You've finally upgraded your production line, but your new high-speed machine keeps jamming. The problem might be your preforms, which worked perfectly before. What’s going on here?

The critical difference lies in precision. A fully-automatic machine requires preforms with much tighter inner diameter (ID) tolerances than a semi-automatic machine. Human operators can subconsciously adjust for minor flaws, but a high-speed mechanical system cannot. This small, overlooked detail is the most common cause of jamming.

I’ve seen this exact scenario play out many times. The initial excitement of a new, faster machine quickly turns into deep frustration. You've invested a significant amount of capital to boost your output, only to find the machine stops more than it runs. It’s a costly and confusing problem. This article will walk you through why this happens and, more importantly, how to fix it for good. We’ll look at the hidden details of preform quality that become critical when you make the leap to automation.

Key Takeaways for a Smooth Transition to Automation

| Area of Concern | Semi-Automatic Process ("Manual Forgiveness") | Fully-Automatic Process ("Mechanical Precision") | Key Action Required for Upgrade |

|---|---|---|---|

| Preform Loading | Operator manually inserts preform, can adjust for slight size variations. | Mechanical gripper and mandrel require exact dimensions for a successful load. | Implement strict quality control for preform Inner Diameter (ID). |

| Supplier Standard | Supplier QC may focus on weight and thread, sufficient for manual handling. | Supplier must guarantee tight tolerances on all critical dimensions. | Vet and select an "automation-ready" preform supplier. |

| Troubleshooting | Operator can immediately identify and discard a problematic preform. | Machine alarms and stops the entire line, causing downtime. | Establish clear communication and specification sheets with your supplier. |

| Core Principle | Human flexibility masks minor inconsistencies in raw materials. | Machine precision exposes all inconsistencies in raw materials. | Upgrade your material standards to match your new machinery's capability. |

The Excitement and Frustration of a New Automatic Line?

You’ve decided to upgrade. The semi-automatic machines served you well, but the market demands more volume, more speed. The new fully-automatic bottle blowing machine arrives, and the excitement is real. This machine represents growth, efficiency, and a new chapter for your business. Then, you hit a wall.

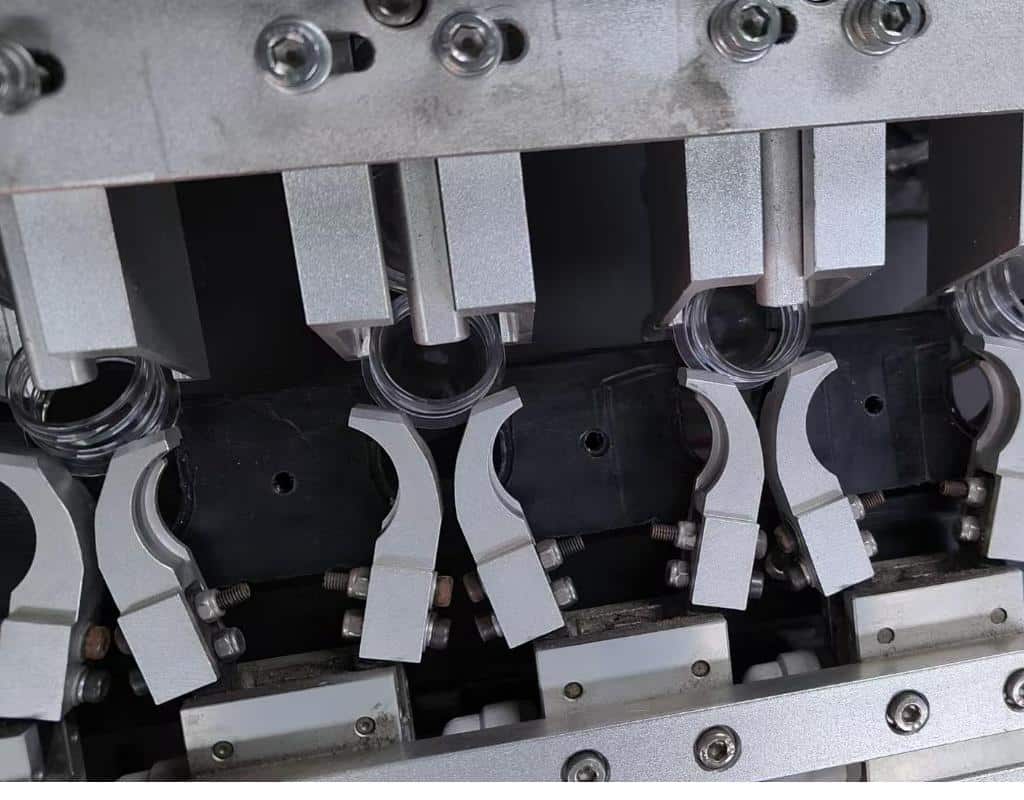

The machine constantly alarms and stops, always at the same point: preform loading. The mechanical arm picks up a preform but can't place it on the heating mandrel. It’s a maddening cycle of start, alarm, stop, reset. What could possibly be wrong with this brand-new, state-of-the-art equipment?

This is exactly what happened to a client of mine in South Africa. In 2023, they were running smoothly with two of our semi-automatic machines. Business was good, so in early 2025, they invested in a brand-new, two-cavity fully-automatic machine. The installation went perfectly, but production was a nightmare. The machine would not run for more than a minute without a preform jamming as it tried to enter the heating oven. He called me, frustrated, convinced the heating bases on our machine were faulty. He insisted his preforms were fine; after all, he’d been using them for years without a single issue. This is where the real investigation began, and it highlights a fundamental misunderstanding that many people have when upgrading. The problem wasn't the new machine, and it wasn't exactly the preforms themselves. The problem was the mismatch between the two.

The Critical Difference: "Manual Forgiveness" vs. "Mechanical Precision"?

You are running a semi-automatic line, and your operator is a star. They load preforms quickly and efficiently without a second thought. But why can they handle preforms that a new machine can't?

The answer is "manual forgiveness." A human hand is an incredibly sophisticated tool that can feel and adjust for tiny imperfections. A machine, however, operates on pure logic and pre-programmed specifications. It lacks the ability to adapt. Your old process had a hidden, unmeasured tolerance built right in: your operator's skill.

Let's break this down. In your old semi-automatic process, an operator picks up a preform and places it onto the heating mandrel. If a preform's opening is a fraction of a millimeter too small, the operator subconsciously applies a little more force or a slight twist to seat it properly. If it's a bit too large, they adjust their grip to ensure it doesn't wobble. They are performing thousands of micro-corrections every day without even realizing it. They are your first line of quality control, filtering out problems through touch and feel.

Now, consider the fully-automatic process. It’s a world of unforgiving precision. A mechanical system uses grippers and mandrels machined to exact specifications, with tolerances measured in hundredths of a millimeter. It follows a simple, binary path: does the preform fit, yes or no? There is no "almost." There is no "let me just wiggle it a bit." If the preform’s dimensions are not exactly within the pre-defined range, the sequence fails. The machine can't force a preform that's too tight; it can't secure a preform that's too loose. It does the only thing it's programmed to do when specs aren't met: it stops and sounds an alarm.

This was the core of the issue for my South African client. I told him, "Your operator was your quality control. The new automatic machine is a ruthless inspector that never takes a break." The move to automation isn't just about replacing a person with a machine; it's about shifting from a system that tolerates variation to one that demands absolute consistency. This realization is the first step to solving the problem. The preforms that were "good enough" for the old system are now revealing their hidden inconsistencies under the microscope of automation.

The Real Culprit: A Deep Dive into Preform Inner Diameter (ID) Tolerance?

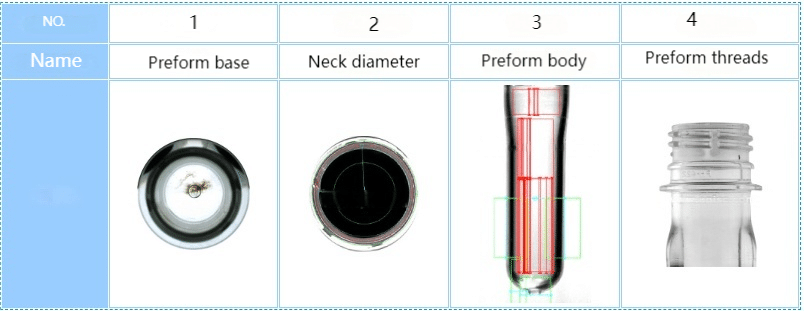

Your machine keeps jamming. You suspect the preforms, but they look identical. Where exactly is the problem hiding? It's in a dimension you probably never even thought to measure before.

The most common cause of preform loading errors in automatic machines is an inconsistent Inner Diameter (ID). This is the measurement of the opening of the preform neck. If this dimension varies even slightly beyond the machine's tolerance, it will cause a jam or a dropped preform.

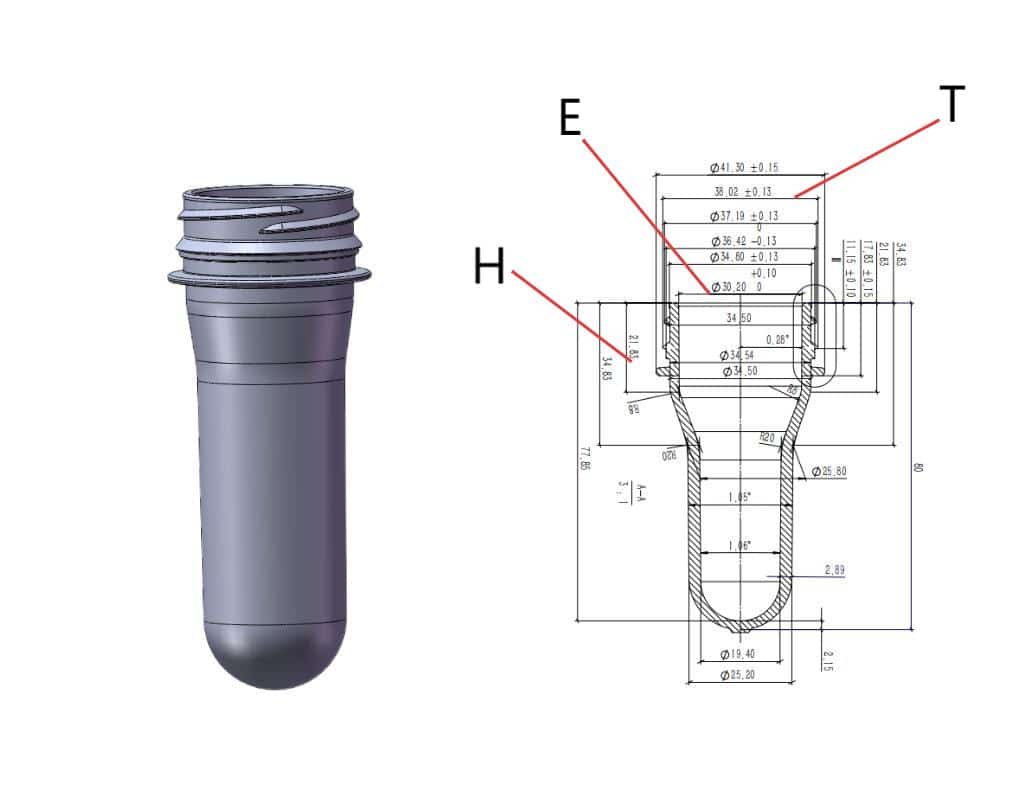

Let's get specific. The Inner Diameter, or ID, is the hollow space inside the preform's neck finish. When the preform is loaded into the heating oven, it's placed onto a metal post called a heating mandrel. This mandrel is a precise size, and the preform ID must be perfectly matched to slide on smoothly and securely.

Understanding Tolerance

In manufacturing, "tolerance" is the acceptable range of variation for a specific dimension. Nothing can be made to the exact same size every single time. So, an engineer defines a target dimension plus or minus an acceptable error. For example, a standard 30/25 preform neck might have a target ID of 25mm. A good tolerance for an automatic machine might be +/- 0.1mm. This means any preform with an ID between 24.9mm and 25.1mm is acceptable.

Why a Tiny Deviation Causes Big Problems

This is where the rubber meets the road. A deviation of just 0.2mm can shut down your entire production line. Here's how:

| Preform ID Measurement | Result on Automatic Machine | Why it Happens |

|---|---|---|

| ID is too small (e.g., 24.8mm) | JAM | The preform cannot be inserted onto the 25mm heating mandrel. The loading mechanism pushes, meets resistance, and triggers a fault. |

| ID is correct (e.g., 25.0mm) | SUCCESS | The preform slides onto the mandrel with a perfect fit, ready for heating. |

| ID is too large (e.g., 25.2mm) | DROP or MISALIGNMENT | The preform is too loose on the mandrel. It can wobble during transport through the oven, heat unevenly, or even fall off, causing a jam. |

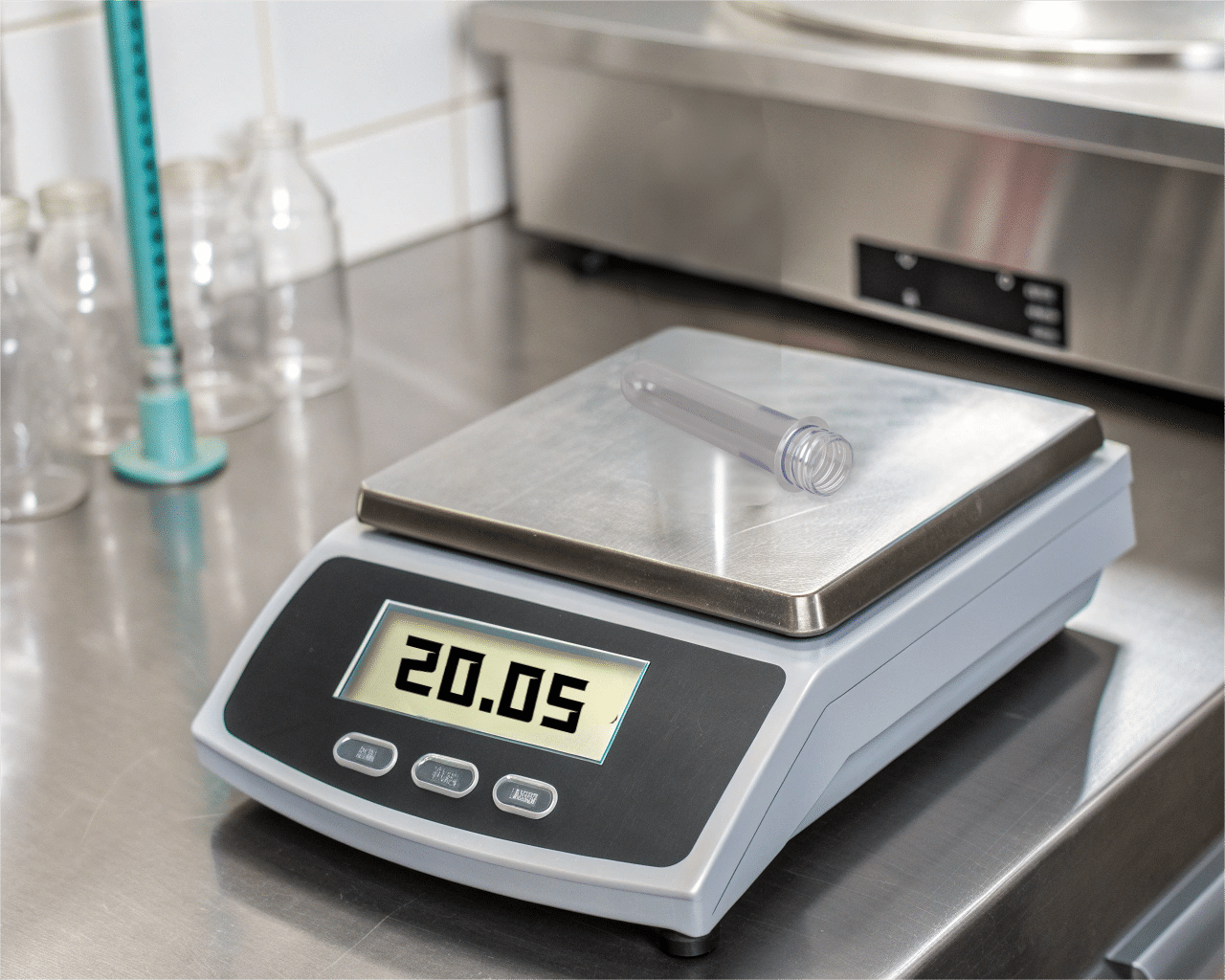

This is precisely what I asked my client in South Africa to investigate. Following my instructions, they took a digital caliper and started measuring the ID of the preforms from their "problem batch." The results were shocking to them. They found preforms with IDs as small as 24.7mm and as large as 25.4mm. The variation was huge. The preforms they thought were perfectly fine were, in fact, all over the place. This discovery was their "aha!" moment. The problem wasn't the machine; it was the inconsistent quality of the raw material that was now being exposed by the machine's precision. For anyone running into this issue, the first step is always to get a caliper and measure. You can't fix what you don't measure. A clear understanding of the right preform neck size and its required tolerance is non-negotiable for automation.

Why Your Old Preform Supplier Might No Longer Be Suitable?

You have a great relationship with your preform supplier. They've given you good prices and reliable delivery for years. Now, after your upgrade, their product is causing problems. How can this be?

Many preform suppliers cater primarily to the semi-automatic market, which is more forgiving of dimensional variations. Their quality control may focus only on weight and neck thread, not the tight inner diameter tolerance required by high-speed automation. Their product isn't "bad," it's just not right for your new process.

Think about it from the supplier's perspective. Their largest customer base might be hundreds of small to medium-sized businesses running semi-automatic machines. In that world, if the preform weight is correct (meaning the final bottle will have the right amount of plastic) and the neck thread is correct (so the cap will fit), they consider the preform "qualified." The subtle inconsistencies in the inner diameter were never a source of complaints because human operators always compensated for them. Your complaint about ID tolerance might be the first time they've ever had to address it in detail.

This was a difficult conversation for my South African client. He had worked with his supplier for years and felt loyal to them. But when he presented his measurements and explained the requirements of his new automatic machine, the supplier was unable to guarantee the necessary tolerance. Their manufacturing process and quality control, which relied on older preform molds and less stringent checks, simply weren't set up to produce the level of consistency he now needed.

The quality level that is perfectly acceptable for one technology can be completely insufficient for the next. Upgrading your machine means you must also upgrade your expectations for your raw materials. Your supplier relationship must evolve from a simple transaction to a technical partnership. If your current supplier cannot meet the new, stricter specifications, you are left with a simple business choice. You can either de-rate your brand-new, expensive machine to run slower and accommodate the poor preforms, or you can find a new supplier who can deliver the quality your investment deserves. For my client, the choice was clear. He had to find a supplier who understood the demands of automation.

The Solution: How to Qualify Preforms for Your Automatic Line?

You’ve identified the problem: your preform's inner diameter tolerance is inconsistent. So, what's the next step? You need a clear, systematic process to ensure every preform you buy is right for your machine.

The solution involves three key steps: clear communication with your supplier, implementing simple in-house measurement tools, and always testing samples before placing a large order. This proactive approach prevents downtime and ensures your automatic line runs smoothly.

This is the exact plan I laid out for my client, and it transformed his operation from constant frustration to smooth efficiency. Here’s a detailed breakdown of how you can do the same.

1. Communication: Speak the Language of Precision

You can no longer just order "30/25 preforms." You must be specific.

- Request a Specification Sheet: Ask your potential supplier for a technical "spec sheet" for the preform you intend to buy. This document should list all critical dimensions and, most importantly, their guaranteed tolerances. If a supplier can't provide one, that's a major red flag.

- Clearly State Your Needs: Tell them you are running a high-speed automatic machine from a specific brand. Inform them of your required inner diameter and the tolerance you can accept (e.g., "We require an ID of 25.0mm with a tolerance of +/- 0.1mm"). This puts the responsibility on them to confirm they can meet your requirements.

2. Measurement Tools: Trust, But Verify

Once the preforms arrive, you need a quick and easy way to check them. You don't need a fancy lab.

- Digital Caliper: This is an essential, inexpensive tool. Randomly select 20-30 preforms from a new batch and measure the ID of each one. Record the results. This will give you a clear picture of the consistency.

- "Go/No-Go" Plug Gauge: This is an even simpler tool. It's a custom-made metal plug with two ends. The "Go" end is machined to the minimum acceptable ID (e.g., 24.9mm), and the "No-Go" end is machined to the maximum acceptable ID (e.g., 25.1mm).

- If the "Go" end fits, the preform is not too small.

- If the "No-Go" end does not fit, the preform is not too large.

- This provides a simple pass/fail test that anyone on your factory floor can perform in seconds.

3. Sample Testing: The Ultimate Confirmation

Never commit to a massive order from a new supplier without a trial run.

- Request a Sample Batch: Before signing a contract, ask for a sample box of a few thousand preforms from a real production run.

- Test on Your Machine: Run the entire sample batch on your automatic bottle blowing machine. This is the ultimate test. Does it run smoothly? What is the jam rate? If it runs perfectly, you have found a good partner.

After his initial problems, my client implemented this exact system. He now requires a spec sheet from all potential suppliers. His receiving department uses a Go/No-Go gauge to check every shipment that comes in. He found a new supplier who understood his needs and was happy to provide a sample batch for testing. His machine has been running without jamming issues ever since. This system puts you in control and makes preform quality a predictable science, not a frustrating game of chance.

What to Look for in an "Automation-Ready" Preform Supplier?

You're ready to find a new preform supplier who can meet the demands of your automatic line. It’s about more than just price and delivery times. You need a true technical partner.

An "automation-ready" supplier understands and can guarantee tight tolerances for all dimensions, not just weight. They have a strong internal Quality Control (QC) department, can provide inspection reports, and have proven experience supplying other factories that use high-speed machinery.

Switching suppliers can feel daunting, but it’s a critical step to maximizing the return on your machinery investment. When I advised my client on finding a new partner, I gave him a checklist of things to look for. This isn't just about buying a product; it's about buying into a process of quality and consistency.

Checklist for an "Automation-Ready" Supplier

| Feature | What to Look For | Why It's Important |

|---|---|---|

| Technical Documentation | They readily provide detailed specification sheets for every preform, including all dimensions and their tolerances. | This shows they measure and control their process to a high degree of precision. It's a sign of professionalism and transparency. |

| Robust Quality Control | They have a dedicated QC department and can provide you with batch-specific inspection reports (Certificates of Analysis). | This proves they aren't just making promises. They have a system to verify the quality of their product before it leaves their factory. |

| Proven Experience | They can name other companies with high-speed automatic machines that they currently supply. (Ask for references if possible). | This is the best proof that their product works in a real-world, high-demand environment. They understand the stakes and the specific challenges of automation. |

| Material Knowledge | They can discuss technical aspects like resin IV (Intrinsic Viscosity) and its impact on the blowing process. | This indicates a deeper level of expertise beyond just molding plastic. They can be a valuable resource for troubleshooting other potential blowing defects. |

| Mold Quality | They invest in high-quality, precision-engineered preform molds. They should be able to talk about their mold maintenance program. | The quality of the preform is a direct reflection of the quality of the mold it came from. Well-maintained, high-cavitation molds are essential for consistency. |

Finding a supplier who ticks these boxes might mean you pay a slight premium per preform. However, this is not a cost; it is an investment. Let's say a higher-quality preform costs $0.001 more. If that preform prevents just one hour of downtime per month on a machine that should be producing 2,000 bottles per hour, the savings in lost production and operator frustration will pay for the premium many, many times over. When you buy a high-performance car, you don't fill it with the cheapest fuel. The same logic applies here: high-performance machines require high-performance raw materials.

A Note on Other Preform Parameters Critical for Automation?

You've solved the inner diameter issue, and your machine is running much better. But for peak performance and perfect bottles, there are a few other preform dimensions that automation is very sensitive to.

Beyond the inner diameter, the consistency of the Neck Support Ring, minimal Eccentricity (wall thickness variation), and stable Material IV (Intrinsic Viscosity) are also critical for a smooth, reliable automated blow molding process. Each parameter affects a different stage of the operation.

While ID tolerance is the most common show-stopper for loading, these other factors play a huge role in the transport, heating, and blowing stages. A truly "automation-ready" preform will be consistent across all these metrics. Let's look at why they matter.

1. Neck Support Ring (支撑环)

The neck support ring, also called the flange, is what the preform hangs from as it travels through the machine.

- Why it matters: The mechanical transport system is designed to grip this ring. If the ring's diameter or thickness is inconsistent, the grip can be too loose (causing wobbling or drops) or too tight (causing stress or jams). Furthermore, if the ring surface isn't flat and perpendicular to the preform body, the preform will hang at an angle.

- Impact of inconsistency: An angled preform will not pass through the heating oven correctly. One side will be closer to the heating lamps than the other, leading to uneven heating. This is a primary cause of inconsistent wall thickness in the final bottle, a problem that can be difficult to troubleshoot. It's a classic example of how a tiny flaw in the raw material can lead to major defects in the finished product. This is where a comprehensive PET bottle mold design guide can be helpful to understand the entire process.

2. Eccentricity (偏心度)

Eccentricity refers to how centered the core of the preform is. In simple terms, it's a measure of how even the wall thickness is all the way around the preform body.

- Why it matters: The goal of the heating process is to bring the entire preform wall to a uniform, optimal temperature for stretching and blowing. If one side of the preform wall is thicker than the other, it will heat differently.

- Impact of inconsistency: The thicker section will not get hot enough, while the thinner section may overheat. When the preform is blown, the hotter, thinner section will stretch too much, creating a weak spot in the bottle. The cooler, thicker section won't stretch enough, resulting in an uneven material distribution. This can lead to issues with bottle strength, clarity, and volume.

3. Material IV (Intrinsic Viscosity - 特性粘度)

IV is a measure of the length of the polymer chains in the PET resin. It's a key indicator of the material's strength and processing characteristics.

- Why it matters: Your machine's heating and blowing parameters are dialed in for a specific IV value. A stable IV ensures that every preform behaves identically under the same conditions.

- Impact of inconsistency: If your supplier provides a batch of preforms with a lower IV than usual, the material will overheat with your standard settings, becoming too runny and weak. If the IV is too high, it won't get hot enough and will be difficult to blow. This forces your operators to constantly adjust machine settings, defeating the purpose of a stable, automated process.

A good supplier controls their process from raw resin to finished preform, ensuring the IV is consistent from batch to batch. Understanding these details is what separates a frustrating production experience from a truly efficient, "lights-out" operation.

Conclusion: Precision In, Perfection Out - The Golden Rule of Automation

Upgrading your machinery is a major step forward, but the machine itself is only half of the equation. Your raw materials must be upgraded to the same high standard.

Investing in high-quality, dimensionally consistent preforms is not an extra cost; it's a fundamental investment in the uptime and efficiency of your new automated line. A reliable machine partner will not only provide the equipment but also guide you through these critical details to ensure your success.

Frequently Asked Questions (FAQ)

1. What is the typical inner diameter (ID) tolerance required for a high-speed automatic PET blow molding machine?

While it varies slightly by machine manufacturer, a good rule of thumb for a high-speed automatic machine is a tolerance of ±0.1mm to ±0.15mm from the nominal ID. For example, for a standard PCO1881 preform with a target ID of 21.74mm, an acceptable range would be 21.64mm to 21.84mm. Anything outside this narrow window significantly increases the risk of jamming or dropping preforms. Always confirm the specific requirement in your machine's technical manual or with the manufacturer.

2. Can the preform loading system on my machine be adjusted to handle more variation in preform ID?

To a very limited extent, yes, but it is not a solution to poor preform quality. Some machines allow for minor adjustments in the gripper pressure or mandrel alignment. However, these adjustments are intended to fine-tune the machine for a consistent batch of preforms, not to compensate for a batch with wide variations. Attempting to open up the tolerances on the machine to accept bad preforms will often lead to other problems, such as poor preform stability in the oven or increased wear on the loading components. The correct approach is to fix the raw material, not detune the machine.

3. Besides the preform ID, what are other common causes for preform jamming during the heating process?

Beyond the ID, jamming can be caused by several other preform issues. A warped or non-flat Neck Support Ring can cause the preform to hang at an angle and hit the sides of the oven tunnel. Excessive flashing (thin slivers of extra plastic) on the neck finish or support ring can get caught in the transport mechanism. Another common cause is preforms sticking together due to static electricity, which can be a problem in dry climates. Installing an anti-static air blower at the preform unscrambler can often solve this issue.

4. What is the best way to communicate these technical requirements to a new preform supplier to ensure I get the right product?

The most effective way is through formal documentation. Don't rely on a verbal agreement. Provide the potential supplier with a Preform Specification Sheet that you create. This document should clearly list:

- Preform drawing or model number.

- Required weight and tolerance (e.g., 21.0g ± 0.2g).

- Neck finish specification (e.g., PCO1881).

- All critical dimensions and their required tolerances, especially the Inner Diameter (e.g., ID: 21.74mm ± 0.1mm).

- Resin requirements (e.g., 100% virgin PET, specified IV range).

Require the supplier to sign and return this sheet, formally agreeing that they can and will meet these requirements. This becomes part of your purchasing agreement.

5. Do "automation-ready" preforms with tighter tolerances cost significantly more than standard ones?

They may cost slightly more, but the difference is usually very small—often fractions of a cent per preform. The cost difference is minimal when you consider the massive financial impact of machine downtime. A supplier who can hold tight tolerances typically does so through better molds, newer machinery, and more robust QC, which leads to higher efficiency and less scrap on their end, offsetting much of the cost. When you calculate the Total Cost of Ownership, including lost production from jams, the higher-quality preform is almost always the cheaper and more profitable option.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

📞 Contact: Vivian

🏭 Zhongshan Jindong Machinery Co., Ltd.

🌍 www.ibottler.com

📧 Vivian@ibottler.com | 💬 WhatsApp: +86-13106288777

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr