and lower labor costs long-term, while a semi-automatic version has a lower initial investment but requires more manual intervention.

Choosing between semi-automatic and fully automatic can feel like a big decision. I remember when I first started guiding clients through this; it often came down to balancing current budgets with future growth plans. Let's dive deeper into what sets these two types apart for a 4-cavity setup. This will help you understand which one aligns best with your production goals and resources. We will look at factors like initial cost, labor, output, and maintenance.

Key Differences: Semi-Automatic vs. Fully Automatic 4-Cavity Machines

When considering a 4-cavity blow moulding machine, the primary decision often revolves around the level of automation. Both semi-automatic and fully automatic machines have their place, but they cater to different operational scales and investment capabilities.

A semi-automatic 4-cavity machine typically requires manual loading of preforms into the heating section and manual transfer of heated preforms to the blowing station. The bottle ejection might be automatic, but the initial stages depend on an operator. This means:

- Lower initial investment cost.

- More labor-intensive operation.

- Production speed is somewhat dependent on operator skill and speed.

- Simpler mechanics might lead to easier maintenance for less experienced teams.

On the other hand, a fully automatic 4-cavity machine integrates all processes from preform loading to bottle ejection. This includes:

- Higher initial investment cost.

- Significantly reduced labor requirements; often one operator can oversee multiple machines.

- Consistent and higher production output.

- More complex system requiring skilled technicians for maintenance and troubleshooting.

Here's a simple comparison:

| Feature | Semi-Automatic 4-Cavity | Fully Automatic 4-Cavity |

|---|---|---|

| Preform Loading | Manual | Automatic (e.g., hopper and unscrambler) |

| Preform Transfer | Manual/Semi-Automatic | Automatic |

| Bottle Ejection | Automatic/Semi-Automatic | Automatic |

| Labor Cost | Higher | Lower |

| Output Rate | Moderate | High & Consistent |

| Initial Cost | Lower | Higher |

| Flexibility | Can be better for very small, varied batches | Best for continuous, high-volume production |

| Operator Skill | Basic to Moderate | Moderate to Skilled (for oversight) |

I had a client in the beverage industry who started with a 2-cavity semi-automatic machine. As their demand grew, the labor costs and limitations in output became a bottleneck. They eventually upgraded to a 4-cavity fully automatic machine, and the difference in their production efficiency was night and day. It really depends on your specific business stage and growth trajectory.

How Does a Fully Automatic 4-Cavity Blow Moulding Machine Work?

Ever wondered how those plastic bottles get made so quickly and uniformly? Curious about the magic behind a fully automatic 4-cavity blow moulding machine? It's a fascinating process.

A fully automatic 4-cavity blow moulding machine works by automatically feeding PET preforms, heating them to the right temperature, stretching and blowing them into bottle shapes within four molds simultaneously, and then ejecting the finished bottles.

The journey from a small plastic preform to a finished bottle is a precise sequence of events. Understanding this process helps you appreciate the technology and identify what to look for in a machine. It's not just about speed; it's about precision at every step. Let’s break down the operational flow of these impressive machines from start to finish.

Step-by-Step Operational Flow

A fully automatic 4-cavity blow moulding machine operates through a sequence of synchronized steps to transform PET preforms into finished bottles. Here's a more detailed look:

Preform Loading and Unscrambling:

- PET preforms are loaded into a hopper.

- An automatic unscrambler or sorter orients the preforms correctly (usually neck-up) and feeds them onto a conveyor or loading rail. This ensures a continuous and orderly supply to the heating system.

Preform Heating:

- The preforms travel through an oven equipped with multiple infrared heating lamps.

- The lamps are arranged in zones, and their intensity can be adjusted to ensure uniform heating of the preform body. The neck area is usually shielded from heat to maintain its shape and thread integrity.

- Preforms are typically rotated as they pass through the oven to achieve even temperature distribution. The goal is to bring the PET to its ideal pliable temperature for stretching and blowing.

Preform Transfer to Molds:

- Once heated, robotic arms or a transfer mechanism precisely and swiftly moves four preforms simultaneously into the four open blow molds.

Clamping, Stretching, and Blowing:

- Clamping: The two halves of each of the four blow molds close tightly around the preforms, sealing the neck area.

- Stretching: A stretch rod descends into each preform, stretching it vertically towards the bottom of the mold. This axial orientation helps improve the strength and clarity of the bottle.

- Pre-blowing (Optional): A low-pressure air is sometimes introduced to slightly inflate the preform, helping it take the general shape of the mold and ensuring even wall thickness.

