Struggling to choose a PET preform? You worry that the wrong choice will lead to production delays, budget overruns, and a product that just doesn't work.

The neck finish is the most critical interface of your bottle. It dictates the cap you can use, the performance of your product on the filling line, and your final cost. Choosing the right standard from the start is the key to a successful launch.

The world of PET preforms can seem complex. With dozens of standards, it's easy to get lost. But this decision is more than just a technical detail; it's a strategic choice that impacts your entire business. It affects your supply chain, your production efficiency, and even how your customer perceives your brand. I want to help you navigate this landscape. In my 16 years in the PET packaging industry, I've seen how the right neck finish can make a project soar, and how the wrong one can cause significant headaches. This guide will be your map, helping you select the perfect neck finish based on your specific application.

Why is the neck finish your bottle's most important feature for market fit?

Feeling overwhelmed by preform choices? You know the neck finish matters, but you're not sure how it connects to your business goals. This uncertainty can be paralyzing.

The neck finish is a strategic decision that defines your product's cost structure, user experience, and supply chain compatibility. Getting it right ensures a smooth path from concept to consumer.

When we talk about a bottle, we often focus on the body's shape, the label, or the color. But from a manufacturing and strategic point of view, the most important part is the small, threaded section at the top: the neck finish. It’s the very first decision you should make, even before you think about the final bottle design. Why? Because this single feature creates a ripple effect across your entire project. It's the critical link between your product, your production line, and your customer. Overlooking its importance is a common mistake for newcomers, a mistake that can lead to costly redesigns and missed market opportunities. I’ve seen this happen firsthand, and my goal is to help you see the neck finish not as a technical specification, but as the foundation of your product's success.

The Strategic Triangle: Cost, Compatibility, and Consumer

Choosing a neck finish isn't just about picking a size. It's about balancing three critical business factors. I call this the Strategic Triangle.

Cost Structure: The neck finish directly impacts material usage. A lighter neck standard, like the PCO 1881 for carbonated drinks, uses less PET resin than its older counterpart, the PCO 1810. This might seem like a tiny saving, perhaps just a gram or two per preform. But when you are producing millions of bottles, these grams turn into tons of saved material. This translates into massive cost reductions. The cap is also part of the equation. A smaller, lighter neck finish requires a smaller, lighter cap, further reducing your costs and your environmental footprint. Your choice of a preform mold will be determined by this neck finish, locking in your cost structure for years to come.

Supply Chain & Production Compatibility: Standardization is the language of modern manufacturing. When you choose a common, industry-standard neck finish (like a 30/25 for water or a 24/410 for lotion), you are plugging into a global supply chain. This means caps, closures, and even dispensing pumps are readily available from numerous suppliers. This competition keeps prices down and ensures you're never reliant on a single source. More importantly, it ensures compatibility with existing machinery. Filling lines, cappers, and even some bottle blowing machines are often tooled for specific neck standards. Deviating from the norm can mean expensive custom tooling or, worse, discovering your chosen bottle can't be filled at your co-packer's facility.

Consumer Experience & Brand Perception: The neck finish is the primary point of interaction for your customer. How easy is the cap to open? Does the bottle pour smoothly without dripping? For a food jar, is the opening wide enough to comfortably fit a spoon? These are all user experience questions determined by the neck finish. A 38mm neck on a juice bottle provides a smooth, glug-free pour. A 63mm wide-mouth neck on a jam jar allows for easy access. The right choice enhances functionality and makes your product a pleasure to use, building brand loyalty. The wrong one can lead to frustration and negative reviews. The entire journey from concept to reality is mapped out in a good PET bottle mold design guide, and the neck finish is Chapter One.

Ultimately, the neck finish is the DNA of your container. It sets the rules for everything that follows. By treating this decision with the strategic importance it deserves, you lay a solid foundation for a product that is cost-effective, manufacturable, and loved by your customers.

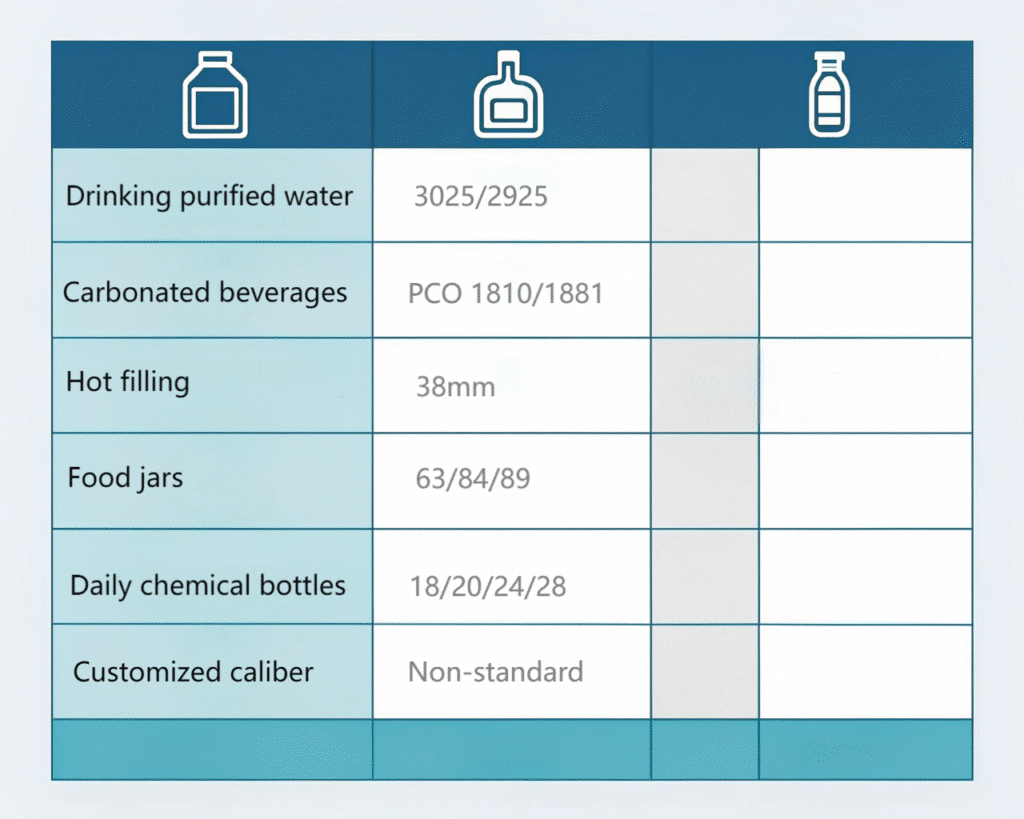

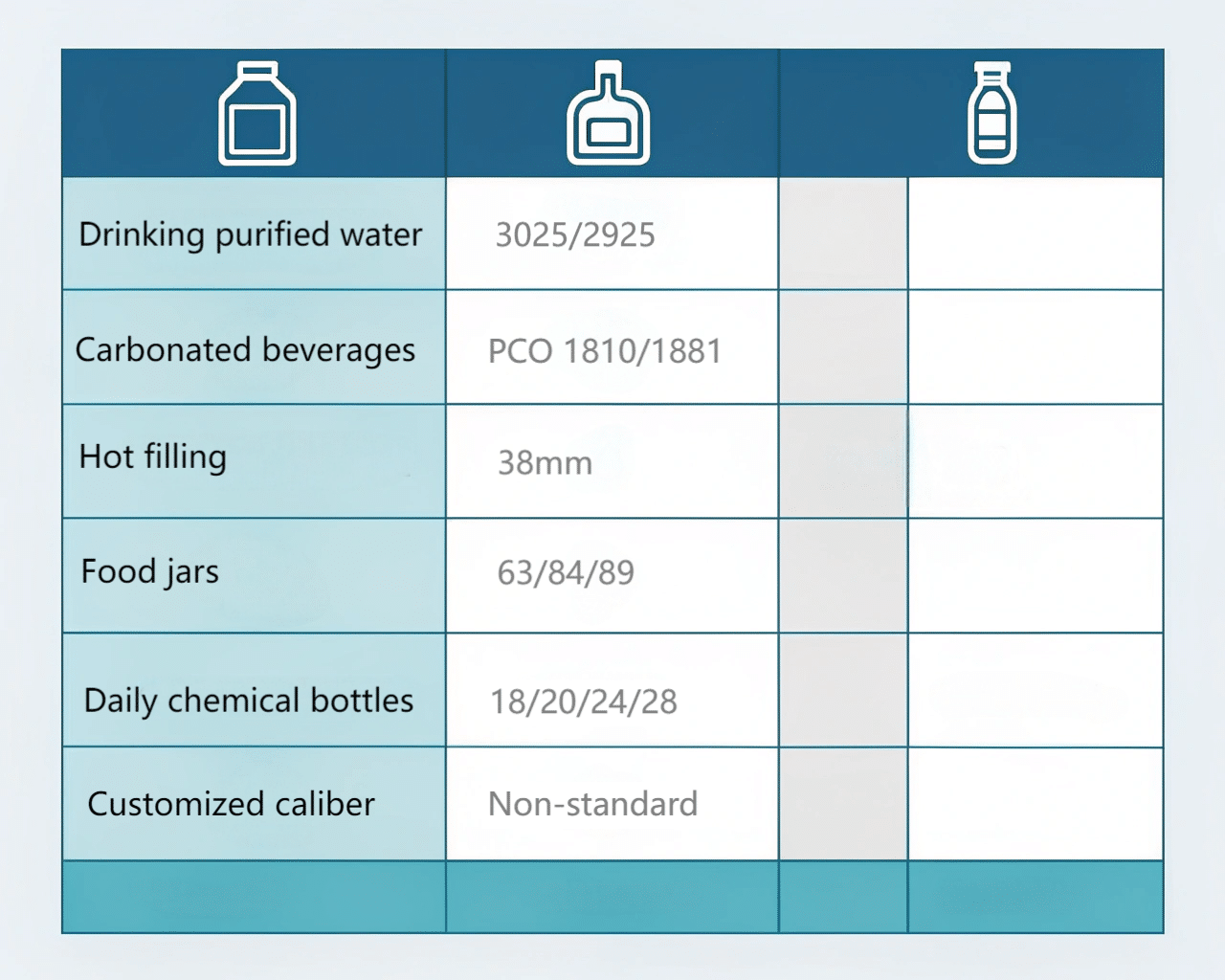

The Ultimate Preform Neck Finish Reference Chart (Categorized by Industry Application)?

You need to find the right neck finish, but scrolling through endless lists of technical codes is confusing. You're afraid of choosing a standard that isn't right for your industry.

Here is a clear, application-focused chart. It groups the most common neck finishes by industry, so you can easily find the standards relevant to your specific product.

To make this process easier, I've created a comprehensive reference chart. But instead of just listing numbers, I've organized it the way you think about your business: by industry application. This is your starting point. Find your industry, see the common standards, and understand the "why" behind them. This chart is the culmination of years of experience, designed to be a practical tool that cuts through the noise and helps you make a confident decision. Think of this as your quick-reference guide before we dive deeper into each category.

Preform Neck Finish Standards by Application

| Industry Application | Neck Finish Standard | Common Dimensions (mm) | Key Characteristics & Notes |

|---|---|---|---|

| Still Water | 30/25 High Neck | T: 30, E: 25, H: 21 | The classic, taller neck. Very common globally, robust, but uses more material. |

| 29/25 Short Neck | T: 29, E: 25, H: 17 | Lightweight version of 30/25. Significant material savings. Dominant in many markets. | |

| PCO 1881 (Short) | T: 28, E: 21.74, H: 17 | Originally for CSD, but its lightweight nature has led to adoption for still water. | |

| Carbonated Soft Drinks (CSD) | PCO 1881 | T: 28, E: 21.74, H: 17 | The global standard. Short height, lightweight, excellent pressure resistance & sealing. |

| PCO 1810 | T: 28, E: 21.74, H: 21 | The older, taller predecessor to 1881. Heavier, less common now but still in use. | |

| BPF (British Plastic Federation) | Similar to PCO but with slight dimensional differences. Primarily UK market. | ||

| Hot-Fill & Aseptic (Juices, Teas) | 38mm 2-Start (1845) | T: 38, E: 32.7, H: 18.55 | Wide mouth for smooth pouring, robust design to handle heat and vacuum pressure. |

| 38mm 3-Start (1690) | T: 38, E: 32.7, H: 13.5 | Shorter neck, faster capping application (3 threads instead of 2), material saving. | |

| 28mm PCO 1810/1881 | Can be used for hot-fill with specific bottle designs (e.g., base panels) to absorb vacuum. | ||

| Food Jars (Jams, Pickles, Spreads) | 63mm | T: 63 | Common wide-mouth size for small to medium jars. Easy user access. |

| 89mm | T: 89 | For larger jars (e.g., pickles, powders). Maximum accessibility. | |

| 110mm | T: 110 | Very large format jars, often for foodservice or bulk products. | |

| Cosmetics & Personal Care | 24/410 | T: 24 | The workhorse for lotions, soaps, and fine mist sprayers. Huge ecosystem of closures. |

| 28/410 | T: 28 | Common for larger pumps (e.g., shampoo, conditioner). Also very versatile. | |

| 20/415 | T: 20 | Smaller diameter, often used for facial serums, treatments, and smaller sprayers. | |

| 18/410 | T: 18 | Common for droppers, treatment pumps, and smaller cosmetic products. |

This chart serves as your high-level map. Now, we will explore the specific economic and engineering stories behind the most important standards in each of these categories. My goal is to equip you not just with the "what," but with the "why," so you can fully understand the implications of your choice. Making the right selection is a core part of a good preform neck size selection guide, as it prevents downstream problems.

The Economics of Hydration: Neck Finishes for the Mineral Water Industry (e.g., 29/25, 30/25)?

You're launching a water brand and see different neck sizes. You wonder if the small difference between 29/25 and 30/25 really matters for your bottom line.

That tiny difference is everything. Choosing a lightweight neck like 29/25 over the older 30/25 standard can save tons of plastic and thousands of dollars in a high-volume business.

.png)

The bottled water industry is a game of scale. Margins on a single bottle are razor-thin, so profitability is driven by volume and relentless cost optimization. In this environment, every fraction of a gram of PET resin counts. This is why the evolution of the standard water bottle neck is such a perfect case study in the economics of packaging. It's a story about how a few millimeters of plastic can create millions of dollars in savings and significantly reduce environmental impact. For anyone entering this market, understanding this principle is not just helpful; it's fundamental to building a competitive business.

The Old Guard: 30/25 High Neck

For many years, the 30/25 neck finish was the undisputed king of still water bottles. The "30" refers to the outer thread diameter (30mm), and the "25" refers to the inner opening diameter (25mm). It was robust, reliable, and universally accepted by bottlers and cap manufacturers. The relatively tall neck height (around 21mm) provided a solid grip for consumers and a large sealing surface. It was, and still is, a perfectly functional design. If you were starting a water company 15 years ago, you wouldn't think twice. You'd choose the 30/25. But the world changed. The pressure to reduce costs and improve sustainability grew immensely. And that's when engineers looked at that 21mm of height and asked a simple question: "Do we really need all of that?"

The Lightweight Revolution: 29/25 Short Neck

The answer was a resounding "no." This led to the development of the 29/25 short neck, also known as the 29/25 low profile. While the inner diameter remained the same for a consistent drinking experience, the outer thread diameter was shaved down to 29mm and, most importantly, the neck height was reduced to around 17mm. This 4mm reduction was revolutionary.

Let's break down the math, because this is where it gets really interesting.

- Saving per Bottle: Reducing the neck height and diameter saves approximately 0.5 to 1.0 gram of PET resin per preform, depending on the specific design. The matching cap also becomes lighter, saving an additional 0.3 to 0.5 gram of HDPE/PP plastic.

- The Power of Scale: Let's be conservative and say the combined saving is 1 gram per bottle.

- For a small production of 1 million bottles, that's 1,000,000 grams, or 1,000 kilograms (1 metric ton) of plastic saved.

- For a medium-sized producer making 50 million bottles a year, that's 50,000 kilograms (50 metric tons) of plastic saved.

- For a major brand producing 1 billion bottles, that's 1,000,000 kilograms (1,000 metric tons) of plastic saved.

At a market price of, say, $1,300 per metric ton of PET resin, that 50-ton saving for the medium producer translates to a $65,000 annual reduction in raw material costs alone. This doesn't even account for lower shipping costs (because the preforms are lighter) and the marketing benefits of having a more sustainable package. This is why the 29/25 neck has become the dominant standard for still water in many parts of the world. It delivers the same performance with less material. It's a pure economic and environmental win. When designing a new water bottle, this choice is paramount, as it will fundamentally affect the entire blow bottle mold you commission.

Handling the Pressure: The Engineering Behind Necks for Carbonated Drinks (e.g., PCO 1881)?

You're developing a soda or sparkling water. You know it needs a special bottle, but you don't understand why a simple water bottle neck won't work. This could lead to dangerous failures.

Carbonated drinks are under pressure. The neck finish must be engineered to create a perfect, gas-tight seal that can withstand forces up to 60-90 psi, preventing leaks and preserving carbonation.

Carbonated soft drinks (CSDs) present a unique engineering challenge. Unlike a simple bottle of still water, a bottle of soda is a pressure vessel. The dissolved carbon dioxide (CO₂) is constantly trying to escape, exerting significant force on the bottle and, most critically, on the seal between the bottle and the cap. This is where the neck finish moves from a simple container opening to a piece of high-performance engineering. The choice here is not about preference; it’s about safety, product integrity, and performance.

This is something I stress to all my clients entering the CSD market. I once had a client in Mexico who was developing a new line of sparkling water. They were familiar with water bottling and loved the economics of the 30/25 neck finish. Despite my strong recommendation to use the industry standard for CSDs, PCO 1881, they insisted on using a 30/25 preform. The project hit a wall. First, they couldn't find a 25-gram 30/25 preform short enough for their 500ml bottle design; most were designed for taller 1.5L water bottles. The lighter 18g preform was too thin to handle the pressure. The final blow came when their co-packer told them their entire high-speed filling line was standardized for the PCO 1881 neck. They couldn't fill the bottles even if they had them. They had to come back to me, acknowledge the mistake, and we redesigned the entire project around the correct standard. This story is a perfect illustration of why standards exist: they ensure safety, compatibility, and efficiency across the entire supply chain.

The Physics of Fizz: Why CSDs Need a Special Neck

A typical 2-liter bottle of soda can have an internal pressure of around 4 atmospheres, or about 60 psi. On a hot day in the back of a car, this can climb even higher, approaching 90 psi. The neck finish and cap have to contain this force reliably for the entire shelf life of the product. Here's what makes it so challenging:

- Gas Permeability: PET is a fantastic material, but it's not perfectly impermeable to CO₂. Over time, gas molecules will slowly migrate through the plastic. The seal at the cap is the weakest point.

- Sealing Surface: A perfect seal must be maintained. Any microscopic imperfection, any creep or deformation of the plastic under pressure, can create a pathway for CO₂ to escape, leaving the product flat.

- Top Load and Stress Cracking: The neck area must also withstand the vertical forces ("top load") of stacking during storage and transport, all while being under constant internal pressure, which can make it susceptible to stress cracking.

PCO 1881: The Engineered Solution

The industry's answer to these challenges is the PCO 1881 neck finish. "PCO" stands for "Plastic Closures Only," and "1881" is the drawing number from the International Society of Beverage Technologists (ISBT) that defines the standard. It replaced the older, taller PCO 1810 standard for the same reasons 29/25 replaced 30/25: it performs better with less material.

Here's a breakdown of its key engineering features:

| Feature | Engineering Purpose | Benefit |

|---|---|---|

| Short Height (17mm) | Reduces material usage in both the preform and the cap. | Lower cost, lower weight, reduced environmental impact. |

| Specialized Thread Profile | Designed for high thread engagement with the cap, ensuring it won't strip or "jump" under pressure. | Maximum safety and reliability. Prevents caps from blowing off. |

| Bore Seal (Inner Seal) | The cap has a flexible flange that pushes against the inner wall of the neck finish, creating a primary, gas-tight seal. | Highly effective at trapping CO₂. It's the most critical sealing point. |

| Top Seal (Outer Seal) | A secondary seal is often created where the top edge of the neck finish meets a liner or ridge inside the cap. | Provides redundancy and prevents leaks if the primary seal is compromised. |

| Tamper-Evident Band | The breakaway band is integrated into the design, providing clear evidence if the bottle has been opened. | Ensures product safety and consumer confidence. |

Choosing the PCO 1881 is not just about picking a part; it's about adopting a system that has been tested and proven to handle the unique demands of carbonation. It's the reason you can buy a soda from anywhere in the world and be confident it will be fizzy when you open it. It also prevents costly and frustrating issues, like the ones my Mexican client faced, and ensures your preform mold and bottle design are aligned with global manufacturing standards from day one.

Product Integrity First: Neck Standards for Hot-Fill & Aseptic Products (e.g., 38mm 2-start)?

You're bottling a natural juice. You know it needs hot-filling to be shelf-stable, but you're worried about the bottle deforming or collapsing after it cools.

Hot-filling creates a vacuum. You need a wider, more robust neck finish like the 38mm standard, which provides structural integrity and a superior seal to withstand these forces.

When you move into the world of products like juices, teas, and sports drinks, you face a new set of challenges that go beyond just holding liquid. These products often require a "kill step" to eliminate microorganisms and ensure shelf stability without refrigeration. The most common method is hot-filling. This process involves heating the product to around 85-95°C (185-203°F), filling it into the bottle, capping it, and then cooling it down. This simple-sounding process puts extreme stress on the PET bottle, and the neck finish is on the front line of this battle. It must be designed not just to seal, but to manage the powerful forces of thermal expansion and contraction.

The Science of Suck: Understanding the Hot-Fill Vacuum

The physics are straightforward but powerful. When you fill the bottle with hot liquid, the air and the liquid itself are expanded. You then cap the bottle, sealing it. As the bottle and its contents cool down, the liquid and the headspace air contract. This contraction creates a partial vacuum inside the bottle. The outside atmospheric pressure is now greater than the internal pressure, and it is constantly trying to crush the bottle.

This vacuum is actually desirable—it pulls the tamper-evident band on the cap down tightly and helps preserve the product's freshness. However, if the bottle and neck finish are not designed for it, you'll see a range of common PET blow molding defects in the final product. The most common is "paneling," where the flat sides of the bottle suck inward. A poorly designed neck can also deform, compromising the seal and leading to spoilage. To combat this, hot-fill PET bottles often have special design features like structural ribs or vacuum panels in the base. But the first line of defense is a strong, stable neck finish.

Why 38mm is the King of Hot-Fill

This is why the 38mm neck finish is the dominant standard in the hot-fill industry. It excels for several key reasons:

- Structural Rigidity: A wider diameter is inherently more rigid and resistant to deformation than a narrow one. The 38mm neck provides a solid, stable foundation that is less likely to ovalize or distort under the vacuum forces.

- Superior Sealing Surface: The wider sealing surface (the flat top of the neck finish, or "land") allows for a larger, more reliable seal with the cap. This is often an induction-sealed foil liner that is welded to the bottle neck, creating a hermetic seal that is critical for product integrity.

- Enhanced User Experience: For products like juices and teas, a wider opening provides a smoother, "glug-free" pouring experience, which is a significant plus for the consumer.

- Compatibility with Oxygen-Scavenging Caps: Many juices are sensitive to oxygen, which can degrade vitamins and cause off-flavors. The 38mm standard has a wide ecosystem of advanced closures, including caps with oxygen-scavenging liners that actively absorb any residual oxygen in the headspace.

Within the 38mm family, you will often hear about "2-start" or "3-start" threads. This refers to the number of parallel threads running around the neck.

- 38mm 2-Start: This is a very common standard. It requires about a full 360-degree turn to apply or remove the cap, providing a very secure feel.

- 38mm 3-Start: This version is designed for higher-speed capping lines. With three interlocking threads, the cap only needs to be turned about 120 degrees to be fully secured. This can shave precious fractions of a second off the capping process on a multi-thousand bottle-per-hour line. It also often features a shorter neck height, saving on material.

The choice between them often comes down to the speed of your filling line and specific cost targets. But in both cases, the 38mm diameter is the key to creating a package that can withstand the rigors of hot-filling and deliver a safe, fresh product to the consumer. For these applications, the proper function of a chiller connected to the blow mold is also critical to ensure the PET crystallizes correctly and can withstand the heat.

Functionality & Freshness: A Guide to Wide Mouth Necks for Food Jars (e.g., 63mm, 89mm)?

You want to package jam or pickles in a PET jar. You need a jar that's easy for customers to get a spoon into, but also seals perfectly to keep the product fresh.

Wide-mouth neck finishes are the answer. Standards like 63mm and 89mm prioritize user access while being designed for compatibility with advanced sealing technologies that guarantee product freshness.

When we move from beverages to solid or semi-solid foods like jams, sauces, powders, or pickles, the priorities for the neck finish shift dramatically. While pressure resistance or vacuum performance might be less of a concern, two new factors take center stage: user accessibility and seal integrity for freshness. The package is no longer just a vessel for pouring; it's a container that the user needs to interact with directly, often with a utensil. This is the domain of wide-mouth PET jars, and the neck finish is what makes them functional, safe, and convenient.

Accessibility is Everything

The primary driver for a wide-mouth neck is simple: can the customer get the product out easily? No one wants to struggle to fit a spoon into a jar of peanut butter or fight to grab the last pickle. The choice of diameter is a direct function of the product and its intended use.

- 45mm to 58mm: These are often used for spices, spreads, and creams. They offer a good balance between accessibility and a smaller footprint.

- 63mm: This is a hugely popular standard. It's the classic "jam jar" size, perfect for easily scooping out product with a tablespoon. It feels comfortable in the hand and is extremely versatile for products ranging from pasta sauces to mayonnaise.

- 70mm & 82mm: These are common "next-step-up" sizes, often used for pickled onions, olives, or larger quantities of sauces.

- 89mm & 110mm: These large-format necks are for products where maximum access is required. Think large containers of protein powder where a scoop is needed, bulk spices for food service, or even non-food items like craft supplies.

Choosing the right diameter is a critical part of the user experience. A jar that is difficult to use is a jar that a customer is unlikely to buy again. When designing the jar, this consideration must be balanced with the overall aesthetic and the volume of the container. We often create several 3D printed samples of different neck sizes for clients so they can physically test them and see which one feels best for their specific product.

Sealing for Shelf Life

While user access is the most visible feature, the engineering of the seal is just as critical for food products. A poor seal can lead to spoilage, contamination, and a ruined brand reputation. Wide-mouth neck finishes are designed with a very flat and wide top surface, known as the "land." This is the critical area that interfaces with the closure to create the seal.

There are two primary sealing methods used with these jars:

Liner-Based Sealing: The cap contains a liner made of a specific material (like foam or pulp paper with a plastic or foil layer). When the cap is tightened, the liner compresses against the land of the neck finish, creating a tight seal. This is common for products like powders or nuts that don't require a hermetic seal.

Induction Sealing: This method provides a much higher level of protection and tamper evidence. A multi-layer liner is placed inside the cap. After the jar is filled and capped, it passes under an induction coil. The coil generates an electromagnetic field, which heats up a foil layer in the liner. This heat melts a polymer layer on the liner, welding it directly onto the land of the PET jar. This creates a hermetic (airtight) seal. When the consumer opens the cap for the first time, they have to peel off this foil seal, giving them clear evidence that the product is fresh and untouched. This is the gold standard for products like peanut butter, coffee, and sauces.

The design of your blow bottle mold for a wide-mouth jar must be extremely precise to ensure the land area is perfectly flat and free of defects, otherwise, the induction seal can fail. This combination of user-friendly access and high-tech sealing is what makes PET jars a safe, lightweight, and shatterproof alternative to traditional glass packaging.

Aesthetics & Dispensing: Neck Finishes in the Cosmetics & Personal Care Aisle?

You're launching a cosmetic line. Your product needs a pump or a sprayer, and you're lost trying to match your bottle to the right accessory. You fear costly mismatches.

The solution is in standardized neck finishes like 24/410. These are universal interfaces designed to connect your bottle to a global ecosystem of pumps, sprayers, and droppers perfectly.

In the cosmetics and personal care aisle, the bottle is more than just a container—it's a statement. It communicates luxury, efficacy, and brand identity. At the same time, it must be a functional tool that dispenses lotion, sprays a fine mist, or delivers a precise drop of serum. The neck finish is the critical junction where these two worlds—aesthetics and functionality—meet. The choice of neck here is less about pressure or vacuum and almost entirely about providing a standard interface for a vast array of dispensing systems. It's about creating a package that looks beautiful and works flawlessly every time.

The Universal Language: Understanding Codes like 24/410

If you browse any packaging supplier's catalog for pumps, sprayers, or caps, you'll see codes like "24/410," "28/415," or "20/410." This isn't jargon; it's a precise language that ensures a pump from a supplier in Asia will fit perfectly on a bottle made in Europe. Let's break down the code:

- The First Number (e.g., 24): This is the nominal diameter of the neck opening in millimeters. A "24/410" neck has a 24mm diameter. This is straightforward.

- The Second Number (e.g., 410): This refers to the thread style. It dictates the height of the neck and the number of thread turns. The most common styles are:

- 400: A shallow thread, one full turn.

- 410: A taller neck with 1.5 thread turns. This is very common for pumps and sprayers as the taller "skirt" of the closure hides the threads for a cleaner look.

- 415: A taller neck still, with 2 full thread turns. This provides a very secure fit, often used for products that might leak.

So, a 24/410 neck finish is a standard interface with a 24mm diameter and a 410 thread style. By choosing this standard for your bottle, you instantly gain access to thousands of compatible lotion pumps, fine mist sprayers, and disc-top caps from suppliers all over the world. This standardization de-risks your project immensely. You can source your bottle from one vendor and your pump from another, confident they will fit together perfectly.

Choosing the Right Standard for Your Product

The choice of cosmetic neck standard depends entirely on the product you are dispensing.

| Standard | Common Applications | Why it Works |

|---|---|---|

| 18/410, 20/410 | Facial serums, eye creams, treatment pumps, droppers, nasal sprays. | The small diameter is suited for dispensing small, controlled amounts of high-value product. |

| 24/410 | The workhorse. Hand soaps, lotions, body creams, hair styling products, fine mist body sprays. | The most versatile size. A massive ecosystem of dispensing options is available for this standard. |

| 28/410 | Shampoo, conditioner, body wash, larger format lotions. | Used when a larger dose (output) is needed per pump. The wider diameter accommodates more powerful pump engines. |

| 28/415 | Can be used for similar applications as 28/410, but often chosen for trigger sprayers or products where a more secure seal is desired. | The extra thread turn provides more engagement and a tighter seal. |

Beyond the functional fit, the neck finish also plays a role in aesthetics. A 24/410 neck on a 100ml bottle looks proportional and elegant. Putting a massive 28/410 neck on that same small bottle would look clunky and unbalanced. The design of the bottle and the choice of neck must work in harmony. This is a key part of our PET bottle mold design guide; ensuring the final product is not only functional but also visually appealing on the shelf. The precision of the preform mold is also critical here, as any inconsistency in the thread can cause leaks or make the pump sit crooked, ruining the premium feel of the product.

Matching the Neck to the Niche: A Final Decision Framework?

You've learned about all the options. Now you face the final decision and want to be sure you're considering every angle for your unique product.

Use a strategic framework. By answering a series of key questions about your product's core needs, you can systematically navigate the options and select the ideal neck finish with confidence.

We've traveled from the high-pressure world of sodas to the high-stakes aesthetic of cosmetics. You now have a map of the most common PET preform neck finishes and understand the "why" behind their use in different industries. But how do you apply this knowledge to your specific project? To bring it all together, I've developed a simple decision framework. This isn't a rigid set of rules, but a series of strategic questions to guide your thinking. By walking through this process, you can move from a broad understanding to a specific, defensible choice for your product.

Your Four-Step Decision Framework

Ask yourself these four questions in order. Your answers will point you directly to the most suitable neck finish standard.

Step 1: What is my product's single most critical performance requirement?

You must be honest here. While every product needs to be cost-effective and look good, there is always one primary driver that trumps the others.

- Is it Cost? (e.g., Bottled Water, Value Beverages)

- Your focus should be on lightweight standards. Look at 29/25 for water or PCO 1881 for CSDs. Every gram saved is money in your pocket.

- Is it Pressure Containment? (e.g., Carbonated Drinks, Sparkling Water)

- There is no substitute. Your choice must be a pressure-rated standard like PCO 1881. Safety and product integrity are non-negotiable.

- Is it Heat & Vacuum Resistance? (e.g., Juices, Teas, Sauces)

- You need a robust, wider neck. Start with the 38mm family (2-start or 3-start) designed specifically for the rigors of hot-filling.

- Is it User Access? (e.g., Jams, Powders, Pickles)

- The decision is driven by the consumer's hand or utensil. Choose a wide-mouth standard (63mm, 89mm, etc.) that allows for easy scooping and access.

- Is it Dispensing Functionality? (e.g., Cosmetics, Soaps, Cleaners)

- Your primary goal is compatibility. Select a standard like 24/410 or 28/410 that has a large, established ecosystem of pumps, sprayers, and closures.

Step 2: What are the established standards in my specific market niche?

Once you know your primary requirement, look at what the successful players in your field are doing. This isn't about copying; it's about leveraging collective wisdom and ensuring supply chain compatibility. If every major juice brand uses a 38mm neck, there's a strong reason for it. This decision will also affect your machinery. It's crucial to know if your blow mold can fit your machine, and standard necks often mean more compatible molds.

Step 3: What is the availability of preforms and closures for this standard?

A technically perfect but obscure neck finish is a business liability. Choose a standard that has a deep and competitive supply chain for both preforms and caps. This protects you from price hikes and supply disruptions. Your purchasing manager will thank you for choosing a widely available standard like PCO 1881 or 24/410.

Step 4: Can I validate my choice with a prototype?

Before you invest thousands of dollars in a high-cavity preform mold or blow bottle mold, validate your choice. Get samples of the preform. Test the chosen cap or pump. Even better, get a 3D-printed model of your final bottle design. Hold it in your hand. See how it feels. Perform a filling test if possible. This small, upfront step can save you from a massive, costly mistake down the line. It's the final confirmation that your on-paper decision works in the real world.

By following this framework, you transform the complex task of choosing a neck finish into a logical and strategic process, ensuring the foundation of your packaging is perfectly aligned with your product, your market, and your business goals.

Conclusion

Choosing the right preform neck is a crucial strategic decision. By matching the standard to your specific application—be it cost, pressure, heat, or dispensing—you ensure a successful product launch.

Frequently Asked Questions (FAQs)

1. What do the numbers in a neck finish like "30/25" or "24/410" actually represent?

These numbers are a standardized code that describes the neck's dimensions and thread style.

- In a code like 30/25, the first number (30) is the nominal outer thread diameter in millimeters, and the second number (25) is the nominal inner opening diameter in millimeters. This style is common for beverages.

- In a code like 24/410, the first number (24) is the nominal outer diameter in millimeters. The second number (410) refers to the thread standard, which dictates the height of the neck and how many turns the thread makes. The "410" style is very common in the cosmetics industry for pumps and sprayers.

2. If the neck finish is the same, can I use one preform (e.g., a 20g preform with a 30/25 neck) to produce different bottle shapes or volumes?

Yes, to a certain extent. The neck finish is fixed by the preform mold, but the body of the preform can be blown into various shapes and sizes in the blow bottle mold. However, there are limits. This is governed by the "stretch ratio." A 20g preform designed for a 500ml bottle cannot be stretched to create a well-formed 1.5L bottle; it would be too thin. Conversely, trying to make a 250ml bottle from it would result in thick, poorly distributed material. Generally, a single preform weight is optimized for a specific range of bottle volumes and shapes.

3. How does the choice of neck finish (e.g., a lightweight 29/25 vs. a heavier 38mm) impact the final cost of the bottle?

The impact is significant and comes from two main sources:

- Resin Weight: The neck finish directly affects the weight of the preform. A lightweight 29/25 preform for a 500ml water bottle might weigh 13g, while a robust 38mm preform for a 500ml hot-fill juice bottle could weigh 24g or more. This extra PET resin is a direct material cost.

- Closure Cost: The cap is the second part of the equation. A smaller, lighter cap for a 29/25 neck is significantly cheaper than a larger, heavier, and more complex cap required for a 38mm hot-fill neck. When producing millions of bottles, these combined savings are a major factor in the final cost of goods.

4. For a startup in the beverage industry, what are the top 3 "safest" or most common neck finishes to start with?

For a startup, sticking to mainstream standards is the smartest way to minimize risk and ensure a wide, competitive supply chain for caps and preforms. The three safest choices are:

- 29/25 (or 30/25): For Still Water. It is the global standard, and you will have no trouble finding preforms and caps.

- PCO 1881: For Carbonated Soft Drinks. This is the non-negotiable global standard. It ensures safety and compatibility with all CSD fillers.

- 38mm 2-Start: For Hot-Fill Juices and Teas. This is the most common standard for this application, providing excellent performance and a wide availability of caps.

5. Where can I find the official technical specification drawings for these international standard neck finishes?

Official technical drawings are maintained by industry standards organizations. The primary source for beverage-related finishes is the ISBT (International Society of Beverage Technologists). You can visit their website to find detailed drawings for standards like PCO 1881, PCO 1810, and various 38mm finishes. For cosmetic standards like the 410/415 series, the specifications are often maintained by major packaging associations and are widely adopted by manufacturers. As a packaging solutions provider, we at iBottler can also provide technical support and drawings for all major international standards to ensure your project is built on the right specifications from the start.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

📞 Contact: Vivian

🏭 Zhongshan Jindong Machinery Co., Ltd.

🌍 www.ibottler.com

📧 Vivian@ibottler.com | 💬 WhatsApp: +86-13106288777

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr