Table of Contents

Welcome to the official blog of Zhongshan Jindong Machinery Co., Ltd. I am Vivian, the second generation successor of this 20-year-old PET bottle blowing machine manufacturing company. In this industry, choosing the right bottle blowing machine is crucial to ensuring production efficiency and quality. Today, I want to share about common mistakes when choosing a PET bottle blowing machine and how to avoid them. At the same time, I will also introduce our company’s products and services to help you make a more informed choice.

Before discussing the specific details, let us first understand the basic situation of PET bottle blowing machines. PET bottle blowing machine is an important equipment for producing plastic bottles and is widely used in beverage, pharmaceutical, daily chemical and other industries. A high-quality bottle blowing machine can not only improve production efficiency, but also ensure product quality and reduce the scrap rate. However, there are many types of bottle blowing machines on the market with different functions and performances, which poses a selection problem for buyers.

To help you make the right decision, I will discuss in depth the following aspects:

01

Basic understanding of PET bottle blowing machine: including its working principle, application scope and common types on the market.

02

Common mistakes when choosing a bottle blowing machine: including ignoring the performance of the machine and only using price as the basis for decision-making.

03

Introduction to Zhongshan Jindong Machinery’s products and services: including our technical advantages, customer cases and after-sales services.

At the end of the article, I will also provide answers to some frequently asked questions to help you understand the PET bottle blowing machine more comprehensively. At the same time, I will also leave a link to our company’s website so that you can learn more about our products and services.

- Basic understanding of PET bottle blowing machine

What is a PET bottle blowing machine?

PET bottle blowing machine is equipment used to produce PET plastic bottles. Plastic bottles are manufactured by heating and blowing preform bottles in a mold. This kind of machine is usually divided into two types: semi-automatic bottle blowing machine and fully automatic bottle blowing machine. Semi-automatic blow molding machines require manual placement of pre-shaped bottles and removal of finished bottles, while fully automatic blow molding machines can complete the entire process automatically.

Application scope of bottle blowing machine

PET bottle blowing machines are widely used in many industries, such as beverages, medicine, cosmetics and daily necessities. It can produce plastic bottles of various shapes and sizes to meet the packaging needs of different products. For example, it can be used to produce mineral water bottles, beverage bottles, pharmaceutical bottles, cosmetic bottles, etc.

Common types of bottle blowing machines on the market

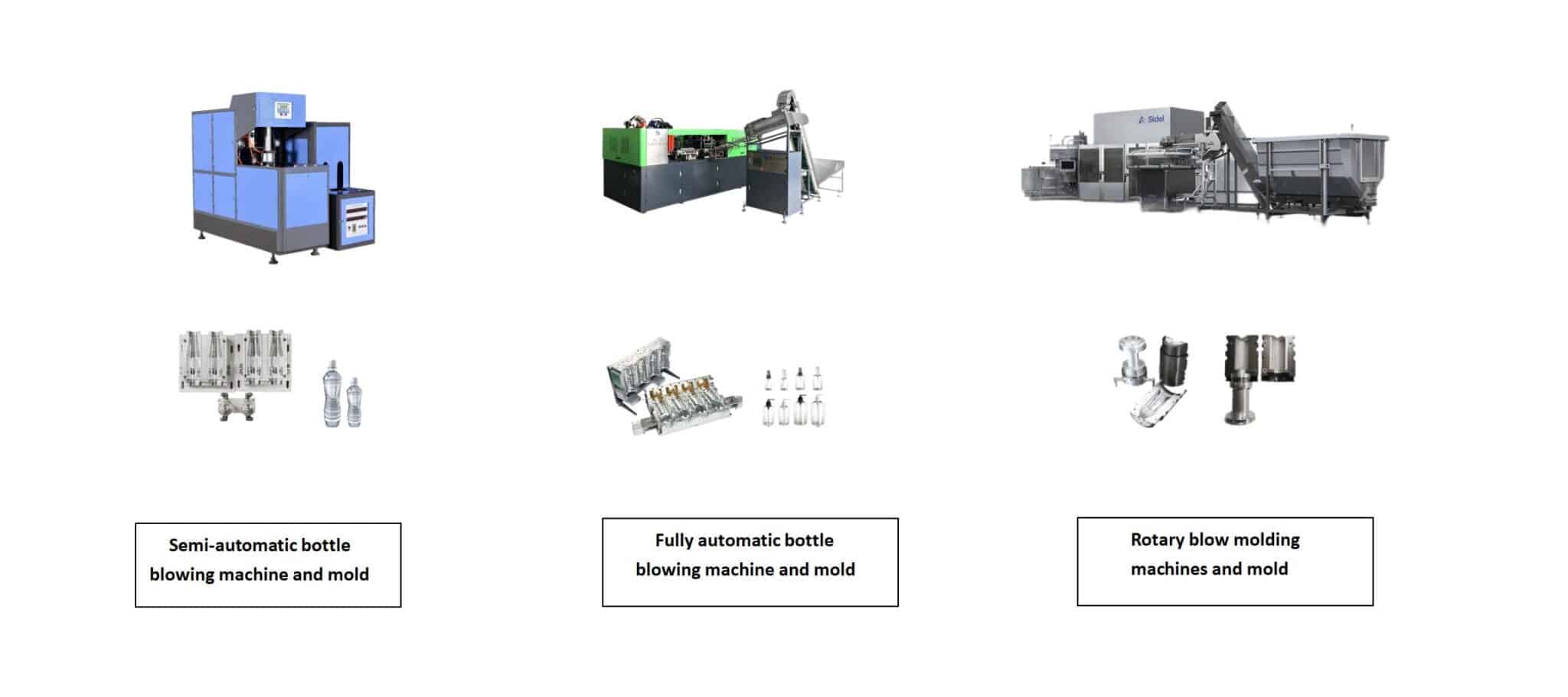

There are many types of bottle blowing machines on the market, and different models are suitable for different production needs. Here are some common blowjobs

Bottle machine type:

| Type | Features | Scope of application |

|---|---|---|

| Semi-automatic bottle blowing machine | Manual operation, lower cost | Small-scale production |

| Linear fully automatic bottle blowing machine | High degree of automation and higher efficiency | Mass production |

| Rotary fully automatic bottle blowing machine | High-speed production, suitable for large-volume orders | Large-scale production, fast delivery requirements |

Choosing the right type of blow molding machine is crucial to improving production efficiency and reducing costs. Understanding the characteristics and application range of various types can help you make a more appropriate choice.

- Common mistakes when choosing a bottle blowing machine

When choosing a PET bottle blowing machine, many buyers may make some common mistakes, which may affect production efficiency and product quality, or even lead to higher long-term costs. Here are some common mistakes to avoid:

1. Ignoring the matching of machine performance and production capacity: Choosing a blow molding machine that does not match production needs leads to low efficiency and waste of resources. First, determine what kind of plastic bottle you produce, whether it is a water bottle, a cosmetic bottle, or a wide-mouth bottle. What is the capacity of the plastic bottle? Furthermore, are you sure what your production requirements are? These are crucial.

For example, choosing a high-capacity blow molding machine for small-scale production will result in a large investment that cannot be recovered in the short term. If you produce cosmetic bottles, but purchase a bottle blowing machine for producing water bottles, the product scrap rate may be high. So first determine your product, and then choose a blow molding machine with corresponding performance.

2. Make your decision based on price alone: While budget is an important consideration, the performance, quality and long-term operating costs of the blow molding machine should also be considered. A low-priced bottle blowing machine may require a low initial investment, but may not be cost-effective in the long run due to higher maintenance and operating costs. Just like some of my customers, because they had no experience, they chose some low-priced bottle blowing machines with poor performance. As a result, the later maintenance costs were very high, so low price is not the deciding factor in choosing a bottle blowing machine.

3. Ignoring after-sales service and technical support: High-quality after-sales service and technical support are crucial to ensuring long-term and stable operation of the bottle blowing machine. Choosing a supplier without good after-sales service may leave you with no one to solve the problem when there is a problem with the machine. For example, one of my customers in the Middle East chose a Chinese middleman to purchase three bottle blowing machines. The middleman purchased these bottle blowing machines from three factories respectively, resulting in three bottle blowing machines and three operating systems. The customer The operator has a headache and no one follows up on the after-sales service, so be sure to choose a real manufacturing factory with after-sales and technical service support.

4. Not considering machine upgrades and scalability: As your business develops, you may need to upgrade or expand your production equipment. Choosing a blow molding machine with good upgradeability and scalability can help you respond to market changes more flexibly in the future. For example

At that time, the bottle blowing machine was purchased to produce only one bottle, but in the future you will add three bottles to the production, which will involve some scalability of the bottle blowing machine. A good factory can quickly solve these problems in a short time, but a factory without technology It will only make the buyer buy a new bottle blowing machine, so be sure to choose a factory with independent programming capabilities and manufacturing capabilities.

5. Ignoring energy efficiency and environmental protection factors: Highly energy-efficient blow molding machines can not only reduce operating costs, but also reduce the impact on the environment. Environmental protection and energy efficiency become important considerations when you choose equipment.

To help you avoid these mistakes and choose the right blow molding machine, next I will introduce our company’s products and services and how we help customers overcome these challenges.

- Product and service introduction of Zhongshan Jindong Machinery

Factory overview

As a PET bottle blowing machine manufacturer with a history of 20 years, Zhongshan Jindong Machinery Co., Ltd. knows the importance of choosing a suitable bottle blowing machine for the company. Our products and services have the following characteristics:

1. Rich industry experience: Our team has many years of industry experience and is able to provide customers with professional consultation and advice to ensure that they choose the bottle blowing machine that best suits their needs. There are many types of bottle blowing machines with a wide range of applications, but choosing a bottle blowing machine suitable for your own production is what buyers really need.

2. Professional processing equipment: Our advanced production equipment can ensure high quality and high efficiency of products. Our bottle blowing machines adopt the latest technology to ensure that each piece of equipment can meet the high standard requirements of customers. We have our own R&D team and can write the system ourselves. When there is a problem with the bottle blowing machine, we have corresponding engineers who can solve and deal with the problem. .

3. Pay attention to product details: We strictly inspect and control every detail of the product to ensure that each bottle blowing machine shipped from the factory can achieve optimal performance.

4. Comprehensive after-sales service: We provide comprehensive after-sales service, including installation, commissioning, training and maintenance, etc., to ensure that customers can use our equipment smoothly and get quick and effective solutions when they encounter problems.

5. Customized solutions: We understand that different customers may have different needs, so we provide customized solutions, from preform injection molding, blowing, filling, packaging, etc., we can provide design and customization services.

to meet the requirements of various buyers.

Through these services and product features, we help our customers avoid common mistakes when choosing a blow molding machine and ensure that they get the best blow molding machine for their products.

FAQs

Why choose Zhongshan Jindong Machinery ?

When choosing a bottle blowing machine, you may consider multiple factors, such as technical parameters, price, service, etc. As the person in charge of Zhongshan Jindong Machinery Co., Ltd., I would like to emphasize why our products and services can be your best choice.

What are the main applications of PET bottle blowing machines?

PET bottle blowing machines are mainly used to produce PET plastic bottles, which are widely used in beverage, pharmaceutical, cosmetics and other industries.

How to judge the quality of a bottle blowing machine?

It can be evaluated from aspects such as machine stability, production efficiency, and energy consumption.

What technical parameters should you pay attention to when purchasing a bottle blowing machine?

Attention should be paid to the machine’s production capacity, energy efficiency ratio, ease of operation, etc.

What after-sales services does Zhongshan Jindong Machinery provide?

We provide a full range of services including equipment installation, operation training, regular maintenance and technical consultation.

What is the process of customizing a bottle blowing machine?

After customers put forward their needs, we will design, produce and provide installation and debugging services according to the needs.

To learn more, please log in now:(http://www.ibottler.com)