- Final Blowing: High-pressure compressed air is then injected into the stretched preforms, forcing the plastic to expand outwards and conform to the exact shape of the mold cavity. This happens in all four molds at the same time.

Cooling:

- The newly formed bottles are held within the molds for a short cooling period. Chilled water circulates through channels in the molds to rapidly cool the plastic, allowing it to solidify and retain its shape. Efficient cooling is crucial for cycle time and bottle quality.

Bottle Ejection:

- After cooling, the molds open.

- An ejection mechanism, often robotic arms or air-assisted systems, removes the four finished bottles from the molds and places them onto an output conveyor.

Recycle: The entire process repeats for the next cycle. The system is designed for continuous operation, minimizing downtime.

Understanding this cycle helps in appreciating the precision engineering involved. Each step needs to be perfectly synchronized for optimal performance and quality bottle production.

Output Capacity and Efficiency of a 4-Cavity Automatic Machine?

Concerned about meeting increasing customer orders? Wondering if a 4-cavity automatic machine can truly deliver the required throughput? Let's look at the numbers.

A 4-cavity automatic blow moulding machine can typically produce between 3,000 to 6,000 bottles per hour (BPH), depending on bottle size, design complexity, and preform quality.

When I talk to clients about upgrading, output is always a top concern. They need reliable figures to plan their production and justify the investment. The efficiency of these machines isn't just about speed; it's about consistent, high-quality output with minimal waste. Let's delve into what factors influence the production rate and overall efficiency.

Factors Influencing Output and Efficiency

The theoretical output of a 4-cavity automatic blow moulding machine is impressive, but several factors can influence the actual production rate and overall operational efficiency. It’s not just about the number of cavities.

Bottle Design and Size:

- Smaller, simpler bottles generally allow for faster cycle times. For example, a 500ml water bottle will usually have a higher BPH than a complex 1-liter bottle with thick walls or an intricate shape.

- The cooling time required also varies with bottle thickness and design. Thicker sections need longer to cool, which extends the cycle time.

Preform Quality:

- Consistent preform weight, dimensions, and material quality (Intrinsic Viscosity - IV) are crucial. Poor quality preforms can lead to defects, higher rejection rates, and inconsistent blowing, all of which reduce effective output.

- Using preforms from a reputable supplier or ensuring your in-house preform production is top-notch is key.

Machine Condition and Maintenance:

- A well-maintained machine operates closer to its optimal speed. Regular maintenance, including lubrication, checking seals, and ensuring the pneumatic and hydraulic systems are in good order, prevents unexpected downtime.

- Worn molds or components can also lead to quality issues and slower cycles.

Heating System Efficiency:

- Precise and stable heating of preforms is vital. An efficient oven with good temperature control ensures preforms reach the ideal blowing temperature quickly and evenly, minimizing delays and defects.

- The type and configuration of heating lamps play a significant role.

Cooling System Performance:

- The efficiency of the mold cooling system directly impacts cycle time. A robust chilling unit and well-designed cooling channels in the molds are necessary for rapid solidification of the bottles.

Compressed Air System:

- A stable supply of clean, dry, high-pressure air is essential for the blowing process. Insufficient air pressure or volume can lead to incomplete bottle formation and slow down the machine.

- The recovery rate of the air compressors must match the machine's consumption.

Operator Skill and Automation Level:

- While fully automatic machines reduce manual intervention, skilled operators are still needed for setup, monitoring, quality checks, and minor adjustments.

- The seamless operation of integrated systems like auto-loaders and take-out systems also contributes to overall efficiency.

My South African client, whom I mentioned earlier, initially projected a certain output when they decided on their 4-cavity fully automatic machines. We worked closely to optimize their preform selection and fine-tune the machine settings. They found that investing a bit more in high-quality preforms significantly reduced their defect rate and allowed the machine to run consistently at its higher speed range, ultimately exceeding their initial output targets. This is a common experience: quality inputs and good practices maximize efficiency.

Preform Feeding and Bottle Take-out Systems: How Automation Saves Labor?

Tired of the repetitive manual labor involved in loading preforms and removing bottles? Looking for ways to streamline your production line and reduce operational costs? Automation is key.

Automated preform feeding and bottle take-out systems in a 4-cavity machine dramatically reduce manual labor, ensure consistent operation, and can integrate seamlessly with downstream equipment like fillers.

I've seen firsthand how much labor can be saved by automating these crucial steps. Manually loading thousands of preforms and removing bottles shift after shift is not only tedious but also prone to inconsistencies and can be a source of bottlenecks. Let's explore how these automated systems work and the benefits they bring.

The Mechanics of Automated Infeed and Outfeed

In a fully automatic 4-cavity blow moulding setup, the preform feeding and bottle take-out systems are critical for achieving high efficiency and reducing reliance on manual labor.

1. Automated Preform Feeding System:

This system typically consists of several components working in unison:

- Preform Hopper/Bin: This is where a large quantity of preforms is initially loaded. It acts as a buffer storage.

- Elevator/Conveyor: Preforms are transported from the hopper to an unscrambler, usually via an inclined cleated conveyor or a similar lifting mechanism.

- Unscrambler (Sorter): This is a crucial device. Preforms often arrive in bulk and are randomly oriented. The unscrambler uses mechanical or vibratory methods to orient each preform correctly (typically neck-up) and align them for feeding into the machine's heating section. Centrifugal unscramblers or vibratory bowl feeders are common.

- Feed Rails/Star Wheel: Once oriented, preforms are channeled onto feed rails or a star wheel system that delivers them in a precisely timed manner to the preform holders or mandrels that carry them through the heating oven.

Benefits of Automated Preform Feeding:

- Reduced Labor: Eliminates the need for an operator to manually load preforms one by one or in small batches.

- Consistent Supply: Ensures a steady and uninterrupted flow of preforms to the machine, maximizing uptime.

- Higher Speed: Automated systems can feed preforms at speeds that match the machine's maximum production capacity, something difficult to achieve consistently with manual feeding.

- Reduced Contamination: Minimizes human handling of preforms, reducing the risk of contamination.

2. Automated Bottle Take-out System:

Once the bottles are blown and the molds open, an automated system removes them:

- Robotic Arms/Ejectors: Most modern fully automatic machines use robotic arms with specially designed grippers or pneumatic ejectors to pick all four bottles simultaneously from the opened molds.

- Conveyor System: The bottles are then placed onto an output conveyor. This conveyor can transport the bottles to quality inspection stations, labeling machines, or directly to a filling line (air-veyor systems are common for PET bottles to maintain hygiene and orientation).

Benefits of Automated Bottle Take-out:

- Labor Savings: No need for an operator to manually reach in and remove bottles.

- Speed and Synchronization: The take-out system is perfectly synchronized with the machine's cycle, ensuring quick removal and preventing delays.

- Safety: Reduces the risk of operator injury associated with reaching into the molding area.

- Integration: Facilitates seamless integration with downstream equipment, creating a fully automated production line from blowing to packing.

I recall a client who was hesitant about the added cost of a fully integrated auto-loader for their first automatic machine. After just a few months of operation, they told me it was the best part of their investment because it freed up an operator to focus on quality control and other tasks, significantly improving their overall workflow.

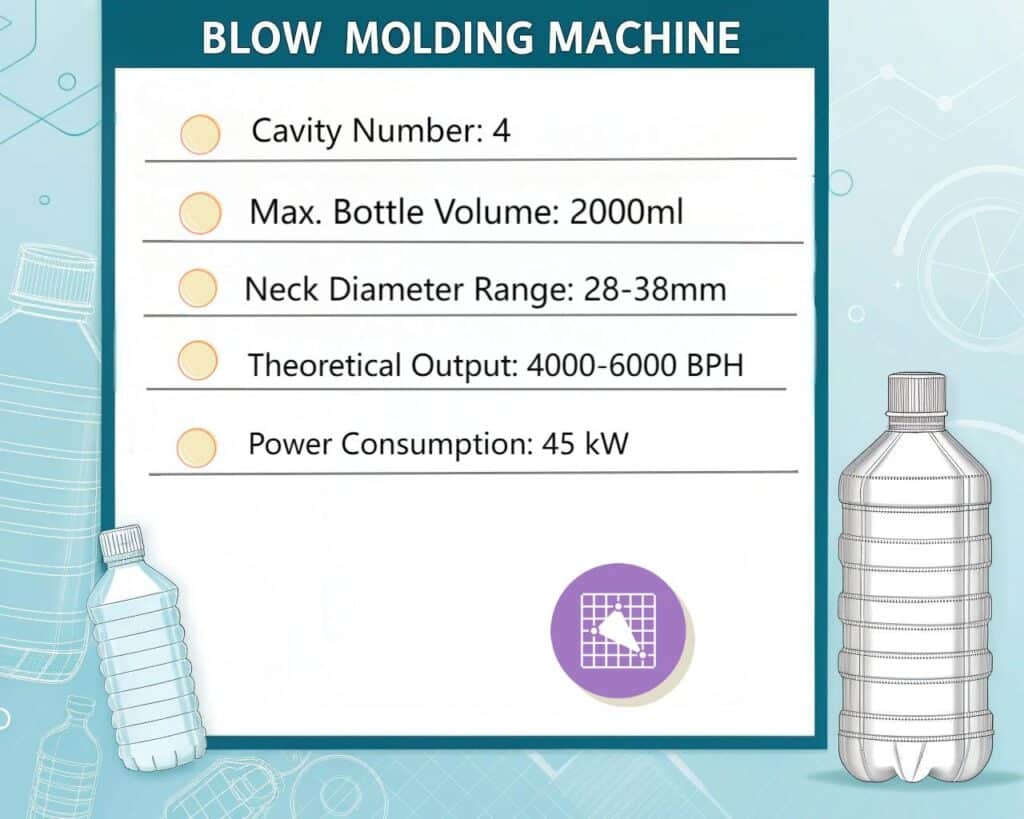

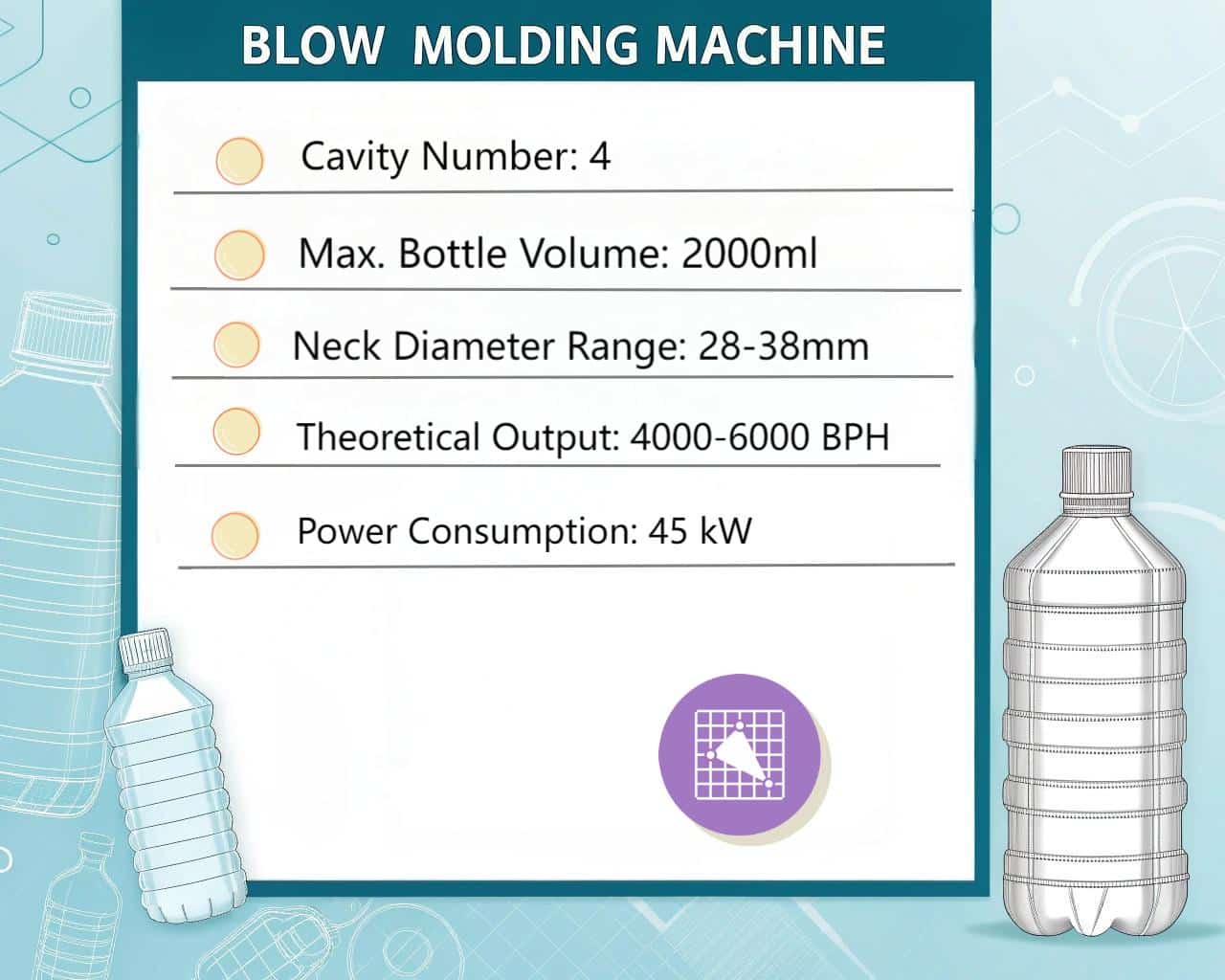

Key Technical Specifications You Should Know?

Feeling overwhelmed by technical data sheets for blow moulding machines? Unsure which specifications truly matter for your bottle production needs? Let's clarify the essentials.

Key technical specifications include cavity number (4), maximum bottle volume, neck diameter range, theoretical output (BPH), clamping force, mold dimensions, power consumption, and required air pressure/volume.

When you're looking to buy a machine, the spec sheet can look like a foreign language. But understanding these key parameters is crucial for selecting a machine that fits your current and future production requirements. Let’s break down some of the most important technical specifications and why they matter.

Decoding the Data: Essential Machine Parameters

When evaluating a 4-cavity fully automatic blow moulding machine, several technical specifications are paramount. These numbers define the machine's capabilities and its suitability for your specific products.

Number of Cavities:

- Specification: 4 (as per our discussion)

- Importance: Directly impacts the number of bottles produced per cycle.

Maximum Bottle Volume (ml or L):

- Specification Example: 500ml, 1500ml, 2000ml.

- Importance: Defines the largest size of bottle the machine can produce. Ensure this aligns with your product range. A machine designed for 2L bottles might not be optimal for very small bottles (e.g., 100ml) and vice-versa, though some offer flexibility.

Neck Diameter Range (mm):

- Specification Example: 20mm - 38mm.

- Importance: Determines the range of preform neck finishes the machine can handle. This needs to match your preform specifications and cap requirements. Common standards include PCO1810, PCO1881, 30/25, etc.

Theoretical Output (Bottles Per Hour - BPH):

- Specification Example: 4000 - 6000 BPH.

- Importance: Indicates the maximum production speed. As discussed, actual output can vary based on bottle size, weight, and complexity.

Clamping Force (Tons or kN):

- Specification Example: 30 Tons - 70 Tons.

- Importance: The force applied to keep the mold halves tightly shut during the high-pressure blowing process. Insufficient clamping force can lead to flash (excess material leaking from the mold) or inconsistent bottle quality, especially for larger bottles or those with complex designs.

Maximum Mold Dimensions (L x W x H in mm):

- Specification Example: 400 x 500 x 350 mm.

- Importance: Defines the physical size of the blow molds the machine can accommodate. This is linked to the bottle volume and design. You need to ensure your existing or planned molds will fit.

- Mold Thickness Range (mm): Also important, as it affects how the mold sits in the clamping unit.

Main Power Consumption (kW):

- Specification Example: 25 kW - 75 kW (can vary significantly based on heating elements and machine size).

- Importance: Impacts operational costs. Consider the total power, which includes heaters, motors, and control systems. Look for energy-efficient designs.

Heater Power (kW):

- Specification Example: 15 kW - 50 kW.

- Importance: A significant portion of the total power consumption. Efficient oven design and lamp control can save energy.

Required Air Pressure (Bar or PSI) & Volume (m³/min or CFM):

- Low Pressure Air (for pneumatic actuation): Example: 8-10 Bar.

- High Pressure Air (for blowing): Example: 25-40 Bar.

- Volume: Example: 2.0 - 5.0 m³/min for high pressure.

- Importance: Crucial for bottle formation. The machine needs a consistent supply of clean, dry compressed air at the specified pressures and volumes. Your air compressor system must be adequately sized.

Here’s a table summarizing these critical parameters:

| Specification | Typical Range (for 4-Cavity Auto) | Why It Matters |

|---|---|---|

| Max. Bottle Volume | 100ml - 2000ml | Defines product size capability |

| Neck Diameter | 20mm - 38mm (common) | Compatibility with preforms/caps |

| Theoretical Output | 3000 - 6000 BPH | Production speed potential |

| Clamping Force | 30 - 70 Tons | Ensures mold integrity during blowing |

| Max. Mold Dimensions | Varies by manufacturer | Physical fit of your molds |

| Total Power Consumption | 25 - 75 kW | Operational energy cost |

| High-Pressure Air | 25 - 40 Bar / 2-5 m³/min | Essential for blowing; impacts compressor choice |

When I work with clients selecting a machine, we always start with their bottle drawings and desired output. From there, we meticulously go through these specifications to ensure the chosen machine is a perfect match, not just for today, but for their anticipated growth.

Common Bottle Types Made with 4-Cavity Automatic Machines?

Planning to produce a specific type of bottle? Wondering if a 4-cavity automatic machine is versatile enough for your product line? It's a valid question.

4-cavity automatic machines are highly versatile and commonly produce PET bottles for water, carbonated soft drinks (CSD), juice, tea, edible oil, sauces, detergents, and some cosmetic products.

The adaptability of these machines is one of their biggest strengths. I've seen them used for an incredibly diverse range of products. The key is usually the material (PET) and the general size range. Let's look at some of the most common applications for these workhorses of the bottling industry.

Versatility in Bottle Production

Four-cavity fully automatic PET blow moulding machines are designed to cater to a wide array of bottle types, primarily driven by the food and beverage industry, but also extending to household and personal care products. The suitability depends on the bottle's volume, neck finish, and design complexity, all within the machine's specifications.

Common Applications Include:

Beverage Bottles:

- Mineral Water & Purified Water: This is perhaps the largest segment. Standard sizes range from 250ml, 330ml, 500ml, 600ml, 1L, to 1.5L. The lightweight nature and clarity of PET make it ideal.

- Carbonated Soft Drinks (CSD): These bottles require specific base designs (e.g., petaloid base) to withstand the internal pressure of carbonation. 4-cavity machines can handle these specialized molds.

- Juices (Hot-fill & Aseptic-fill): For juices, especially those requiring hot-fill, the machine might need specific configurations, and the preforms/bottles are designed to withstand higher temperatures without deformation. Some machines are adapted for heat-set bottles.

- Ready-to-Drink Teas & Coffees: Similar to juices, these may require heat-set capabilities depending on the filling process.

- Energy Drinks & Sports Drinks: Often in sleek, custom shapes, well within the capabilities.

Food Product Bottles:

- Edible Oils (e.g., sunflower, olive): PET is a popular choice for its shatter resistance and clarity. Sizes can range from 250ml to 2L.

- Sauces, Ketchup, Dressings: Many condiments are now packaged in PET bottles for convenience and safety.

- Syrups & Concentrates: Custom shapes and sizes are common.

Household & Personal Care Bottles:

- Detergents & Cleaning Agents: While some use HDPE, PET is also used for liquid detergents, dish soap, and window cleaners, especially where clarity is desired.

- Hand Sanitizers: A huge market, with many small to medium-sized PET bottles.

- Shampoos, Conditioners, Lotions (Smaller Volumes): Though many high-end cosmetics use other plastics or glass, PET is common for mass-market personal care items. The machine's ability to handle various neck finishes is important here for different types of pumps and caps.

Factors Determining Suitability:

- Material: Primarily Polyethylene Terephthalate (PET).

- Volume: Typically up to 2 liters. Larger volumes often use machines with fewer cavities or different blowing technologies.

- Neck Finish: Must match the machine's preform holder and neck tooling specifications.

- Shape Complexity: While versatile, extremely intricate designs or those with very sharp angles might require specialized mold making and careful process tuning. Round, oval, and rectangular bottles are common.

I had a client who started producing only water bottles. Later, they wanted to expand into juices. We reviewed their existing 4-cavity machine's specs. While it was great for water, for hot-fill juices, they eventually invested in a machine specifically designed for heat-set bottles to ensure product integrity. It shows that while versatile, specific application needs are key.

Cooling System and Power Consumption: What to Expect?

Worried about the operational costs like energy and cooling? Understanding these aspects is crucial for calculating the true cost of ownership for a 4-cavity blow moulding machine.

An efficient cooling system (water chiller) is vital for cycle time and bottle quality. Total power consumption will include heaters, motors, and the chiller, typically ranging from 25kW to 75kW overall.

These are practical concerns for any manufacturer. The cooling system isn't just an add-on; it's integral to performance. And power consumption directly hits your bottom line. Let's break down what you need to know about these two critical operational aspects.

Managing Heat and Energy Usage

The cooling system and overall power consumption are significant factors in the day-to-day operation and profitability of a 4-cavity automatic blow moulding machine.

1. Cooling System:

Purpose: The primary role of the cooling system is to rapidly solidify the molten plastic after it has been blown into the bottle shape. Efficient cooling is essential for:

- Reducing Cycle Time: The faster the bottle cools to a stable state, the sooner the mold can open and eject the bottle, leading to higher output.

- Ensuring Bottle Quality: Proper cooling prevents deformities, ensures dimensional stability, and contributes to the desired mechanical properties and clarity of the bottle.

- Mold Temperature Control: Maintaining a consistent mold temperature is key for consistent bottle production.

Components:

- Water Chiller: This is the heart of the cooling system. An industrial chiller supplies cooled water (or a water-glycol mixture) at a specific temperature and flow rate. The chiller's capacity (often measured in tons of refrigeration or kW) must be matched to the heat load of the blow moulding machine and molds.

- Mold Cooling Channels: Blow molds are designed with internal channels through which the chilled water circulates, drawing heat away from the plastic. The design of these channels (their placement, diameter, and path) significantly impacts cooling efficiency.

- Pumps and Pipework: To circulate the coolant between the chiller and the molds.

Considerations:

- Chiller Sizing: Undersizing the chiller will lead to inadequate cooling, longer cycle times, and potential quality issues. Oversizing leads to unnecessary energy consumption.

- Water Quality: Using treated water can prevent scaling and blockages in the cooling channels and chiller, maintaining efficiency.

- Ambient Temperature: High ambient temperatures can place a greater load on the chiller.

2. Power Consumption:

Major Consumers:

- Heating Oven: The infrared lamps used to heat the PET preforms are the largest single consumer of electricity. Modern machines use energy-efficient lamps and control systems (e.g., PID controllers, individual lamp adjustments) to optimize heating and reduce waste.

- Main Drive Motors: Motors for the clamping unit, stretching mechanism, and other moving parts.

- Hydraulic System (if applicable): Some machines use hydraulic clamping, which has its own motor and pump. Servo-electric machines are becoming more common for energy savings.

- Pneumatic System: While air compressors are separate, the machine's demand influences their run time and energy use.

- Control System & Electronics: PLC, HMI, sensors, etc.

- Chiller: The chiller itself is a significant power consumer. Its consumption should be factored into the total operational cost.

- Auxiliary Equipment: Preform loaders, unscramblers, and conveyors also add to the total load.

Energy Saving Features:

- Look for machines with servo-driven movements instead of purely hydraulic or pneumatic where possible.

- Advanced heater control and oven insulation.

- Air recovery systems that recycle some of the high-pressure blowing air.

- "Sleep" or "standby" modes for reduced consumption during short downtimes.

I always advise clients to get a detailed breakdown of power consumption for the machine and the recommended chiller. It’s also wise to consult with an energy expert to ensure your factory’s power supply can handle the load and to explore any local incentives for energy-efficient machinery. One client in a region with high electricity costs found that investing a bit more in a machine with servo drives and an advanced air recovery system paid off within two years due to lower energy bills.

Space Requirement and Auxiliary Equipment for a 4-Cavity Blow Moulding Setup?

Planning your factory layout? Concerned about how much space a 4-cavity machine and its supporting equipment will actually take up? This is a critical logistical step.

A 4-cavity blow moulding setup needs considerable space not just for the machine, but also for auxiliary equipment like air compressors, a chiller, preform storage, and product outfeed conveyors.

It’s easy to underestimate the total footprint. I've seen clients focus only on the machine dimensions and then scramble to fit everything else in. Proper planning for space and the necessary auxiliary gear ensures a smooth installation and efficient workflow. Let's detail what you'll need to accommodate.

Planning Your Production Floor

Setting up a 4-cavity automatic blow moulding line involves more than just the machine itself. A well-planned layout considers all necessary auxiliary equipment, material flow, and maintenance access.

1. Main Blow Moulding Machine Footprint:

- The machine itself will have specific dimensions (Length x Width x Height). Manufacturers provide these, but remember to add space around it for:

- Operator Access: For monitoring, adjustments, and HMI interaction.

- Maintenance Access: Crucial for routine checks, repairs, and mold changes. Allow at least 1-1.5 meters of clear space on service sides.

- Electrical Cabinets: Often attached or freestanding nearby.

2. Essential Auxiliary Equipment and Their Space Needs:

High-Pressure Air Compressor System:

- Compressor Unit(s): Can be quite bulky. Needs good ventilation.

- Air Dryer: Essential for removing moisture from the compressed air.

- Air Receiver Tank(s): Stores compressed air to ensure a stable supply.

- Filters: For oil and particulate removal.

- Space Impact: This system can take up a significant area, often housed in a separate utility room or a designated zone.

Low-Pressure Air Compressor (if separate):

- Supplies air for pneumatic controls and actuators. Sometimes sourced from the plant's general compressed air line if the quality is sufficient.

Water Chiller Unit:

- Similar to air compressors, chillers have their own footprint and require good airflow for their heat exchangers (if air-cooled) or connections to a cooling tower (if water-cooled).

- Space Impact: Can be placed outside or in a utility area, but pipework to the machine needs to be considered.

Preform Feeding System:

- Hopper & Elevator/Unscrambler: These are usually integrated with or placed right next to the machine's infeed. The hopper needs space above for loading preforms (e.g., from bags or octabins).

- Space Impact: Adds to the length/width at the machine's start.

Bottle Take-Out Conveyor System:

- Conveyors to transport finished bottles away from the machine to quality control, labeling, or packing areas.

- Space Impact: Extends from the machine's outfeed, length depends on downstream processes. Airveyors for PET bottles are common and can be routed overhead to save floor space.

3. Material Storage and Movement:

- Preform Storage: Space for storing bags, boxes, or octabins of preforms. Needs to be clean and dry. Consider forklift/pallet jack access.

- Finished Bottle Staging Area: Space for accumulating packed bottles before shipping or transfer to a warehouse.

- Mold Storage: If you have multiple molds for different bottle types, you'll need a safe, accessible storage area for them. Molds can be heavy, so consider lifting equipment.

4. Utilities and Other Considerations:

- Electrical Supply: Power distribution panels and conduits.

- Water Supply & Drains: For the chiller (if water-cooled or for makeup water).

- Waste Management: Area for rejected preforms and bottles.

Example Layout Considerations:

| Component | Approximate Space Needed (Example) | Notes |

|---|---|---|

| 4-Cavity Machine | 6m x 3m x 3.5m (LWH) | Plus 1-1.5m access around |

| High-Pressure Compressor Set | 3m x 2m | Ventilation, noise considerations |

| Chiller Unit | 2m x 1.5m | Ventilation, piping access |

| Preform Hopper/Loader | Adds 1-2m to machine length | Access for loading |

| Outfeed Conveyor | Variable length (e.g., 5-10m) | Depends on downstream integration |

| Preform Storage Area | 5m x 5m (minimum) | Depends on inventory levels |

| Finished Goods Staging | 5m x 5m (minimum) | Depends on production rate/pickup schedule |

When I helped my South African client install their first 4-cavity machine, we spent a good amount of time with the factory blueprints. We had to account not just for the machine, but also for the new, larger compressor and chiller they needed. We even mapped out forklift paths to ensure smooth material flow. Taking this time upfront saved a lot of headaches during installation and commissioning. Always get detailed layout drawings from the machine supplier and plan thoroughly!

Conclusion

A 4-cavity blow moulding machine offers a significant leap in bottle production capacity and automation, suitable for growing businesses. Careful consideration of its type, workings, and requirements is key.

FAQs

Q1: What is the typical ROI period for a 4-cavity fully automatic blow moulding machine?

A1: The Return on Investment (ROI) varies greatly based on factors like initial cost, labor savings, output volume, bottle price, and local energy costs. However, for businesses with high demand, the ROI can often be realized within 2 to 5 years due to increased efficiency and reduced labor. My South African client, for instance, projected a 3-year ROI based on their increased output and reduced reliance on manual labor across multiple shifts.

Q2: How much technical skill is needed to operate a fully automatic 4-cavity machine?

A2: While fully automatic machines handle most operations, skilled operators are needed for setup, programming (HMI operation), quality control, routine maintenance, and basic troubleshooting. They don't need to be engineers, but specific training on the machine is essential. Many suppliers offer training packages.

Q3: Can I use molds from a different machine brand in a new 4-cavity machine?

A3: Sometimes, but not always. Mold compatibility depends on platen dimensions, mold thickness specifications, clamping mechanism, and sometimes the type of neck tooling. It's crucial to check with the machine manufacturer. Modifications might be possible but can be costly.

Q4: What are the main maintenance tasks for a 4-cavity automatic blow moulding machine?

A4: Regular maintenance includes lubrication of moving parts, checking and replacing seals and O-rings, cleaning heaters and reflectors, inspecting pneumatic and hydraulic systems for leaks, ensuring the safety systems are functional, and periodically checking mold condition. Following the manufacturer's recommended maintenance schedule is vital.

Q5: How does a 4-cavity machine compare to a rotary blow moulding machine in terms of output?

A5: Linear machines like a 4-cavity model typically have outputs from a few thousand up to around 6,000-8,000 BPH. Rotary blow moulding machines are designed for much higher outputs, often starting from 10,000 BPH and going up to 80,000 BPH or more. Rotary machines are a much larger investment and are suited for very high-volume, continuous production of a limited range of bottle types.

📖 Learn More About PET Blow Molds and Blow Molding Machines

To better understand how PET blow molds and blow molding machines work together, explore the following resources:

Blow Molding – Wikipedia

Learn about various blow molding processes including extrusion and injection stretch blow molding.PET Blow Molds – iBottler

Discover our custom PET blow molds designed to fit your production needs.Bottle Blowing Machines – iBottler

Explore automatic and semi-automatic machines compatible with your mold designs.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr