You are looking for precise dimension data for your 2L bottle project because the wrong size leads to a massive waste of logistics and inventory costs. I will provide you with the core engineering data you urgently need.

The standard 2L PET bottle height is typically between 300mm and 330mm, and the standard base diameter is around 100mm to 105mm. These core physical dimensions change significantly based on the content; CSD bottles are wider and shorter to manage pressure, while water bottles are taller and lighter to save material.

I have been working with large-volume bottle engineering for many years. I understand you need more than just a number; you need to understand the "why" behind the numbers. The real engineering story for a 2L bottle involves pressure, cost, and logistics. Simply copying dimensions can lead to disaster on the production line. We can now dive into these critical specifications.

The Direct Answer: Standard 2L PET Bottle Dimensions (Height & Diameter)?

Logistics efficiency depends entirely on the exact bottle size. You must determine if your 2L bottle fits standard cartons and pallets. I often see customers pay extra shipping fees because they ignored this detail.

The universally accepted dimensions for a 2L PET bottle are a diameter of 100mm to 105mm and a height of 300mm to 330mm. These dimensions must comply with international standards for stacking and shelving. The base shape is the biggest factor affecting the final height measurement, especially for Carbonated Soft Drinks (CSD) or pure water bottles.

I always tell my clients that bottle size is a logistical tool first. The diameter and the height are not just for measurement; they are key factors for your entire supply chain. My professional experience is clear: The 2L bottle base diameter and height must work with international standard pallets and standard supermarket shelf depths. If the diameter is too large, you lose space on the pallet, potentially reducing container loading volume by 10%. If the height is too high, you will have stability problems when stacking cartons, causing the cargo to collapse. I call this "logistics compatibility." Suppliers must understand these strict limits. They must make sure your bottle is not rejected by the final retail channel. This is often an overlooked detail, but the cost to fix it is extremely high.

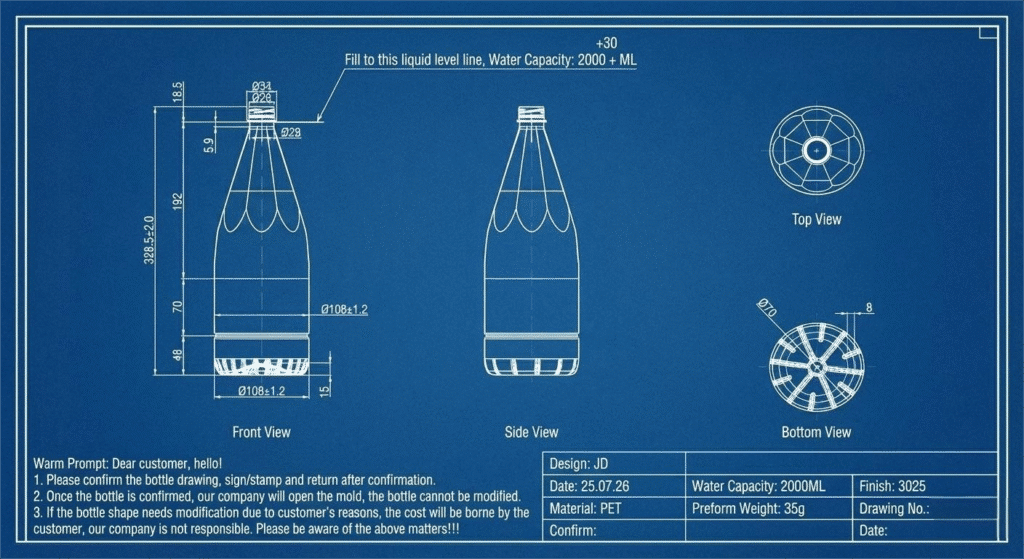

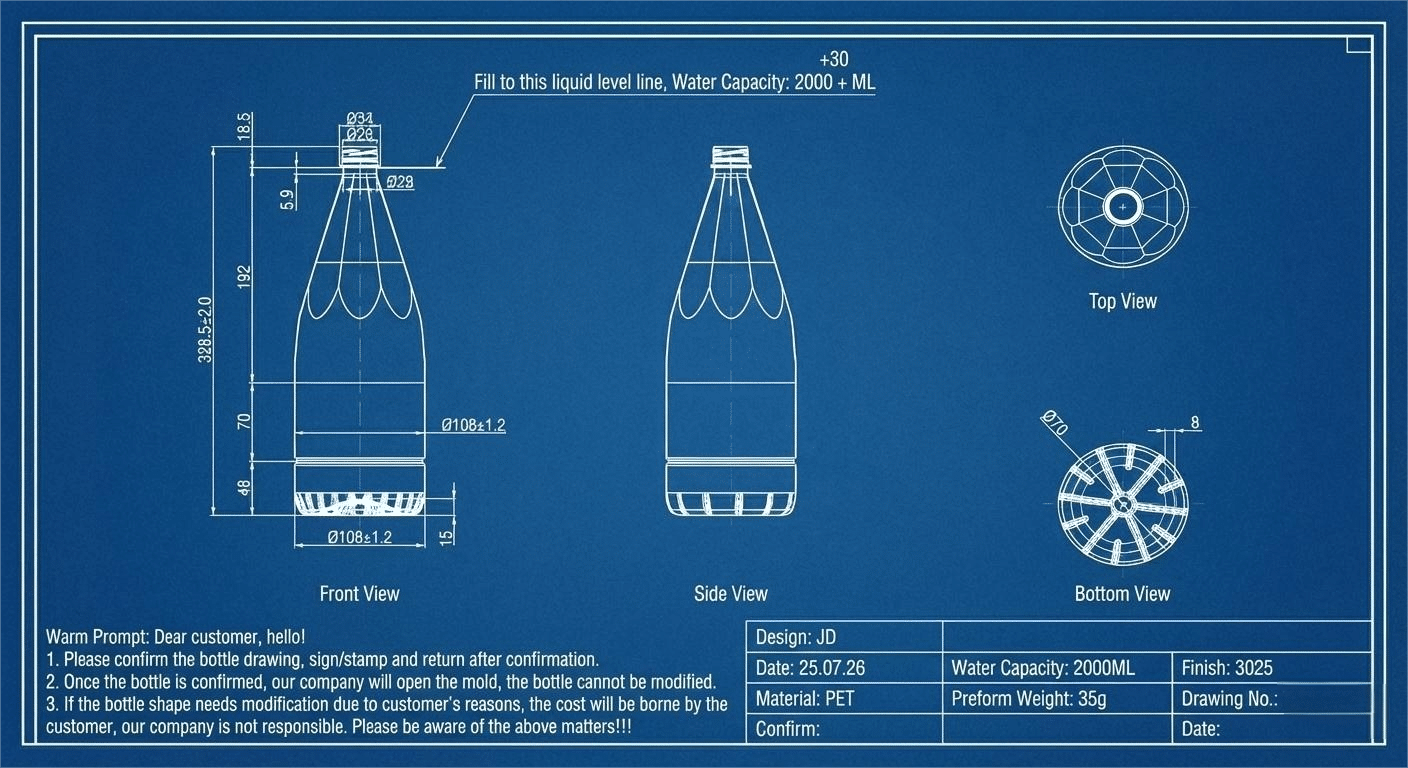

The bottle's bottom structure is another critical dimension variable. The 2L bottle has a high center of gravity, making it inherently unstable. The rigidity of the base structure is the key to stable operation on the filling line. Different contents need very different base designs. CSD bottles must use a five-petal base to distribute high internal pressure and ensure the bottle stands safely. Water bottles typically use a flat base design, which helps with lightweighting, but this flat base cannot handle any internal pressure. My team spends a lot of time engineering this crucial part. We use structural analysis to perfect the base rigidity. This ensures the bottle stands straight and moves smoothly at high speeds on the conveyor. The transition from a round body to a stable base needs careful engineering. If you are looking for technical details on this, you can refer to our PET bottle mold design guide to understand these pressure factors. The mold design is where the stability is created; you cannot fix instability later. I have compiled a comparison table of typical dimensions for your reference:

| Specification | 2L CSD Bottle (PCO 1881) | 2L Water Bottle (3025) | 2L Oil Bottle (32mm/39mm) |

|---|---|---|---|

| Typical Height | 305 mm | 325 mm | 315 mm |

| Typical Diameter | 100 - 103 mm | 98 - 100 mm | 105 mm (Often wider) |

| Base Structure | Petaloid (Five-Lobed) | Flat Base | Flat or Reinforced Base |

| Primary Goal | Withstand Pressure | Minimize Material Cost | Resist Chemical Cracking |

The base design is not interchangeable. Trying to use a water bottle mold for CSD will result in the bottle exploding. The engineering around the dimensions is complex. It ensures the bottle performs its function safely and cost-effectively.

Engineering Philosophy: Why CSD, Oil, and Water Designs Must Differ?

You might think all 2L bottles are the same, but using a water bottle design for soda will lead to an explosion. I will now explain the fundamental engineering differences between them.

The 2L CSD bottle must resist 100+ PSI internal pressure, which requires a heavy, multi-lobed base. The 2L oil bottle must resist chemical corrosion and stress cracking. The 2L water bottle design focuses only on achieving the lowest possible material weight for cost savings.

-1.jpg)

This section is the core of bottle engineering. We must match the bottle design to the content because the design drive for each bottle type is completely different. For Carbonated Soft Drinks (CSD), the design is centered around "anti-explosion performance." The bottle must withstand the enormous pressure built up by carbonation. This means the bottle must have very specific features, including high wall thickness, high material crystallinity, and the mandatory petaloid base. The resin must have a higher Intrinsic Viscosity (IV) to guarantee molecular chain strength. We usually advise clients to consider this during the blow bottle mold design phase, increasing venting slots and cooling efficiency.

However, the design drive for oil and chemical bottles is completely different. Their design centers on "anti-leakage and chemical stability." Oils, sauces, and detergents contain surfactants. These surfactants can attack the PET material over time, causing stress cracking, which leads to costly leaks. The engineering solution for oil bottles is not just about pressure; it is about resistance to chemical attack. We need to use thicker walls, especially at the bottle's base and neck, to fight this stress. The PET bottle preform weight must be high enough to resist the long-term corrosive effects of the contents. My team has developed many specialized molds for these challenging liquids to ensure the oil bottle does not fail on the shelf.

I see a clear trade-off between pressure and corrosion. The CSD bottle design is about immediate, high-stress resistance. The oil bottle design is about long-term chemical resistance. These differences mean:

- CSD: Requires the highest precision on the neck finish (like 1881) for perfect sealing. The walls must have uniform thickness to handle hoop stress.

- Oil: Requires a more robust material choice. The neck material and the cap seal must be chemically inert. The wall thickness distribution might be adjusted to reinforce areas prone to stress cracking, such as the gate area and the shoulder.

Then we have the water bottle. The water bottle design is a constant race for lightweighting. Water is not carbonated and is not corrosive. The only pressure comes from the top load during stacking. The design philosophy here is about the balance of "grams versus strength." Water bottlers use the most efficient mold designs. They adopt the newest, lightest neck standards, like 29/25 or 30/25. This allows them to use the minimum possible preform weight, saving huge amounts of money on raw materials in high-volume production. In contrast, the oil bottle weight must remain high enough to resist content corrosion. I must emphasize this: Using a 40g flat-bottom water bottle preform for CSD or oil products will lead to catastrophic failure. The engineering philosophy for each content type completely dictates the final bottle specification. You must always choose the design based on what is inside the bottle.

The Critical Spec: Neck Finish - 1881, 3025, and Wide Mouths?

You might focus only on the bottle body, but the neck is the most important part. The wrong neck size will stop your entire filling line. I will show you the key industry standards now.

The neck finish determines the required cap supplier, the preform mold, and the capper head on your filling line. Common 2L bottle neck standards are PCO 1881 (for CSD/pressure), 3025/2925 (for water/lightweighting), and 32mm/39mm specialized finishes (for oil/condiments).

When I start a new project, I always ask about the neck finish first. The bottle neck is not just the cap holder; it is the interface that connects the bottle to the entire packaging ecosystem. Choosing the neck finish is a "system matching decision." This decision affects the preform mold, the blow bottle mold, the cap supplier, and the capping machine on the filling line. You cannot change one without changing the others. If a client chooses a PCO 1881 neck, their cap supplier must supply 1881 caps, and the capper head on the filling machine must be configured for 1881 caps. A professional engineer must ensure this perfect alignment. You can refer to my guide on how to choose the right preform neck size, which can help you avoid common selection errors.

The biggest challenge for neck finish design is "leak prevention." For CSD bottles, the 1881 neck finish is the industry standard. It has the highest sealing requirement. It must create an airtight seal that can withstand enormous internal pressure. The thread profile and the sealing surface (the 'lip') must be engineered to micron-level precision. Even a small defect on the thread can cause a costly leak.

Edible oil bottles use different standards, typically 32mm or 39mm. This is distinctly different from the 38mm finish used for juice. The 32mm and 39mm designs are specifically targeted to fit special oil bottle caps (often press-on caps or anti-theft screw caps) that facilitate pouring while preventing drips. Oil is a fluid that seeks small gaps. The neck finish requires special design features, such as robust seal ring positions and high-precision threads, to prevent the oil from wicking up the threads and leaking. This neck design must be very precise. My team often uses advanced tooling to maintain this precision, helping clients avoid expensive recalls due to leakage. The choice of the neck finish is usually a direct result of the design philosophy:

- 1881 (CSD): Maximum pressure resistance, using minimum material for high strength.

- 3025/2925 (Water): Maximum material reduction, requiring minimum strength.

- 32mm/39mm (Oil): Focused on anti-drip safety, adapting to special press-on or handle caps.

The neck finish specification also dictates the design of the preform mold. I use high-precision steel molds to manufacture the neck, ensuring the threads are always perfect. Investment in a high-quality mold is necessary to ensure a reliable seal on the filling line.

The Cost Driver: Determining Optimal Preform Weight (3 Factors)?

Every single gram of PET resin represents cost. An inefficient 2L preform design adds thousands of dollars to your expenses. I will teach you how to choose the perfect preform weight to save material.

The 2L preform weight is a direct cost factor. It must balance three elements: the content's internal pressure, the required top-load stacking strength, and the lowest possible raw material cost. Water bottles are typically 38g to 42g, while CSD bottles are 46g to 52g.

.png)

The weight of the preform is the single largest cost driver in PET bottle manufacturing. My clients always ask me for the lightest preform possible, but I always tell them we must balance cost and performance. When determining the weight, we must consider three main factors.

First is material IV and strength. CSD bottles need high internal pressure resistance. This requires a higher IV (Intrinsic Viscosity) resin. A higher IV means a stronger molecular chain. This requires a higher preform weight, typically between 46 grams and 52 grams for a 2L bottle, ensuring the bottle does not rupture. Water bottles use a lower IV resin. The required strength is much lower, allowing the preform weight to drop to 38 grams or 42 grams. For a production volume of millions of bottles, this difference of 8 to 10 grams per bottle translates into massive cost savings. I can show clients exactly how the mold designs for different weights differ.

Second is the necessary top-load strength. The bottle must not collapse when stacked 5 or 6 layers high on a pallet. This is the top-load requirement. I use finite element analysis (FEA) to simulate this stacking pressure. The analysis tells me the minimum wall thickness needed at the shoulder and the base. This analysis determines the lowest safe preform weight. We design the mold to distribute the material efficiently. The goal is to place the material exactly where the strength is needed. This achieves the minimum preform weight.

Third is the weight optimization trade-off. I often see new companies choose a higher preform weight just to be safe. This is wasted money. A professional bottle engineering team works hard to achieve the same performance with a lower weight. We optimize the wall thickness distribution. This means we use a lighter preform, but we design the mold to stretch the material perfectly. This results in an even wall thickness and an equally strong bottle. For example, we can design a 48g CSD bottle that performs as well as a competitor's 52g bottle. This 4-gram difference saves my client money on every single unit. My job is to find this perfect balance.

I have summarized the typical weight ranges:

| Bottle Type | Typical Preform Weight (2L) | Primary Cost Driver |

|---|---|---|

| CSD | 46g – 52g | Strength (PSI) & IV Resin |

| Water | 38g – 42g | Material Savings (Lowest Possible Weight) |

| Oil/Sauce | 50g – 60g | Chemical Resistance & Top Load |

I often use my data list to show clients the different cavity and weight options available. We ensure the initial preform mold investment aligns with long-term cost goals.

Mould Selection: Cavity Count, Material, and Tooling Philosophy?

A mold is not just a block of metal; it is an extension of your machine. Buying the wrong mold material or size will stop your production immediately. I will guide your mold purchasing decision.

The blow mold cavity count is fixed by the blowing machine model you select first. Mold materials for 2L PET bottles are primarily 7075 Aluminum (for fast cycle CSD/Water) or S136 Stainless Steel (for corrosive Oil/Chemical products).

The biggest mistake I see new clients make is choosing the mold before the machine. The mold cavity count is determined by the blowing machine model you have already selected. This is a fixed engineering reality. If your machine is a 2-cavity machine, your mold must be a 2-cavity mold. The investor should always select the machine first based on the required production output. The fixed cavity count of that machine is the only factor that determines the mold's cavity count. The mold supplier must design the mold to match the machine's exact technical interface. This includes mounting dimensions, cooling line locations, and the locking mechanism. I tell all clients to consult my guide on worried about blow mold fit before they buy anything. This completely eliminates the risk of installation failure.

The choice of mold material is also critical, especially for large 2L bottles. The material choice depends on the cycle speed and the content.

- 7075 Aviation Aluminum: CSD and water bottles require the fastest possible cycle time for efficiency. This means the mold must dissipate heat very quickly. 7075 aluminum is the perfect material. It offers superior thermal conductivity. This allows for a shorter cooling time and a faster production rate. I use a high-quality surface coating to ensure durability.

- S136 Stainless Steel: Oil, sauces, and chemical containers can cause corrosion on the mold surface over time. This ruins the bottle's finish. S136 stainless steel offers excellent corrosion resistance. It is often required for these types of products. It also allows for a higher surface polish. This creates a visually perfect bottle surface. Although the cycle time is slower than aluminum, the mold life and finish quality are superior for corrosive liquids.

The tooling philosophy for a 2L mold is about managing thermal mass. A 2L mold is larger. It holds more heat. This requires an efficient cooling system. The cooling channel design inside the mold is just as important as the cavity shape. We use computational fluid dynamics (CFD) to optimize the cooling channel layout. This ensures even cooling across the large surface area of the 2L bottle. Efficient mold design reduces waste. It ensures the bottle is dimensionally stable right out of the machine.

The Design Challenge: Handling Pressure, Heat, and Ergonomics?

Making a large 2L bottle stand up straight under pressure is complex engineering. Poor design creates a safety hazard or an unusable product. I will show you the critical design elements that solve these problems.

2L CSD bottles require a mandatory Petaloid Base to safely manage high internal pressure. Oil bottles need integrated handles or grip grooves for user ergonomics. Heat-set bottles for juice must have vacuum panels to manage bottle shrinkage after hot filling.

Designing a 2L bottle is a complex balancing act. We must manage three primary forces: internal pressure, heat, and human interaction.

High-Pressure Structure is mandatory for CSD. For any 2L CSD bottle, the base must be a five-petaloid base. This is not optional. The five-lobed or "flower" design distributes the immense internal pressure from carbonation. It ensures the bottle remains stable and does not round out. The center of the base must be designed to withstand the highest stress concentration. I have seen new companies try to use a flat base for CSD. This always results in bottle failure and safety hazards. The petaloid design requires specialized engineering. We must ensure perfect material distribution during the stretch-blow process to reinforce these pressure points.

Managing Heat for Hot-Fill Products is the second major challenge. Products like tea or juice are hot-filled (up to 85°C). The bottle must withstand this heat without deforming. As the product cools, it creates a vacuum inside the bottle. This vacuum would crush a standard PET bottle. The engineering solution is to design "vacuum panels" or "ribs" into the 2L bottle side wall. These panels flex inwards when the vacuum forms. This maintains the bottle's structural integrity. This requires adding special features to the mold, increasing its complexity.

Ergonomics for Consumer Use is the third factor. A 2L bottle is heavy when full. Consumers need a way to pour it easily. This requires integrating handles or specialized grip features (e.g., dimples or side grooves). For a 2L oil bottle, this grip is critical to prevent slipping. We must integrate these features into the mold design. This often means adding complex, moving parts (inner inserts) to the mold to create the handle space. This increases the mold's complexity and the initial investment cost. The design must look good, but it must function perfectly in the consumer's hand. I always recommend using 3D bottle proofing services to test 3D-printed samples. I check the grip and stability before cutting the final steel. This ensures the bottle is safe and easy to use.

Logistics and Packaging: Ensuring the 2L Bottle Fits the Supply Chain?

The perfect bottle is useless if the boxes fail or the pallets fall over. Logistics costs are bottle engineering costs. I will detail how the 2L size impacts the supply chain.

The overall 2L bottle dimension is critical for efficient logistics. Carton design and pallet stack height must maximize container space while preventing tipping. Large bottle stability is essential for smooth transfer through the high-speed filling line.

A 2L bottle project does not end when the bottle leaves the mold. It ends when the bottle is on the retail shelf. The dimensions we discussed earlier directly affect the entire supply chain and your final cost.

The first logistical consideration is packaging efficiency. The dimensions of the 2L bottle must be optimized for the carton. The carton must be optimized for the standard shipping container (20ft or 40ft). I often calculate the total units per container before we finalize the bottle design. A change of just 2mm in the bottle's diameter can mean fitting an extra 500 units per container. This small engineering change saves thousands of dollars in shipping costs over a year. The carton's stacking strength is also vital. The carton must support the weight of the stacked bottles without collapsing. The base of the 2L bottle must be perfectly flat and rigid to distribute the stacking load evenly across the carton.

The second major area is filling line stability and speed. A 2L bottle is a large object. This means the filling line must run slower than a line running 500ml bottles. This is a physical constraint. The blow mold supplier must ensure the 2L bottle has excellent stability. The bottle base and neck must be stable enough to be precisely gripped by the filling line's clamps and sensors. I see many bottles fail here. They sway or tip over at high speeds. This causes line stoppages and product waste. My engineering team pays close attention to the bottle's center of gravity and the strength of the bottle's base to prevent this. We use the technical specifications of the client's blowing machine list and filling line equipment as a core input for our mold design.

Furthermore, we must think about palletizing. A 2L bottle stack is high. The high center of gravity increases the risk of the whole pallet tipping. The mold design must ensure uniform wall thickness. This uniform thickness is required to give the bottle a high top-load rating. This top-load strength allows for safer, higher stacking on the pallet. This maximizes warehouse space. The smallest bottle defect, such as a thin base or an uneven neck, can compromise the top-load strength. This leads to pallet failure. My goal is to design a bottle that performs perfectly on the shelf and safely in the warehouse.

How iBottler Provides Engineering Solutions for Your 2L Bottle?

You have seen the complex engineering for a 2L bottle. Getting the design wrong is an expensive mistake. I will show you how my team ensures your project's success and high quality.

At iBottler, we provide complete engineering solutions for your 2L bottle project. We design the bottle, optimize the preform weight, and manufacture the mold to perfectly match your specific blowing machine's exact mounting dimensions and technical needs.

My job at iBottler is to turn a complex engineering problem into a simple, reliable solution for you. We understand that a 2L bottle is not just one product. It is a CSD bottle, an oil bottle, or a water bottle. Each needs a unique engineering approach.

Our first commitment is to customized design. We start by deeply understanding your content and your machine. We use structural simulation software to design a 2L bottle. This design is optimized for your product (water, oil, CSD). We adjust the mold to ensure the bottle's performance and cost reach the optimal balance. For example, for a CSD bottle, we use the analysis to find the absolute minimum preform weight (e.g., 46g). This weight still meets the safety and pressure requirements. For an oil bottle, we specify the required mold material (e.g., S136 steel). This prevents corrosion and ensures a long mold life.

Our second commitment is to technical guarantee and seamless integration. The single biggest risk in buying a mold is the fit. The mold must physically and digitally match your blowing machine. I guarantee that the 2L mold we deliver will have the correct cavity count and the exact mounting dimensions for your chosen machine. This avoids expensive installation failures. We use the machine's technical drawings to design the mold from day one. I have seen clients buy cheap molds that do not fit the machine. The production stops for weeks. We eliminate this risk completely. Our expertise ensures your project moves smoothly from mold delivery to full production startup. We provide the complete engineering package. This includes the mold design, the optimal preform specification, and the technical support for installation. My personal goal is to make sure your 2L bottle is safe, cost-effective, and perfectly produced on your line.

Conclusion

The 2L PET bottle size is a complex engineering decision. It balances content type, cost, and logistics. You must match the bottle design (neck, base, and weight) to the product inside to guarantee safety and efficiency.

Frequently Asked Questions (FAQs)

Q: What is the correct workflow: Should I choose the mould first or the blowing machine first?

A: You must choose the blowing machine first. The machine's fixed cavity count (e.g., 2 cavities or 4 cavities) and interface data are fixed. The mold must then be custom-engineered to match the machine's exact technical specifications. Choosing the mold first is a major risk.

Q: What is the "Petaloid Base" and why is it mandatory for 2L CSD bottles?

A: The petaloid base is a domed, multi-lobed base design. It is mandatory for 2L CSD bottles because it helps distribute and withstand the high internal pressure generated by the carbonation. This prevents the bottle from exploding or rounding out at the bottom, ensuring safe storage.

Q: Why do 2L water bottles use 3025/2925 neck finishes instead of the CSD standard 1881?

A: The 3025/2925 neck finishes are lightweighting standards. They use less PET material than the 1881 CSD neck. The 1881 neck must be stronger to withstand high pressure. The lighter 3025/2925 neck helps water bottlers significantly reduce raw material costs in high-volume production.

Q: What is the biggest risk when designing a 2L oil bottle (chemical incompatibility or pressure)?

A: The biggest risk is chemical incompatibility (corrosion). Oils, sauces, and detergents contain surfactants and chemicals. These can attack the PET material over time. This leads to stress cracking and potential leakage. The bottle must be engineered for chemical resistance. This often requires specialized materials or barrier layers in the preform.

Q: How much does a professional need to over-engineer the preform weight for a 2L CSD bottle?

A: For CSD, the preform weight is determined by strength (PSI) and wall distribution, not volume. A professional mold supplier will use structural analysis. This determines the lowest possible weight (e.g., 46g) that still meets the required top-load and internal pressure strength. We avoid unnecessary material waste.

Article Summary: 2L PET Bottle Key Specifications

| Specification Area | CSD Bottle (Pressure) | Water Bottle (Lightweight) | Oil Bottle (Chemical) |

|---|---|---|---|

| Typical Height | Shorter (Approx. 305mm) | Taller (Approx. 325mm) | Moderate (Approx. 315mm) |

| Preform Weight | High (46g – 52g) | Low (38g – 42g) | Very High (50g – 60g) |

| Mandatory Base | Petaloid Base (5-Lobed) | Flat Base | Flat or Reinforced Base |

| Neck Finish | PCO 1881 (High Seal) | 3025/2925 (Lightweight) | 32mm/39mm (Anti-drip) |

| Mould Material | 7075 Aluminum (Speed) | 7075 Aluminum (Speed) | S136 Steel (Corrosion) |

| Design Focus | Anti-Explosion | Cost Reduction (Material) | Anti-Seepage/Ergonomics |

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr