You need a budget. You ask, "How much for a 2-cavity machine?" It's a good question, but the answer is complex. You need more than just one machine to start production.

The total startup budget for a 2-cavity PET blowing line varies wildly. A reliable, industrial-grade semi-automatic line (with machine, mold, and auxiliaries) can range from $8,000 to $30,000 USD. A fully-automatic line starts around $20,000 and can exceed $100,000 USD.

I know you need a starting point. Giving you a single number would be irresponsible. The purpose of this article is to clear the fog. I want to show you the approximate investment ranges for different choices, and more importantly, why they cost what they do.

Let's start by breaking down every key part of your total startup cost.

Foreword: Answering that "Tricky" Question—What's the Real Budget to Start a 2-Cavity Line?

You need a budget. You search online, but the answers are confusing. You are not sure what you really need to start. Buying just one machine is clearly not enough.

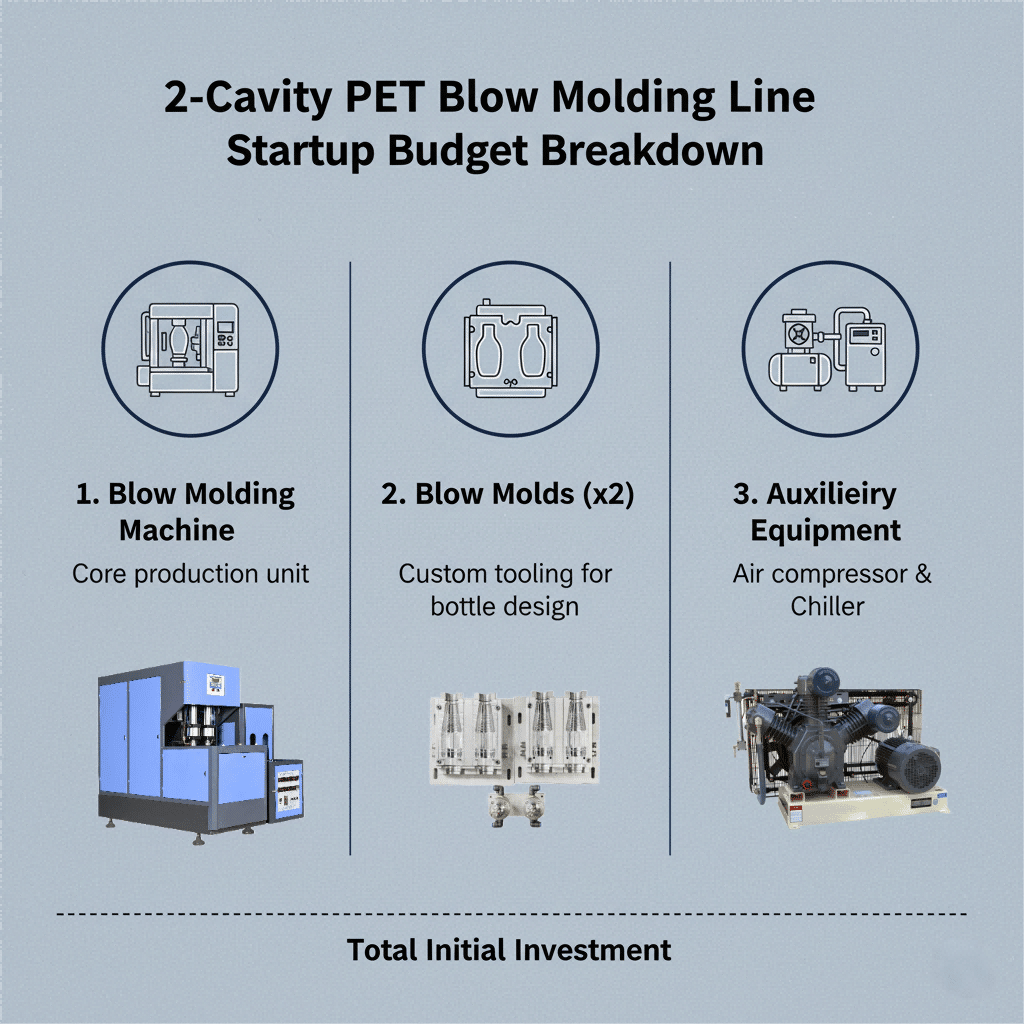

"What is the approximate budget to start a 2-cavity PET blowing production line?" This is a more accurate question. The total startup cost has three core parts: 1. The blowing machine, 2. The blow bottle mold, and 3. The necessary auxiliary equipment.

I get asked this question every single day. In my experience, the biggest mistake a new buyer makes is budgeting only for the blowing machine itself.

I had a client who happily told me he bought a "cheap" blowing machine. Then he asked me, "What else do I need?" His face changed when I told him he still needed a blow bottle mold compatible with his machine, a high-pressure air compressor, a water chiller, filters, and a dryer. The total price for these auxiliaries was almost as much as his "cheap" machine.

He was not wrong; he just did not know.

So, the goal of this article is to break this all down transparently. A responsible supplier will not just sell you a machine. We will help you plan a complete production line. This "total startup budget" mainly includes:

- Blowing Machine (Main Machine): This is the "engine." It can be semi-automatic or fully-automatic.

- Blow Bottle Mold (Mold): This is the "shaper." Your bottle design dictates its cost.

- Auxiliary Equipment (Auxiliaries): This is the "life support system."

- High-Pressure Air Compressor: Absolutely essential.

- Water Chiller: Strongly recommended for stable production.

- Air Filters & Dryer: Essential to protect the machine and product.

- Preform Dryer: Essential for PET material.

This is like asking, "How much does a car cost?" You must first tell me if you need a family sedan or a heavy-duty truck. Their prices are worlds apart. In the bottle-blowing world, this "core question" is: Do you need a semi-automatic line or a fully-automatic line?

The Core Budget Divider: Semi-Automatic vs. Fully-Automatic Line?

You want to start your project, but your budget is tight. The words "fully-automatic" make you nervous. Is there another way to start?

Yes. A semi-automatic line is a low-barrier entry. The total startup budget (with auxiliaries) can be $8,000 - $30,000 USD, but it needs more labor. A fully-automatic line has a higher initial cost ($20,000 - $100,000+ USD) but has lower long-term running costs and higher efficiency.

Choosing between semi-auto and fully-auto is the first major split in your budget.

Choosing between semi-auto and fully-auto is the first major split in your budget.

- Semi-Automatic Line: You trade "lower upfront investment + higher labor cost" to get started.

- Fully-Automatic Line: You use "higher upfront investment" to get "lower long-term running costs and higher capacity."

Your business model, your local labor costs, and your capacity needs will decide which path is more profitable for you.

I have a client in Africa. When he first started, local labor costs were very low. He wisely chose a 2-cavity semi-automatic line. His business grew fast. Two years later, his labor costs went up, and market demand grew. He came back to me and bought a fully-automatic line. Was that first semi-auto line a "waste"? Not at all. It was the correct "startup" decision. It was his successful first step.

Let's use a table for a clear comparison:

Comparison: 2-Cavity Semi-Auto vs. 2-Cavity Fully-Auto Line

| Feature | Semi-Automatic Production Line | Fully-Automatic Production Line |

|---|---|---|

| Core Process | Manual preform loading, manual bottle removal | Automatic preform loading, automatic bottle ejection |

| Total Startup Budget | $8,000 - $30,000 USD | $20,000 - $100,000+ USD |

| Labor Cost | High (Needs 1-2 operators) | Low (Needs 1 operator to supervise) |

| Capacity (500ml) | ~800-1000 BPH (Bottles Per Hour) | ~1800-2500 BPH (Bottles Per Hour) |

| Pros | Very low initial investment, flexible mold change | High efficiency, low running cost, stable quality |

| Cons | Labor-dependent, low capacity, quality varies | High initial investment |

Semi-Automatic Line ($8,000 - $30,000)

This budget range typically includes: one 2-cavity semi-automatic blowing machine, one preform heating oven (heater), one essential high-pressure air compressor, a basic 2-cavity mold, and basic filters. The operator must manually place preforms into the heater and then manually transfer the heated preforms into the blowing machine. This is perfect for startups, those with very tight budgets, or those who have many different bottle types and need to change molds often.

The higher end of this range ($20,000 - $30,000) usually involves larger bottles (like 5 liters) or special wide-mouth jars. These require a larger, non-standard machine and a much more complex, expensive mold.

Fully-Automatic Line ($20,000 - $100,000+

This is a complete "system." This budget includes: one fully-automatic blowing machine with an auto-loader, a high-pressure compressor, one mold, a water chiller (to cool the mold and bottle, keeping quality stable), and a full set of air purification systems (dryer and filters).

Why the huge price gap ($20k to $100k)? It comes down to configuration. The $20,000 machine is an entry-level, pneumatic (air-driven) machine. The $100,000 machine is likely a high-speed, all-servo (electric-driven) machine built with premium components for 24/7, high-precision production. We will cover this next.

The Bottle's "ID Card": How Do Volume, Neck, and Shape Affect the Total Budget?

You thought all mold prices were similar. But then you got a quote for a 5-liter bottle mold and were shocked. Why is it so expensive?

Because your bottle's specifications directly dictate the mold's cost, and sometimes, even the machine's model. Large volumes (like 5L), special neck finishes (like 120mm wide-mouth), or complex shapes will all significantly increase the blow bottle mold cost and, in turn, the total line budget.

Having clear bottle specifications is the first step to getting an accurate budget. The mold is a major part of that budget. Let's break down these three factors:

1. Volume (Capacity)

This is a simple physics problem.

- 500ml Bottle Mold: The mold is small and light. It might be made from 7075 aluminum, which is fast to machine.

- 5L Bottle Mold: The mold is huge and very heavy. It consumes much more metal, and the machining time is much longer.

- Impact on the Machine: A standard 2-cavity blowing machine has a fixed "platen stroke" (opening distance) and "mold thickness" allowance. It might only be able to fit a 2L mold, max. If you want to produce 5L bottles, you need a special "large-capacity 2-cavity machine." This machine needs a stronger frame, a longer stretching cylinder stroke, and a larger heating oven. This non-standard machine is, by itself, more expensive than a standard one.

2. Neck Finish (Opening)

This is a classic case study for us. We once planned a line for a client producing 120mm wide-mouth PET food jars.

- Standard Neck: For example, a 28/410 water bottle neck. The preform molds and blow molds for these are standard items. The cost is controllable.

- 120mm Wide-Mouth:

- Mold Cost: The mold structure for this jar is extremely complex. To ensure the neck rim is perfectly flat and seals correctly, the "neck insert" and "bottom insert" of the mold must be made from high-hardness S136 stainless steel and require a high-precision mirror polish. This makes the mold cost far higher than a standard mold.

- Machine Cost: The client only needed semi-automatic capacity. But no standard semi-auto machine could heat a 120mm preform. We had to custom-build a special heating oven for him, using special "mandrels" (preform holders) to hold this massive preform. This customization significantly increased the machine's cost.

- In the end, the total budget for this "semi-auto 2-cavity wide-mouth jar line" was almost double the budget for a "semi-auto 2-cavity water bottle line."

3. Shape

- Simple Shape: A round bottle is the easiest to machine.

- Complex Shape: A bottle with a handle, an embossed logo, or an asymmetrical "off-set" design. This complex PET bottle mold design requires a 5-axis CNC machine for fine-milling. The programming is more complex, and the machining time is longer. In mold making, time is money. A complex shape can easily add 30-50% to the mold cost compared to a simple round bottle of the same volume.

Configuration Determines "Class": Different Choices for Machine, Mold, and Auxiliaries?

You have two quotes. One is $25,000. The other is $65,000. Both claim to be a "2-cavity fully-automatic line." Why the huge price gap?

The answer is in the "class" of the configuration. It's just like building a computer. A machine built with high-end servo motors, German pneumatic parts, and an S136 steel mold will have a totally different price than one built with standard air cylinders, local-brand parts, and an aluminum mold. The total price can easily be two or three times different.

We will recommend a "good enough and works well" configuration package based on your specific needs and budget. Let's see where the money goes:

1. Machine Configuration (Main Machine)

- Drive System (The Core Difference):

- Pneumatic (Air-Driven): The machine's actions (clamping, stretching) are driven by high-pressure air. Pros: Simple structure, low cost. Cons: Noisy, slower, high energy consumption (it uses a lot of air).

- Servo (Electric-Driven): Key actions (stretching, clamping, preform transfer) are driven by servo motors. Pros: Extremely fast, precise positioning, quiet, energy-efficient. Cons: High cost.

- Key Component Brands:

- PLC (Controller): Is it Siemens, Mitsubishi, or a less-known brand?

- Pneumatic Parts: Are they Festo (Germany), SMC (Japan), or a generic brand?

- Valves: Are they special high-speed response valves designed for blowing?

- The price differences of these parts add up quickly.

2. Mold Configuration

- Mold Material:

- 7075 Aviation Aluminum: Most common. Pros: Light, fast heat dissipation (meaning faster cycle time), easy to machine, moderate cost. Cons: Shorter lifespan than steel.

- S136 / P20 Steel: Pros: Extremely durable, long life, good for high-abrasion areas (like the neck) or special materials. Cons: Hard to machine, slow heat dissipation, high cost.

- Cooling Design: Is it simple drilled water channels, or a complex "conformal cooling" design? The latter can dramatically shorten cooling time and increase output, but it costs much more to make.

3. Auxiliary Configuration (Support System)

This is the most overlooked area, but it's also where budgets can diverge.

- High-Pressure Air Compressor: The brand (e.g., Atlas Copco vs. a generic brand) and the air output (m³/min) can double the price.

- Water Chiller: Its cooling capacity (HP or Tons) and brand directly affect the price.

- Air Purification System: Is your product (like mineral water) food-grade? Then you need more stages of precision filters (oil removal, dust removal) and a refrigerated air dryer to ensure the compressed air is 100% pure. This is all extra cost. If the air is not clean, you will get black spots or oil stains inside your bottles, which is a very common bottle defect.

I remember a 2-cavity line we configured for a European lab client. They needed extreme stability. They used the bottles for precision experiments. We selected top-tier components for everything: the main machine (all-servo), the mold (S136 steel), and the auxiliaries (German-brand compressor + multi-stage filtration). The total budget was high, but the client said: "It's worth every penny. I cannot tolerate any defects in my bottles." Your needs determine the configuration's class.

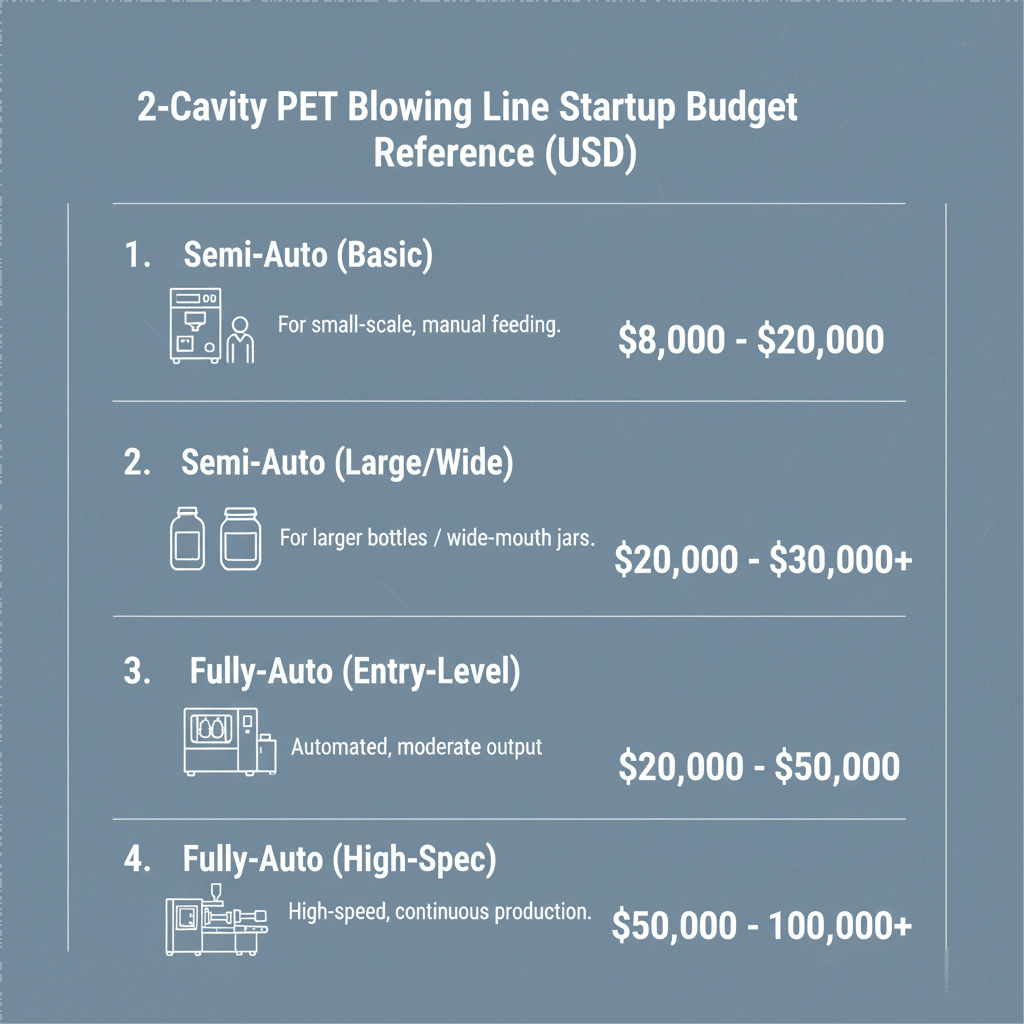

Total Startup Budget Reference: A (Mostly) Clear Range Table?

You understand all the factors. But you are still thinking, "Okay, okay, just show me the numbers!" You need a summary table to make sense of it all.

Alright, here is the summary table. Please remember, this is only a total startup budget estimate based on "Main Machine + One Basic Mold + Essential Auxiliaries." A basic semi-auto line starts at $8,000, while a high-spec automatic line can pass $100,000.

This table gives you a general idea of the investment. But remember, the complexity of the mold, the brands of the auxiliaries, shipping, and installation will all affect the final number.

2-Cavity PET Blowing Line: Total Startup Budget Reference

| Production Line Type | Typical Application | Approx. Total Startup Budget (USD) |

|---|---|---|

| Industrial-Grade Semi-Auto 2-Cavity (Basic) | Startup / Small-batch water, beverage, daily chemicals (500ml-2L) | $8,000 - $20,000 |

| Industrial-Grade Semi-Auto 2-Cavity (Large/Wide) | 5L bottles, 120mm wide-mouth jars (requires customization) | $20,000 - $30,000+ |

| Fully-Auto 2-Cavity (Entry-Level Linear) | Low-to-mid volume water, beverage (pneumatic, basic config) | $20,000 - $50,000 |

| Fully-Auto 2-Cavity (Servo/High-Spec) | Mid-to-high volume, high requirements, hot-fill/CSD (servo, high-spec) | $50,000 - $100,000+ |

What does this budget include?

- 1. Blowing Machine: The semi-auto or fully-auto main machine.

- 2. One Mold: One set of a 2-cavity basic bottle mold.

- 3. Essential Auxiliaries: One high-pressure air compressor, one water chiller, and basic air filters and a dryer.

What does this budget not include?

- Shipping, insurance, and your country's import duties.

- Engineer's installation and training fees (unless specified in the quote).

- Extra molds (if you have multiple bottle types).

- Your factory modification costs (power, water pipes, air pipes).

- Your initial raw material costs (the first batch of PET preforms).

A client of mine came to me with this exact table. He said, "My budget is $30,000. I thought I could only afford a semi-auto line for my 5L water bottles." I told him, "No, based on your needs, $30,000 is enough for us to configure a high-quality 5L semi-auto line. Or, we could see if this budget works for an entry-level fully-automatic line for a smaller (500ml) bottle."

This table is your starting point for budgeting and comparing suppliers.

Beyond the Budget: What "Extra" Costs Do You Need to Consider?

You have $50,000 saved for the equipment. The supplier's quote is exactly $50,000. You think you are all set. But then, the bills from the shipping company and customs arrive.

Your "Total Project Investment" is much more than the number on the equipment quote. You must budget extra for shipping, import duties (which can be 10-20% or more of the equipment value), factory modifications, and your first batch of raw materials (preforms).

These "extra" or "hidden" costs are what new buyers forget most often. A complete budget needs to cover every step from purchase to production.

1. Multiple Mold Sets

The budgets in the table above include only one mold. If you have 3 different bottle types, you need to buy two extra blow bottle molds. This is a direct, obvious extra cost.

- My Advice: Before we cut any expensive steel, we strongly recommend you get a 3D-printed sample. This lets you feel and approve the bottle's design before you commit to the mold.

2. Higher-Spec Auxiliaries

Our budget includes "essential" auxiliaries. But what if your standards are higher?

- You produce food-grade beverages and need a higher-standard air purification system.

- You are in a tropical region with high ambient temperatures. You need a larger-capacity water chiller.

- These will increase the budget for the auxiliary portion.

3. Shipping, Duties & Installation

This is a significant expense.

- Shipping: A full-auto line might need one 40-foot High Cube (40'HQ) container. You have ocean freight, port fees, and local trucking fees.

- Duties: Every country has different import tariffs and taxes. You must consult a local customs broker.

- Installation: Will you install it yourself with our videos? Or do you need our engineer to fly to your country for a week to set it up and train your staff? The service fee and travel costs for the latter must be budgeted.

4. Factory Modifications & Utilities

The machines arrive. You need a "home" for them.

- Power: Is your factory's power supply sufficient? Is it 3-phase 380V/50Hz (or another spec)?

- Water: You need to run water pipes to connect the chiller to the molds and machine.

- Air: You need to run high-pressure and low-pressure air pipes.

5. Initial Raw Materials

You need to buy your first batch of PET preforms. This is your starting operational capital. You will buy them based on your preform neck size and gram weight.

We help our clients list all these "extra" costs. We provide a "Total Project Investment Estimate" to avoid bad surprises later.

Why Such a Big Budget Difference? Where is the Supplier's Value?

You see a machine on Alibaba for $10,000. We quote you a "similar" line for $25,000. You think we are too expensive.

You are not just buying hardware. A supplier who only sells you a machine, and a partner who plans a complete line and takes responsibility for the final result, offer completely different value. Our quote includes 16 years of industry experience and a commitment to your success.

When the price is very different, ask yourself what you are losing.

1. Solution Optimization Ability

A bad supplier sells you what you ask for. A good partner asks why you need it, and then sells you what you need.

- Case Study: Client A wanted a 2-cavity fully-auto line. After analyzing his market (many bottle types, small batches) and labor costs, we recommended a 4-cavity semi-automatic line instead. His total investment was lower, his mold changes were more flexible, and his actual profit was higher. That is the value of a good solution.

2. Project Management & Integration

We do not sell a blowing machine, a compressor, and a mold. We sell a system that is guaranteed to work together.

- Our Value: We ensure the mold and machine are a perfect match. We ensure the compressor's air output and pressure exactly meet the machine's needs.

- A "Bargain" Supplier: They ship you 3 boxes and wish you good luck.

- Case Study: I had a client who "pieced together" a line from three different suppliers. The mold did not fit the machine. The compressor was too small. He spent 6 months arguing with them. He could have been producing and making money for those 6 months. He "saved" $5,000 upfront but lost $50,000 in sales.

3. Technical & After-Sales Support

This is the most important. When your machine stops at 2 AM, who can you call?

- Our quote includes: clear English manuals, a spare parts package, online video support, and optional engineer-on-site service.

- A cheap supplier's phone number might not work after you have paid.

4. Experience

Our 16 years of experience means we have seen all the common blowing defects. We know how to fix them by optimizing the mold design or adjusting the process. This experience is built into the solution we provide you.

Choosing a supplier is, essentially, choosing a partner.

Getting Your Accurate Budget: Let the Numbers Serve Your Project?

You have read this guide. You have a clearer idea of the budget range. But you still do not have the exact number for your project.

Now is the time to get an accurate, no-obligation quote. Contact us today. Provide your bottle specs (volume, neck, weight), your desired output, and your automation needs. Our experts will provide you with a detailed, competitive, and fully transparent production line budget within 24 hours.

To give you an accurate budget, we need you to provide:

- Bottle Specifications:

- Volume (ml or L)

- Neck Finish (e.g., 28/410)

- Gram Weight

- A bottle drawing or sample picture is best. We can also help you with the 3D design and sampling.

- Desired Output:

- How many bottles per hour (BPH) do you want to produce?

- Automation Needs:

- Do you prefer semi-automatic or fully-automatic?

You now have a much clearer understanding of the budget to start a 2-cavity PET blowing line. The next step is to apply this information to your specific project.

Contact us. Our experts will provide a detailed, competitive, and fully transparent line budget, for free.

Let accurate numbers guide your smart investment decision.

Conclusion

The "cost" of a 2-cavity PET blowing machine is much more than the machine itself. It is the total startup budget for an "ecosystem" of a machine, a mold, and auxiliaries. Your choices—semi-auto vs. full-auto, bottle specs, and configuration level—will determine the final price.

Total Startup Cost: Key Factor Summary

| Cost Component | Key Influencing Factor | Why It Matters |

|---|---|---|

| 1. Automation Level | Semi-Auto vs. Fully-Auto | This has the biggest impact on the total budget and long-term labor costs. |

| 2. Machine Config | Servo vs. Pneumatic, Component Brands | Determines the machine's speed, precision, energy use, and durability. |

| 3. Blow Bottle Mold | Bottle Volume, Neck, Shape, Mold Material | A complex bottle needs an expensive mold and may even require a custom machine. |

| 4. Auxiliaries | Compressor, Chiller, Dryer Brands & Specs | The "essential" support system. Its quality determines your production stability. |

| 5. "Extra" Costs | Shipping, Duties, Installation, Factory Mods | Must be included in your Total Project Budget to avoid shortfalls. |

| 6. Supplier | Experience, Support, Integration Ability | A supplier selling hardware vs. a partner selling a successful solution have very different values. |

Frequently Asked Questions (FAQ)

Q: What is usually included in a supplier's quote? What else do I need to buy?

A: You must check the quotation list very carefully. A complete quote should clearly list: the blowing machine itself, if a mold is included (and its specs), which auxiliaries are included (brand, model), the spare parts list, and the service terms (installation, training, warranty). Our budget ranges already include the basic necessities (machine, one mold, high-pressure compressor, etc.), but you still must check the details on your quote and consider extra costs like shipping and duties.

Q: What are the "essential" auxiliary machines for a 2-cavity line?

A: A high-pressure air compressor is absolutely essential; it provides the power to blow the bottle. A suitable water chiller is also extremely important to cool the mold, ensuring production stability and bottle quality. For PET material, a hopper dryer is also strongly recommended to dry the preforms and prevent blowing defects. These basic auxiliaries are included in our estimated startup budget ranges.

Q: Is a used 2-cavity production line worth considering?

A: A used machine might have a tempting price, but the risks are high, especially when buying a full line. It is difficult to assess the condition and remaining lifespan of the machine, mold, and auxiliaries. For beginners, we usually do not recommend buying used equipment. The lack of unified technical support can lead to more problems. A "cheap" used machine could cost you more in repairs and downtime than a new one.

Q: How long is the delivery and installation time for a 2-cavity line?

A: This depends on the type and configuration you choose. A realistic timeline is: 15-30 days manufacturing time for a semi-auto line; 30-60 days for a fully-auto line. Add 20-40 days for ocean shipping. On-site installation and training take about 1 week. Therefore, it is reasonable to plan for 2 to 4 months from placing your order to starting production.

Q: Besides budget, what is the most important thing to consider when choosing a 2-cavity line?

A: The supplier's integration and service capabilities are critical. Choosing a supplier who can provide a "machine + mold + auxiliaries" total solution and offer reliable technical support is far better than piecing together equipment from different places. A good supplier ensures all components work together perfectly and takes responsibility for the final production result.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr