- More than 2000+ customers' choice

- 20 years of factory experience

- One-stop solution

- After-sales guarantee

Popular product series

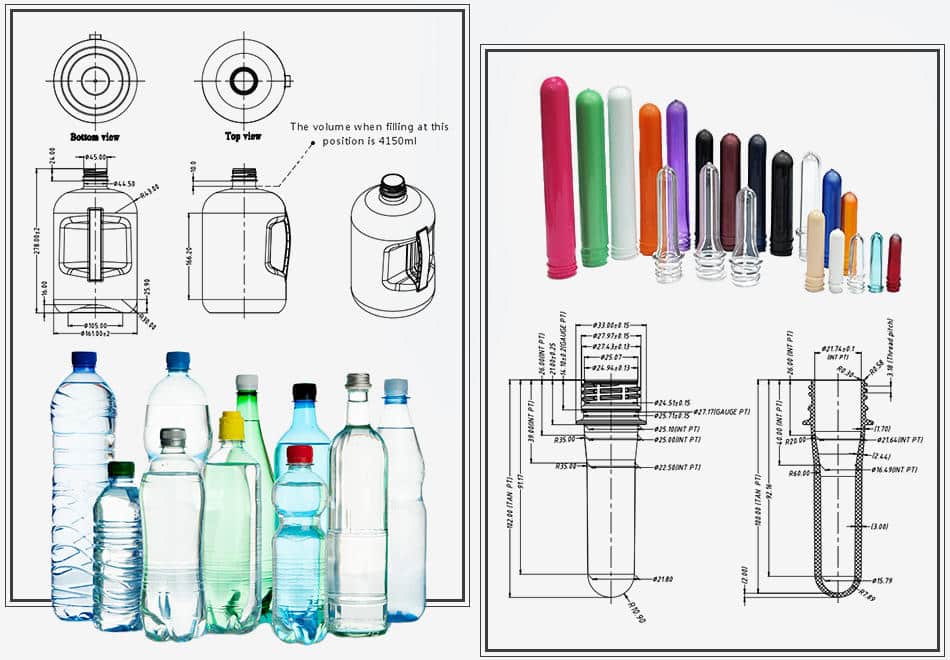

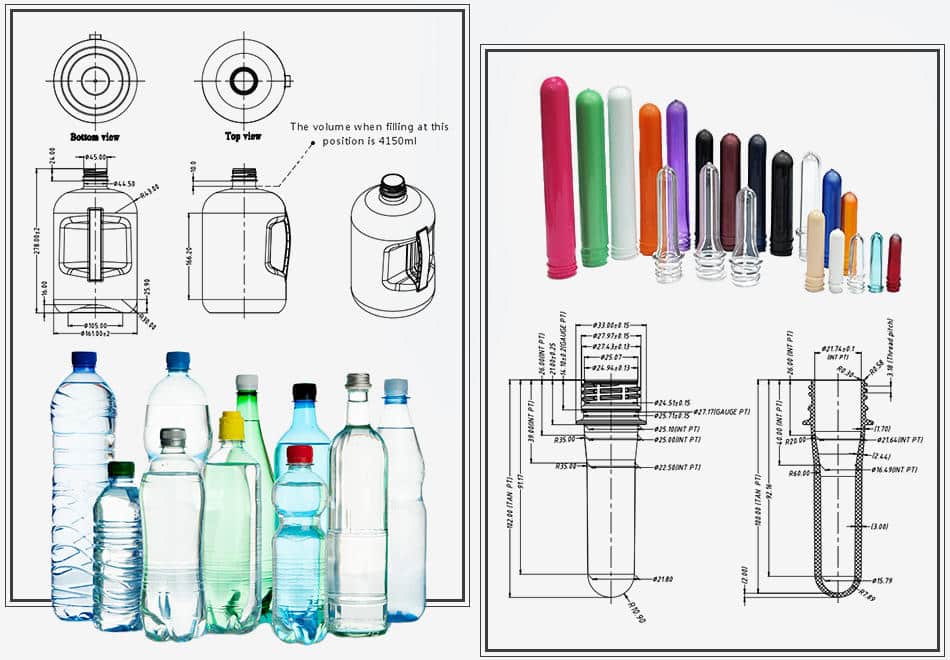

Free bottle design

Free proofing

Our Solutions

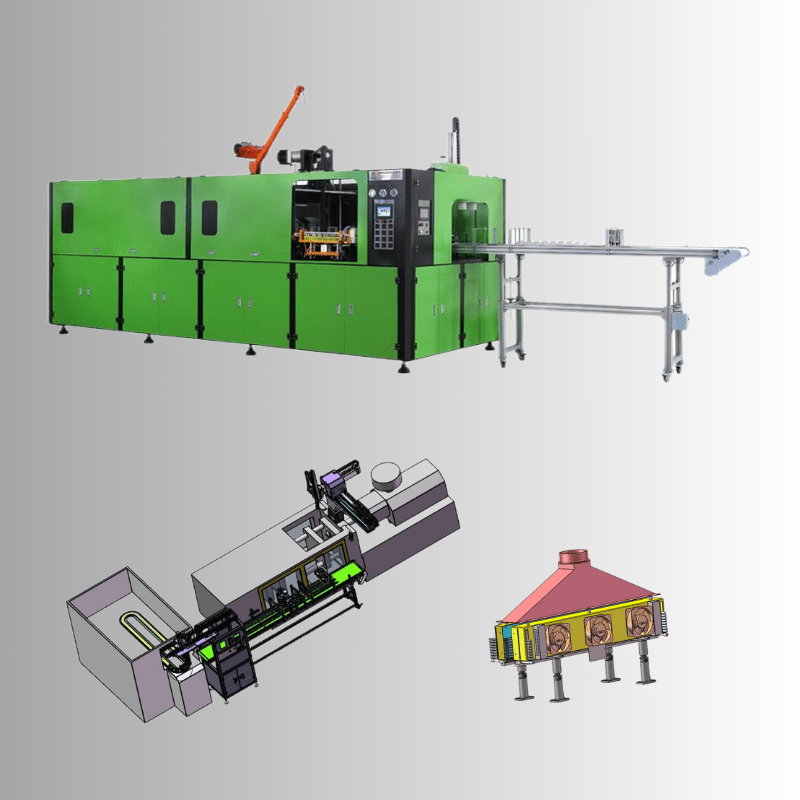

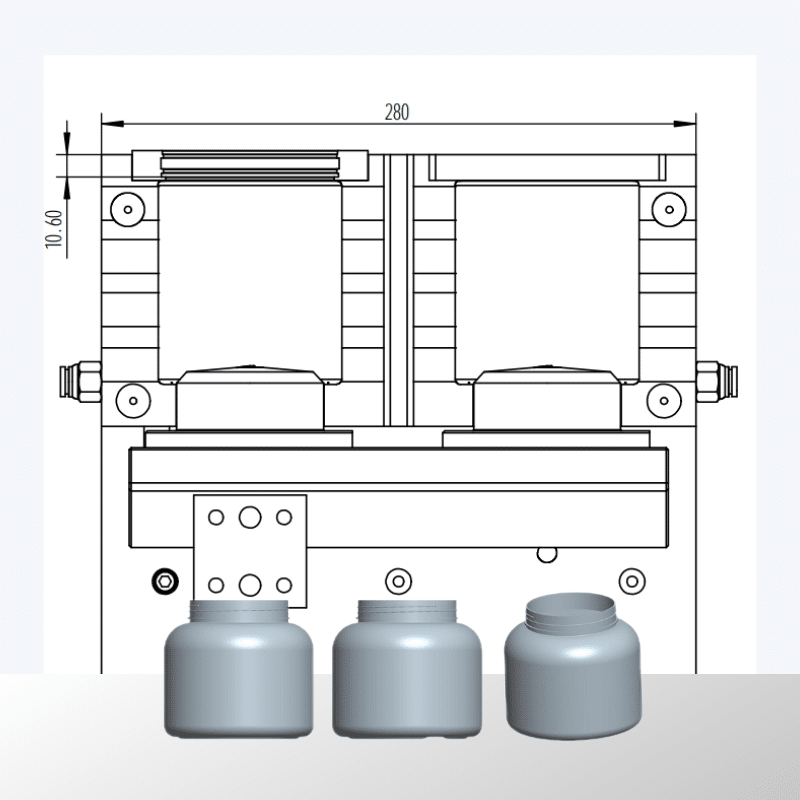

- Wide Mouth Jar Blowing Machine

- Maximum diameter: 120mm

- Output: 1500pcs/h

- Maximum capacity: 2L

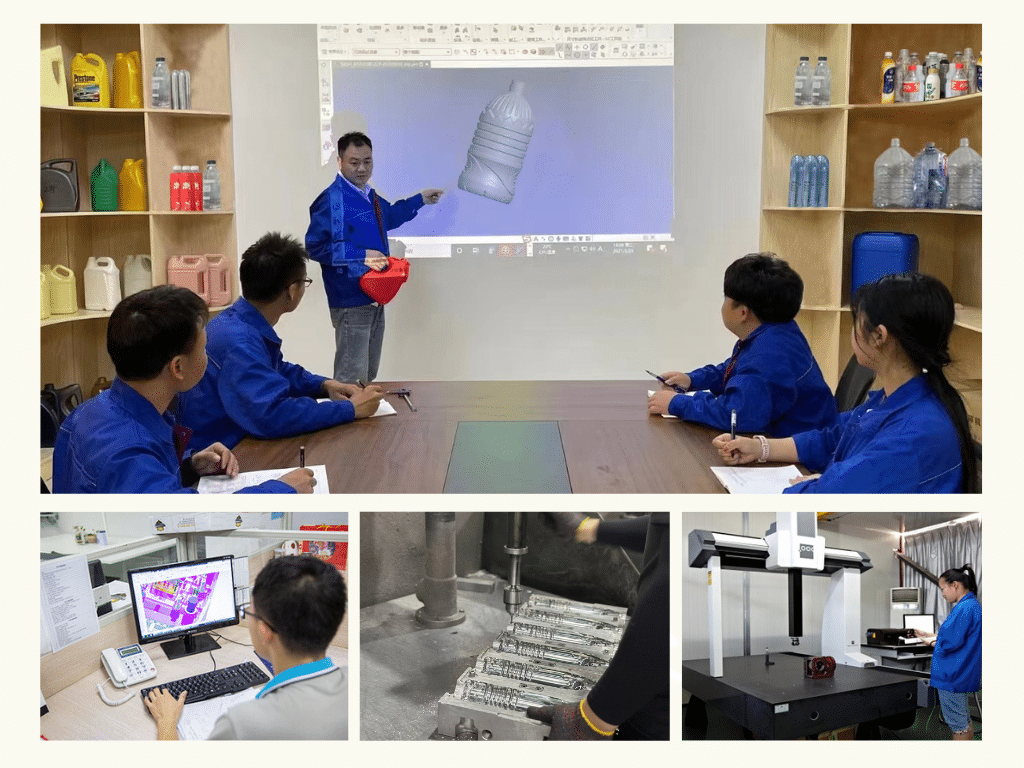

STEP.1

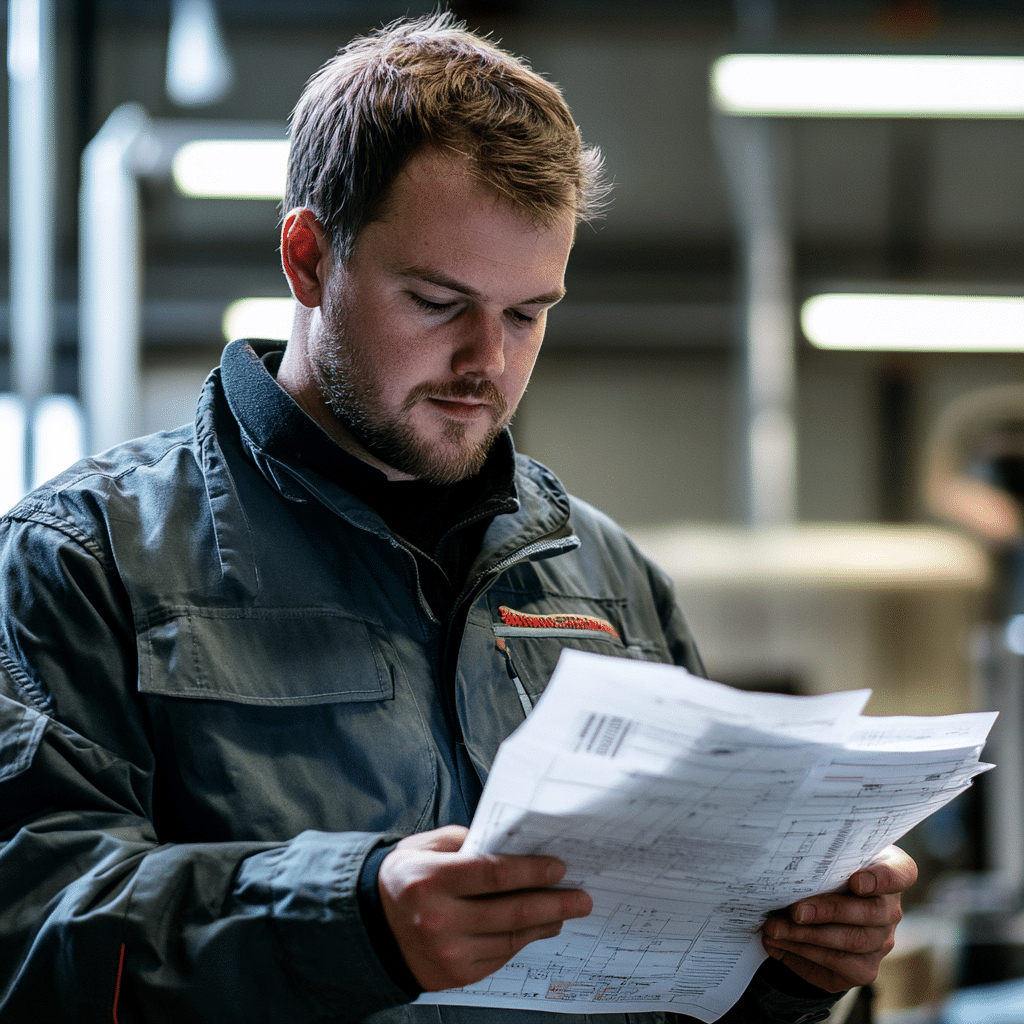

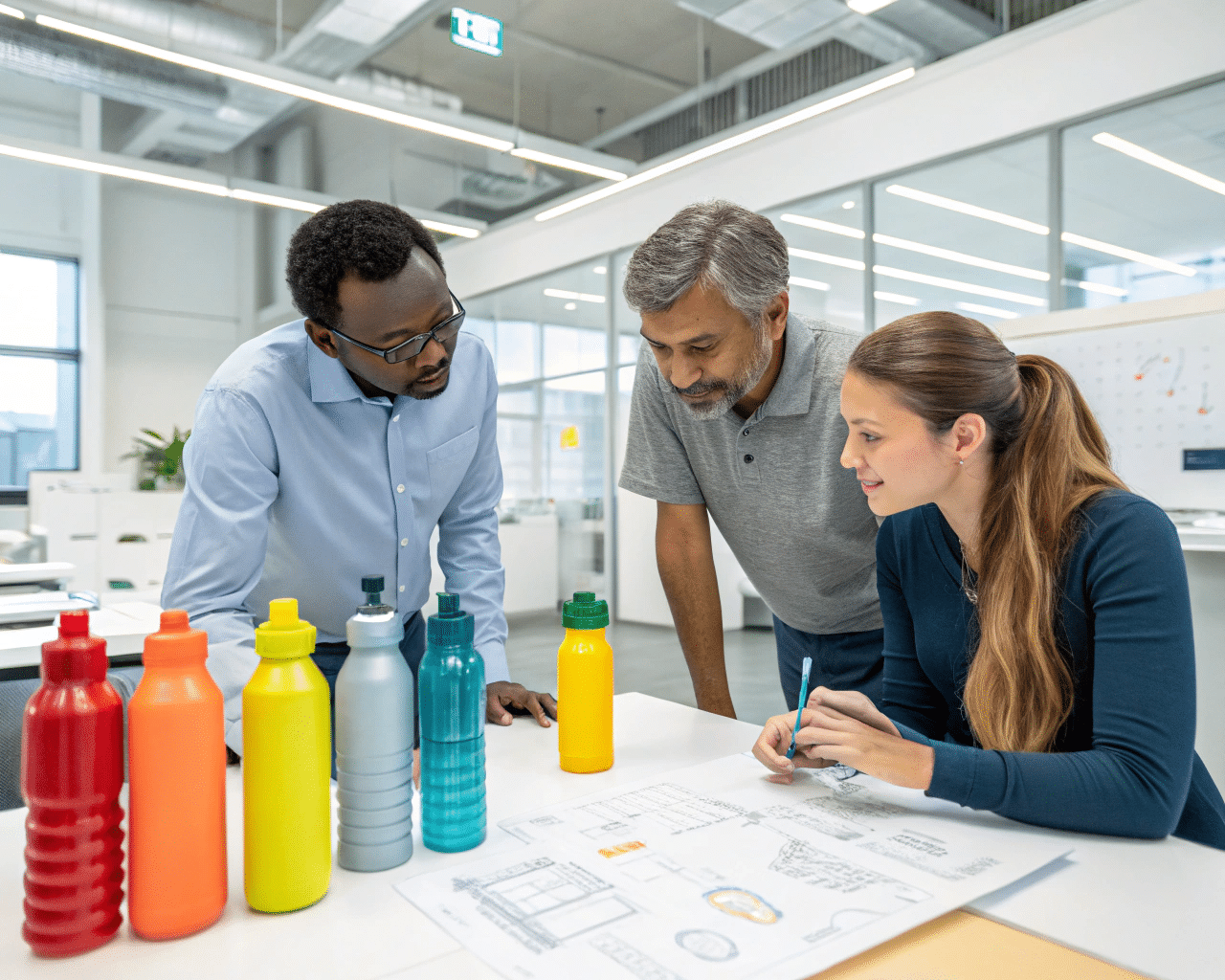

Define the Plan

STEP.2

Bottle Design

STEP.3

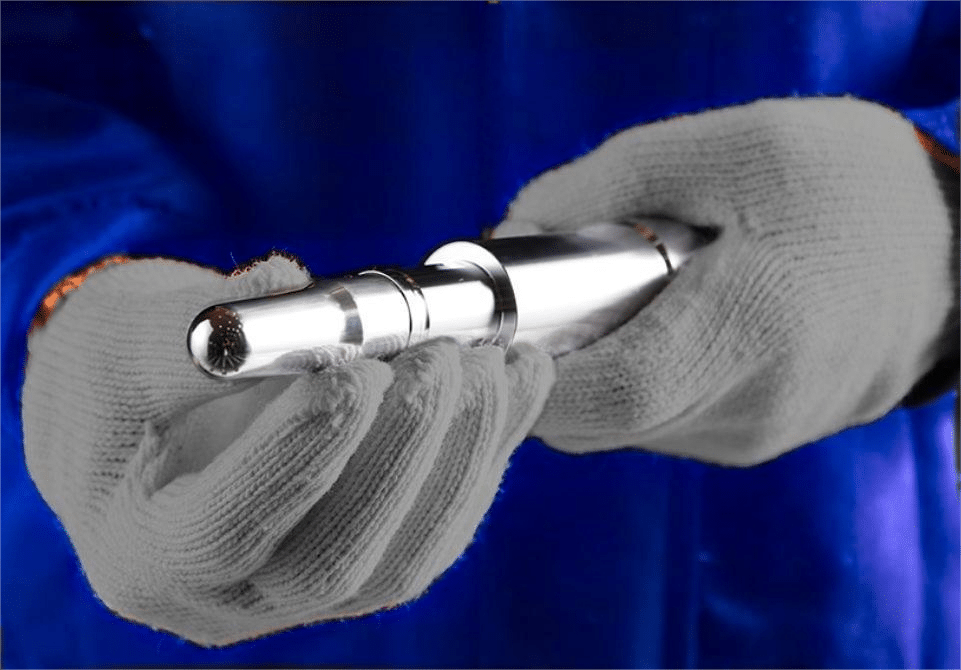

Precision Manufacturing

STEP.4

Installation & Delivery

Injection, Blowing & Filling

- Injection Molding

- Injection Molding

- Injection Molding

Our Solutions

1.jpg)

Our Solutions

Injection, Blowing & Filling

Injection Molding

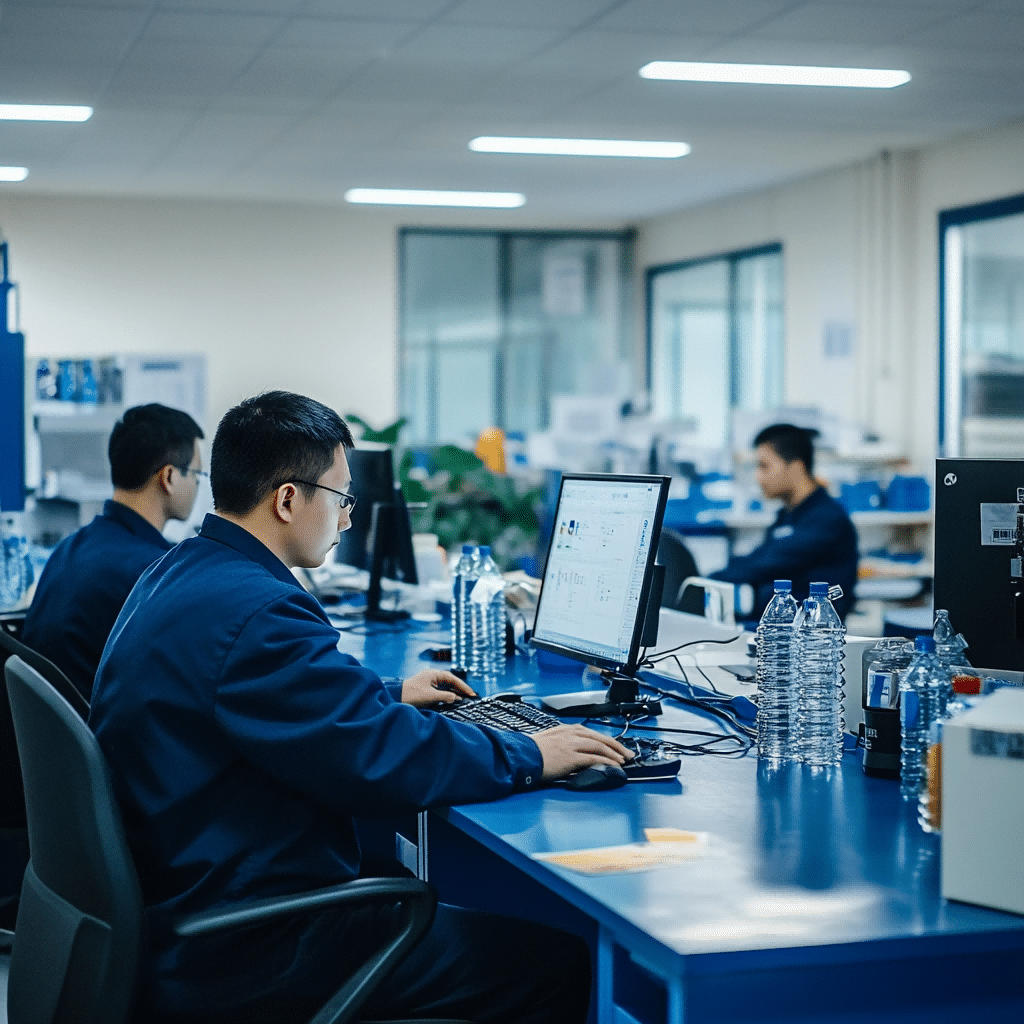

The complete injection molding production line has advanced precision processing equipment to achieve full process quality control from mold manufacturing to finished product output.

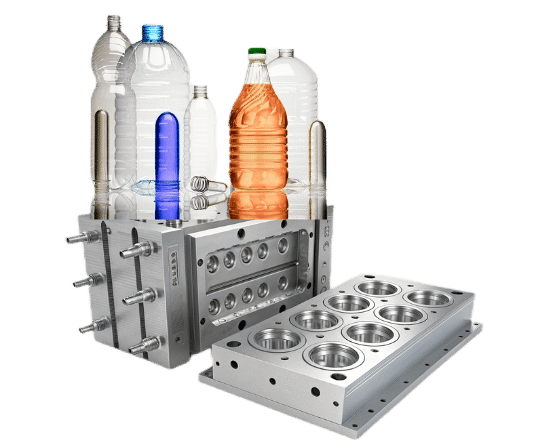

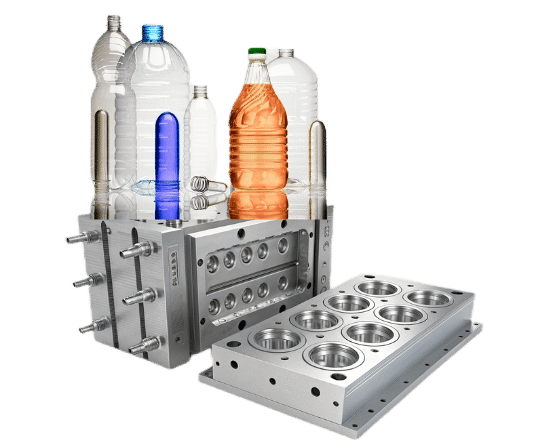

Blow Molding

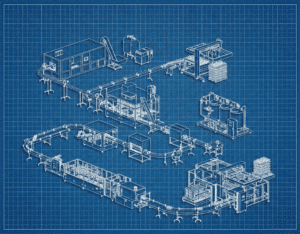

We provide a full range of solutions for 0-50L PET plastic bottle production lines, including bottle design, plant planning, and follow up on the project progress to ensure a smooth start of production.

Bottle Filling

We provide filling production lines within 3600pcs/h, which are applied to mineral water, juice, carbonated beverages, etc., and provide comprehensive installation and commissioning services

One-Stop Bottle Packaging

Injection, Blowing & Filling

Injection Molding

The complete injection molding production line has advanced precision processing equipment to achieve full process quality control from mold manufacturing to finished product output.

Blow Molding

We provide a full range of solutions for 0-50L PET plastic bottle production lines, including bottle design, plant planning, and follow up on the project progress to ensure a smooth start of production.

Bottle Filling

We provide filling production lines within 3600pcs/h, which are applied to mineral water, juice, carbonated beverages, etc., and provide comprehensive installation and commissioning services

Injection Molding

The complete injection molding production line has advanced precision processing equipment to achieve full process quality control from mold manufacturing to finished product output.

Blow Molding

We provide a full range of solutions for 0-50L PET plastic bottle production lines, including bottle design, plant planning, and follow up on the project progress to ensure a smooth start of production.

Bottle Filling

We provide filling production lines within 3600pcs/h, which are applied to mineral water, juice, carbonated beverages, etc., and provide comprehensive installation and commissioning services.

Our Solutions

STEP.1

Define the Plan

STEP.2

Bottle Design

STEP.3

Precision Manufacturing

STEP.4

Installation & Delivery

| NO. | Name | Parameters | Name | Parameters |

|---|---|---|---|---|

| 1 | Number of cavities | 2 cavities | Maximum capacity | 2L |

| 2 | Output | 1500PCS/H | Maximum bottle mouth diameter | 120MM |

| 3 | Power | 42kw | Total machine weight | 3.5T |

15%

Improve efficiency

10%

Cost reduction

Comprehensive problem solving

What can we solve?

Enhance Production Stability

Reduce Production Costs

Shorten Delivery Time

Smart production

Reduce Operational Costs

Optimize Material Usage

Strength factory-Jindong

Helping businesses reach their goals

Never fail, learn from the experts

Friendly and efficient business coaches

Why Choose us?

Helping businesses reach their goals

Never fail, learn from the experts

Friendly and efficient business coaches

- Some partners

15%

Improve efficiency

10%

Cost reduction

Comprehensive problem solving

What can we solve?

Reduce Production Costs

Enhance Production Stability

Shorten Delivery Time

Leading Technology, Trusted Quality

Strength Testimony

Our Values

01

Free Design

Free bottle design service to meet personalized needs and optimize packaging.

02

Tailored Plans

Tailored production plans to ensure maximum production efficiency.

03

Fast Sampling

Fast sampling service to shorten development cycle and speed up market launch.

04

Expert Setup

Professional installation and commissioning services to ensure stable equipment operation.

05

24/7 Support

24/7 tech support for quick response and issue resolution.

06

Global After-Sales

Global after-sales network for long-term maintenance and tech support, ensuring continuous operation.

Their real feedback

Words From Clients

Why we choose Jindong Machinery?

As a long-term customer of this factory, I am deeply satisfied with their credit and service. They consistently provide high-quality PET blow molding machines and molds with excellent product quality, which gives me an advantage in the market competition. Every time we have a problem, their after-sales service responds quickly and always provides professional technical support at the first time to ensure the smooth operation of the production line. What I appreciate more is that they pay great attention to communication with customers and are willing to listen to our needs and feedback.

"Professional Team"

"Good after-sales service"

"High quality"

Know more Contact us now

FAQ

A: Yes, we have a professional installation team with rich installation experience and can provide on-site installation service to ensure that your equipment is put into production quickly. Our engineers will provide you with detailed operation training during the installation process to help your team get started as soon as possible.

A: We value after-sales service and have a professional team on standby to provide timely remote technical support and maintenance services. In addition, we provide spare parts services to ensure the normal operation of the equipment, minimize downtime, and protect your production.

A: Of course, we have a database of more than 80% brands of blow molding machine molds, which can be well matched with your blow molding machine. Of course, we will also assist you in measuring the installation data of the mold to ensure that the installation size is correct and can be 100% produced.

A: Our blow molding machines are made with high-precision processing equipment after 20 years of factory experience. The core parts of the machine are made of high-quality materials to ensure stability and durability even under long-term production. We also provide long-term after-sales support so that you don’t have to worry about it. docking, according to your factory to provide the whole line design and planning, to product customization, installation and commissioning to produce bottled mineral water.

Vivian-Overseas Manager

+8613106288777

- Professional, Precise & Efficient

- Trustworthy & Experienced

- Smooth Communication, Fast Response

Highly-viewed articles

More example solutions

Knowledge

How to Plan Your PET Blowing Factory Layout? (Space, Power & Utilities)

Factory planning goes beyond simple floor dimensions. You must account for material flow, vertical clearance for automatic loaders, power stability, and utility piping. A correct layout optimizes efficiency and ensures your bottle blowing machine operates at peak performance without maintenance struggles.

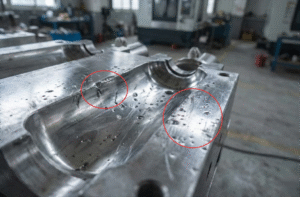

5 Signs Your PET Blow Mold Needs Maintenance (Before It Breaks)

A PET blow mold is a precision instrument, not just a block of steel. Signs like air leakage at the neck, reduced cooling efficiency, or visible burn marks are early warnings. Identifying these symptoms early allows for preventive maintenance, saving you from expensive repairs and ensuring your production line runs at peak efficiency.

Why Do You Need a Bottom Orientation Notch for Bottle Labeling?

A bottom orientation notch acts as a mechanical anchor, locking your bottle into a fixed position on the conveyor. This forces the bottle to face the labeling machine correctly every time, ensuring labels apply perfectly to flat surfaces or specific areas, preventing defects on high-speed lines.

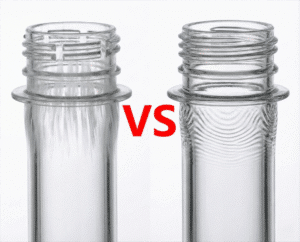

Causes and Solutions for Flow Marks on PET Preform Threads

Flow marks (ripples) on PET preform threads are usually caused by the “hesitation effect,” where the melt cools too quickly against the mold surface, or the injection speed is insufficient to maintain the heat of the flow front. Unlike silver streaks caused by moisture, flow marks are solid, concentric ridges. You can solve this by optimizing profiled injection speeds, increasing nozzle temperature, or improving mold venting.

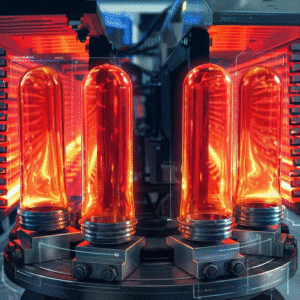

How to Optimize PET Blowing Machine Temperature Settings: A Guide to the Perfect “Heating Profile”?

Optimizing the temperature settings of a PET blowing machine requires a mastery of thermodynamics, balancing the “Glass Transition” state of the material against its crystallization limit. By establishing a strategic heating profile—low energy at the neck, stabilized heat soak in the body, and high-intensity penetration at the base—you can eliminate stress whitening, ensure uniform material distribution, and achieve cycle times under 2 seconds per cavity.

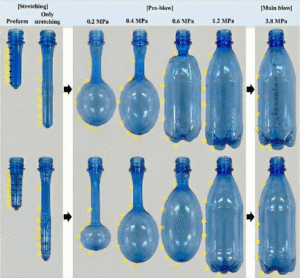

Why Is Your PET Bottle Not Fully Formed? The Critical Role of Pre-Blow vs. Main Blow Pressure?

Incomplete bottle forming, often called a “short shot,” is rarely just a heating issue. It is a failure of synchronization between the pre-blow pressure, which distributes the material, and the main blow pressure, which locks the shape into the mold. Without this balance, no amount of heat will save your production.

Professional Customized solutions

After mold making free sample

- Optimize bottle design to reduce costs

- Designer docking improves efficiency

- Contact specialists are online at any time

Professional preform design

After mold making free sample

- Optimize preform design to reduce costs

- Designer docking improves efficiency

- Contact specialists are online at any time

- Zhongshan Jindong Machinery Co., Ltd.

- Futian 5th Road, Shite Industrial Zone, Gangkou Town, Zhongshan City, Guangdong Province, China

Stay updated on the latest PET packaging trends and technologies, avoid production pitfalls, and optimize your processes!

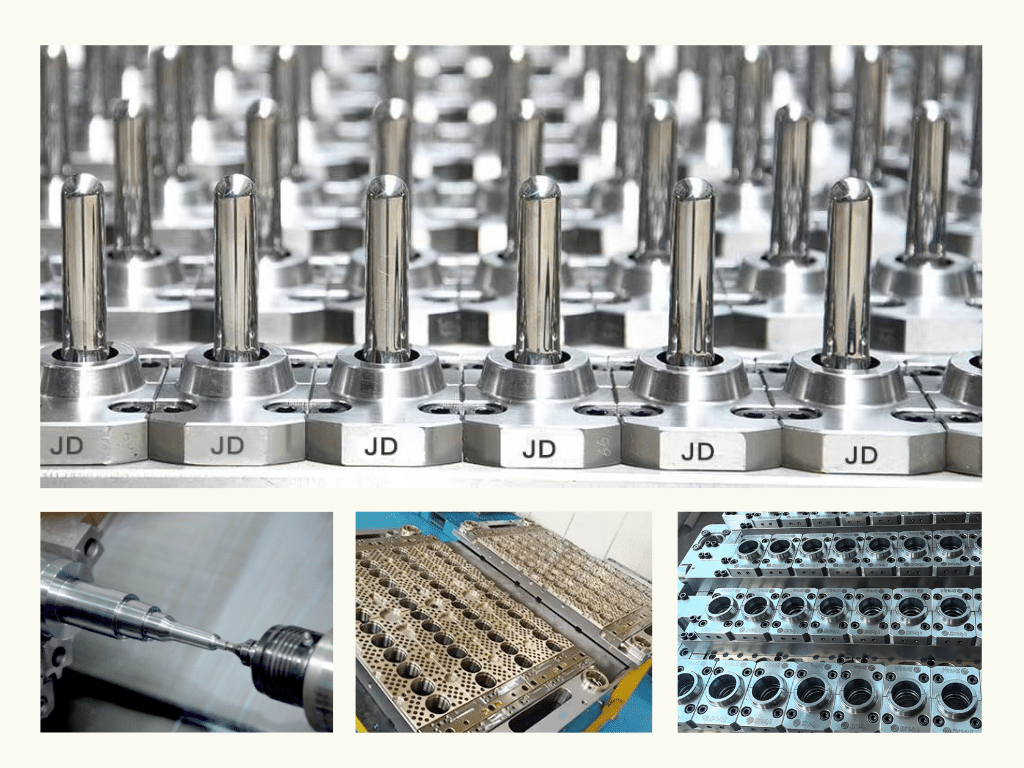

Advanced processing equipment

Our mold workshop covers an area of 4,000 square meters, with 5 Hardinge lathes, 10 CNC machines and a 500 square meter testing room.

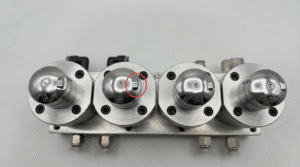

High precision matching

Advanced processing technology ensures high-precision matching and interchangeability between mold components.

Free preform design

Our designers have more than 10 years of experience in preform injection molding industry to provide you with free design services

Free proofing

After the preform mold is completed, we will provide 500-1500 preform samples according to your needs.

Strict quality inspection

Stay updated on the latest PET packaging trends and technologies, avoid production pitfalls, and optimize your processes!

Stay updated on the latest PET packaging trends and technologies, avoid production pitfalls, and optimize your processes!

Industry Insights & Practical Tips

Stay updated on the latest PET packaging trends and technologies, avoid production pitfalls, and optimize your processes!

.png)

-1024x819.png)