Production is running smoothly, then you see it. One bad bottle, again and again. It's frustrating when your multi-cavity mold has a single problem cavity, ruining your efficiency.

The most common reason for a single cavity failure is an issue isolated to that specific cavity's support systems. This includes the dedicated heating lane, valve block, sealing unit, or cooling channel. A systematic, step-by-step check is the fastest way to find the root cause.

It's a familiar story. Just yesterday, a client from Belgium called me. He was running a 6-cavity mold, and one cavity consistently produced under-inflated bottles. His production numbers were suffering, and he was getting frustrated. He wanted to immediately start taking the mold apart. I told him to pause and follow a logical process. This exact process, from the outside in, is what I'm going to share with you today. It saves time, money, and prevents unnecessary downtime. Let's diagnose this like a pro.

First, Confirm the Pattern: Is It Truly a Consistent, Single-Cavity Issue?

You think you have a single bad cavity, but are you sure? Assumptions can lead you down the wrong path, wasting hours on the wrong problem.

First, you must scientifically confirm the defect is tied to one specific cavity every single time. Random defects often point to inconsistent raw materials, like issues with a single cavity in a large preform mold. A consistent defect points to the machine or the blow mold itself.

To properly diagnose the problem, we need to eliminate variables. My first instruction to my Belgian client was exactly this: "Are you 100% certain it's always cavity #2?" This is the absolute foundation of all multi-cavity mold troubleshooting. Without this confirmation, you're just guessing. The goal here is to separate two main possibilities: a problem with a small batch of incoming preforms, or a problem with a specific lane of the blowing process.

How to Reliably Track and Confirm

The method is simple but crucial. You need to physically mark the bottles as they come out of the machine.

- Prepare for Marking: Get some permanent markers, ideally in different colors if you want to be extra clear. Inform your quality control team and the machine operator about what you are doing.

- Mark Each Cavity's Output: As the bottle blowing machine cycles, have someone carefully and safely mark each bottle with its corresponding cavity number. For a 6-cavity mold, you'll write '1', '2', '3', '4', '5', '6' on the bottles as they exit.

- Collect a Statistically Significant Sample: Don't just check one or two cycles. Let the machine run for at least 15-20 minutes. Collect a large batch of these marked bottles. You want a big enough sample size to see a clear pattern emerge and rule out any random flukes.

- Analyze the Results: Lay out all the defective bottles you've collected. Is there a clear pattern? Are 95-100% of the defects marked with the same number (e.g., '#2')? If so, you have successfully confirmed a consistent, single-cavity issue. You can now proceed with confidence.

Differentiating Preform vs. Mold Issues

If the defects are random—sometimes #2, sometimes #5, sometimes #1—your problem likely lies elsewhere. The most common culprit for random defects is the preforms themselves. A 48-cavity preform injection mold might have one single cavity with a slight issue. This means that roughly 1 in every 48 preforms fed into your blow molder could be defective. This creates a random-looking failure pattern. In this case, you need to contact your preform supplier or investigate your injection molding process, not your blow bottle mold. Understanding this distinction is critical. My client confirmed that after marking bottles for 30 minutes, every single bad bottle came from the cavity he had marked as #2. Now we knew the problem wasn't the preforms, and we could start our real investigation.

This initial step of confirming the pattern is the most important. It sets the direction for your entire troubleshooting effort. It's the difference between a quick fix and a week of chasing ghosts.

| Troubleshooting Path | Defect Pattern | Likely Root Cause | Next Action |

|---|---|---|---|

| Path A | All defective bottles are from the same cavity number (e.g., #2) | A mechanical or process issue related to that specific cavity. | Proceed to Step 1 of this guide. |

| Path B | Defective bottles come from random cavity numbers. | An issue with the raw material, most likely the preforms. | Quarantine the current batch of preforms and test a new batch. |

| Path C | Defective bottles appear in a repeating pattern (e.g., #2, #6, #10) | Could be an issue with a shared system, like a heating zone or air supply line. | Investigate the common element for that pattern. |

Step 1: Check External Factors - The Heating Profile for That Specific Lane?

The machine is still running. Before you grab a single tool, look at the heating oven. The simplest explanation is often the correct one, and heating is a critical, easily-checked external factor.

A PET preform needs to be heated to the perfect, uniform temperature before it enters the mold. Inconsistent heating is a primary cause of many common PET blow molding defects, and if one preform isn't heated correctly, it won't blow correctly.

Each cavity's preform travels down its own lane in the heating oven, passing a series of heating lamps. If there's an issue with just one of these lanes, it will only affect the corresponding cavity. This is the least invasive check you can do, and it should always be your first step after confirming the cavity pattern. It involves no downtime and can often solve the problem in minutes. Many times, operators jump to complex mechanical issues when the root cause is a simple burnt-out lamp.

Visual Inspection of the Heating Lamps

This is your first and easiest check.

- Look for Dead Lamps: Carefully look into the heating oven while it's safely operating (following all safety procedures and using proper PPE). Each lane has a stack of lamps. Can you see a lamp that is not glowing in the lane corresponding to your problem cavity? A single burnt-out lamp can create a cold spot on the preform.

- Check for Dimming or Flickering: Sometimes a lamp is at the end of its life. It may still be glowing but at a much lower intensity, or it might be flickering. This inconsistency is just as bad as a completely dead lamp.

- Observe Obstructions: Look for anything that could be blocking the heat. Has a piece of debris, a fallen label, or even a stray preform somehow gotten lodged in the heating oven, blocking a lamp or a reflector? It sounds unlikely, but I have seen it happen.

Deeper Analysis of the Heating System

If a visual check doesn't reveal anything obvious, you may need to dig a little deeper into the heating parameters and hardware.

Understanding Heating Zones

Modern blow molding machines have multiple heating zones, each controlled independently. This allows for precise control over the preform's temperature profile, which is essential for complex bottle shapes. The top lamps might heat the neck area, while lower lamps heat the body and base. You must ensure all lamps within the specific lane for your problem cavity are functioning as programmed.

Verifying with a Pyrometer

For a more scientific approach, you can use a non-contact infrared pyrometer or thermal camera.

- Safely stop the machine right after the preforms have exited the heating oven.

- Quickly measure the temperature profile of a preform from the "good" cavity lane.

- Immediately measure the temperature of a preform from the "bad" cavity lane in the exact same spots.

- Compare the readings. If the preform from the bad lane has a significant cold spot (a deviation of more than 5-10°C) that corresponds to the defect on the final bottle, you've found your culprit.

| Preform Section | Good Cavity Preform Temp. | Bad Cavity Preform Temp. | Analysis |

|---|---|---|---|

| Neck Finish | 85°C | 84°C | Within tolerance. |

| Shoulder | 105°C | 106°C | Within tolerance. |

| Mid-Body | 110°C | 92°C | Problem Found! Cold spot indicates a failed lamp in the middle zone. |

| Base | 98°C | 99°C | Within tolerance. |

Check Reflectors and Ventilation

The lamps are only one part of the equation. Each lamp has a reflector behind it to direct the heat onto the preform. If the reflector for one lamp is dirty, oxidized, or misaligned, it will be less effective. Similarly, the ventilation system in the oven removes excess heat. If a vent is blocked in one specific area, it could cause a localized hot spot. Ensure the entire heating lane—lamps, reflectors, and ventilation—is clean and in good working order.

Step 2: Inspect the Machine-to-Mold Interface - The Individual Valve Block?

The heating is perfect, but the problem persists. Now we move to the next logical step: the air delivery system. The point where the machine delivers high-pressure air to the mold is a critical interface.

Each cavity is controlled by its own dedicated set of valves, often housed in a single unit called a valve block. This block manages the entire blowing sequence for one cavity: pre-blow, high-pressure blow, and exhaust. A tiny malfunction here will only affect one bottle.

This is one of the most common culprits for single-cavity defects. These valves are high-performance components, cycling thousands of times per hour. Seals wear out, solenoids get sluggish, and internal components can fail. A slight delay in opening, a small leak, or a valve not closing completely will dramatically alter the airflow and timing for that single cavity, resulting in a defective bottle. When my Belgian client confirmed the heating was okay, this was the next area I told him to investigate.

The Function of the Valve Block

To understand why it fails, you must first understand what it does. For each blowing cycle, the valve block for a single cavity performs a precise, high-speed sequence:

- Pre-Blow Valve: Opens for a fraction of a second to release low-pressure air (around 10-15 bar). This stretches the preform to the general shape of the mold without touching the cold cavity walls.

- High-Pressure Blow Valve: Immediately after, this valve opens, releasing high-pressure air (up to 40 bar) to fully form the bottle against the mold cavity walls.

- Exhaust/Recycle Valve: After the bottle is formed and cooled slightly, this valve opens to release the high-pressure air from the bottle before the mold opens.

Any deviation in the timing or pressure of this sequence for just one valve block will lead to a defect in just one cavity.

Common Failure Modes and How to Spot Them

You are essentially looking for signs that one valve block is not behaving identically to the others.

Listening for Leaks

This is a simple but surprisingly effective first check.

- With the machine stopped but pressurized, carefully and safely listen near each valve block. You might hear a faint but distinct hissing sound from the problem cavity's block.

- This indicates a worn seal or a valve that isn't closing completely. This leak can reduce the available pressure during the high-pressure blow, leading to an under-formed bottle. An efficient air compressor system is vital, but a leak will undermine even the best system.

Checking Solenoid Function

Each valve is typically activated by an electric solenoid.

- Most machines have indicator lights on the solenoids. During a cycle, watch the lights for the good cavities and compare them to the bad one. Does the light on the suspect valve block flicker, seem dim, or turn on/off at a slightly different time?

- You can sometimes feel the solenoid activate. Safely touch the top of the solenoids for a good cavity and the bad cavity (if accessible and safe to do so). The "click" of the activation should feel sharp and instantaneous. A sluggish or weak-feeling activation could indicate a failing solenoid coil.

Temperature Differences

A constantly leaking valve will cause air to expand, which creates a cooling effect (the Joule-Thomson effect). After running for a while, a leaking valve block or fitting might feel noticeably colder to the touch than its neighbors. It's a subtle clue, but a very reliable one.

If you suspect a valve block, the best course of action is often to use a repair kit provided by the machine manufacturer. These kits typically contain all the necessary seals, O-rings, and gaskets to rebuild the valve. It is often faster and more reliable than trying to identify the single failing O-ring inside a complex valve assembly.

Step 3: Analyze the Mechanical Components for That Cavity?

The heating is fine, and the valves seem perfect. Now we must look at the moving parts that are unique to that single cavity. Wear and tear is inevitable, and components can become misaligned or worn over time.

For each cavity, there are dedicated mechanical parts that perform critical functions. The stretch rod and the sealing unit are the two primary suspects. A problem with either of these will only ever affect one cavity.

These components ensure the preform is positioned correctly and that the high-pressure air is delivered without leaks. Even minor wear on a stretch rod tip or a tiny nick in a sealing ring can lead to consistent and frustrating bottle defects. This was the exact solution for my client in Belgium. After checking the heating and valves, we moved to the mechanicals, and he discovered a small air leak from the sealing cylinder for cavity #2. The fix was a simple, inexpensive O-ring.

The Stretch Rod: The Heart of Orientation

The stretch rod's job is twofold: it mechanically stretches the preform vertically, and it acts as the nozzle to inject the high-pressure air.

Centering and Alignment

The stretch rod must be perfectly centered as it enters the preform and stretches it downwards.

- Visual Check: With the mold open, manually cycle the stretch rod down. Does it travel straight and true, perfectly in the center of where the preform neck would be? Or does it seem to be off to one side?

- Consequences of Misalignment: If it's off-center, it will pull the preform to one side. This results in uneven material distribution, causing one side of the bottle wall to be thin and the other to be thick. This is a very common cause of defects. A proper PET bottle mold design relies on this centering.

Stretch Rod Tip Wear

The very tip of the stretch rod is a high-wear item.

- Inspection: Examine the tip of the rod for the problem cavity. Compare it to a rod from a good cavity. Is it chipped, rounded over, or visibly shorter?

- Impact of Wear: A worn tip can affect how the preform is initially stretched, and it can also cause turbulence in the high-pressure air being injected, leading to forming issues.

The Sealing Unit: Containing the Pressure

The sealing unit (or sealing cylinder) presses down on the preform neck finish, creating a tight seal before the high-pressure air is injected.

Seal Integrity

This is the most critical function. Any leak here means a loss of blowing pressure.

- The "Soap Bubble" Test: With the system pressurized but stopped, you can spray a soap and water solution around the sealing area of the suspect cavity. If bubbles form, you have found your leak.

- O-Rings and Seals: As was the case with my client, the rubber O-rings and seals inside the sealing unit are consumable parts. They harden, crack, and wear over time. A leak here is very common and directly reduces the pressure available to form the bottle, resulting in an under-blown or "soft" bottle. Replacing these seals is typically a quick and easy fix.

Here is a table summarizing the mechanical checks:

| Component | Check | Potential Problem | Resulting Defect |

|---|---|---|---|

| Stretch Rod | Alignment/Centering | Rod is not perfectly centered. | Uneven wall thickness, off-center gate. |

| Stretch Rod | Tip Condition | Tip is worn, chipped, or deformed. | Poor material distribution, stress cracking. |

| Sealing Unit | Seal Leak Test | Air is escaping around the preform neck. | Under-blown bottle, weak or undefined details. |

| Sealing Unit | Physical Seals | O-rings are cracked, hard, or worn. | Pressure loss, inconsistent blowing. |

Checking these dedicated mechanical components is a crucial step. It requires a more hands-on approach than checking the heating, but it is often where you will find the root cause of a persistent single-cavity problem.

Step 4: Investigate the Mold's Cooling Channels?

You have checked all the external systems. The heating, the air valves, and the mechanical actuators are all working perfectly. It is now time to consider the mold itself. The first place to look inside the mold is its lifeblood: the cooling system.

Every half of each blow bottle mold cavity has intricate channels drilled through it. Cold water, supplied by a chiller, constantly flows through these channels to solidify the hot plastic bottle rapidly. If the cooling for one cavity is inefficient, it will cause defects.

Uneven or insufficient cooling is a major source of bottle quality problems. The plastic needs to "freeze" in its final shape almost instantly after being blown against the mold walls. If one part of the mold is warmer than another, the plastic in that area will cool slower, leading to shrinkage, warping, and dimensional instability. A blocked or restricted cooling channel in a single cavity is a hidden enemy that will only affect that one production lane.

Why Cooling is So Critical

The rate of cooling determines the final molecular structure (crystallinity) of the PET, which in turn dictates the physical properties of the bottle, such as its strength, clarity, and stability.

- Cycle Time: Efficient cooling is the biggest factor in determining your overall cycle time. The faster you can solidify the bottle, the faster you can open the mold and start the next cycle.

- Bottle Quality: Inconsistent cooling leads to a host of problems. A warm spot on the mold can cause that area of the bottle to be hazy, weak, or distorted. It can also cause issues with thermal stability, where the bottle shrinks or deforms after being filled with product.

Diagnosing Cooling Channel Problems

Finding a cooling problem requires some detective work, as the channels are internal to the mold block.

Check Flow and Temperature Differential

This is the most direct way to check for a blockage.

- Isolate the Cavity: If possible, disconnect the main "in" and "out" water lines for the entire mold.

- Test Each Circuit: Using a separate pump and flow meter, or even just a bucket and stopwatch, measure the flow rate through each individual cavity's cooling circuit. Connect the water supply to the "in" port of cavity #1 and measure the output from the "out" port. Repeat for every cavity.

- Compare Results: Is the flow rate for the problem cavity significantly lower than the others? A restriction of 20-30% is enough to cause problems.

- Check Temperature: Use a surface thermometer to measure the temperature of the mold cavity wall right after a production run. Is the problem cavity noticeably warmer than the good cavities? This is a clear sign of poor cooling.

| Cavity Number | Inlet Water Temp | Outlet Water Temp | Flow Rate | Surface Temp | Analysis |

|---|---|---|---|---|---|

| Cavity #1 (Good) | 10°C | 14°C | 10 L/min | 18°C | Normal |

| Cavity #2 (Bad) | 10°C | 12°C | 6 L/min | 25°C | Problem! Low flow, low heat transfer. |

| Cavity #3 (Good) | 10°C | 14°C | 10.2 L/min | 18°C | Normal |

| Cavity #4 (Good) | 10°C | 14.1°C | 9.9 L/min | 19°C | Normal |

Common Causes of Blockages

What causes these restrictions?

- Scale and Rust: Over time, minerals from the water can build up inside the channels, especially if you are not using properly treated water. Rust particles can also flake off and create a blockage.

- Debris: Sometimes, during maintenance, a small piece of a rubber O-ring or Teflon tape can get into the water line and become lodged in a narrow channel.

- Incorrect Connections: It's possible that the hoses for one cavity were connected incorrectly, perhaps in reverse, which can affect the efficiency of the designed water flow path.

If you confirm a blockage, you will need to take the mold out of the machine and professionally clean the water channels using a descaling solution or high-pressure flushing. Regular preventative maintenance of your chiller and water supply is the best way to prevent this issue.

Step 5: Examine the Mold Cavity's Venting and Surface?

We have exhausted all the external systems and the internal cooling. The final place to look is the very surface that shapes your product: the mold cavity itself.

Any imperfection on the cavity's surface or any issue with its ability to let air escape will be directly transferred to every bottle it produces. Venting and surface condition are subtle but critical aspects of blow molding.

The high-pressure air that forms the bottle must displace the air already inside the preform and the mold. This original air must have a path to escape. This is achieved through tiny, precisely machined vents. If these vents are blocked on a single cavity, the trapped air will prevent the plastic from fully contacting the mold wall. At the same time, any scratch, ding, or worn spot on the mold surface will create a corresponding flaw on the bottle.

The Critical Role of Venting

Venting is one of the most overlooked aspects of mold troubleshooting.

- What are Vents?: Vents are very shallow channels (typically only 0.02-0.04mm deep) machined into the parting line of the mold. They are shallow enough to let air escape but not so deep that the molten plastic can flow into them, creating flash.

- Consequences of Blocked Vents: When vents become clogged with dust, residue from the PET, or cleaning agents, the air cannot escape quickly enough. This trapped pocket of air gets compressed by the incoming plastic, creating a "diesel effect." The air can superheat and burn the plastic, causing brown or black scorch marks on the bottle. It can also act as a cushion, preventing the bottle from fully forming, leaving details looking soft and undefined.

How to Inspect and Clean Vents

- Get a Good Light and Magnification: You will need a bright light source and a magnifying glass to properly inspect the parting line of the problem cavity.

- Look for Residue: Compare the vents of the bad cavity to a good one. Do you see a build-up of a waxy or dark residue in the vent channels of the bad cavity?

- Cleaning: Vents should be cleaned carefully. Use a soft brass brush or a wooden or plastic scraper. Never use a hardened steel tool like a screwdriver, as this will scratch the mold surface and damage the vent permanently. For stubborn residue, specialized mold cleaning solvents can be used. Regular mold cleaning is essential preventative maintenance.

Inspecting the Cavity Surface

The mold surface is a mirror of your final product. Any damage here is critical.

- Scratches and Dings: A dropped tool or improper handling can easily scratch or dent the aluminum or steel of a mold cavity. Look carefully over the entire surface of the problem cavity. A long scratch in the mold will produce a raised line on the bottle. A small ding will produce a small pimple.

- Wear and Tear: Over millions of cycles, textured areas can become polished and smooth, or sharp corners can become rounded. This is particularly true in areas with high plastic flow, like the base or shoulder. If your bottle has a specific design feature that is not forming correctly on one cavity, inspect that area of the mold for wear.

- Chemical Attack: Using the wrong cleaning chemicals can etch or damage the mold surface. Always use cleaners that are specifically designed for blow molds.

Validating a complex design before cutting metal can prevent many issues. Using techniques like 3D printed samples allows you to physically hold a prototype and confirm that difficult features will mold correctly, reducing the chances of surface-related problems later on.

Advanced Diagnostics: Swapping Components to Isolate the Root Cause?

You have systematically checked everything: heating, valves, mechanicals, cooling, and the mold surface. Yet, the problem in that one cavity remains. It is time for the ultimate diagnostic technique: component swapping.

This method uses the process of elimination to definitively prove which part is faulty. By swapping a suspected bad component with a known good component from another cavity, you can isolate the variable and find your root cause.

This is the most powerful troubleshooting method in your arsenal because it removes all guesswork. If the problem moves with the component you swapped, you have found the culprit. If the problem stays in the original cavity, you know that component is good, and the issue lies elsewhere. This should be your final step before considering a major mold overhaul or calling in an external service technician. It requires some mechanical work but provides a definitive answer.

The Logic of Component Swapping

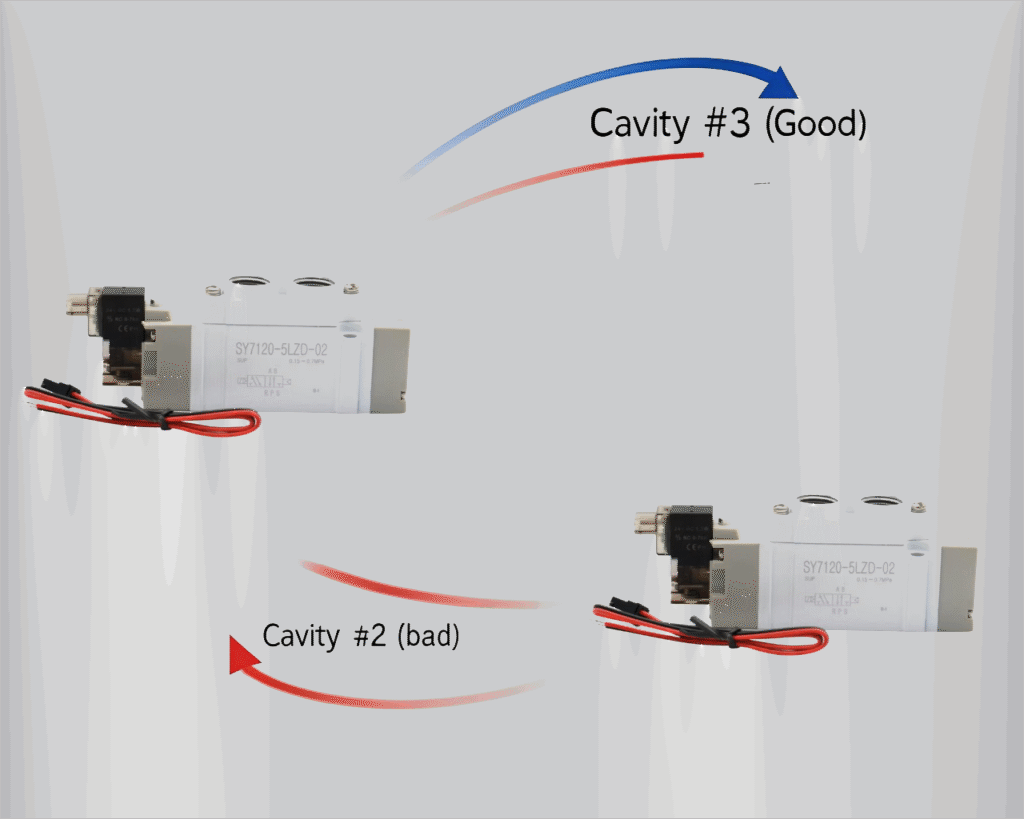

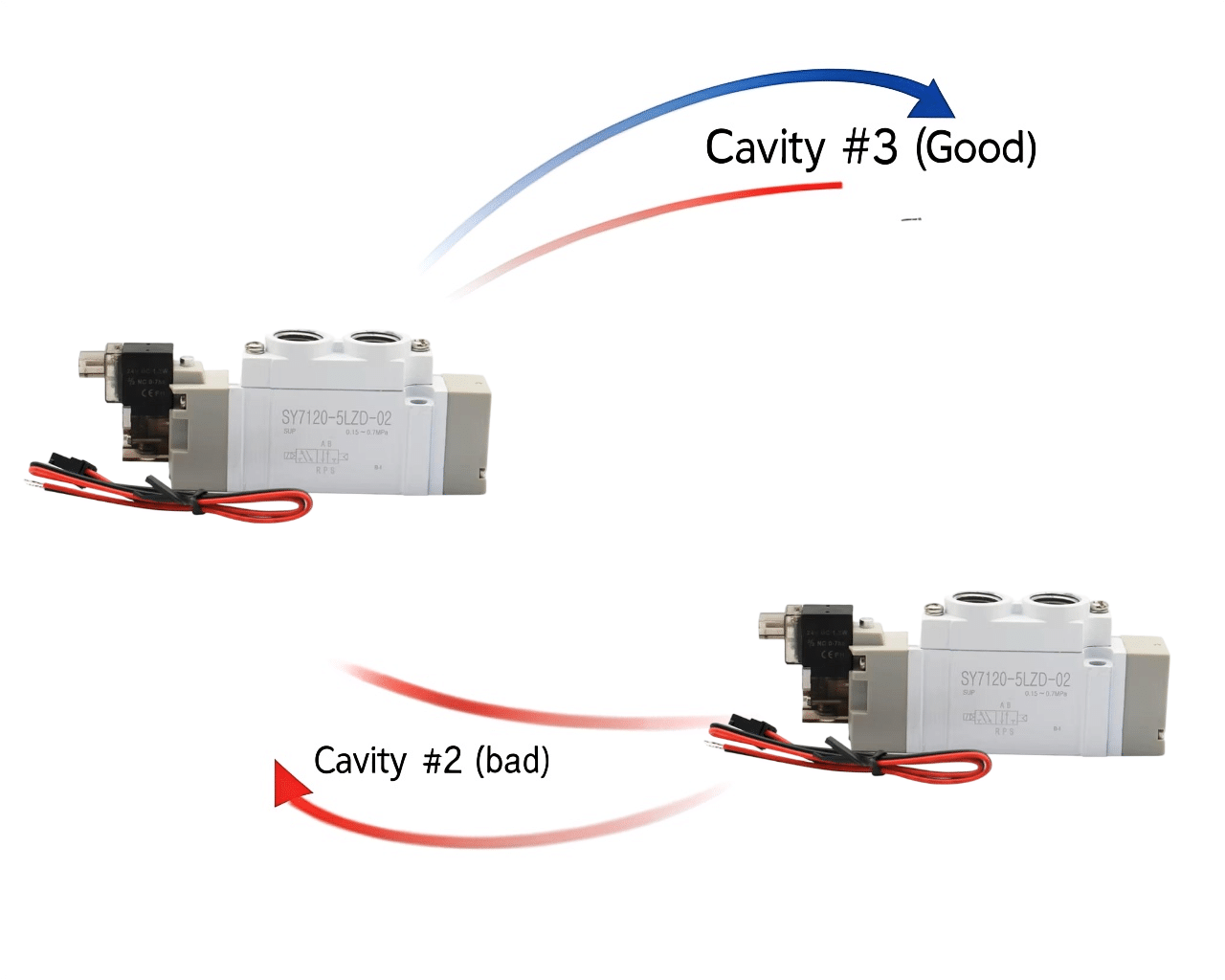

The principle is simple. Let's say you suspect the valve block for cavity #2 is faulty, but you can't find anything obviously wrong with it.

- The Hypothesis: "The valve block for cavity #2 is the cause of the defect."

- The Experiment: You will swap the valve block from cavity #2 (the bad one) with the valve block from cavity #3 (a good one).

- The Possible Outcomes:

- Outcome A: The defect moves. The bottles from cavity #3 are now bad, and the bottles from cavity #2 are now good. This proves your hypothesis. The problem is in the valve block. You can now confidently repair or replace that specific block.

- Outcome B: The defect stays. The bottles from cavity #2 are still bad, and the bottles from cavity #3 are still good. This disproves your hypothesis. You now know for certain that both valve blocks are working correctly, and the root cause is located somewhere else (e.g., in the mold itself, the sealing unit, etc.).

How to Perform a Component Swap Safely and Effectively

This procedure requires careful work.

- Safety First: Always follow proper lock-out/tag-out (LOTO) procedures. Shut down the machine, and release all stored energy (electrical, pneumatic, and hydraulic).

- Label Everything: Before you disconnect a single hose or wire, label everything clearly. Take pictures with your phone. A valve block has multiple air lines and electrical connectors. You must ensure you can put it all back together exactly as it was. Mismatched connections can cause machine damage or safety hazards.

- Choose Your Components: Decide which two components you are going to swap. The most common swaps are for valve blocks, sealing cylinders, or even stretch rods. Start with the component you most strongly suspect.

- Perform the Swap: Carefully remove the two components. Keep track of all fittings, bolts, and gaskets. Install the component from the bad cavity into the good cavity's position, and vice-versa.

- Double-Check Connections: Before restarting, meticulously check that every hose and wire is connected to the correct port on the correct component. Refer to your labels and photos. This is also a good time to ensure you have a perfect match between your mold and machine, as interface issues can cause problems. Knowing your mold and machine mounting dimensions is crucial.

- Restart and Observe: Power the machine back on and start production. Mark the bottles from the two swapped cavities and analyze the results.

This systematic swap is the final court of appeal in diagnostics. It replaces assumptions with certainty and is the fastest way to pinpoint a stubborn, elusive problem.

Conclusion: A Systematic Approach Leads to a Fast Solution?

Finding the cause of a single bad cavity in a multi-cavity mold can feel overwhelming. However, the solution is not guesswork or randomly replacing parts. The key is a logical, systematic process.

By following a step-by-step method—from external factors to internal components—you eliminate variables one by one. This is the fastest path to the root cause, just like it was for my Belgian client.

My client’s problem was a simple leaking O-ring in a sealing cylinder. We found it not by luck, but by methodically checking the heating, then the valves, and then the mechanical components. This logical flow turned a potentially production-stopping headache into a quick, low-cost repair. This systematic approach saves time, minimizes downtime, and empowers you to solve problems confidently.

Summary: Troubleshooting Checklist

For a quick reference on the production floor, here is a summary of the systematic troubleshooting process.

| Step | Area to Investigate | Common Problems | Solutions |

|---|---|---|---|

| 0 | Pattern Confirmation | Random vs. Consistent defect. | Mark bottles from each cavity; analyze a large sample to confirm the issue is tied to one cavity. |

| 1 | Heating System | Burnt-out lamp; dirty reflector; obstruction. | Visually inspect lamps; compare preform temperatures with an IR pyrometer. |

| 2 | Valve Block | Internal seal leak; sluggish solenoid. | Listen for hissing; check solenoid indicator lights; feel for cold spots; use a rebuild kit. |

| 3 | Mechanical Parts | Misaligned stretch rod; worn stretch rod tip; leaking sealing unit. | Visually check alignment; inspect tip for wear; perform a soap bubble test on seals; replace O-rings. |

| 4 | Mold Cooling | Blocked or restricted cooling channel. | Compare water flow rates and temperature differentials between cavities; descale channels if necessary. |

| 5 | Mold Cavity | Clogged vents; scratched or damaged surface. | Inspect parting line vents with magnification and clean carefully; examine cavity surface for imperfections. |

| 6 | Advanced Diagnostics | A stubborn, unidentified issue. | Perform a component swap (e.g., valve block) with a known good cavity to definitively isolate the fault. |

For a convenient, printable version of this checklist to keep near your machine, you can download the PDF below.

➡️ Download the Single-Cavity Troubleshooting Checklist PDF here.

Frequently Asked Questions (FAQs)

1. In your experience, what is the #1 most common cause for a persistent single-cavity defect?

Based on my experience, the most frequent culprit is the individual valve block for that cavity. These components cycle millions of times under high pressure, and the internal seals are consumable parts. A minor leak or a slight delay in solenoid response is very common and has an immediate and direct impact on the bottle formation for that single cavity. It's usually the first place I investigate after confirming the heating is uniform.

2. Which of these troubleshooting steps can be safely performed by a trained operator, and when should I call a senior technician?

A trained operator can and should safely perform the initial checks. This includes confirming the problem pattern (Step 1), visually inspecting the heating oven for failed lamps (Step 2), and listening for obvious air leaks around valve blocks or sealing units (Step 2 & 3). However, when it comes to replacing components, performing a component swap (Step 7), or servicing internal mold components like cooling channels or vents (Step 4 & 5), it is highly recommended to involve a senior maintenance technician. These tasks require a higher level of mechanical skill and a thorough understanding of safety procedures like LOTO.

3. What regular maintenance practices can help prevent these single-cavity issues from occurring?

Prevention is always better than a cure. A robust preventative maintenance schedule is key. This should include:

- Weekly: Visually inspect heating lamps and reflectors. Check for and repair any audible air leaks.

- Monthly: Clean mold parting line vents. Check and clean water filters for the mold cooling system.

- Annually (or based on cycle count): Rebuild all valve blocks and sealing cylinders using manufacturer-specified service kits. Disassemble and professionally clean all mold cooling channels to prevent scale buildup.

4. If the problem is inside the mold itself (e.g., a damaged cavity), is it expensive to repair?

The cost can vary significantly. If the issue is a clogged cooling channel or a dirty vent, the repair is mostly labor and downtime, and the cost is relatively low. However, if the surface of the mold cavity is scratched, dented, or worn, the repair is more complex. Minor scratches can sometimes be polished out, but significant damage may require micro-welding and re-machining, which can be expensive and requires a specialized mold shop. This is why protecting the mold surfaces during handling and cleaning is absolutely critical.

5. My client wants a new bottle shape. How can I ensure we don't design a bottle that is difficult to mold and prone to these issues?

This is an excellent question. Proactive design is crucial. When developing a new shape, you should consult a comprehensive PET bottle mold design guide. Key considerations include avoiding sharp corners, ensuring stretch ratios are within acceptable limits, and designing for uniform wall thickness. Furthermore, using a service for 3D printed samples is a fantastic way to validate a design before cutting expensive metal, allowing you to catch potential molding problems at the concept stage.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr