Your new bottles look great, but they shatter on the first drop. This frustrating problem risks your product and reputation. Where are you going wrong in the process?

Improving drop-test performance involves five key areas: optimizing the preform design, redesigning bottle corners for impact dispersion, mastering the stretch ratio, perfecting the heating profile for uniform wall thickness, and ensuring adequate cooling time. A failure in any one of these can create a critical weak point.

Major brands have enormous budgets for product development. They conduct a battery of tests before a new bottle ever sees a production line, covering everything from food-contact safety and seal integrity to complex distribution simulations. They use standards like ASTM D5276 for drop testing and ISTA 3A for shipping simulation. For them, failure is not an option.

But what about smaller brands? What happens when you don't have a multi-million dollar R&D budget, but your bottles are still breaking? This is the exact situation a client of mine from Bangladesh faced. His company launched a new 500ml beverage, but the bottles were failing catastrophically during shipping. He didn't need a 100-page lab report; he needed practical, effective solutions, and he needed them fast. This article shares the five core tips I gave him that transformed his fragile bottle into a robust container, without breaking the bank.

Key Blow Molding Adjustments for Bottle Durability

| Tip # | Area of Focus | Key Action | Expected Outcome |

|---|---|---|---|

| 1 | Preform Optimization | Ensure sufficient preform weight and a design that correctly distributes material. | Provides a solid foundation, preventing inherently thin or weak sections in the final bottle. |

| 2 | Bottle Base & Corners | Redesign sharp angles into smooth, rounded corners. Choose a base design that disperses impact. | Eliminates stress concentration points, directing impact forces across the bottle surface instead of focusing them. |

| 3 | Stretch Ratio | Balance the axial (vertical) and hoop (horizontal) stretch for optimal molecular orientation. | Creates a strong, interwoven molecular structure throughout the bottle, maximizing the inherent strength of PET. |

| 4 | Heating Profile | Adjust oven zones to ensure the preform is heated uniformly before blowing. | Achieves consistent wall thickness, eliminating the thin, weak spots that are prone to failure on impact. |

| 5 | Cooling Process | Allow adequate cooling time in the mold before ejection. Ensure efficient mold cooling channels. | "Locks in" the bottle's strength and dimensional stability, preventing a weak structure from post-molding deformation. |

Beyond Aesthetics: The High Business Cost of a Failed Drop Test?

A bottle that breaks easily seems like a simple quality issue. But in reality, it's a major business risk that can cost you far more than just the product inside.

A failed drop test is a direct threat to your profitability and brand reputation. The immediate costs of product loss and returns are compounded by the long-term damage from unhappy customers and lost confidence in your brand. It’s a costly problem that erodes your bottom line.

When my client from Bangladesh first called me, his frustration was clear. He had invested heavily in a new beverage line. The product tasted great, the label was vibrant, but a significant percentage of his first major shipment was being rejected by his distributor. Bottles were breaking during transit and while being handled in the warehouse.

Let's break down the real costs he was facing, costs that any business in this situation will encounter:

- Product and Packaging Loss: Every broken bottle is lost inventory. This includes the cost of the beverage, the bottle, the cap, the label, and the carton it was shipped in. These direct costs add up incredibly fast.

- Shipping and Logistics Costs: He had to pay for the initial shipping to the distributor, and now he was facing the cost of reverse logistics—getting the damaged goods back or paying for their disposal.

- Customer Complaints and Returns: The distributor was his immediate customer, and they were unhappy. This strained a critical business relationship. If those bottles had reached the end consumer, the problem would have multiplied, leading to public complaints, negative online reviews, and demands for refunds.

- Brand Reputation Damage: This is the most significant long-term cost. A brand that is perceived as having cheap, unreliable packaging will struggle to gain consumer trust. My client was trying to launch a new product; a reputation for failure at the very beginning could have killed the entire line before it even had a chance to succeed.

He quickly realized that fixing his bottle wasn't just a technical necessity; it was an urgent business priority. Investing in a more durable bottle isn't an expense. It's a critical investment in product integrity, customer satisfaction, and the long-term health of your brand. Solving this problem was about protecting his entire venture.

Why Do PET Bottles Break? The Science of Impact and Stress Concentration?

You drop a PET bottle, and it cracks. It seems simple, but the failure begins at a microscopic level. Understanding why it breaks is the first step to designing a bottle that doesn't.

PET bottles break when impact force finds a weak point, a phenomenon known as "stress concentration." While the PET material itself is strong due to biaxial orientation, sharp corners or thin spots in the bottle's design act as focal points for stress, initiating a crack upon impact.

To understand why a bottle fails, we first need to appreciate why it's so strong to begin with. The magic behind a PET bottle's strength is a process called biaxial orientation. During the stretch blow molding process, the PET preform is stretched in two directions simultaneously:

- Axial (Vertical) Stretch: A stretch rod pushes the preform downward.

- Hoop (Horizontal) Stretch: High-pressure air blows the preform outward to fill the mold.

This two-way stretching pulls the long, tangled polymer chains of the PET material into a highly organized, interwoven grid-like structure. This molecular alignment is what gives the final bottle its incredible strength, clarity, and gas barrier properties.

So, if the material is so strong, why does it break? The culprit is stress concentration. Imagine an impact on the bottle as a wave of energy. In a perfectly designed bottle, this energy wave would spread out evenly across the entire surface, dissipating harmlessly. However, most bottles aren't perfect. They have features that interrupt this energy flow.

Common stress concentration points include:

- Sharp Corners: A sharp 90-degree angle at the base or shoulder of a bottle acts like a dam, stopping the energy wave and forcing all the pressure into one tiny point.

- Thin Spots: Areas of the bottle wall that are significantly thinner than the surrounding areas lack the molecular structure to handle the force.

- Poorly Formed Gates: The small dot at the center of the bottle base where the plastic was injected into the preform can be a weak point if not formed correctly.

When a bottle is dropped, the impact energy travels across its surface until it hits one of these weak points. The energy has nowhere else to go, so it concentrates on that single point, exceeding the material's structural limit and starting a crack. Once the crack starts, it propagates rapidly. For my client in Bangladesh, the failures were consistently starting at the sharp transition between the base and the sidewall. The design was focusing all the impact energy right where the bottle was most vulnerable. The goal of our redesign was simple: eliminate those stress concentration points and allow the impact forces to flow and dissipate as they were meant to.

Tip 1: Optimize Your Preform – The Foundation of a Strong Bottle?

You can’t build a strong house on a weak foundation. In blow molding, the preform is your foundation. No amount of process tweaking can save a bottle that starts from a fundamentally flawed preform.

A robust bottle begins with a correctly designed and sufficiently weighted preform. The material distribution in the preform directly dictates the potential wall thickness in the final bottle. Cutting preform weight to save on resin costs is a false economy that often leads directly to drop-test failures.

The first question I asked my client was, "Tell me about your preform." Often, in a quest to reduce costs, companies push for lighter and lighter preforms. While lightweighting is an important goal for sustainability and cost-saving, there is a point of diminishing returns where the structural integrity is compromised.

The Link Between Preform and Final Bottle

Think of the preform as a blueprint for material distribution. The amount of plastic in any given section of the preform determines how much material will be available to form the corresponding section of the bottle.

| Preform Section | Corresponding Bottle Section | Impact of Insufficient Material |

|---|---|---|

| Below the Neck Finish | Bottle Shoulder | Can lead to thin, weak shoulders that are prone to crushing under top-load pressure. |

| Middle Body | Bottle Sidewall | Results in a thin main body, compromising overall rigidity and hoop strength. |

| Base Area (including gate) | Bottle Base and Corners | This is the critical one for drop tests. A preform with too little material at its tip will inevitably create a thin, fragile base in the final bottle. |

When we examined my client's 500ml bottle, we found that the preform he was using was an off-the-shelf, generic design that was simply too light. It didn't have enough plastic concentrated in the base area. No matter how he adjusted his bottle blowing machine, he was destined to have a thin base because the raw material simply wasn't there to begin with.

Don't Fall into the Lightweighting Trap

The temptation to shave another gram off a preform is strong. If you produce millions of bottles, the resin savings can seem substantial. However, you must weigh those savings against the potential cost of failure. Saving $0.001 on resin per bottle is meaningless if you lose $1.00 per bottle in shipping damages and returns.

Our first step was to work with a supplier of high-quality preform molds to select a new preform. We increased the weight by a seemingly small amount—just 1.5 grams—but we ensured this extra material was primarily located in the lower third of the preform. This single change provided the necessary foundation, giving us enough material to work with in the subsequent process steps to create a much stronger base. This is the non-negotiable first step: start with the right foundation.

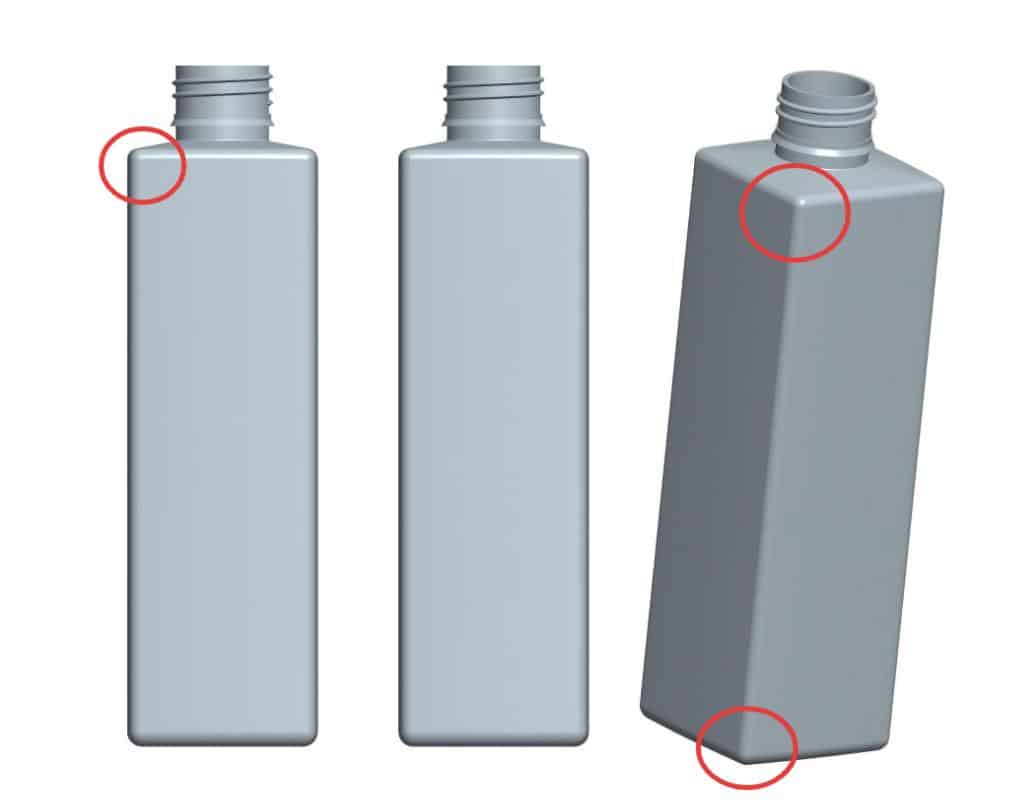

Tip 2: Redesign the Bottle Base and Corners for Impact Dispersion?

If your bottles are failing, the crime scene is almost always the base. This is where the majority of impacts occur, and where small design flaws have major consequences.

The most effective way to improve drop-test performance is to redesign the bottle's base and transition corners to be smooth and rounded. Sharp angles create stress concentration points, while a well-designed, curved base distributes impact forces across a wider area, preventing crack formation.

After we secured a better preform for my Bangladesh client, we turned our attention to the blow bottle mold itself. His bottle had a modern, minimalist look, but this aesthetic choice included a very sharp, almost 90-degree angle where the flat base met the vertical sidewall. On impact, this corner was acting like a glass cutter's score line, creating a perfect point for the bottle to fracture.

The Power of the Radius

The single most important design element for impact resistance is the radius of the corners. A larger, smoother radius allows the shockwave from an impact to flow continuously from the base up into the sidewall, dissipating its energy along the way. A sharp corner forces this energy to stop and concentrate, leading to failure.

We initiated a redesign focused on two areas:

- Base-to-Sidewall Transition: We replaced the sharp angle with a generous, continuous curve. This was our top priority.

- Base Design: The bottle had a relatively flat base. We introduced a more defined "petaloid" or "claw" base design. These contoured feet provide rigidity and create multiple initial points of contact, which helps to absorb and distribute the initial shock of an impact.

Comparing Base Designs for Strength

| Base Design Type | Description | Drop-Test Performance | Common Use |

|---|---|---|---|

| Flat Base | Simple, flat bottom. | Poor. Highly prone to stress concentration at the corners. | Non-pressurized products where drop performance is not critical (e.g., some household chemicals). |

| Star Base | A series of radial ribs forming a star pattern. | Good. The ribs add significant structural integrity. | Still water, juices, products that need a stable, non-rocking base. |

| Petaloid Base | Contoured feet, typically five, resembling flower petals. | Excellent. The rounded feet are designed to flex and absorb impact. This is the standard for durability. | Carbonated soft drinks (CSD), sparkling water, any product requiring high pressure and impact resistance. |

Making these design changes is often the most cost-effective solution. While it requires an upfront investment in modifying or creating a new mold, the change often adds little to no extra material weight to the bottle. In my client's case, we used a 3D printed sample of the new design to validate the concept before cutting steel. The new design, combined with the slightly heavier preform, immediately showed a dramatic improvement in our preliminary drop tests. This step is a perfect example of how smart engineering, guided by a comprehensive PET bottle mold design guide, can solve a problem that material alone cannot.

Tip 3: Master the Stretch Ratio for Optimal Molecular Strength?

You have a good preform and a strong design. Now, you need to execute the blow molding process correctly. The most crucial process parameter for strength is the stretch ratio.

A well-balanced stretch ratio—in both the axial (vertical) and hoop (horizontal) directions—is essential for creating the strong, interwoven molecular grid that gives PET its durability. An imbalance leaves under-stretched, weak areas in the bottle that are prone to failure.

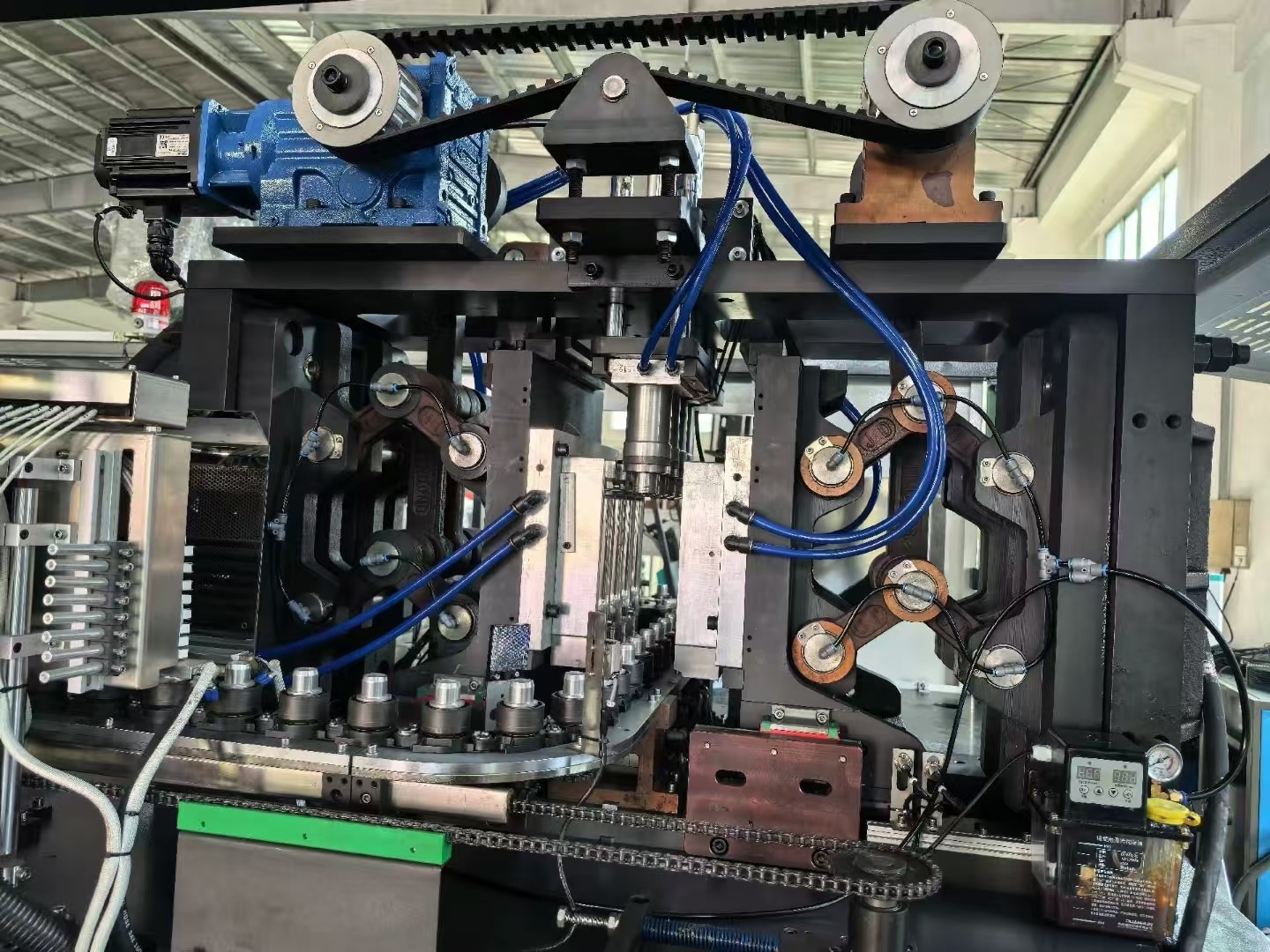

After addressing the foundational issues of preform and mold design with my client, we moved on to fine-tuning his blow molding machine's process parameters. The goal here is to ensure that we are taking full advantage of the PET material's potential through proper biaxial orientation.

Understanding the Two Ratios

- Axial Ratio (Vertical): This is the ratio of the final bottle's length to the preform's length (measured from below the neck support ring). It is primarily controlled by the stretch rod speed and profile.

- Hoop Ratio (Horizontal): This is the ratio of the final bottle's maximum diameter to the preform's diameter. It is primarily controlled by the blow pressure timing and level.

Think of it like weaving a fabric. If you pull hard on the vertical threads (axial stretch) but not the horizontal ones (hoop stretch), you get a weak fabric with lots of gaps. A strong fabric requires balanced tension in both directions. The same is true for a PET bottle. You need to stretch the material evenly in both directions to create a tightly interlocked molecular structure.

Finding the Right Balance

The ideal stretch ratios can vary depending on the bottle shape and size, but a general target is a total stretch ratio (Axial Ratio x Hoop Ratio) of around 10 to 12. More important than the total number, however, is the balance between the two.

For my client's 500ml bottle, we noticed the vertical stretch was too aggressive compared to the horizontal. This was causing the material to become too thin in the vertical direction before it had a chance to blow out properly to the sides. This created weak vertical bands in the bottle.

We made the following adjustments on his machine:

- Slowed the Stretch Rod: We slightly reduced the speed of the stretch rod. This gave the material more time to heat-soak and be ready for the horizontal stretch.

- Introduced Pre-Blow Air Sooner: We adjusted the timing to introduce a low-pressure "pre-blow" slightly earlier in the cycle. This helps to center the preform and initiate the hoop stretch before the main high-pressure blow, leading to more uniform material distribution.

Mastering the stretch ratio is a technical skill, but it is fundamental to performance. It's the step where you transform a simple plastic tube into a high-performance pressure vessel. Getting it right is critical for passing the drop test, and for addressing a wide range of other common PET blow molding defects.

Tip 4: Perfect the Heating Profile for Uniform Wall Thickness?

A chain is only as strong as its weakest link. In a PET bottle, a thin spot is the weakest link, and the primary cause of thin spots is uneven heating.

A perfect heating profile is essential for achieving uniform wall thickness. Uneven heating creates hot and cold spots on the preform, which stretch differently and result in thin, weak sections in the final bottle. Consistency in heating is the key to producing consistently strong bottles.

Even with the right preform, a great design, and a balanced stretch ratio, my client was still seeing some inconsistent failures. The bottles were much better, but some would still break occasionally. The final piece of the process puzzle was to scrutinize his preform heating process.

The Goal: A Perfectly Uniform Temperature

Before the preform enters the mold, it must be heated to the optimal temperature for stretching (typically around 100-110°C). More importantly, this temperature must be uniform all the way around and from top to bottom (excluding the neck finish, which stays cool). If one side of the preform is hotter than the other, the hotter side will stretch more easily and become thinner, creating a weak spot.

Most blow molding machine ovens are divided into multiple, independently controlled heating zones. This allows you to create a "heating profile" by adjusting the power of the lamps in each zone.

Tuning the Oven for Strength

When we analyzed my client's heating setup, we found two common problems:

- Overheating the Middle: The lamps in the middle of the oven were set too high. This caused the body of his preform to get too hot, stretching too quickly and stealing material that was needed for the base.

- Underheating the Base: The lamps aimed at the very bottom of the preform were not powerful enough. This resulted in a "cold," stiff base that resisted stretching, further contributing to a thin transition area.

We implemented a methodical approach to perfect his heating profile:

- Reduce Middle Zone Power: We lowered the power settings for the central heating zones. This prevented the body from becoming excessively soft.

- Increase Bottom Zone Power: We increased the power of the lamps focused on the bottom third of the preform. This delivered the extra heat needed to make the base material pliable and ready to stretch properly.

- Check Ventilation: We also ensured the oven's ventilation system was clean and working correctly. Proper airflow is crucial for removing excess surface heat and preventing the outside of the preform from crystallizing (turning white and hazy), which makes it brittle.

After these adjustments, we performed a wall thickness test on the bottles by cutting them into sections. The result was a much more uniform material distribution, especially in the critical base and corner areas. Perfecting the heating profile is a meticulous process, but it's absolutely essential for consistency. It ensures that every single bottle you produce has the same high level of strength and durability.

Tip 5: Don't Rush the Cooling Process?

In manufacturing, there's always a push for faster cycle times. But in blow molding, rushing the final step—cooling—can undo all the hard work you've put in.

Adequate cooling time inside the mold is critical for locking in the bottle's molecular orientation, strength, and dimensional stability. Ejecting a bottle while it's still too hot will result in a weaker, less stable container that is more prone to failure and deformation.

The final step in our troubleshooting journey with the client in Bangladesh was to review his cycle time. In an effort to maximize output, his operators had been gradually reducing the cycle time, primarily by shortening the cooling phase.

Why Cooling Matters

After the bottle has been blown, it needs to cool down inside the mold long enough to solidify and become stable. The PET needs to drop below its glass transition temperature (around 70-80°C) to lock the oriented molecules in place.

If you eject the bottle when the material is still soft and rubbery:

- The Molecular Structure Relaxes: The tightly woven molecular grid that you created during stretching can partially relax, reducing the bottle's inherent strength.

- Post-Molding Deformation Occurs: The residual pressure inside the bottle can cause it to warp or bulge as it cools outside the confines of the mold. This is especially true for the base, which can become convex ("rocker bottom"), making it unstable and more susceptible to impact failure.

Checking Your Cooling System

Rather than simply extending the cycle time, the better solution is to ensure your cooling is as efficient as possible. This is what we checked on my client's setup:

- Mold Cooling Channels: We verified that the cooling channels drilled into the blow bottle mold were not clogged with scale or debris. Clear channels are essential for good heat transfer.

- Chiller Performance: We checked the temperature and flow rate of the water coming from his industrial chiller. The water needs to be cold enough (typically 8-12°C) and flowing at a high enough rate to effectively remove heat from the mold. His chiller needed a simple maintenance service to restore its performance.

After servicing the chiller and confirming the mold channels were clear, we were able to achieve proper cooling without dramatically increasing the cycle time. We added just 0.2 seconds to the cooling phase to give the bottle that extra moment to stabilize. This final step ensured that the strength we had engineered into the bottle through the preform, design, and process was fully preserved in the final product. It's a reminder that in manufacturing, the finish is just as important as the start.

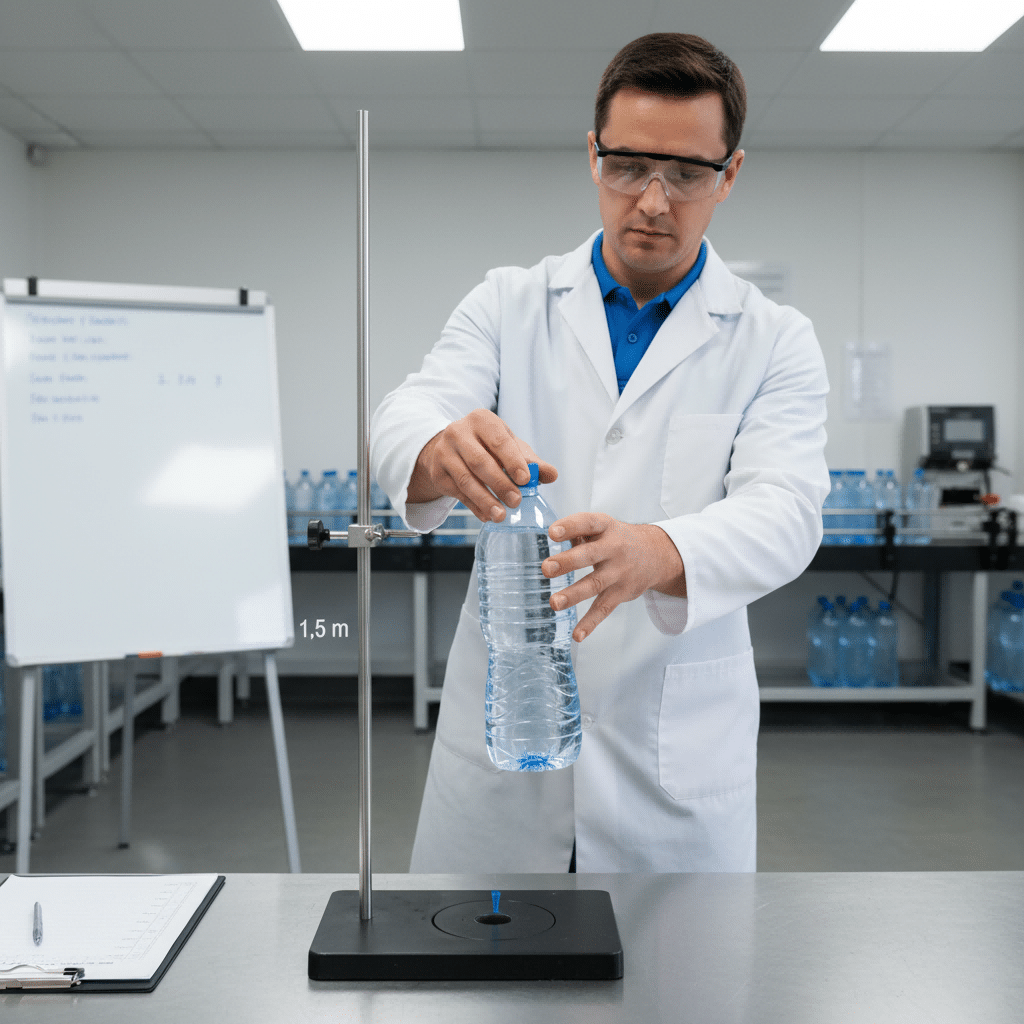

The Final Step Your Supplier Might Be Skipping: A Professional Drop-Test Protocol?

You’ve optimized the preform, redesigned the bottle, and perfected the process. How do you prove it worked? You must test the result in a reliable, repeatable way.

Don't just trust the design; you must verify the performance with a standardized drop-test protocol. A reliable supplier should not only help you engineer a strong bottle but should also be able to perform these tests to provide data and validate the final product as part of the acceptance criteria.

Throughout this entire process with my client, every change we made was followed by a round of testing. This is the crucial final step that closes the loop. It’s not enough to think you’ve fixed the problem; you have to prove it with data. While smaller companies may not be able to replicate a full-blown ASTM or ISTA lab test, they can and should implement a consistent internal protocol.

Elements of a Standard Drop Test

A good drop test is not just randomly throwing bottles on the floor. It needs to be controlled. Here are the key parameters we used to validate my client's new bottle:

| Parameter | Specification | Why It's Important |

|---|---|---|

| Bottle State | Filled with water to the nominal fill level and capped. | Tests the bottle's performance under real-world conditions, as the liquid's weight and hydraulic shock are part of the impact. |

| Drop Height | Standardized height (e.g., 1.5 meters / 5 feet). | Ensures every test is comparable. The height should reflect the likely worst-case scenario in your supply chain. |

| Drop Surface | A hard, flat surface like sealed concrete. | Provides a consistent and unforgiving impact surface. |

| Impact Orientation | A specific number of drops on different points (e.g., flat on base, on the base corner/chime, flat on the side). | Ensures the bottle is robust from all angles, not just its strongest point. |

| Sample Size | A statistically relevant number of bottles (e.g., 20 bottles). | A single successful drop is not proof. You need to test a sample set to ensure consistent performance. |

| Acceptance Criteria | A clear definition of success (e.g., "No more than 1 out of 20 bottles may leak or crack"). | Removes subjectivity and provides a clear pass/fail result. |

For my client in Bangladesh, we performed this test together. The first time we saw 20 of his newly designed bottles survive the test without a single failure, it was a huge moment. It was the definitive proof that our methodical, five-step approach had worked.

As a supplier of molds and machinery, I believe this verification step is part of our responsibility. A good partner doesn't just sell you equipment; they work with you to produce a successful final product. Providing drop-test data and performance guarantees should be a standard part of the commissioning process for any project where durability is a key concern. It's the ultimate confirmation that the job is done right.

Conclusion

A bottle that survives a fall is no accident. It is the result of a deliberate process of optimizing the preform, the design, the machine parameters, and the cooling process.

By systematically addressing these five key areas, you can transform a fragile container into a robust product that protects your beverage and your brand's reputation. This methodical approach empowers any company, large or small, to achieve the durability their customers expect and their business deserves.

Frequently Asked Questions (FAQ)

1. To improve drop strength, is it more effective to add more weight to the preform or to optimize the bottle's design?

Optimizing the bottle's design is almost always more effective and cost-efficient. While adding weight can provide a brute-force solution, it's often a bandage for a poor design. A well-designed bottle with smooth, rounded corners and a strong base can outperform a heavier bottle with sharp angles that create stress concentration points. The best approach is a combination: start with a preform that has sufficient weight, and then focus on a design that uses that material intelligently to disperse impact forces.

2. Do design changes that improve drop performance, like a thicker base, have a negative impact on production cycle time or bottle clarity?

Not necessarily. A thicker base, achieved through better preform design and heating control, can actually improve stability. The biggest impact on cycle time comes from the cooling phase. As long as your mold's cooling channels are efficient and your chiller is performing well, the slightly thicker sections can be cooled effectively without a significant increase in cycle time. Bottle clarity is primarily affected by material quality and processing temperature, not thickness, so these changes should not negatively impact clarity.

3. Is there an industry standard (like an ISO or ASTM standard) for PET bottle drop testing that I can require my supplier to meet?

Yes, several standards exist that can be adapted for this purpose. ASTM D5276 - Standard Test Method for Drop Test of Loaded Containers by Free Fall is a widely recognized standard. For shipping simulations that include drop tests as part of a sequence, the ISTA (International Safe Transit Association) 3A procedure is very common. You can specify in your purchasing agreement that the bottles produced from a new mold must be able to pass a specific test (e.g., a 1.5-meter drop per ASTM D5276) as part of the acceptance criteria.

4. How do the drop-test requirements for carbonated soft drink (CSD) bottles differ from those for still water bottles?

CSD bottles have much more demanding requirements. The internal pressure from carbonation (which can increase significantly at higher temperatures) adds constant stress to the bottle walls. An impact on a pressurized CSD bottle is far more likely to cause catastrophic failure. This is why CSD bottles must have a petaloid base to handle the pressure and are generally designed to be much more robust. Still water bottles can often use simpler and lighter base designs (like a star base) because they only need to withstand the hydraulic shock of the water upon impact, not constant internal pressure.

5. What should I do if my supplier insists their mold is fine, but the bottles produced are consistently failing our drop tests?

This is a common issue that requires a systematic approach. First, you must rule out other variables. Use a high-quality "control" preform to confirm the issue isn't your raw material. Second, meticulously document your process parameters (heating, pressures, timing) to prove the machine is set up correctly. Third, perform and record a standardized drop test to provide clear data on the failure rate. If the problem persists with good preforms and a correct process, the issue is almost certainly in the mold design. At this point, you should present your data to the supplier and request a design review, focusing specifically on stress concentration points like sharp radii. A reputable supplier should be willing to work with you to solve the problem.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr