Struggling with PP bottle production? You're seeing sagging preforms and inconsistent walls. Discover the five key reasons why and how to fix them for good.

PP bottles are tricky due to low melt strength, a narrow heating window, uncontrolled stretching, slow crystallization, and the need for structural design. The solution lies in optimizing preform design, precise heating control, mandatory pre-blowing, efficient mold cooling, and reinforced bottle structures.

I see these frustrations all the time. A client wants the benefits of Polypropylene—high heat resistance, good chemical barriers, suitability for hot-fill or sterilization—but they are completely unprepared for the manufacturing challenge. They think it's just like running PET. It's not. But trust me, once you understand the 'why' behind PP's behavior, the 'how' to fix it becomes much clearer. Let's break down these hurdles one by one.

Yes, It's Tricky: Unpacking the Core Reasons PP is Different from PET?

Ever feel like switching from PET to PP is like learning a new language? The materials look similar, but their behavior is completely different, causing frustrating production failures.

The core difference lies in their molecular structure. PP is semi-crystalline with low melt strength, making it soft and sag-prone when heated. PET is amorphous with high melt strength, giving it the rigidity needed for easy processing. This fundamental distinction impacts everything.

When you get down to the basics, the entire challenge of blowing PP bottles comes from the fact that it is fundamentally not PET. I had a client in the U.S. who learned this the hard way. He was an expert in PET bottle production but took on a new project for a 90°C hot-fill milk bottle. The customer specified PP for its heat resistance. My client thought, "It's just another plastic. I can use my existing PET machine." That assumption was the start of a long, expensive, and frustrating journey for him. He couldn't understand why his preforms were melting, his bottles were inconsistent, and his process was completely unstable. To understand his failure, and to ensure your success, we must first go back to the material science.

The Tale of Two Polymers: Amorphous vs. Semi-Crystalline

The first major difference is the material's internal structure.

- PET (Polyethylene Terephthalate): In its preform state, PET is largely amorphous. You can think of its long polymer chains as a messy bowl of spaghetti. They are tangled but have no real order. This structure is strong and rigid at room temperature and becomes like stiff rubber when heated above its glass transition temperature. It holds its shape well.

- PP (Polypropylene): PP, on the other hand, is semi-crystalline. Imagine that bowl of spaghetti again, but now some sections of the strands have neatly aligned themselves into ordered, crystalline structures. These crystals act like physical cross-links, giving PP its toughness and opacity. The problem is, to blow the bottle, you have to melt these crystals.

This single difference is the root of most of the challenges. When you heat a PET preform, it softens uniformly. When you heat a PP preform, you have to input enough energy to melt those crystalline structures, and the moment they melt, the material's integrity plummets.

Understanding Key Thermal Properties

A simple table can show just how different these materials behave under heat.

| Property | PET (Polyethylene Terephthalate) | PP (Polypropylene) | What It Means for You |

|---|---|---|---|

| Glass Transition (Tg) | ~80°C (176°F) | ~ -10°C (14°F) | This is the temperature where the material goes from rigid to rubbery. PET's high Tg means it's stable in the oven until it hits the processing temp. |

| Melting Point (Tm) | ~250°C (482°F) | ~165°C (329°F) | For PP, you must heat the preform to a point close to its Tm to allow stretching. This is a much finer line to walk than with PET. |

| Processing Window | Wide | Narrow | PET is forgiving. A few degrees here or there is often fine. For PP, a couple of degrees can mean the difference between a perfect bottle and a melted blob. |

| Melt Strength | High | Very Low | This is the most critical difference. When heated to its processing temperature, PET behaves like thick honey; it stretches predictably. PP behaves like melted cheese; it wants to drip and sag. |

My American client's entire experience was based on PET's high melt strength and wide processing window. He was used to preforms that held their shape in the oven. When he put his PP preforms into his PET machine's heating module, they sagged under their own weight before they were even halfway through. This is the first and most visceral lesson in PP blow molding: you are not working with a forgiving material. You must control it at every single step.

Hurdle #1: Low Melt Strength – The Preform Sagging and Stability Problem?

Is your PP preform drooping in the oven like a wilting flower? This sagging is the number one enemy of a stable blow molding process, leading to countless defects.

PP's low melt strength means it can't support its own weight when heated, causing it to sag and decenter. The solution involves a supportive preform design, specialized preform holders (spindles), and a heating process that minimizes time spent in the molten state before stretching.

This was the first problem my U.S. client called me about. "My preforms are turning into bananas in the oven!" he exclaimed. This is the classic manifestation of low melt strength. In a typical PET bottle blowing machine, the preform is held by its neck finish and travels through a heating oven. For PET, this is no problem. It heats, softens, and stays perfectly aligned. For PP, this is a disaster. As the preform body reaches the right temperature for stretching, it has the structural integrity of warm taffy. Gravity takes over, and it begins to droop, bend, and sag.

The Domino Effect of a Sagging Preform

A preform that sags even a few millimeters creates a cascade of failures. It's not a minor issue; it's a process-killer.

- Uneven Heating: As the preform sags, one side gets closer to the heating lamps while the other side moves farther away. The result is a hot side and a cold side. The hot side will be too thin in the final bottle, and the cold side will be too thick.

- Misalignment with Stretch Rod: The blow molding process relies on a steel stretch rod entering the preform perfectly down the center to initiate the vertical stretch. If the preform has sagged, the rod will be off-center. This immediately guarantees an off-center gate and an unstable bottle base.

- Inconsistent Wall Thickness: With uneven heating and an off-center stretch, it's impossible to achieve consistent material distribution. You'll get bottles with one side paper-thin and the other side thick and heavy. This is a primary cause of many common blow molding defects.

- Jam-ups and Machine Stoppages: A severely sagging preform can physically get stuck in the machine, causing jams and forcing you to stop production entirely.

Solution 1: Start with a Better Preform Design

You cannot solve a material problem with process alone. The fight against sagging begins with the preform itself. Unlike PET, where preform designs are somewhat standardized, a good PP bottle often requires a custom-designed preform from a specialized preform mold. The design focuses on adding structural integrity. This can involve:

- A Thicker Core: A thicker wall cross-section provides more mass to resist bending.

- Strategic Thickness Variation: Adding more material in the areas most prone to sagging can help the preform maintain its shape.

- Optimized Gate Area: The transition from the thick gate area to the main body must be gradual to avoid creating a weak "hinge point."

Solution 2: Rethink Your Heating and Handling

This is where my U.S. client's PET machine was failing him. The hardware wasn't designed for a low-strength material.

- Specialized Spindles: Standard PET spindles often just grip the neck. For PP, you often need specially designed spindles that provide some support to the preform's body as it travels through the oven, preventing it from drooping.

- Horizontal Loading: Some machines designed for PP load the preforms horizontally, rotating them like a rotisserie chicken. This uses gravity to its advantage, ensuring all sides are heated evenly and preventing a single side from stretching downwards.

- Minimize Oven Time: The goal is to get the preform to the target temperature as quickly as possible and then immediately move to the blowing stage. A longer, slower heating process just gives the preform more time to sag. This often means using more powerful, high-intensity heating lamps.

We explained to the client that his machine's fundamental architecture was wrong. He was trying to fit a square peg in a round hole. His machine was built for the forgiving nature of PET, not the demanding physics of PP.

Hurdle #2: The Narrow Heating Window – A Fine Line Between Under-Heated and Burnt?

Are you constantly fighting a battle between chalky, under-stretched PP bottles and yellow, burnt ones? This frustration comes from PP's extremely narrow and unforgiving processing window.

PP requires a very specific temperature to stretch properly. Too low, and it remains stiff, leading to haze and poor material distribution. Too high, and it degrades, causing yellowing and brittleness. Achieving success demands an extremely precise and uniform heating profile.

After my client understood the sagging issue, he tried to solve it by turning up the heat to get the preforms through the oven faster. This led to his second frantic phone call: "Now they're catching fire! The necks are brown and the bodies are still cloudy." He had run headfirst into the second great hurdle of PP blow molding: the razor-thin heating window. With PET, you might have a comfortable processing window of 10-15°C. With PP, that window can shrink to as little as 3-5°C. You have almost no room for error.

The Consequences of Missing the Mark

Under-Heated: If the PP preform is not heated enough, the crystalline structures within the plastic do not fully melt. When you try to stretch it, you're fighting against this residual structure. This results in:

- Pearlescence or Haziness: The material is stretched mechanically, but not oriented correctly at a molecular level, causing light to scatter and creating a milky or pearly appearance.

- Poor Material Distribution: The material is too stiff to flow where you want it to go, resulting in thick and thin spots.

- Incomplete Formation: The bottle may not fully blow out to the corners of the blow bottle mold, resulting in soft details and poor definition.

Over-Heated: If you apply too much heat, you cross a different dangerous line. The polymer chains themselves begin to break down (oxidative degradation). This results in:

- Yellowing or Browning: This is a clear visual sign that the material has been damaged.

- Brittleness: The bottle may look okay, but its physical properties are compromised. It will be brittle and have poor drop impact resistance.

- Unpleasant Odor: Burnt plastic gives off a distinct smell, which is completely unacceptable for food or beverage containers.

My client was overheating the surface of his preforms, causing them to burn, while the core of the preform wall remained too cold to stretch properly.

Solution: Precision, Penetration, and Profile Control

You cannot eyeball the heating for PP. It requires a sophisticated heating system and a meticulous approach.

- The Right Lamps: The standard halogen lamps on my client's PET machine were a major part of the problem. They are great at heating the surface of the preform. For PP, you need heat to penetrate through the entire wall thickness quickly and evenly. This is why most dedicated PP bottle blowing machines use high-intensity, short-wave infrared (IR) or ruby lamps. These lamps emit energy that passes through the surface and heats the material from the inside out, leading to a much more uniform temperature profile. This was one of the first upgrades we specified for his new machine.

- Granular Zonal Control: A single "oven temperature" setting is useless. A PP heating oven must be divided into multiple vertical and horizontal heating zones, each with its own independent power control. This allows you to create a precise heating profile that matches the preform's design. For example, you might need to apply more heat to the thicker sections of the preform and less heat near the neck.

- Ventilation is Critical: As the preform surface heats up, you need a controlled flow of air to remove the excess surface heat and prevent it from burning before the core is ready. Proper ventilation systems in the oven are not an optional extra; they are essential for widening that narrow processing window.

Here is a sample comparison of heating strategies:

| Heating Parameter | Typical PET Process | Required PP Process |

|---|---|---|

| Lamp Type | Standard Halogen / IR | High-Intensity Short-Wave IR / Ruby |

| Heating Zones | 5-8 vertical zones | 10+ vertical and horizontal zones |

| Control System | Basic percentage control | Precise, closed-loop temperature feedback |

| Ventilation | Moderate | High-volume, targeted air cooling |

We had to explain to my client that achieving the required precision was impossible with his current equipment. He needed a machine built for the task.

Hurdle #3: Uncontrolled Stretching – Why Pre-Blow is Absolutely Non-Negotiable?

Do your PP bottles look more like random blobs than consistent containers? If you're skipping or miscalibrating the pre-blow stage, you're letting the material run wild.

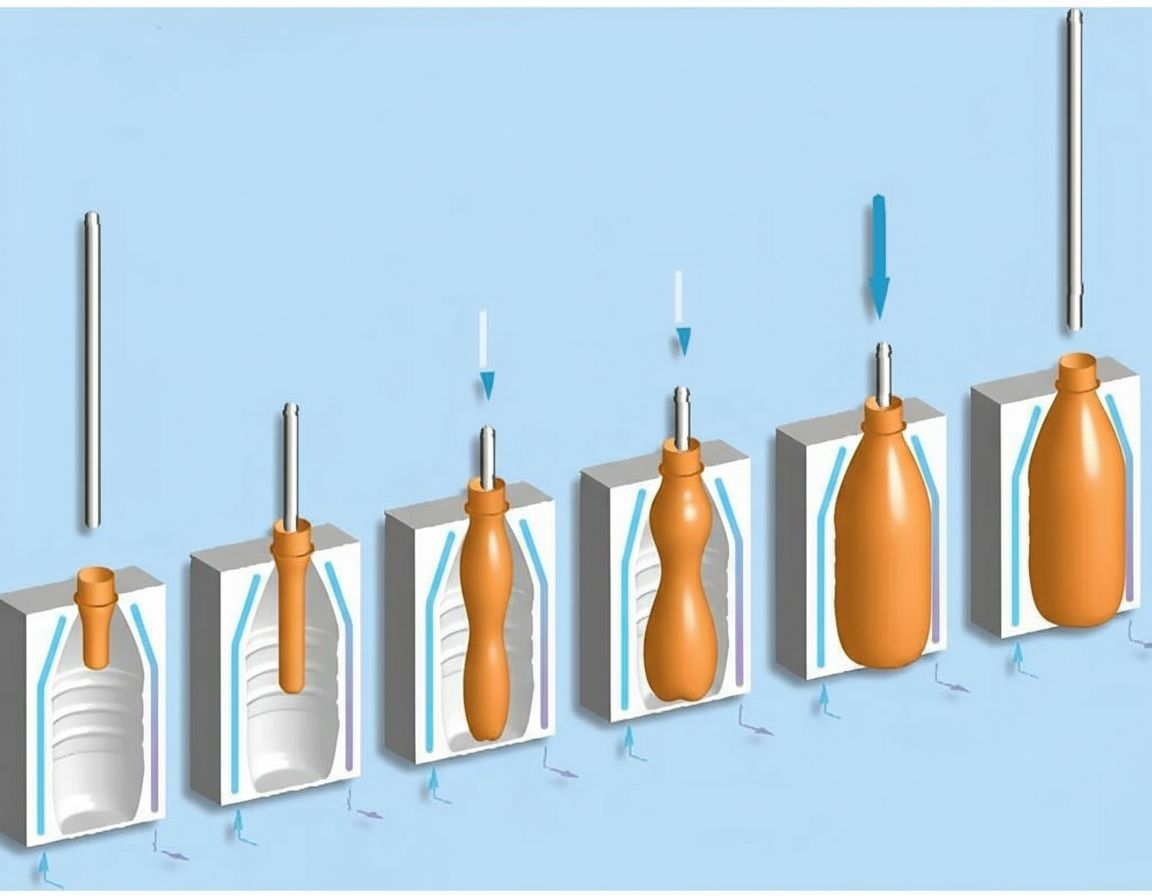

Without a precise pre-blow, low-strength PP material balloons uncontrollably against the mold walls upon high-pressure blowing. Pre-blowing creates a small, stable bubble, centering the stretch rod and guiding the material for even distribution during the final blow.

Once you've successfully navigated the sagging and heating challenges, you bring the perfectly heated preform into the mold. The stretch rod descends, the high-pressure air valves open, and... POP. Or you get a bottle that's paper-thin at the bottom and thick as a brick at the top. This is the third hurdle: controlling the stretch. With PET's high melt strength, the material has a natural tendency to stretch evenly. PP has no such tendency. The moment high-pressure air hits it, the weakest, hottest spot will expand like a cheap balloon, thinning out instantly while the rest of the material barely moves. You cannot control this with main blow pressure alone. The secret weapon is the pre-blow.

The Critical Function of the Pre-Blow Stage

Pre-blow is a short burst of low-pressure air that is introduced at the beginning of the stretching cycle. It is not optional for PP; it is the most critical process step for determining wall thickness distribution.

- Centers the Stretch Rod: As the stretch rod moves down, the pre-blow pressure creates a small, uniform bubble around its tip. This bubble acts as a cushion, ensuring the rod stays perfectly centered in the bottle's final geometry.

- Initiates Radial Stretching: It begins the process of stretching the material outwards (radially) in a controlled manner, preventing it from all flowing downwards (axially) with the stretch rod.

- Sets the Stage for the Main Blow: The pre-blow effectively "pre-shapes" the material into a small version of the final bottle inside the mold. When the high-pressure main blow is activated, it simply inflates this already-stable shape evenly out to the mold walls. Without pre-blow, the main blow is a chaotic, uncontrolled explosion of plastic.

My U.S. client's PET machine had a pre-blow function, but it was basic. He couldn't independently control the timing and pressure with the precision needed for PP. For his milk bottle, the pre-blow had to start at the exact moment the stretch rod passed the halfway point of its stroke, with a pressure of precisely 0.6 MPa, held for just 0.2 seconds. His machine's controls were too slow and imprecise to hit that target consistently.

Mastering Pre-Blow Parameters

Fine-tuning the pre-blow is an art, but it's based on science. The three key parameters you must control are:

- Pre-Blow Pressure: This is the force of the air.

- Too Low: The bubble won't form properly, and you'll get thick bases and thin shoulders.

- Too High: The material will stretch too fast, hitting the mold walls before the stretch rod has finished its stroke, resulting in thin bases and poor vertical stretch.

- Pre-Blow Timing: This is when you introduce the air relative to the stretch rod's movement.

- Too Early: Can cause the preform to "peel" away from the stretch rod, leading to a very thin shoulder area.

- Too Late: The stretch rod will have already pushed most of the material to the base, and the pre-blow will be ineffective. You'll get very thick bases.

- Pre-Blow Duration/Volume: This is how long the low-pressure air flows. It determines the size of the initial bubble.

The ideal combination of these parameters is unique to every bottle shape and preform design. It requires a machine with fast-acting, high-precision valves and a sophisticated control system that allows for independent and precise adjustment of each variable. This is a far cry from the simpler systems often found on older PET machines. A good starting point often involves contrasting with PET, which is more forgiving.

| Parameter | PET Bottle (Typical) | PP Hot-Fill Bottle (Example) |

|---|---|---|

| Pre-Blow Pressure | 0.8 - 1.2 MPa | 0.4 - 0.8 MPa (Lower pressure, more gentle) |

| Pre-Blow Start Time | Simultaneous with or just after stretch rod starts | Often delayed until stretch rod is 40-60% down |

| Process Criticality | Important for optimization | Absolutely non-negotiable for success |

Getting the pre-blow right is the key to unlocking consistent material distribution in PP bottles.

Hurdle #4: Slow Crystallization Rate – The Battle Against Post-Molding Warpage and Shrinkage?

Have you ever produced a perfect-looking PP bottle, only to find it warped and shrunken the next day? This costly problem is a direct result of PP's slow cooling and crystallization.

PP crystallizes much slower than PET, meaning it's not fully stable when ejected from the mold. If not cooled sufficiently, it continues to shrink and warp post-production. The key is optimized mold cooling and potentially a longer cycle time to ensure stability.

Let's assume you've mastered the first three hurdles. Your preform is heated perfectly, the pre-blow is calibrated, and you've produced a beautiful-looking bottle. You eject it from the machine, place it in a box, and go home satisfied. The next morning, you find a box full of twisted, shrunken, and unusable products. This is the fourth hurdle: dimensional stability. This issue stems from PP's semi-crystalline nature. The process of the polymer chains arranging themselves into those orderly crystalline structures takes time and is accompanied by a change in volume (shrinkage). PET cools and solidifies very quickly. PP likes to take its time.

The Science of Post-Mold Shrinkage

When the bottle is ejected from the mold, it may feel solid, but it is not finished. The core of the bottle walls is still hot, and the crystallization process is only partially complete. Over the next few hours (and sometimes even days), two things happen:

- Residual Heat Escapes: The remaining heat slowly dissipates from the plastic.

- Crystallization Continues: The polymer chains continue to slowly organize themselves, moving closer together.

Both of these processes cause the bottle to shrink. If this shrinkage is not uniform across the entire bottle, it leads to warping. The areas that are thicker or were hotter will shrink more, pulling on the rest of the bottle. This is especially problematic in the neck finish area, which needs to be perfectly round to ensure a good seal, and the base, which needs to be flat for the bottle to stand up straight.

Solution 1: Aggressive and Intelligent Mold Cooling

You cannot rush the cooling of PP. The battle for stability is won or lost inside the blow bottle mold. The goal is to remove as much heat as possible before the bottle is ever ejected.

- Optimized Cooling Channels: This is the most important factor. A well-designed PP mold will have a complex network of cooling channels that follow the contour of the bottle. The goal is to have high-volume, turbulent water flow in close proximity to every surface of the bottle, especially critical areas like the neck and base.

- Dedicated Chiller: You cannot cool a PP mold with a simple cooling tower. You need a powerful, dedicated industrial chiller for your molds. It needs to supply water at a consistent, low temperature (e.g., 10-15°C) and a high flow rate to effectively pull the heat out of the mold steel.

- High-Conductivity Mold Materials: While most molds are made from steel, for high-speed PP applications, using mold inserts made from materials with higher thermal conductivity, like aluminum alloys or beryllium-copper, can significantly speed up heat removal in problem areas.

Solution 2: Accept the Cycle Time Reality

This is often the hardest pill for producers to swallow, especially those coming from the world of PET. For a similarly sized bottle, the cycle time for PP will almost always be longer. A significant portion of that cycle is the "holding" or "cooling" time—the time the bottle spends in the closed mold after the blowing is complete.

My U.S. client wanted to achieve the same 3-second cycle time he was getting with PET. We had to explain to him that for his hot-fill PP bottle, a realistic cycle time would be closer to 5 or 6 seconds. Almost all of that extra time was dedicated to in-mold cooling to ensure the bottle was stable upon ejection. Trying to speed this up is a false economy. You may produce more bottles per hour, but you will have a much higher scrap rate due to warpage. It's better to produce 1,000 good bottles per hour than 1,500 bad ones.

Hurdle #5: Designing for Durability – The Need for Structural Reinforcements?

Are your hot-filled PP bottles collapsing or paneling like a crushed can? The bottle's ability to withstand vacuums and heat is not just about the material, but entirely in the design.

PP is softer than PET and highly susceptible to vacuum deformation after hot-filling. A successful hot-fill PP bottle must incorporate structural reinforcements like ribs, vacuum panels, or specific geometries to maintain its shape and integrity as the product cools.

This final hurdle is where material science meets mechanical engineering. It was the last piece of the puzzle for my American client. We had helped him select the right machine and dial in the process, but his original bottle design, which was a simple, smooth-walled cylinder, was still failing. The bottles looked great coming off the line, but after being hot-filled, capped, and cooled, they would collapse inward. This is the challenge of hot-filling: surviving the vacuum.

Understanding the Hot-Fill Vacuum

The process is simple, but the physics are powerful:

- A product (like juice, tea, or in my client's case, milk) is heated to a high temperature (e.g., 90°C).

- It is filled into the PP bottle.

- The bottle is immediately capped.

- As the bottle and its contents cool down to room temperature, the liquid and the air in the headspace contract significantly.

- This contraction creates a strong negative pressure, or vacuum, inside the bottle. The atmosphere outside the bottle is now pushing inward with considerable force.

PET is a very rigid material and can resist this force to a degree. PP is naturally softer and more flexible. Without a proper design, it will simply collapse under this pressure.

Solution: Design a Bottle That "Breathes"

You can't fight the vacuum, so you have to design the bottle to accommodate it in a controlled way. This is less about material choice and more about a smart bottle mold design.

- Structural Ribs: The most common solution is to add horizontal or vertical ribs to the bottle design. These ribs act like the reinforcing bars in concrete or the frame of a building. They add significant rigidity to the bottle walls, preventing them from buckling inward. The shape, number, and placement of these ribs are critical and often require sophisticated computer simulations to optimize.

- Vacuum Panels: This is a more elegant solution. Instead of making the walls rigid, you design specific areas to be flexible. Vacuum panels are specially shaped indented areas on the bottle's body. They are designed to flex inward in a predictable, controlled manner as the vacuum forms. This absorbs the pressure change without distorting the overall shape of the bottle or the label panel. When you see a hot-fill juice bottle with those distinctive indented rectangles on the side, you're looking at vacuum panels at work.

- Smart Base Design: The base is another common point of failure. The vacuum can suck the base upward, making the bottle rock and become unstable. Hot-fill bottle bases are often designed with deep, reinforcing ribs or special "diaphragms" that can flex to absorb the vacuum.

For my client's milk bottle, his original design was a simple, smooth cylinder. It had no chance. Our engineering team redesigned it completely. We added six vertical ribs in the main body and a series of flexible vacuum panels just below the shoulder. We also created a new, reinforced base design. We provided him with 3D printed samples of the new design so he could see and feel the difference. The result? A bottle that could withstand the 90°C hot-fill process and the subsequent vacuum, maintaining its shape and protecting his customer's product. It transformed his failing project into a profitable success.

Your 5-Hurdle Solution Cheat Sheet: A Quick Reference Table?

Feeling overwhelmed? Don't be. While the details are complex, the solutions are systematic. Here is a quick-reference table that summarizes the five main hurdles of PP blow molding and the core strategies to overcome them. Use this as a starting point for troubleshooting your process or planning your next PP bottle project.

| Hurdle # | The Problem (Symptom) | The Root Cause (Material Science) | The Core Solution (Process & Design) |

|---|---|---|---|

| 1 | Preform Sagging "My preforms are bending and drooping in the oven." | Low Melt Strength PP cannot support its own weight when heated to its processing temperature. | Supportive Design & Hardware Use a robust preform design and a machine with hardware (spindles, handling) designed to support the preform. |

| 2 | Inconsistent Heating "My bottles are either cloudy and under-formed or yellow and burnt." | Narrow Heating Window The temperature difference between "not hot enough" and "too hot" is extremely small for PP. | Precision Heating Profile Use high-intensity IR/ruby lamps, granular zonal control, and proper ventilation to achieve a uniform temperature. |

| 3 | Poor Material Distribution "The bottle walls are thick in some spots and paper-thin in others." | Uncontrolled Stretching Without guidance, low-strength PP expands chaotically when high-pressure air is applied. | Mandatory, Calibrated Pre-Blow Use a precisely timed and pressurized pre-blow to create a stable initial bubble and guide the final stretch. |

| 4 | Post-Mold Warpage "My bottles look perfect out of the machine but are warped the next day." | Slow Crystallization Rate PP continues to cool, crystallize, and shrink long after it has been ejected from the mold. | Aggressive In-Mold Cooling Optimize mold cooling channels, use a powerful chiller, and accept a slightly longer cycle time to ensure stability. |

| 5 | Hot-Fill Failure "My hot-filled bottles are collapsing and paneling as they cool." | Low Rigidity / Vacuum Softer PP cannot naturally resist the strong vacuum created when a hot-filled product cools. | Structural Reinforcements Design the bottle with features like ribs and vacuum panels to manage the vacuum forces in a controlled way. |

Conclusion: Turning a "Tricky" Material into a Profitable Product?

Polypropylene is, without a doubt, a tricky material to blow mold. It's unforgiving and demands a level of precision that PET simply does not. However, "tricky" does not mean "impossible." As my American client learned, the key is to stop treating PP like PET. You must respect its unique material properties and address each of the five hurdles with the right knowledge, the right process, and the right equipment.

By understanding the challenges—low melt strength, a narrow heating window, the need for pre-blow, slow crystallization, and vacuum forces—you can systematically overcome them. With a purpose-built bottle blowing machine, a well-designed blow bottle mold, and a precisely controlled process, you can turn this challenging material into a high-value, profitable product that serves demanding markets like hot-fill beverages, medical supplies, and personal care. The challenges are significant, but the rewards for getting it right are even greater.

Frequently Asked Questions (FAQ)

1. Can PP bottles be made as transparent as PET bottles? What factors affect PP's clarity?

No, PP bottles cannot achieve the glass-like "see-through" transparency of PET. However, they can be made very clear, a state often called "contact clarity," where the product inside looks sharp and clear. The main factor affecting PP's clarity is its semi-crystalline structure. These tiny crystal structures scatter light, creating a natural haze. To improve clarity, material suppliers add special "clarifying agents" or "nucleators" to the PP resin. These additives promote the growth of many very small crystals instead of fewer large ones, which reduces light scattering and improves transparency. From a processing standpoint, rapid cooling in a highly polished mold is crucial. The faster you can "freeze" the polymer chains in place, the less time they have to form large, haze-inducing crystals.

2. How much longer is the typical production cycle time for a PP bottle compared to a similarly sized PET bottle, and why?

A PP bottle's production cycle time is typically 20% to 50% longer than a PET bottle of the same size and weight. For example, if a 500ml PET water bottle has a 4-second cycle, a similar PP bottle might require a 5 to 6-second cycle. The primary reason for this is the much longer in-mold cooling time required. As discussed in Hurdle #4, PP crystallizes very slowly. To produce a dimensionally stable bottle that won't warp after ejection, it needs to spend more time in the closed, cooled mold to allow the crystallization process to advance and to remove enough heat from the core of the plastic. Rushing this step is a false economy, as it will lead to a high scrap rate.

3. Can I use a standard PET blow molding machine to produce PP bottles, or are special machine modifications required?

While you might be able to produce a very low-quality PP bottle on a PET machine, for any serious production, the answer is no. You need a machine designed for or significantly modified for PP. The required modifications are substantial:

- Heating Oven: You need to replace standard halogen lamps with high-intensity, short-wave infrared (ruby) lamps for better heat penetration.

- Preform Handling: The spindles that transport the preform through the oven must be designed to support the body of the low-strength PP preform to prevent sagging.

- Process Control: The machine's control system must allow for extremely precise, fast-acting, and independent control over each heating zone and the pre-blow/main-blow parameters.

- Blow Nozzle/Stretch Rod: The mechanics of the blowing station may need to be adapted for the different stretching behavior of PP.

Attempting to run PP on an unmodified PET machine, as my client initially did, will almost certainly lead to failure. We can help ensure your blow mold fit is perfect for the right machine.

4. Are PP preforms as widely available as PET preforms, or do they typically require custom-made injection molds?

PP preforms are far less common in the "stock" market than PET preforms. For PET, there is a vast global market for standardized preforms for things like carbonated soft drinks and water bottles, complete with standard neck finishes. For PP, the situation is different. Because the final PP bottle's performance is so critically linked to the preform's design (to combat sagging, ensure proper heating, etc.), most high-quality PP bottle projects require a custom-designed preform. This means you will likely need to invest in a custom preform mold tailored specifically to your bottle's shape, weight, and application.

5. For a PP bottle that needs to be autoclaved (steam sterilized), what is the most critical design consideration?

The single most critical design consideration for an autoclavable PP bottle is managing extreme thermal expansion and contraction. During autoclaving, the bottle is subjected to high-pressure steam at temperatures around 121°C (250°F) and then cooled back down. A poorly designed bottle will warp, shrink, or even collapse. The design must be incredibly robust. This usually involves:

Thicker Walls: To provide overall structural integrity.

Heavy Reinforcements: A system of aggressive ribs is essential to prevent the walls from buckling under the temperature and pressure changes.

Round Shape: Round bottles handle internal and external pressure much more evenly than square or oval shapes.

Stable Base: The base must be designed to remain flat and stable throughout the cycle.

The design process for an autoclavable bottle is highly technical and almost always requires finite element analysis (FEA) to simulate the stresses of the sterilization process and ensure the bottle will survive.Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr