Blow Molding Knowledge & Insights

Knowledge Base

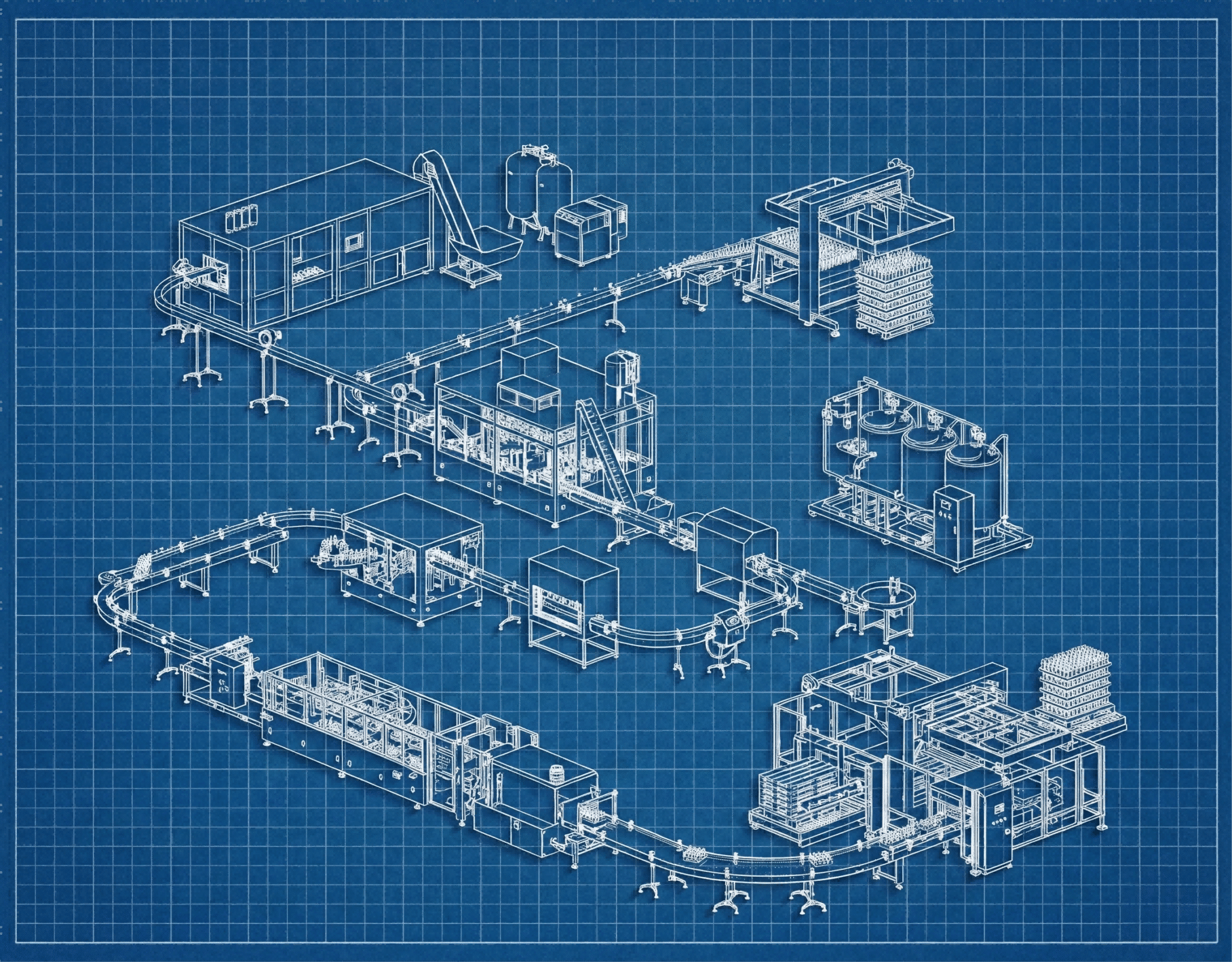

How to Plan Your PET Blowing Factory Layout? (Space, Power & Utilities)

Factory planning goes beyond simple floor dimensions. You must account for material flow, vertical clearance for automatic loaders, power stability, and utility piping. A correct layout optimizes efficiency and ensures

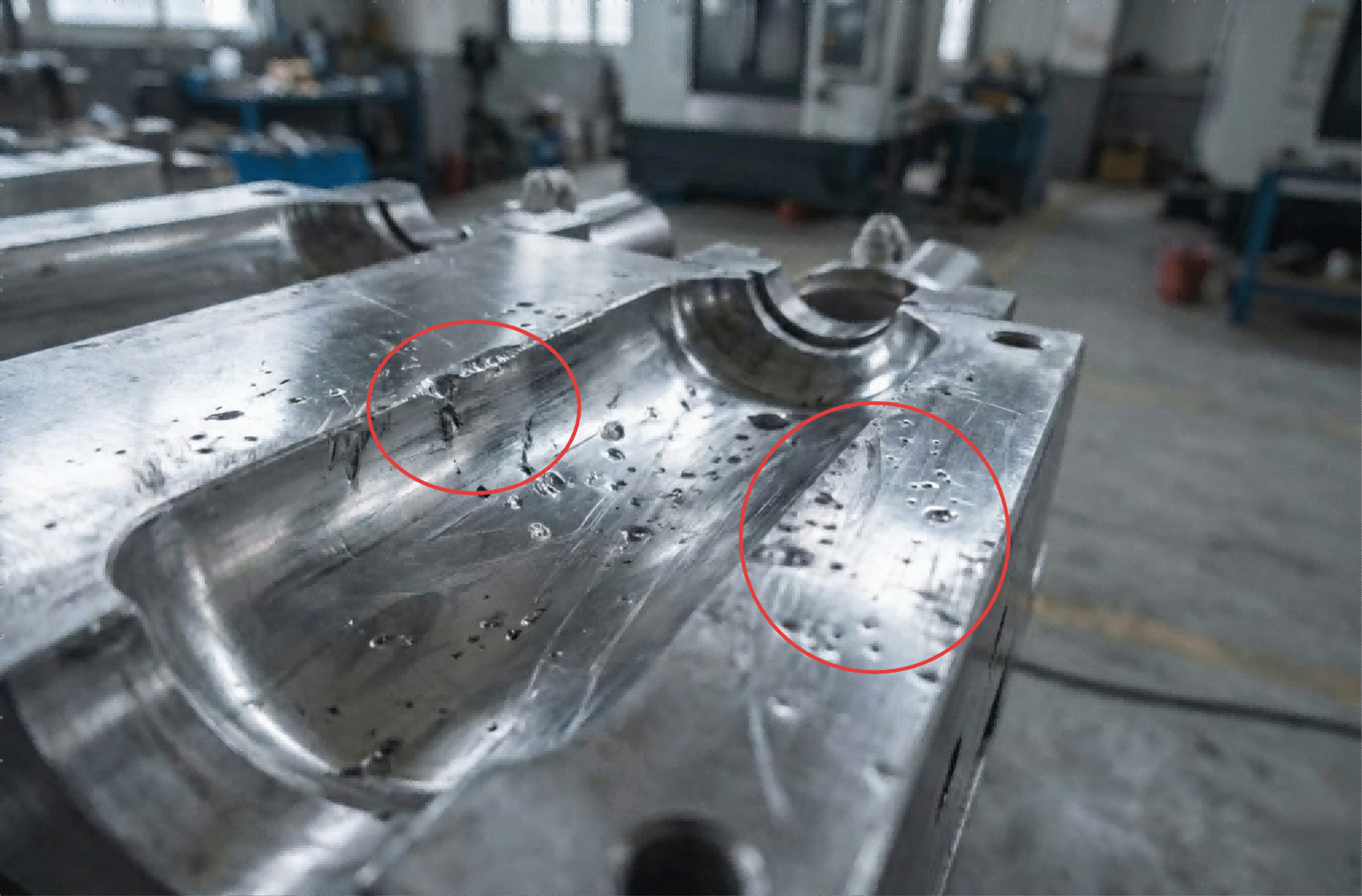

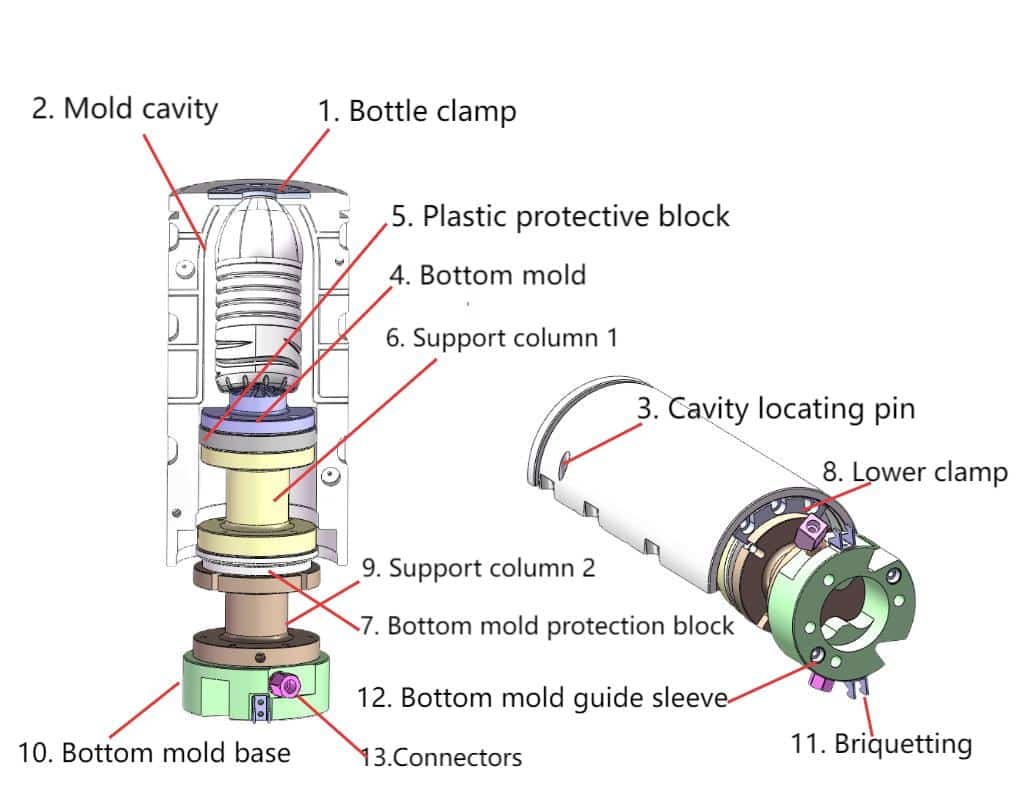

5 Signs Your PET Blow Mold Needs Maintenance (Before It Breaks)

A PET blow mold is a precision instrument, not just a block of steel. Signs like air leakage at the neck, reduced cooling efficiency, or visible burn marks are early

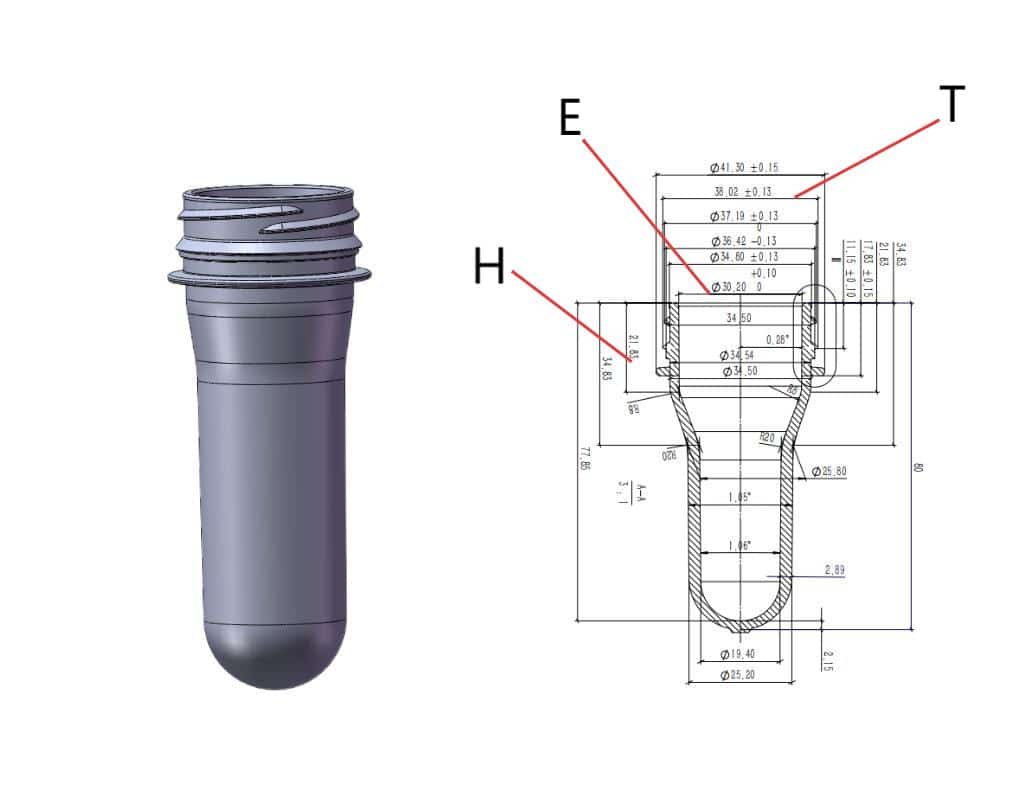

Why Do You Need a Bottom Orientation Notch for Bottle Labeling?

A bottom orientation notch acts as a mechanical anchor, locking your bottle into a fixed position on the conveyor. This forces the bottle to face the labeling machine correctly every

Causes and Solutions for Flow Marks on PET Preform Threads

Flow marks (ripples) on PET preform threads are usually caused by the “hesitation effect,” where the melt cools too quickly against the mold surface, or the injection speed is insufficient

How to Optimize PET Blowing Machine Temperature Settings: A Guide to the Perfect “Heating Profile”?

Optimizing the temperature settings of a PET blowing machine requires a mastery of thermodynamics, balancing the “Glass Transition” state of the material against its crystallization limit. By establishing a strategic

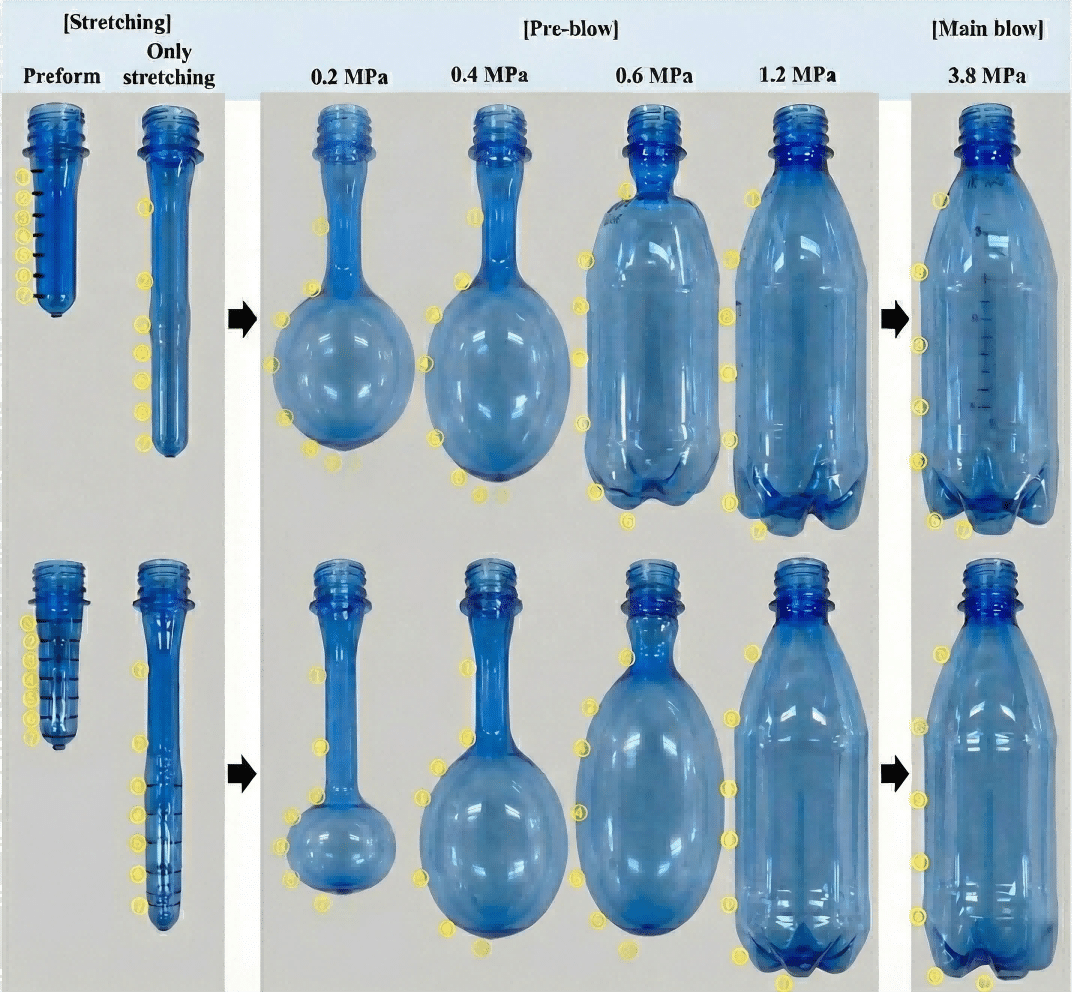

Why Is Your PET Bottle Not Fully Formed? The Critical Role of Pre-Blow vs. Main Blow Pressure?

Incomplete bottle forming, often called a “short shot,” is rarely just a heating issue. It is a failure of synchronization between the pre-blow pressure, which distributes the material, and the

Anatomy of a Valve Gate PET Preform Mold: Key Parts List and Maintenance Guide

A valve gate PET preform mold is a high-precision assembly divided into the Hot Half (manifold, heaters, valve pins) and the Cold Half (core, cavity, lip cavity). Understanding the specific

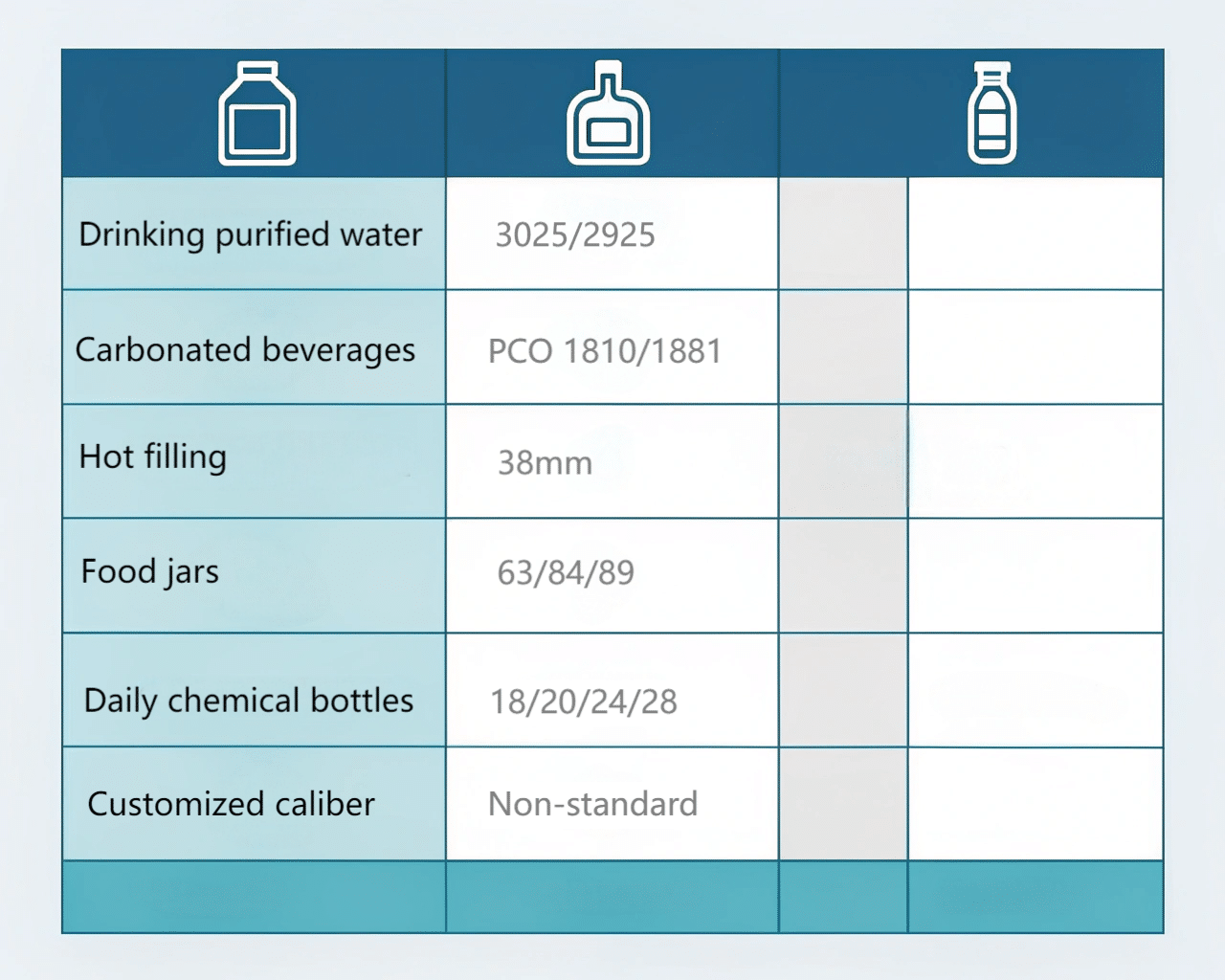

The Hidden Costs of Non-Standard Preform Necks: Why You Should Stick to Standards?

Choosing a non-standard neck finish forces you into a proprietary supply chain, often tripling cap costs and requiring expensive custom preform molds that cannot be sourced off-the-shelf. Sticking to global

Is Switching to a 12g 500ml PET Bottle the Most Profitable Move for Your Water Plant?

Reducing a 500ml bottle from the standard 15g to a lightweight 12g is currently the most attractive cost-reduction strategy in the industry. However, this transition is not just a simple

Wide-Mouth PET Jar Production: Can You Overcome These 8 Technical Challenges?

Successful wide-mouth PET jar production requires specialized machinery with wider heating pitch, tailored “low-power” heating profiles for thick preforms, and rigorous neck cooling systems. This guide details the engineering solutions

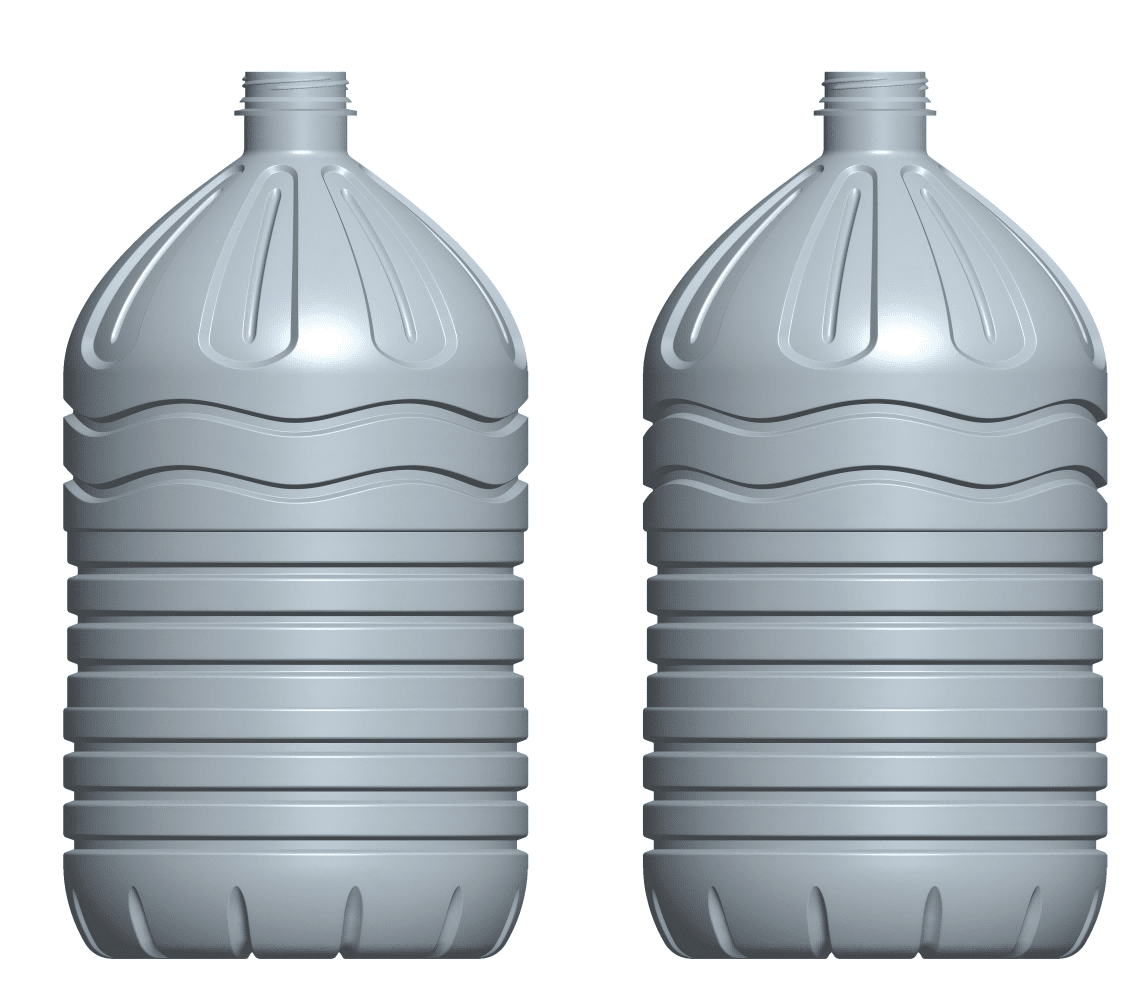

How Can You Optimize 5L PET Water Bottle Design for Maximum Cost-Saving and Durability?

The most effective way to optimize a 5L PET bottle is not simply changing the weight, but re-engineering the structural geometry. By implementing strategic ribbing to prevent vacuum collapse, selecting

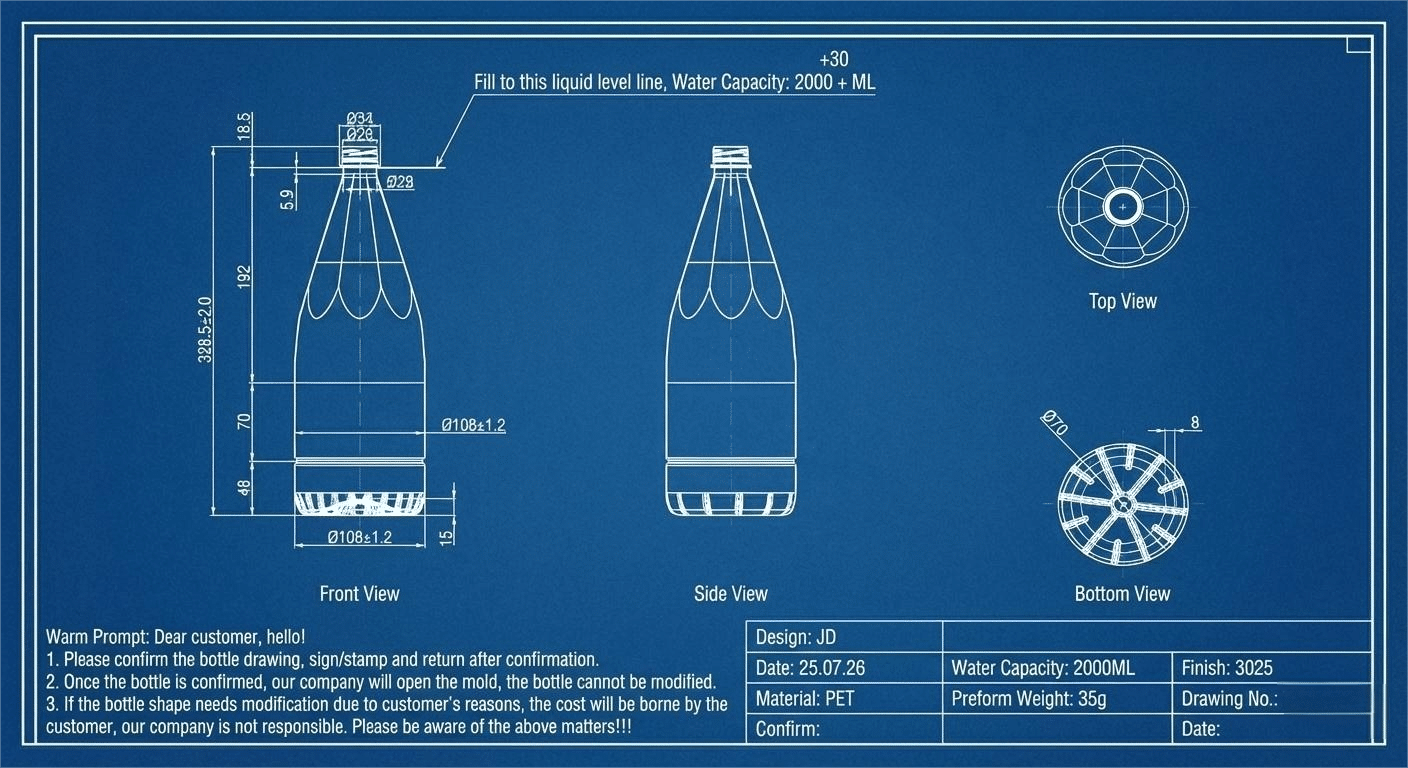

What Size is a 2L PET Bottle? A Comparison of CSD, Oil, and Water Bottle Specifications?

The standard 2L PET bottle height is typically between 300mm and 330mm, and the standard base diameter is around 100mm to 105mm. These core physical dimensions change significantly based on

Why do Guangdong PET blow mould have a greater advantage?

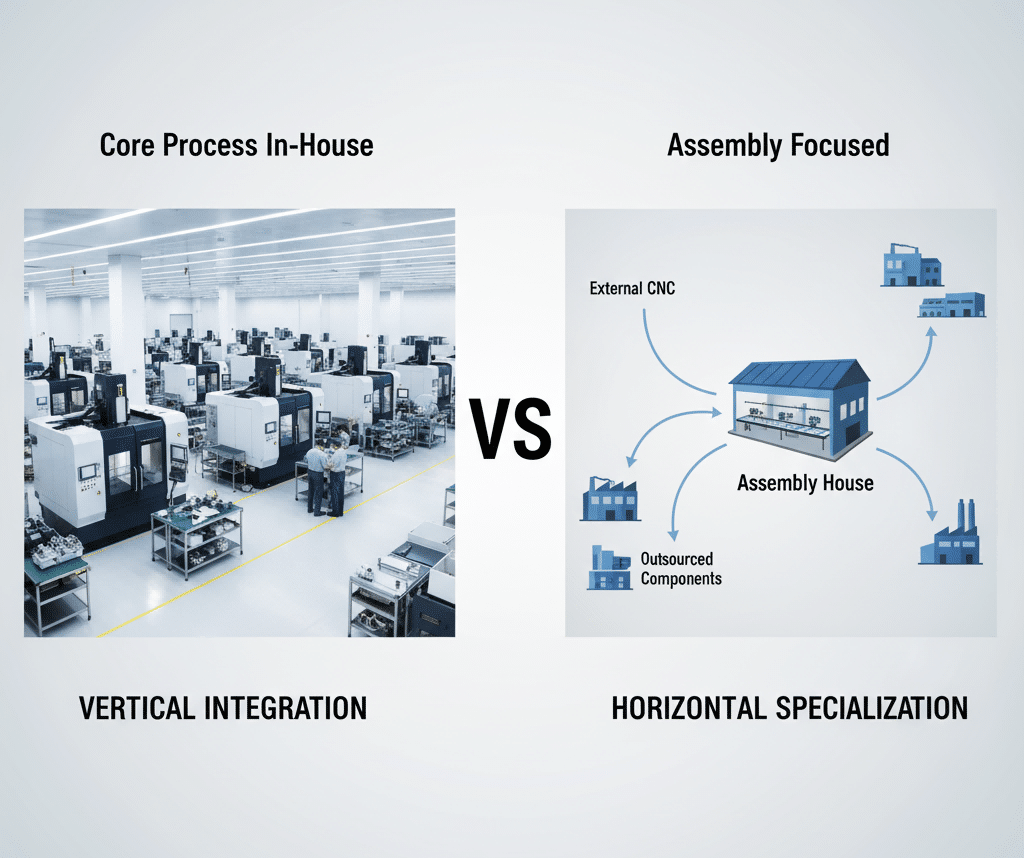

The Guangdong region holds a distinct advantage in blow moulding because its dominant business model—vertical integration—ensures absolute control over design, material sourcing, and core machining processes; this directly minimizes the

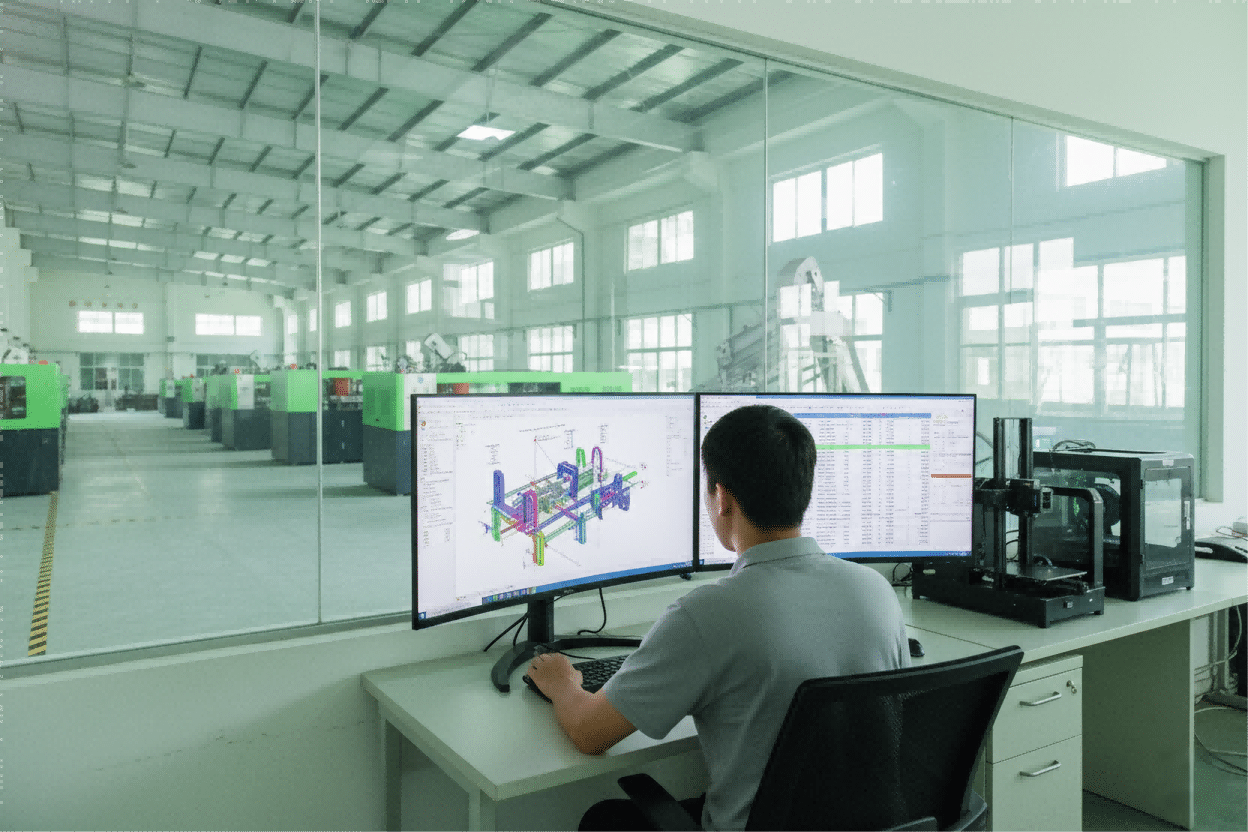

The Guangdong Advantage: Why It Leads China’s PET Blow Molding Machine Industry?

Guangdong leads China’s PET blow molding machine industry because of its unwavering commitment to “in-house core component manufacturing,” which guarantees high precision and long-term stability, contrasting sharply with the “outsourced

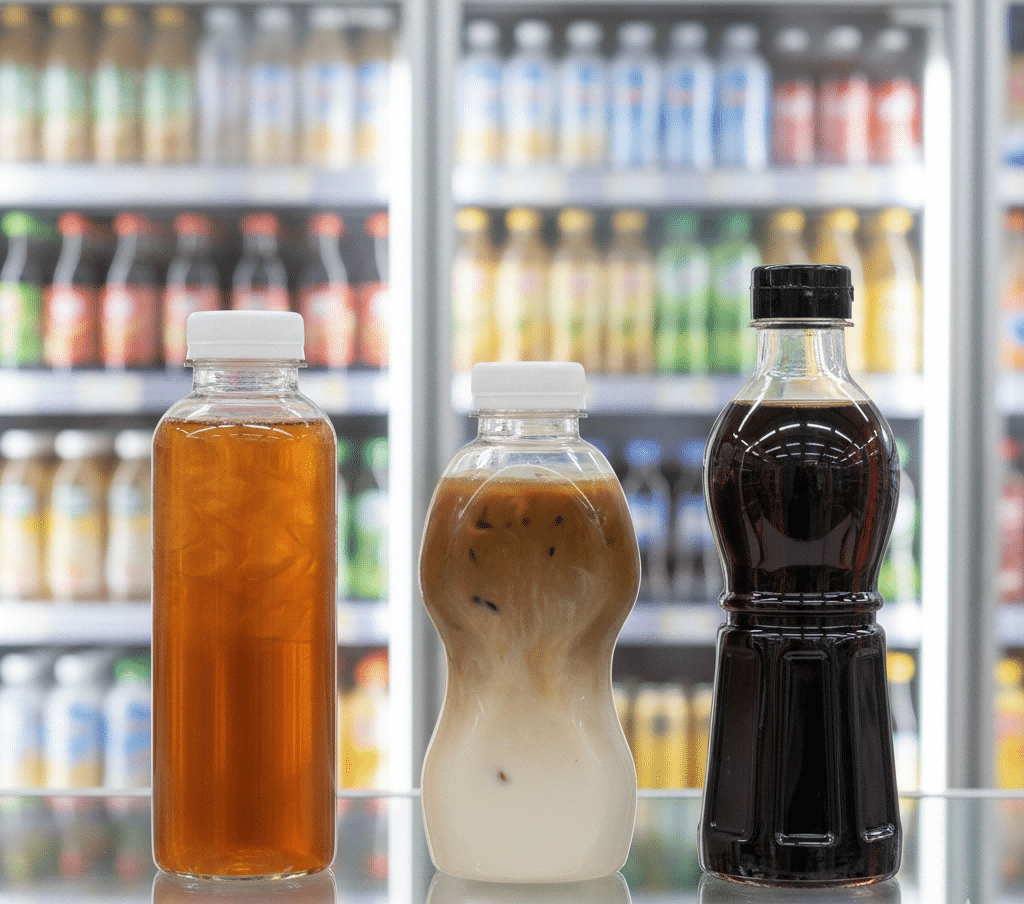

Vietnam’s PET Bottle Market: Opportunities in Tea, Coffee & Sauces (2025)?

Yes, the biggest opportunities in Vietnam’s PET market are in RTD tea, coffee, and sauces. This shift is driven by new manufacturing, young consumers, and a move from glass to

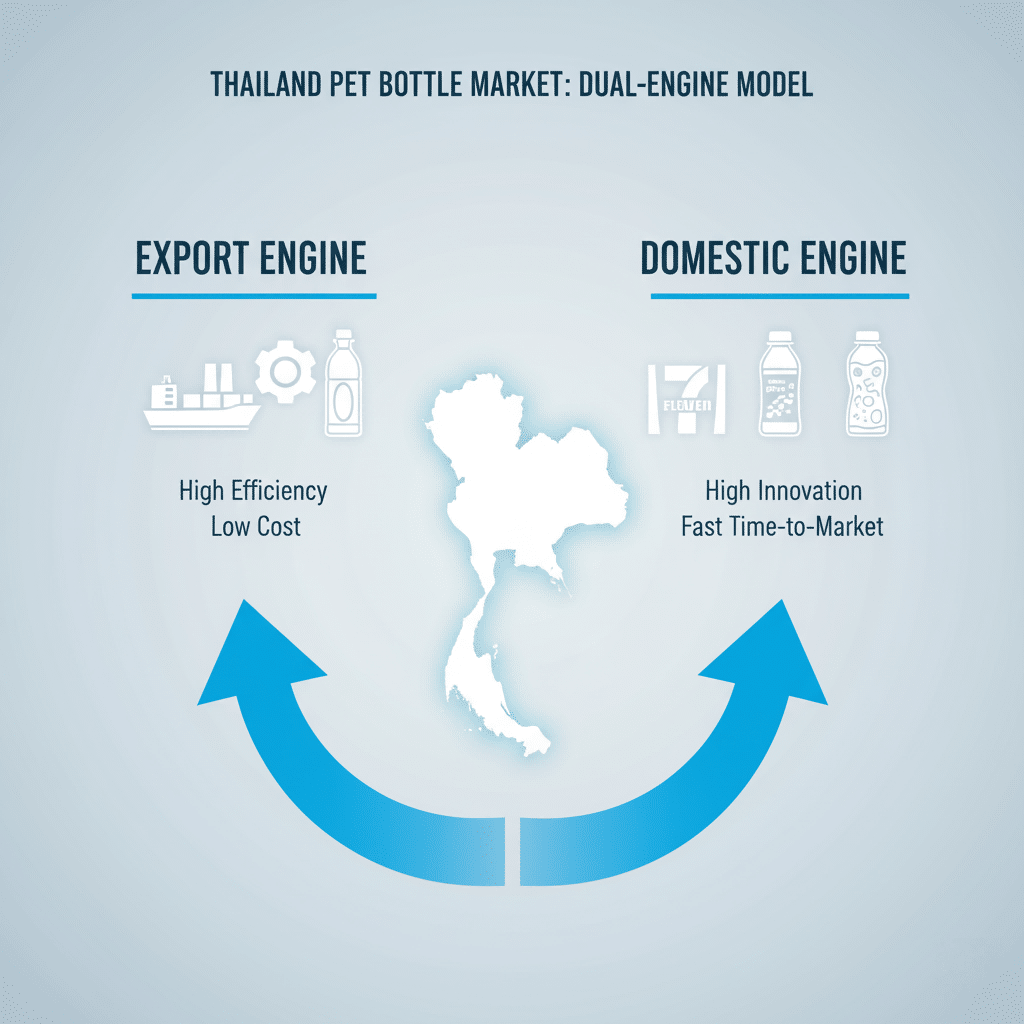

Thailand PET Bottle Market: Top 5 Applications & Opportunities (2025)?

The Thailand PET bottle market is not one single market. It is five separate segments driven by two “engines.” The key to success is you must align your entire business

How much does a small mineral water plant cost in Bangladesh?

For a “small-scale” plant (around 2000 bottles per hour), a realistic starting budget is about $55,000 to $60,000 USD. This minimum budget covers the essential machinery, water treatment, factory setup,

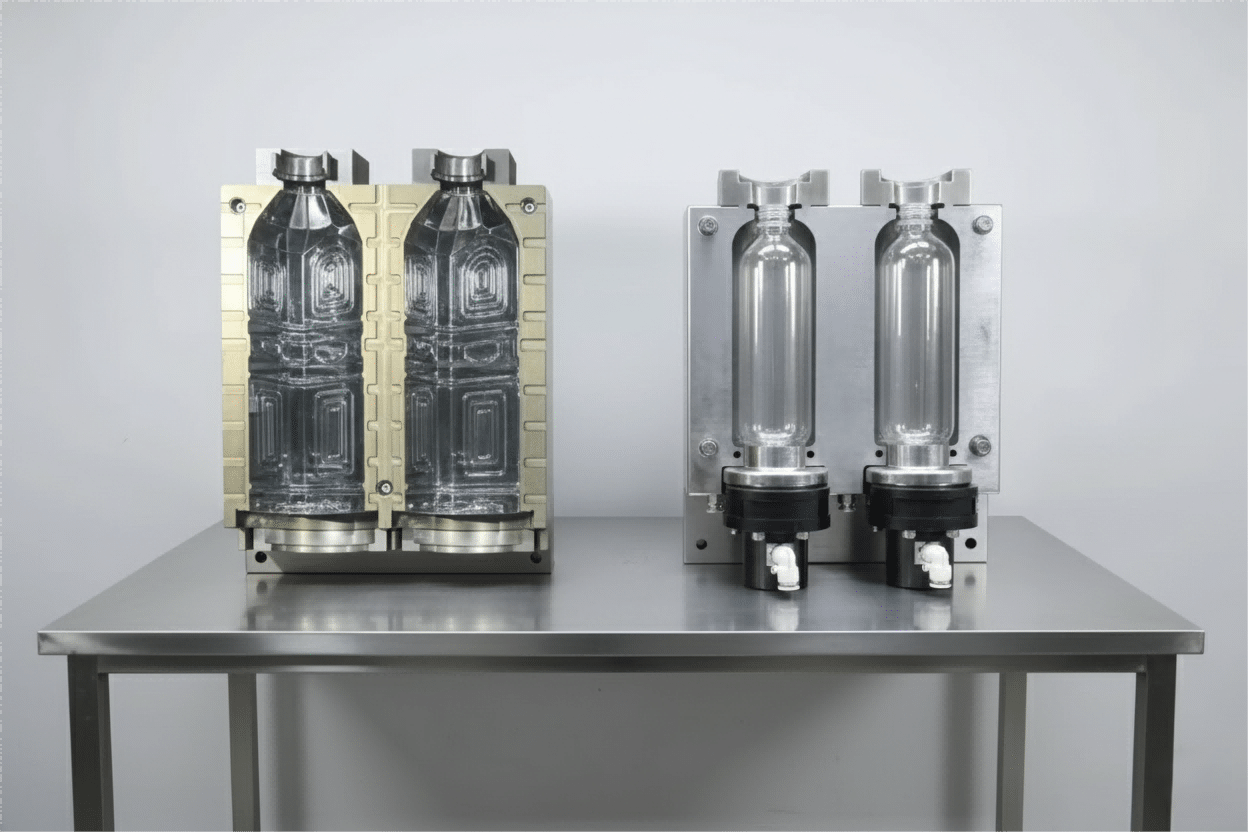

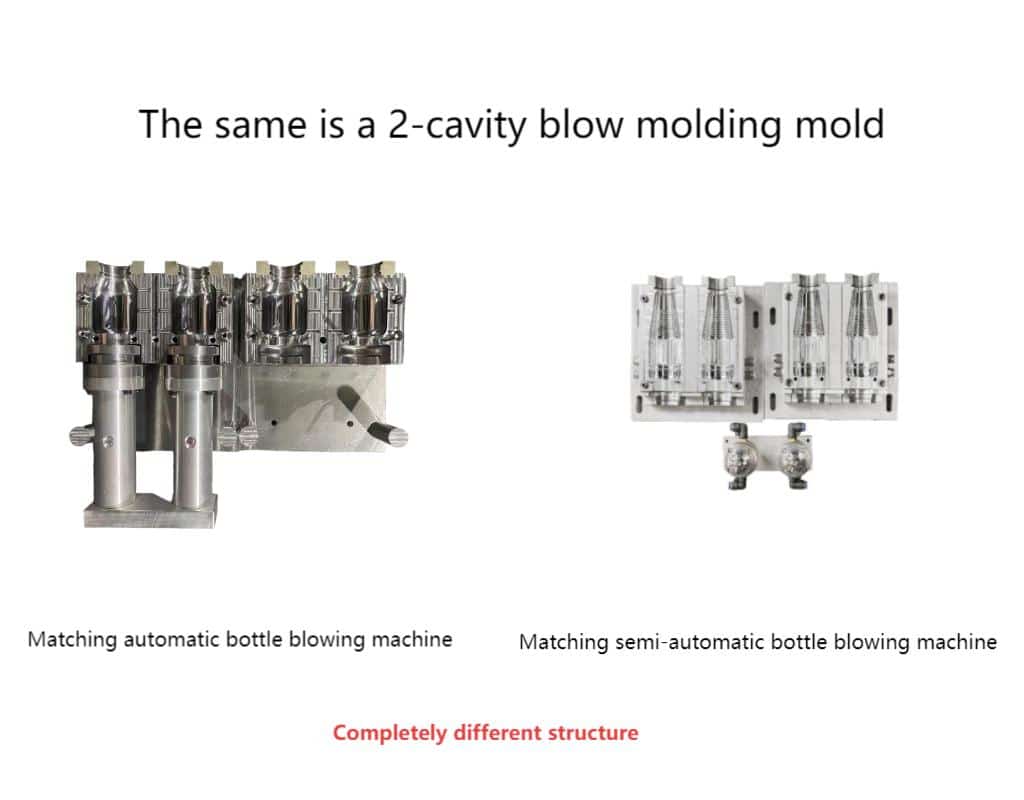

2 Cavity PET Bottle Mould: Types, Specs, and Price Guide (2025)?

A 2 cavity PET bottle mould is a tool that produces two identical PET bottles every time the bottle blowing machine completes one cycle. The “2 cavity” name is determined

5 High-Profit PET Bottle Business Ideas in Nigeria for 2025 (An Investor’s Guide)

The high-profit opportunities in 2025 include: bottled water, local drinks (like Zobo), large-format edible oil bottles, cosmetic bottles, and becoming a preform supplier. Each option has different investment levels, technical

[Startup Guide] Launching a “Honey Dosing Cap Water” Product: OEM vs. In-House Production?

This article is your business map. I am Vivian, with 16 years in PET packaging. I will analyze the two main paths: using an OEM (co-packer) versus building your own

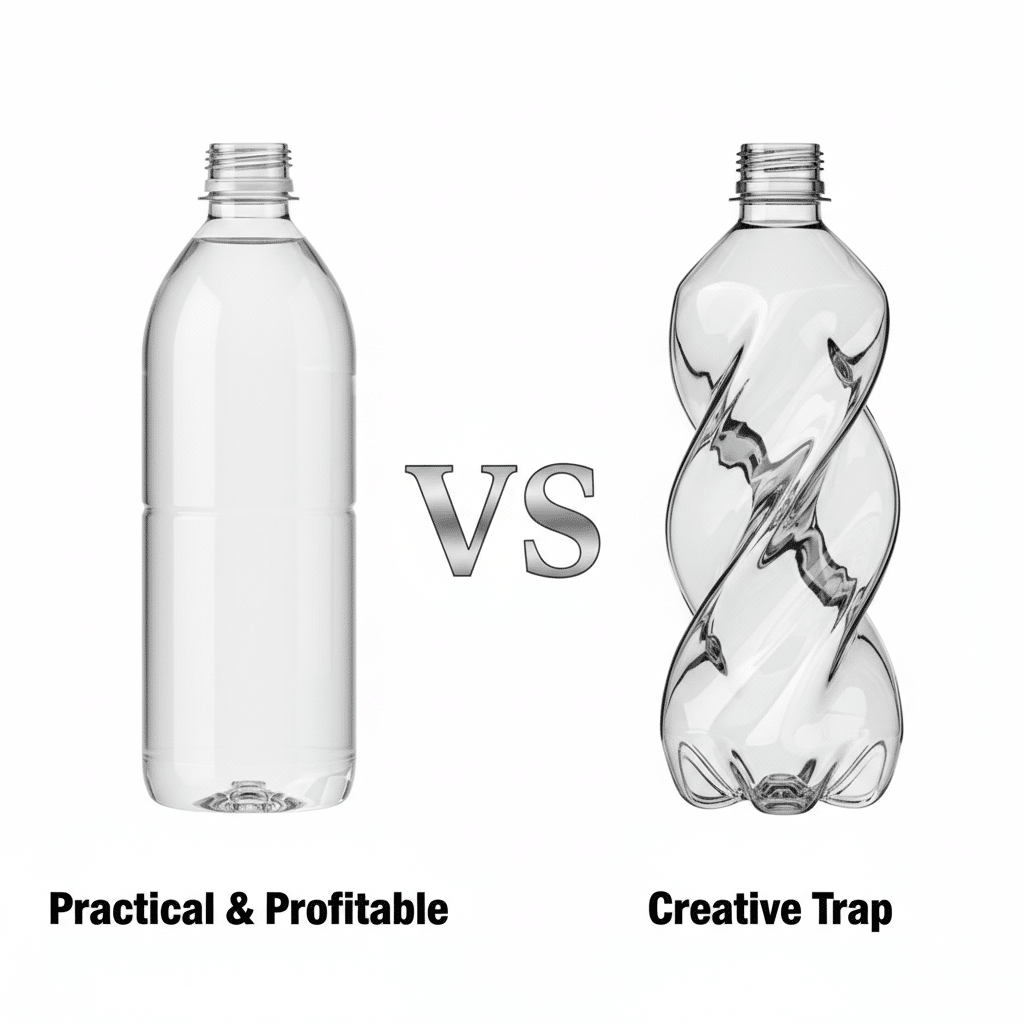

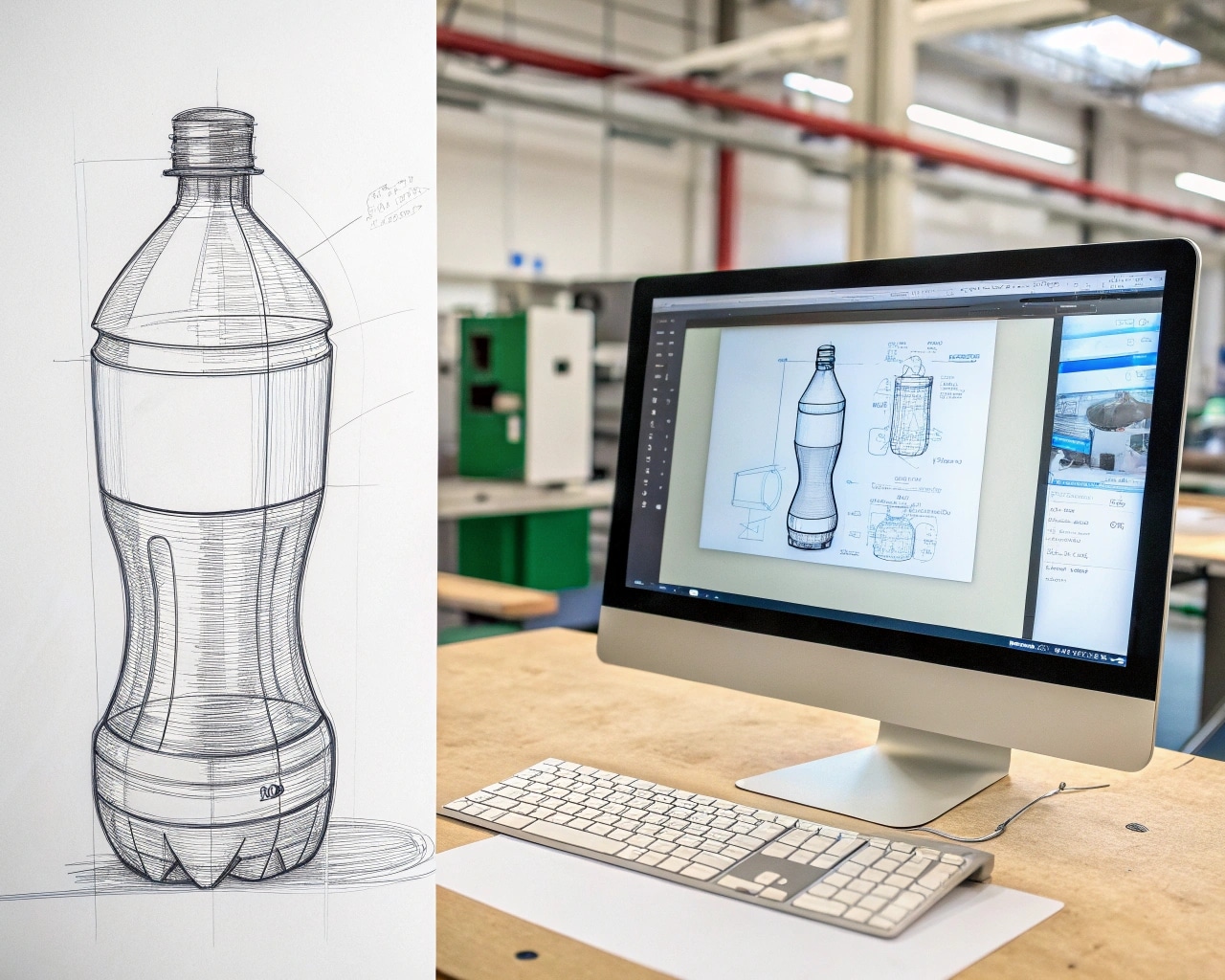

Unique PET Bottle Design: An Analysis of “Pure Innovation” vs. “Strategic Benchmarking”?

Both “Pure Innovation” and “Strategic Benchmarking” are valid paths. Pure innovation risks high R&D costs for a unique identity. Strategic benchmarking uses proven engineering data from big brands, allowing you

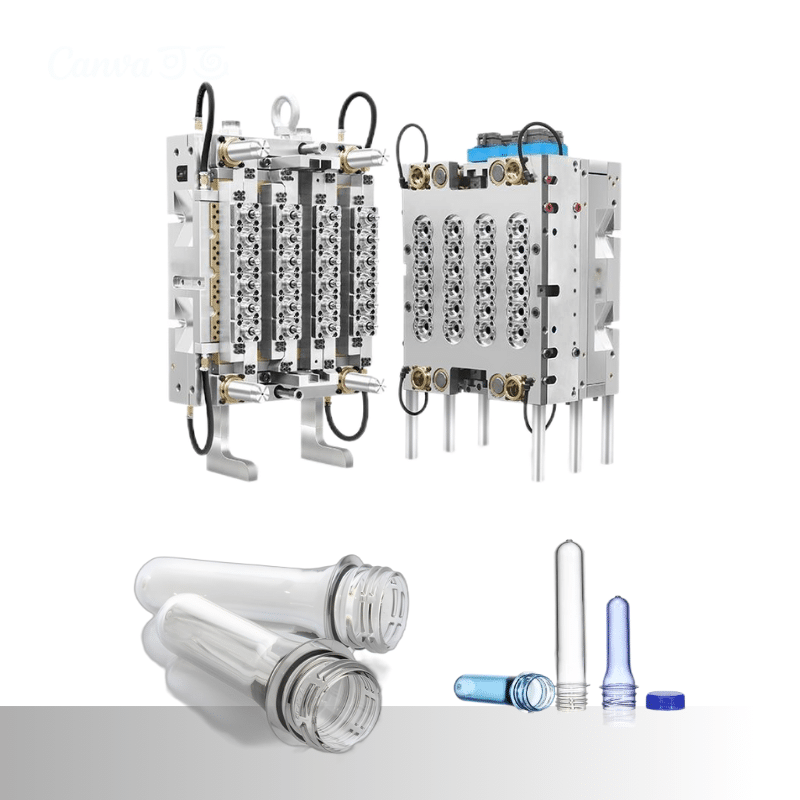

[Sourcing Guide] Preform Mold: Is a “Valve Gate” System Worth the Extra Cost?

Is this “extra cost” a smart investment? As a 20-year mold factory (iBottler), our answer is: **This isn’t a “technical choice”; it’s a “business model” choice.** A valve gate mold

Bottle, Blow Mold & Label: A 3-Step Process to Avoid Product Launch Failure?

As a 20-year blow bottle mold factory, we at iBottler have seen this expensive lesson too many times. The biggest misunderstanding, especially for startups, is thinking “bottle, mold, and label”

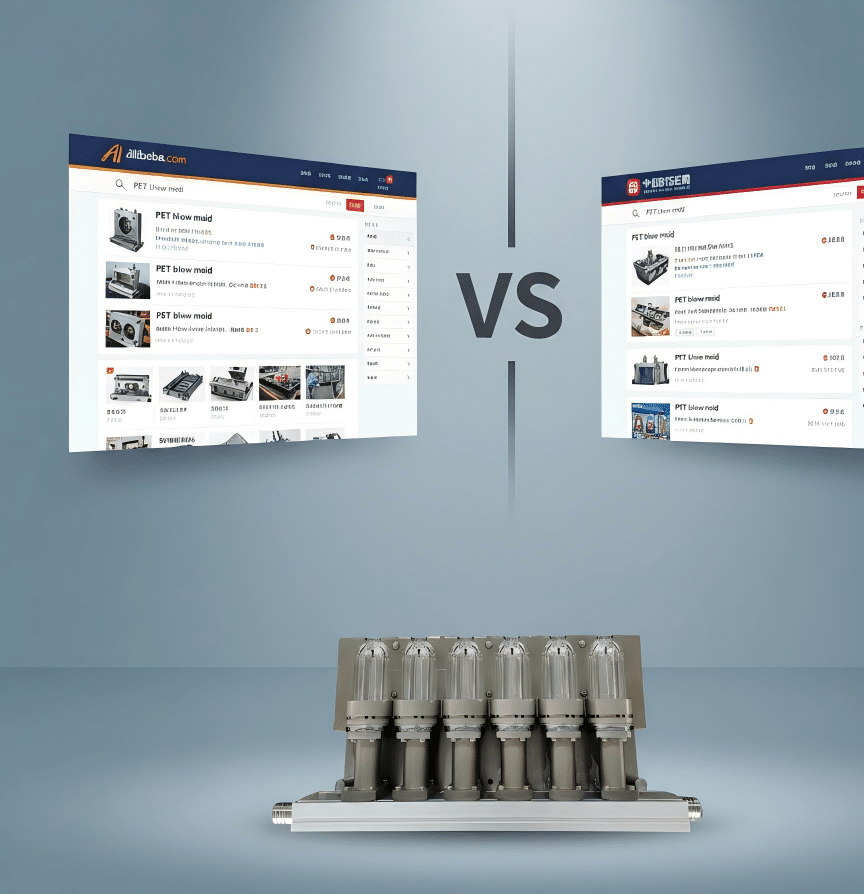

[Sourcing Guide] Alibaba vs. Made-in-China: Which is Better for Blow Molds?

Alibaba offers vast choice, while Made-in-China (MIC) offers industrial focus. Both provide excellent payment protection. However, neither platform can guarantee the technical quality or specialization of a supplier. Your own

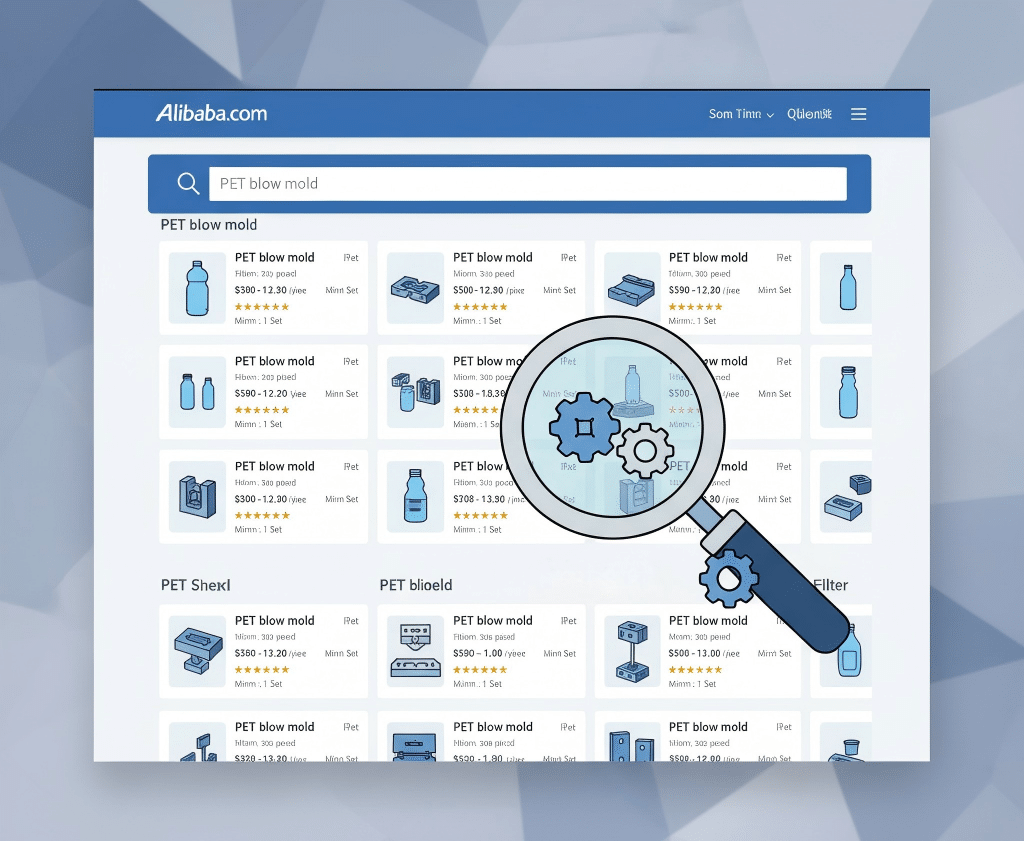

Alibaba Sourcing: How to Spot “Blow Mold Factories” vs. “Traders”?

You can spot a real factory by checking their product list for “red flags” and asking 3 key technical questions that only an engineer can answer. This guide shows you

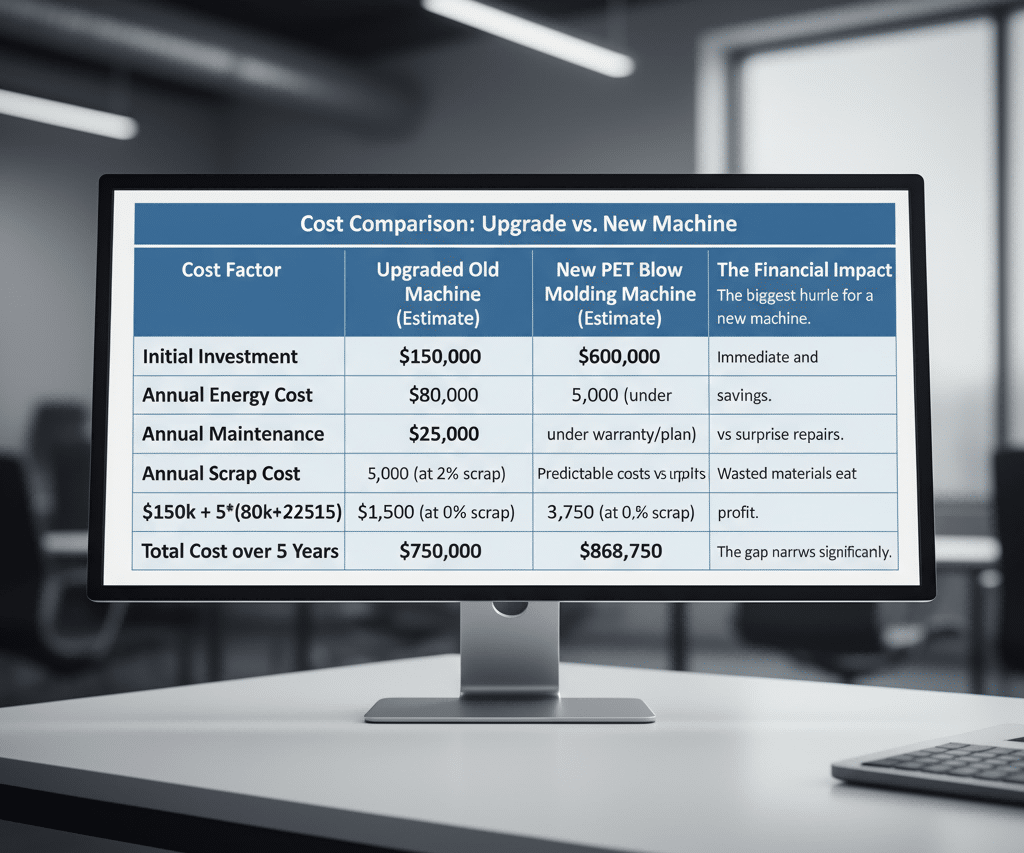

The True 5-Year Total Cost of Ownership (TCO) of a “Cheap” PET Blow Molding Machine?

The true cost is the 5-Year Total Cost of Ownership (TCO). This includes the purchase price plus all future costs like energy, parts, and downtime. A “cheap” machine often has

.png)

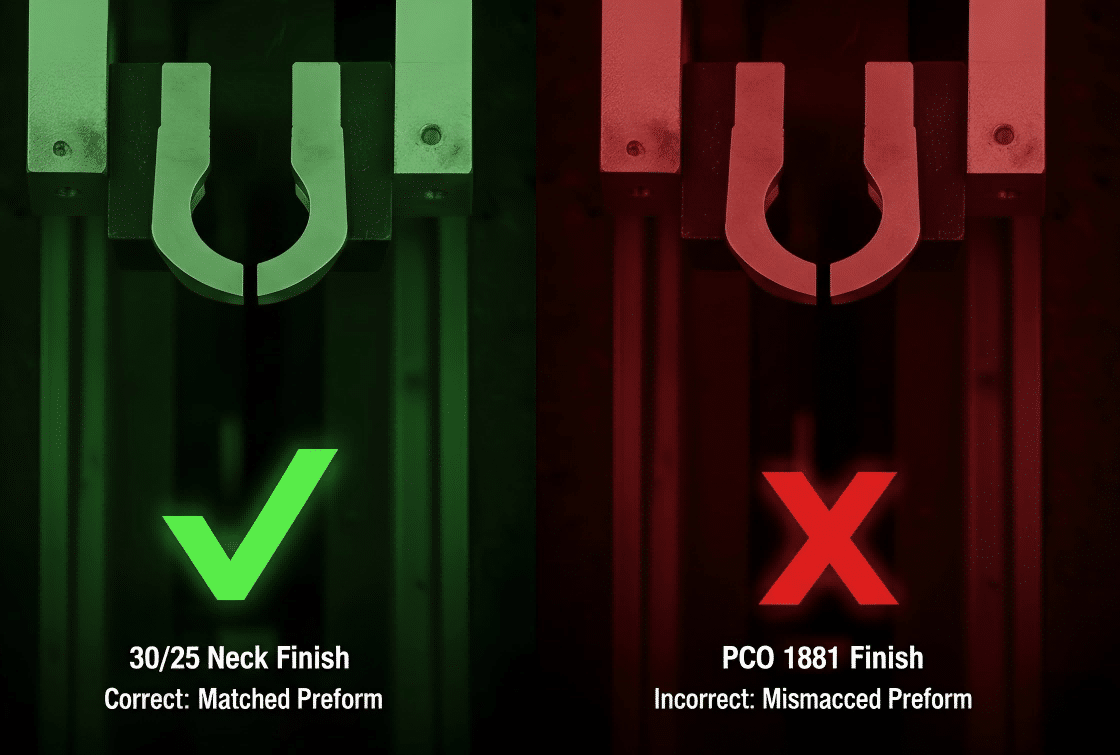

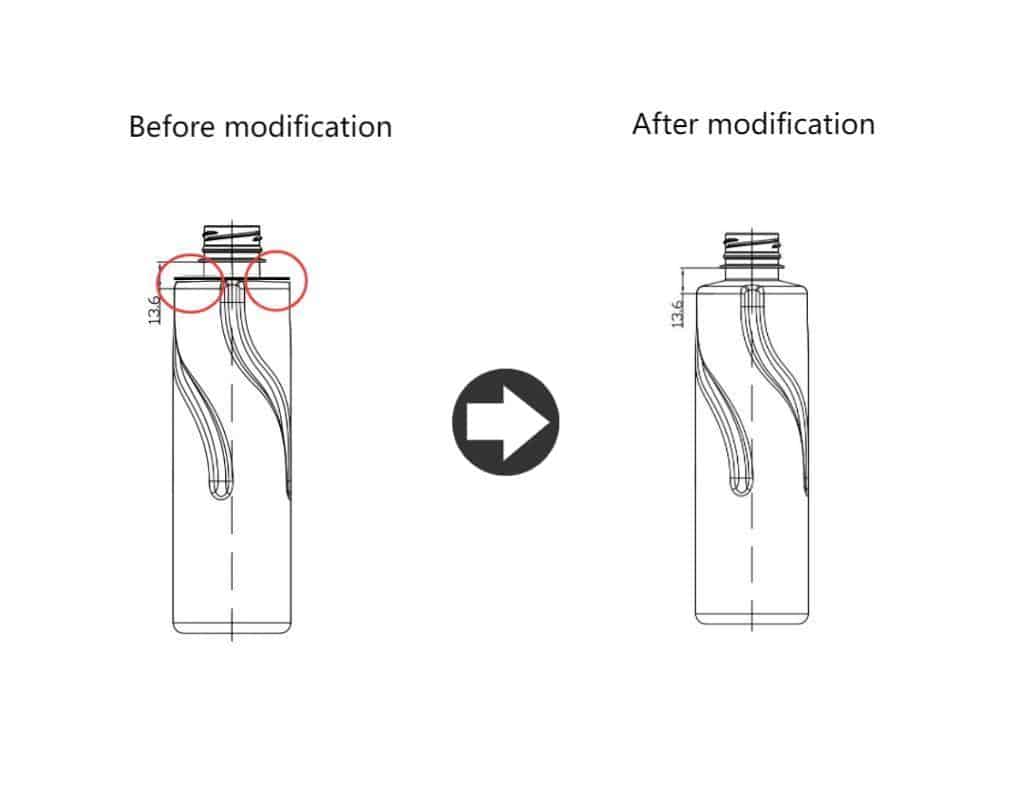

Why Do My 3025 (PCO 1881) Bottle Caps Leak After Blowing?

Your 3025 cap problem is almost certainly not a cap problem. It is a blow molding problem. The blowing process is deforming the preform’s neck, which was already finalized during

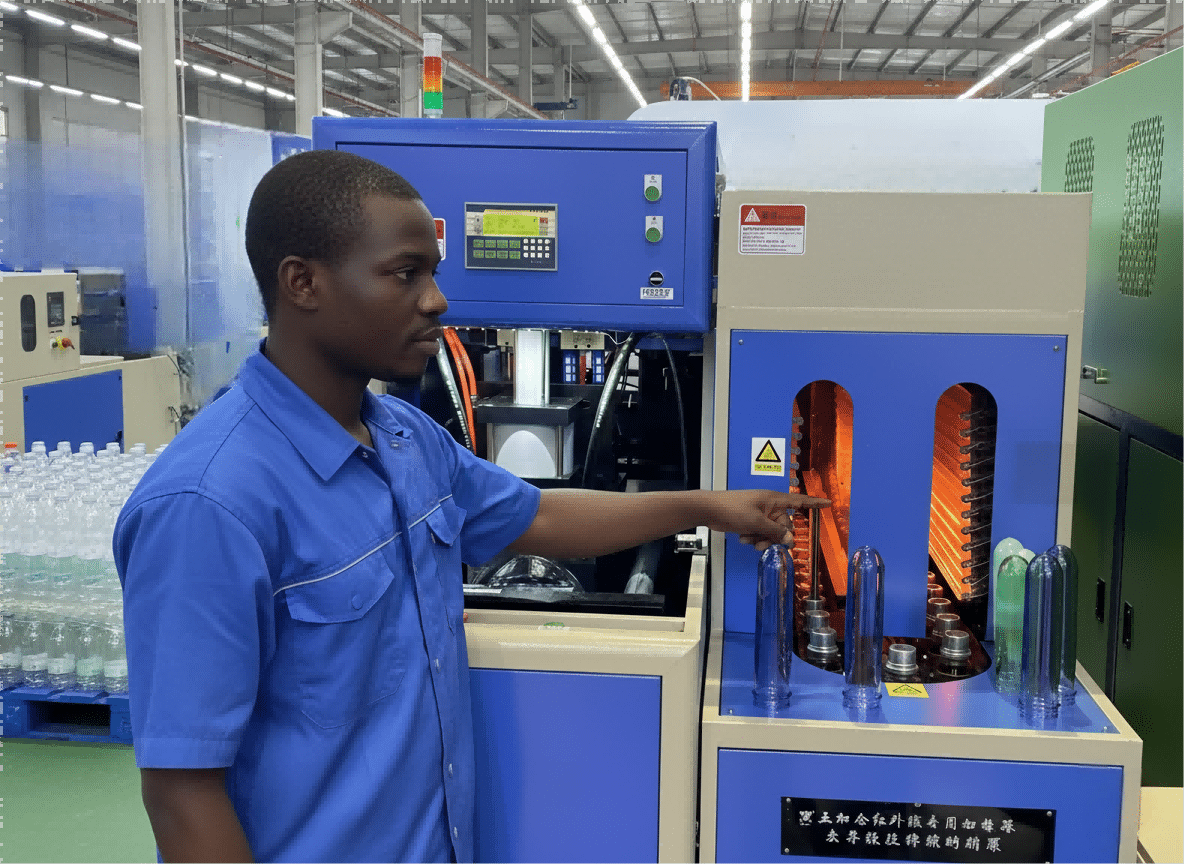

The Ultimate Guide to Semi-Automatic PET Bottle Blowing Machines (Structure, Operation & Cost Analysis)?

A semi-automatic PET bottle blowing machine is the answer. Its key feature is a separate heater and blower, requiring manual steps. This design drastically cuts initial cost, making it the

[Investment Analysis] Blow Molding Machine Selection: 2x 2-Cavity vs. 1x 4-Cavity?

This choice depends entirely on your business stage. For a mature company with stable, single-product orders, 1x 4-cavity machine is more efficient. But for a startup with diverse orders and

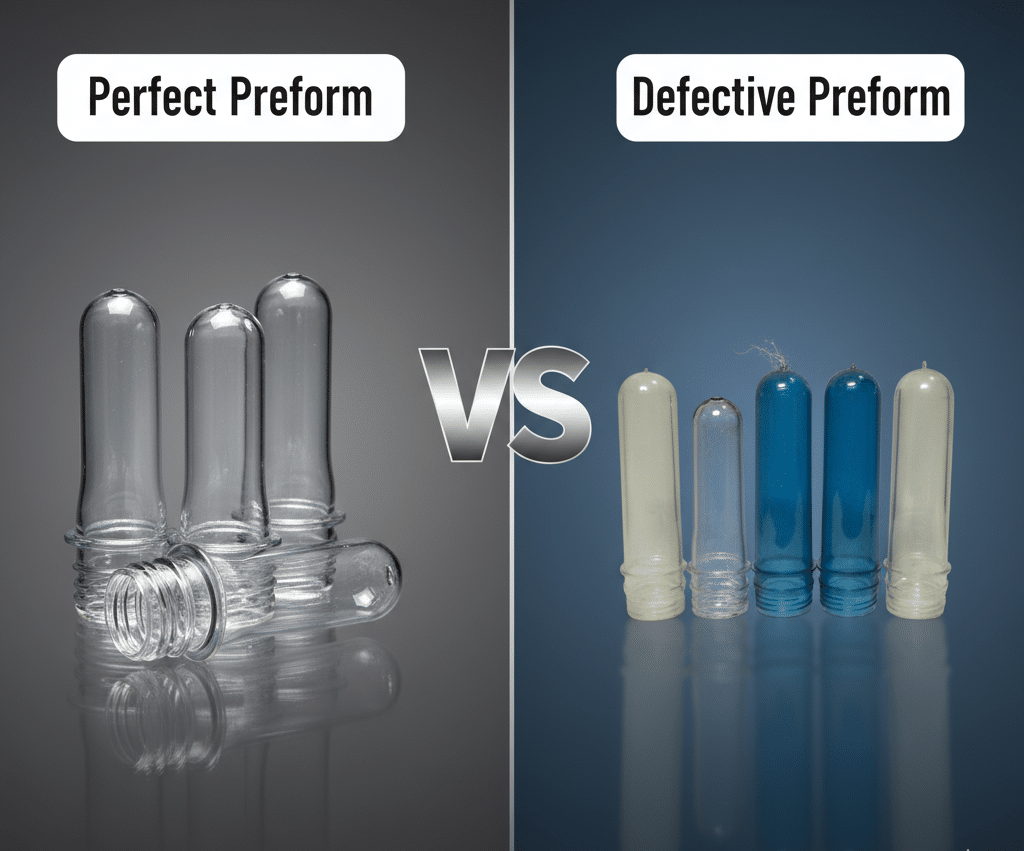

Received Preform Samples? 3 Easily Overlooked “Fatal” Mistakes?

Yes, you should worry. The three most common “fatal” mistakes in a preform inspection checklist are: only checking the cap fit, ignoring the inner diameter, and trusting a “golden sample”

How to Avoid “Preform-Blower Mismatch” (A Critical Purchasing Guide)?

This mismatch is a physical error. It means your new preforms do not fit the essential hardware (grippers, heating seats, and mold neck cavity) of your existing blow molding machine.

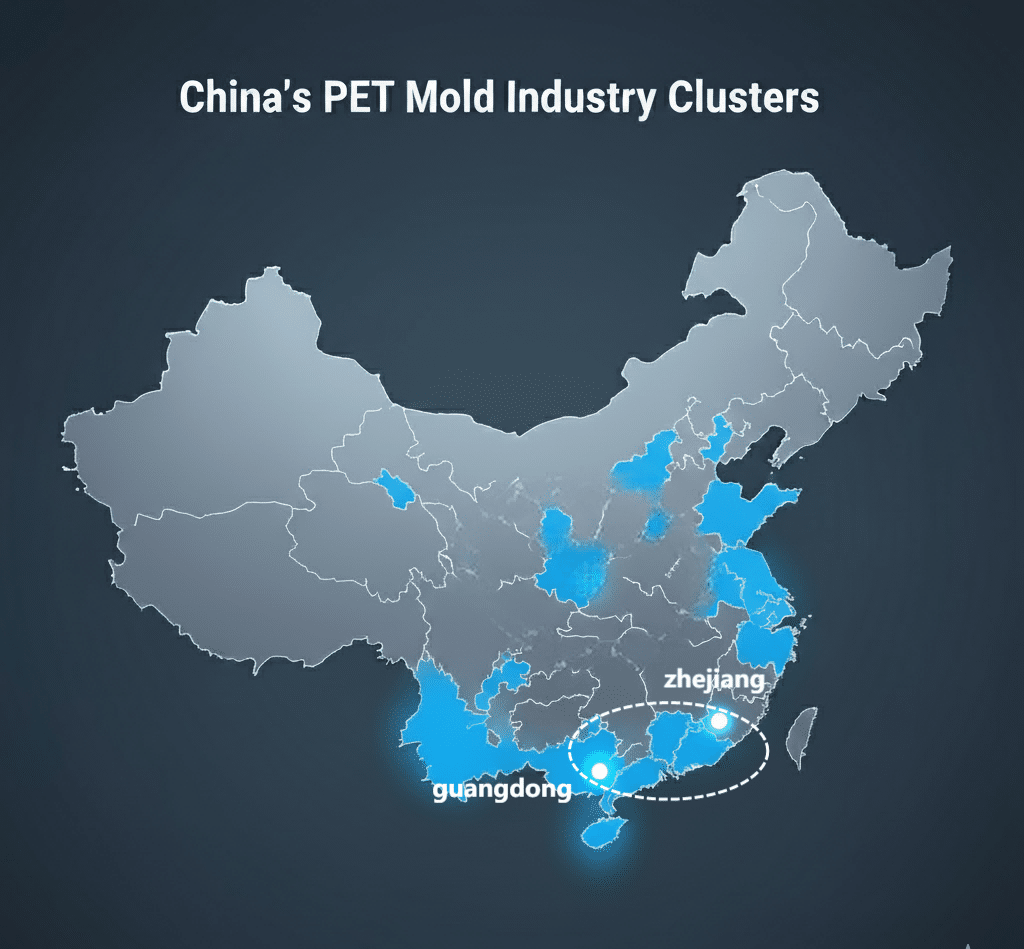

PET Blow Molding Suppliers in China: A Buyer’s Guide to the Regions?

China’s PET blow molding industry has three main hubs: **Guangdong (high-end tech), Jiangsu (turnkey lines), and Zhejiang (parts & basic machines). Your best choice depends on your specific project needs,

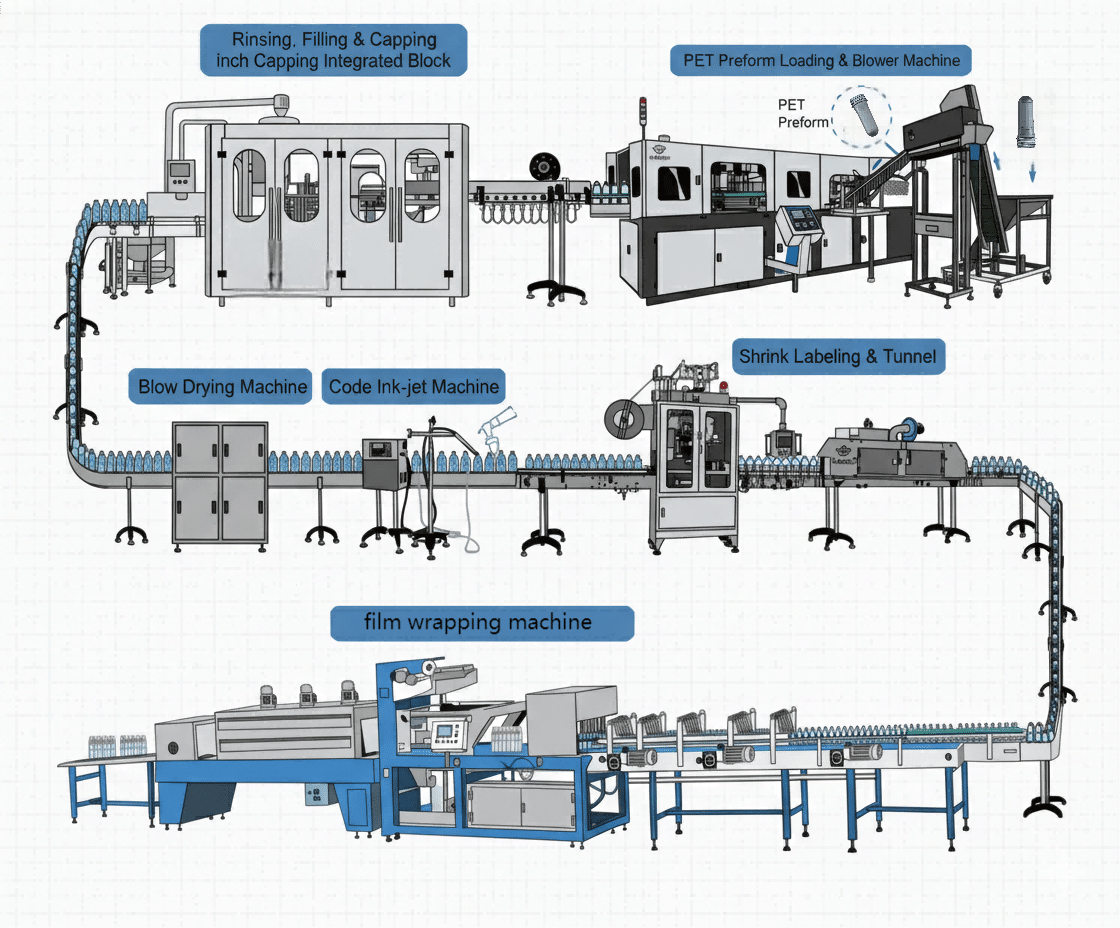

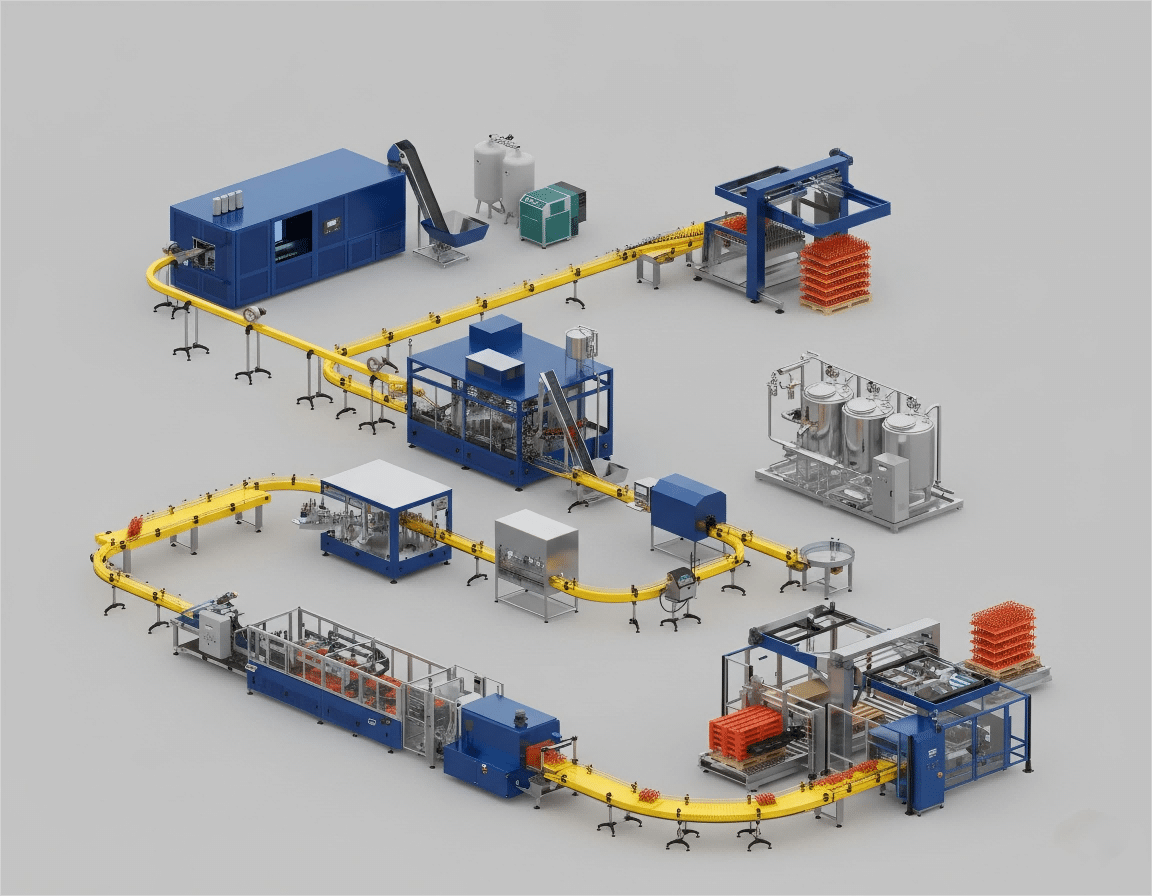

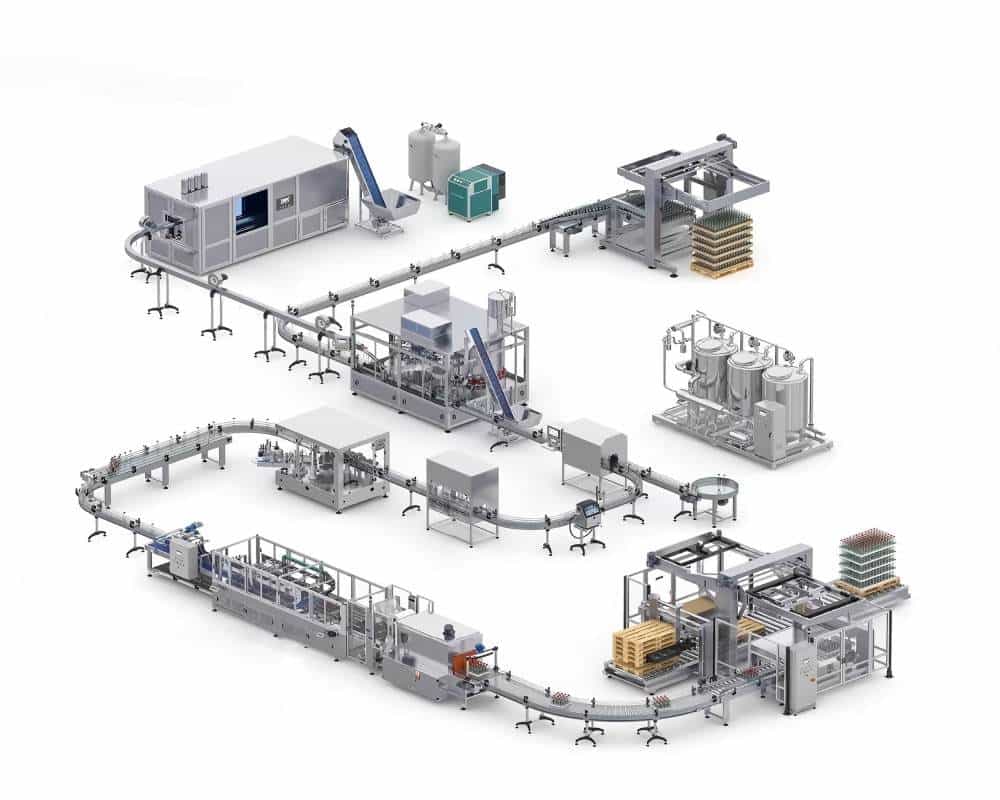

Project Planning: Building a 100k/day Fully-Automatic PET Production Line From Scratch?

Building a 100,000 bottle/day fully-automatic PET line is all about system planning. This includes defining your true BPH (bottles per hour), selecting a high-speed linear blower, creating a preform strategy,

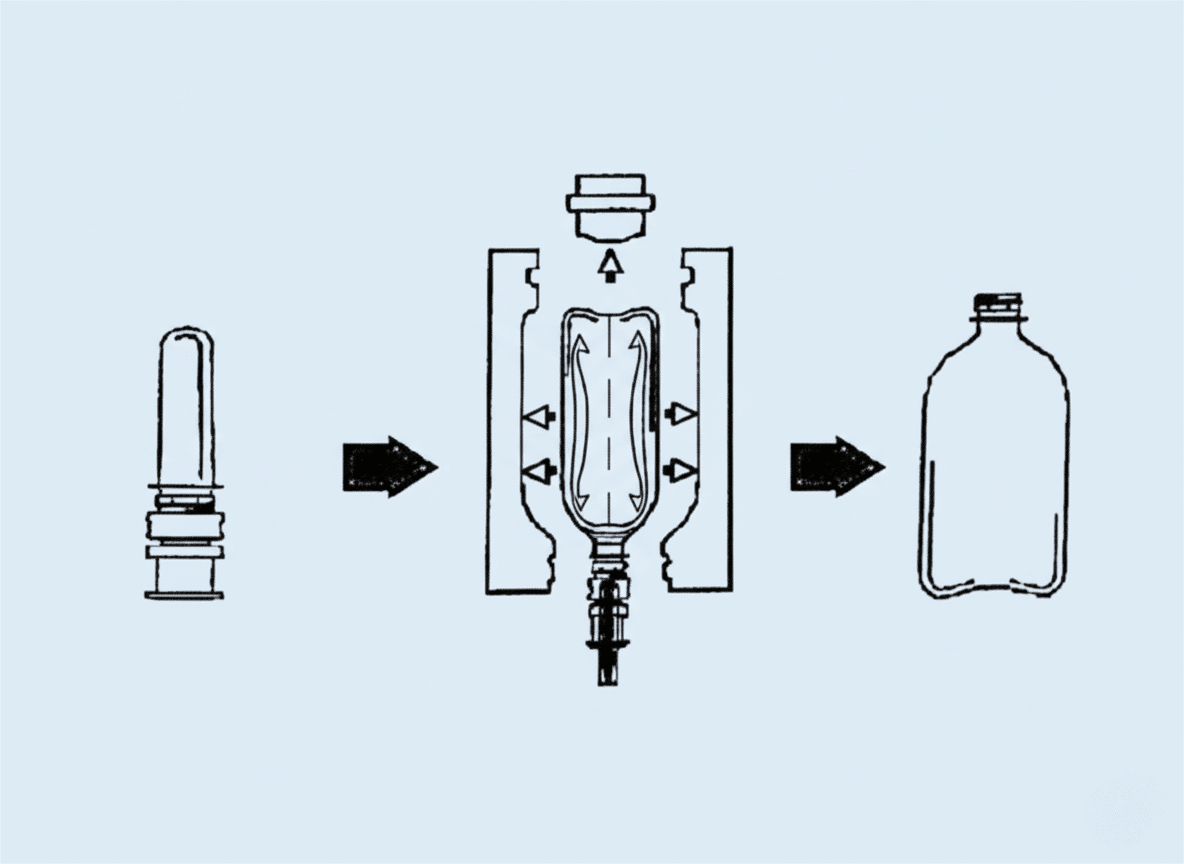

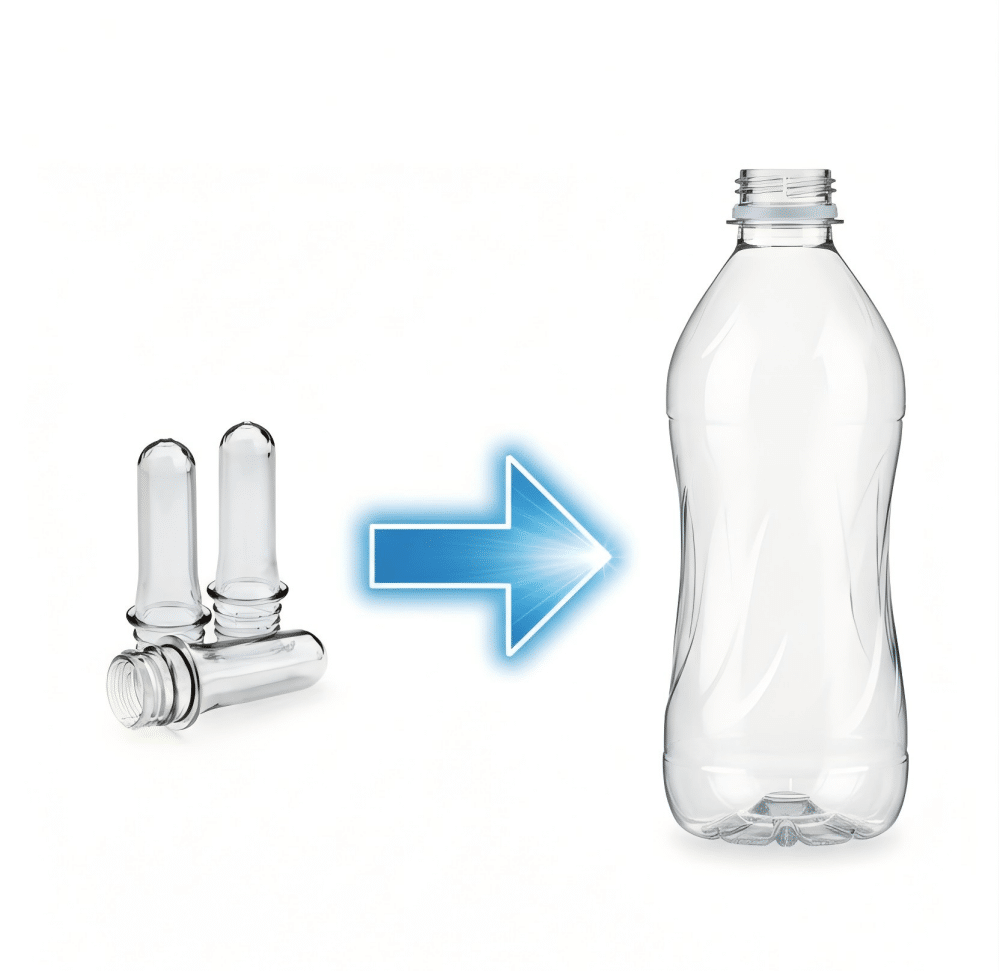

Two-Step PET Blow Molding Explained: A Simple Guide for Beverage Plants & Startups?

Two-step blow molding is the answer. You buy ready-made “preforms” (like test tubes) and your machine just blows them into bottles. It’s flexible, cost-effective, and perfect for startups. This guide

How to Find High-Quality PET Preform Manufacturers in China ?

Finding a reliable PET preform manufacturer in China can feel overwhelming. You are worried about investing thousands of dollars, only to receive a mold that fails, produces bad preforms, or

PET Bottle Mold Design: Why “Practical” & “Profitable” Beats “Creative”?

A “profitable” and “practical” PET bottle mold design focuses on low weight, high strength, and manufacturing efficiency. This beats “creativity” because it lowers your total cost and ensures consumers can

China’s Top 10 PET Blow Mould Factories: A 2025 Buyer’s Guide to Bottle Design & Performance?

This guide ranks China’s Top 10 PET blow mould factories. We focus on what matters: custom bottle design, lightweighting ability, and machine integration. This helps you find a partner, not

Where to Find the Best PET Blow Molds Factory in China? A Regional Guide?

This guide analyzes China’s two primary PET blow mold clusters: Zhejiang (Taizhou) for low-cost volume and Guangdong (PRD) for high-quality, high-tech solutions. It helps buyers select a region based on

How much does it cost to start a water bottle brand?

The cost to start a water bottle brand varies wildly, from $30,000 for a micro-operation to over $200,000 or $500,000 for a competitive, automated small factory. The final price depends

Is the Semi-Automatic Blow Molding Machine Still Worth Buying?

Yes, a semi-automatic blow molding machine is absolutely still worth buying for the right business. Its value is not in speed, but in its high cost-effectiveness, low-risk investment, and simple

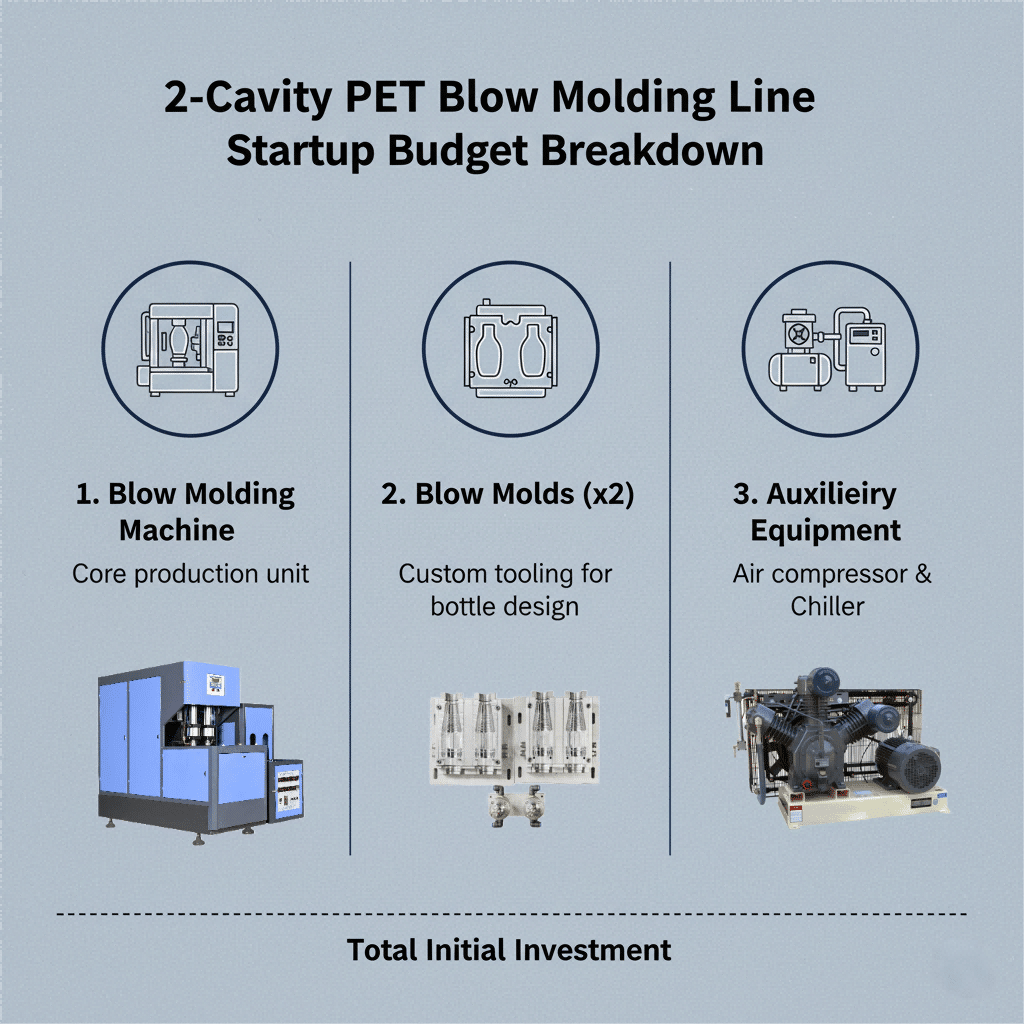

What is the Cost of a 2 Cavity PET Blowing Machine?

The total startup budget for a 2-cavity PET blowing line varies wildly. A reliable, industrial-grade semi-automatic line (with machine, mold, and auxiliaries) can range from $8,000 to $30,000 USD. A

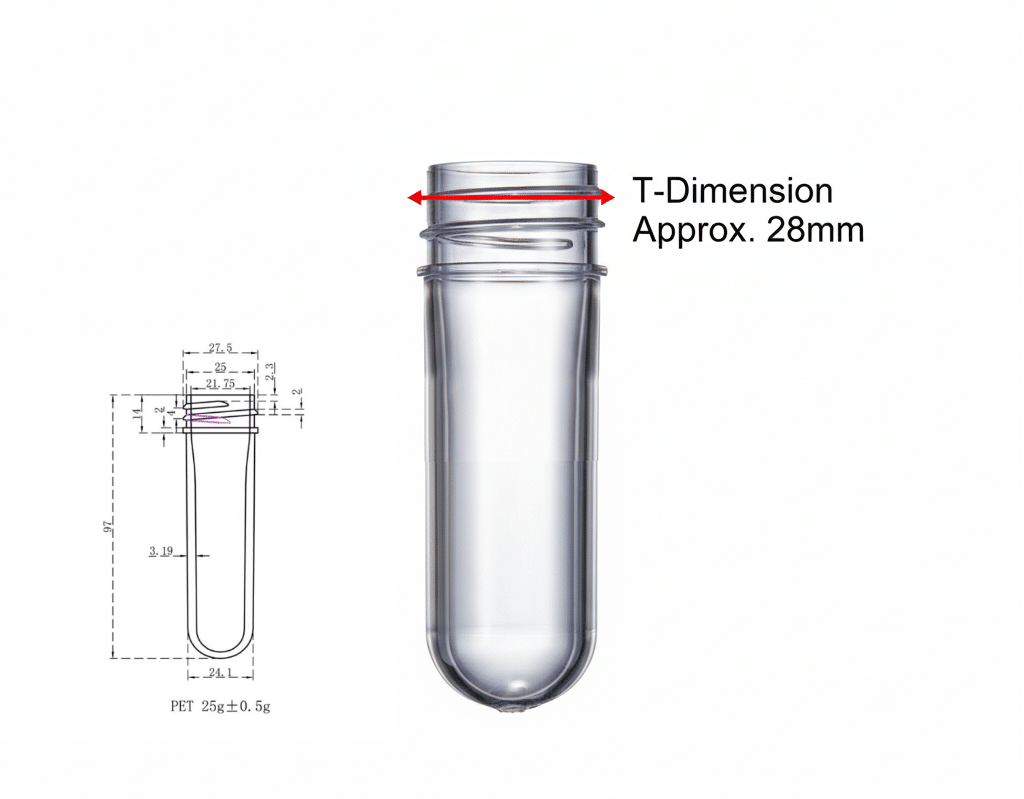

What is a 28/410 bottle neck?

A 28/410 neck finish is a standard size for bottle openings. The “28” means the outer diameter of the threads is approximately 28 millimeters. The “410” is a code from

Why Southeast Asian Bottlers Often Preferemi Semi Automatic Blow Molding Machine?

Yes, semi-automatic blow molding machines are often the most intelligent choice in Southeast Asia. This is not because they are “low-tech,” but because they offer the best return on investment.

How to make a PET plastic bottle?

PET bottles are made using Stretch Blow Molding (SBM). This process takes a pre-made “preform,” heats it to a precise temperature, stretches it lengthwise with a rod, and then inflates

Your First Look at How PET Preforms Are Made: A Beginner’s Step-by-Step Guide

PET preforms are made through a process called injection molding. First, PET resin pellets are thoroughly dried. Next, they are melted into a liquid state in an injection molding machine.

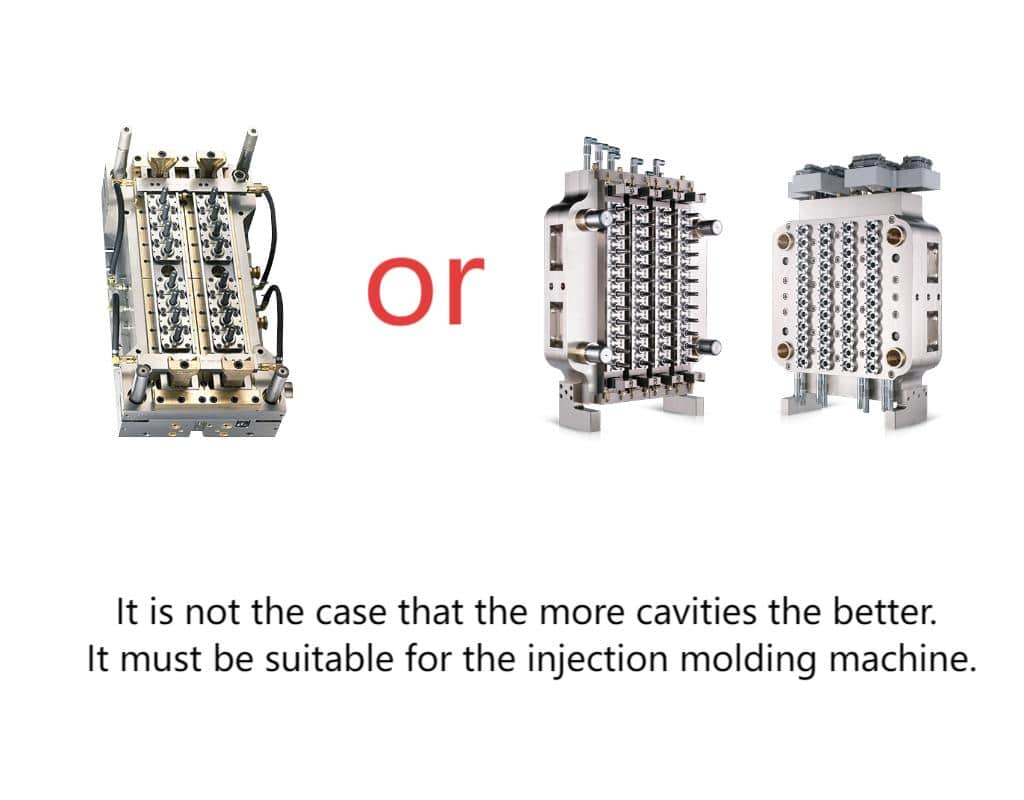

Preform Mold Cavitation: How Many Cavities Do You *Really* Need? (A Cost vs. Output Guide)

To choose the right preform mold cavitation, you must balance four factors: your annual production target, your injection molding machine’s tonnage and specs, your upfront budget, and your long-term cost

Diageo’s PET Shift: Why Premium Spirits Are Embracing Plastic (And How We Make the High-End Molds)?

Diageo’s move to 100% rPET for Seagram’s 7 Crown signals that PET is now acceptable for major spirits. This shift is happening because PET is lighter, won’t break, and offers

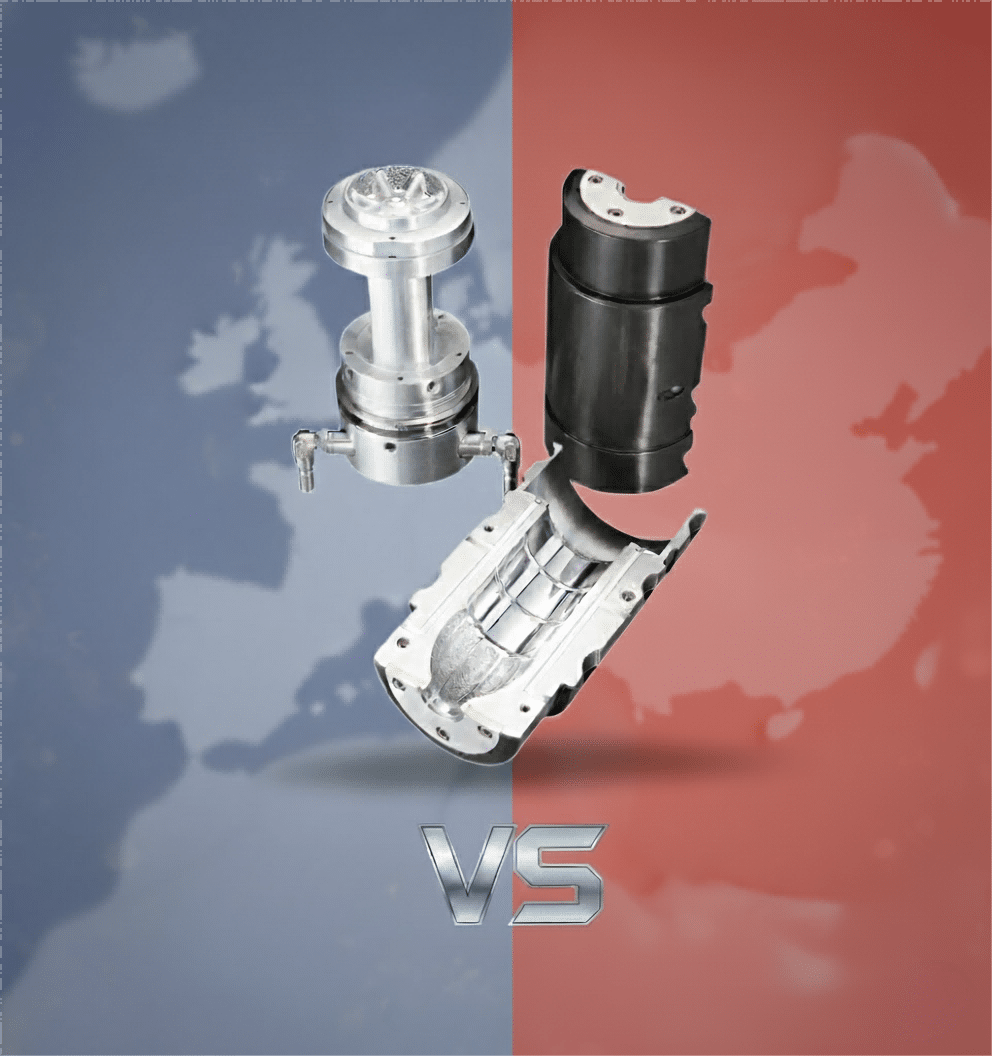

“Made in China” vs. “Made in Europe”: Which Blow Molds Offer a Better Total Cost of Ownership?

The best choice depends on Total Cost of Ownership (TCO), not just the initial price. Top-tier Chinese molds often provide a lower TCO due to faster lead times, greater agility,

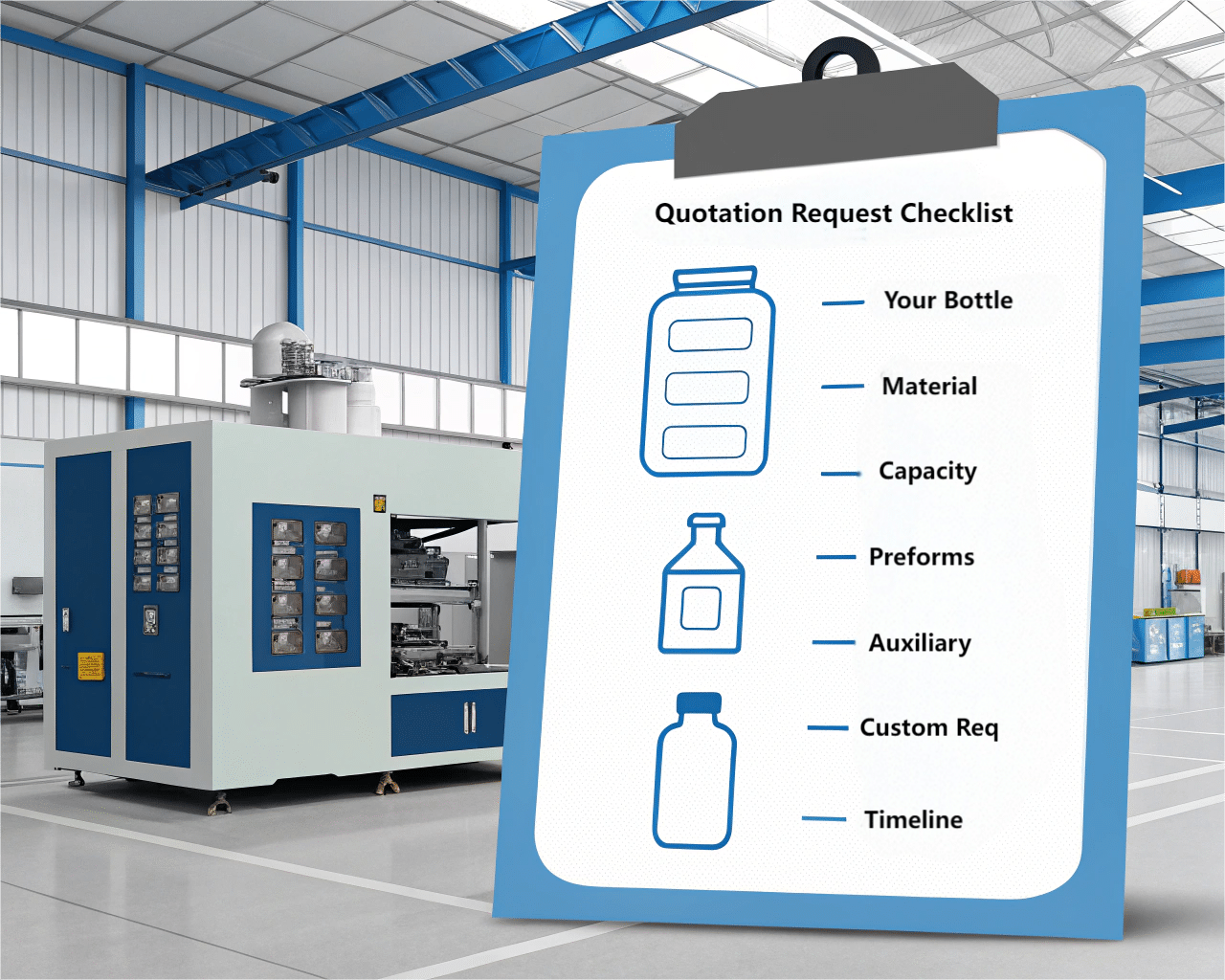

Stop Guessing: How to Write a Blow Mold RFQ That Commands Accurate Quotes (Free Template Included)?

To write an RFQ that gets accurate quotes, you must include five key modules: your core technical specs, your machine compatibility specs, your required material grades, a detailed deliverables list,

3 Ways to Prototype Your Custom Bottle Before Committing to a Production Mold?

The best way to reduce risk in bottle development is to create physical prototypes before ordering the final multi-cavity production mold. You can use 3D printed models for a quick

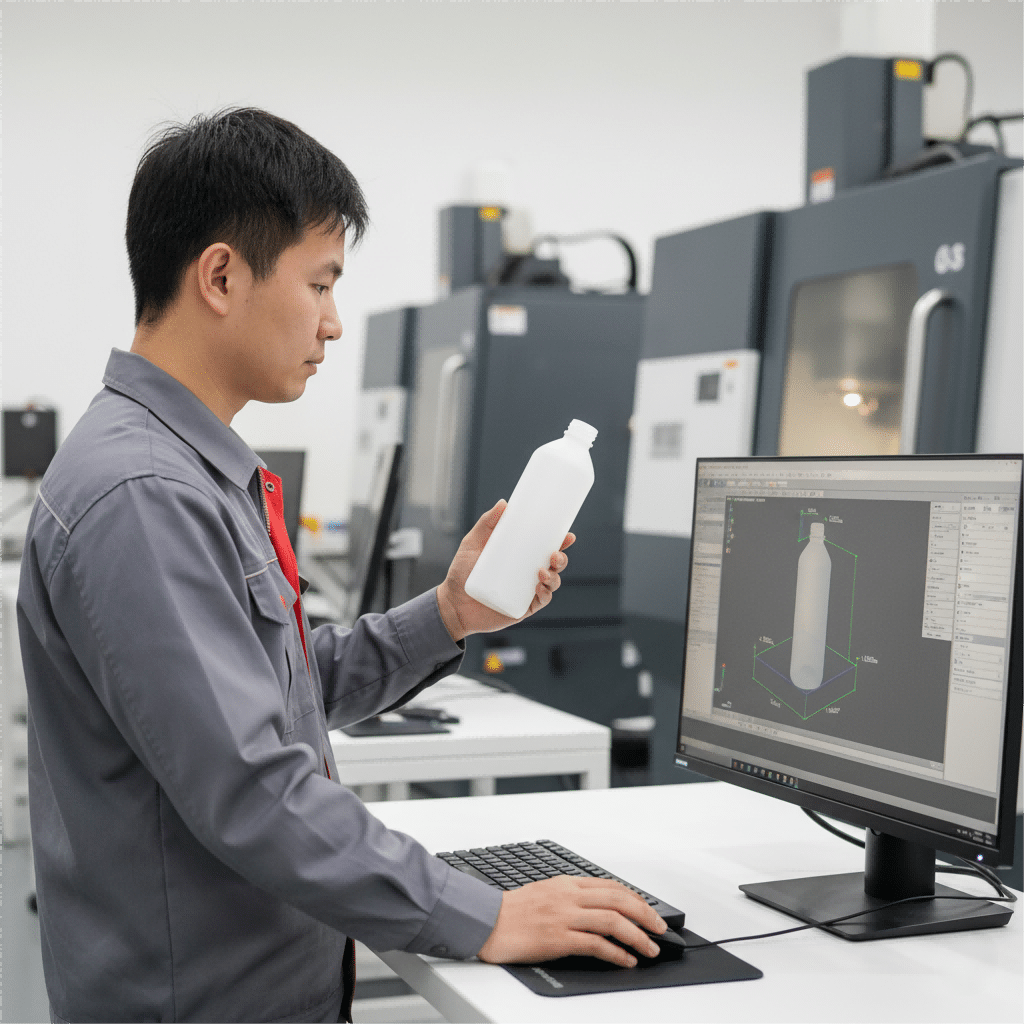

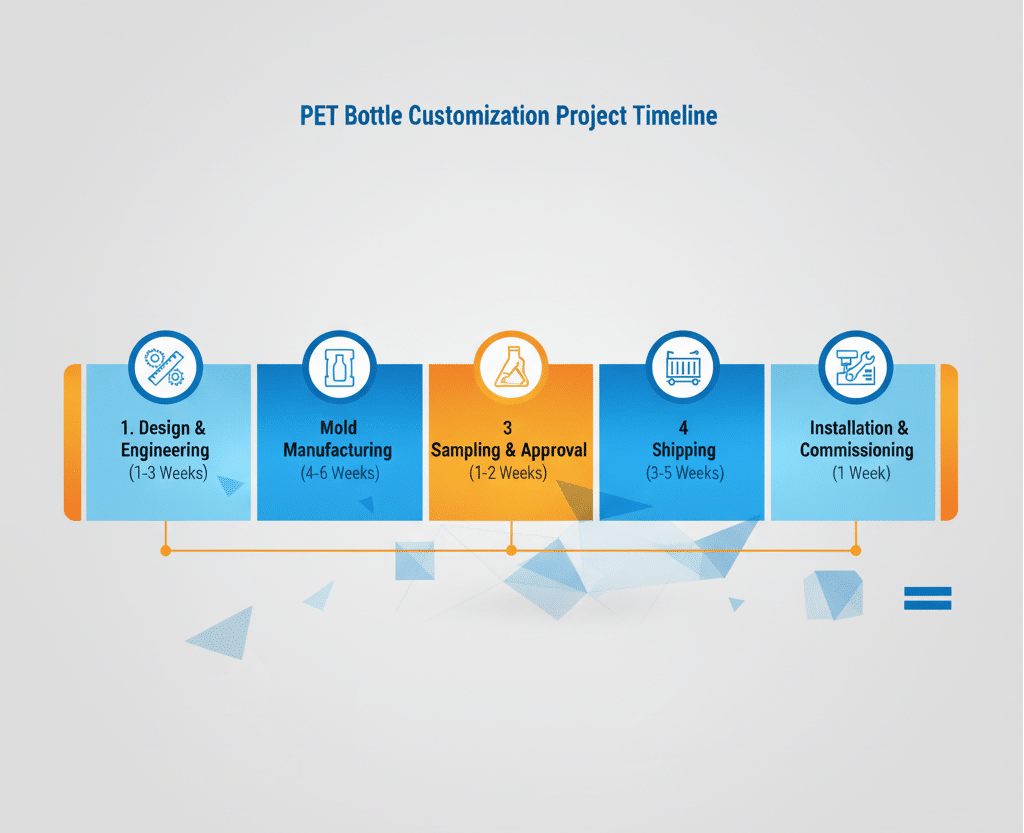

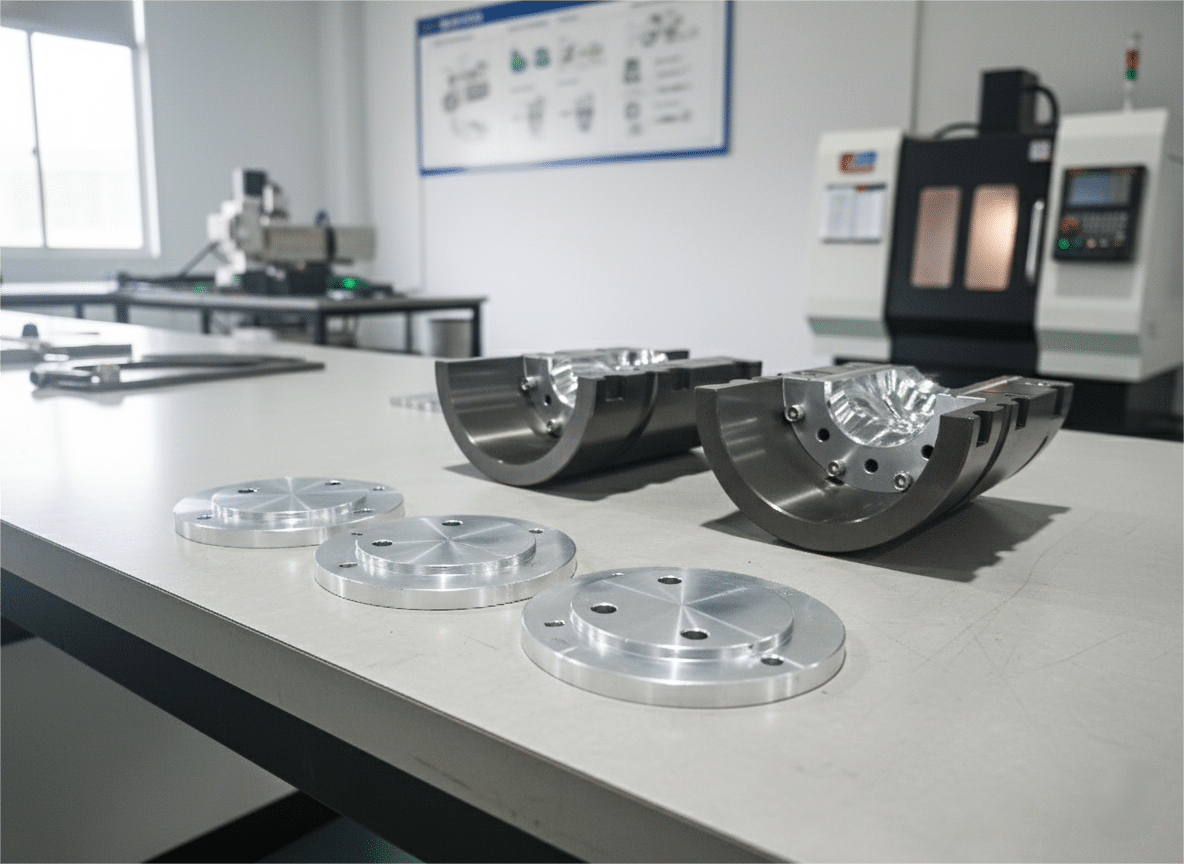

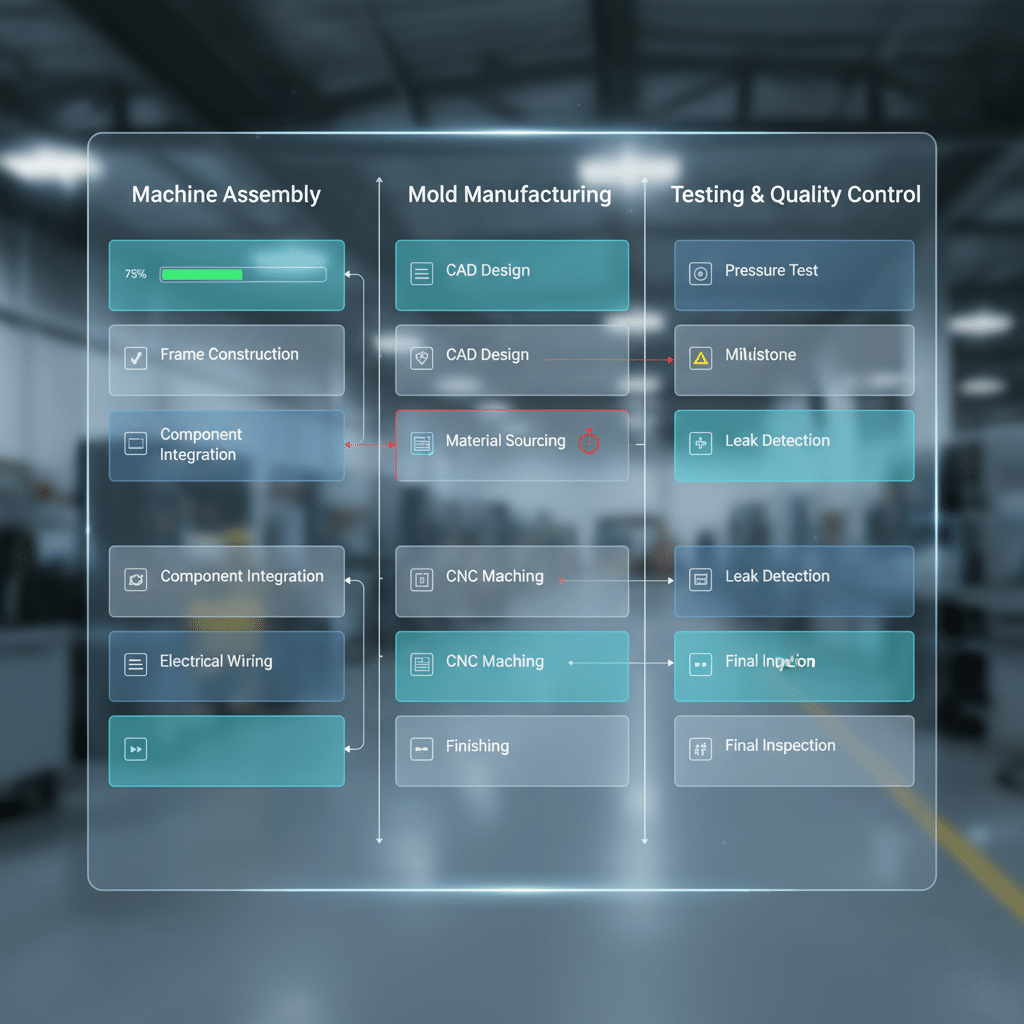

From Idea to Production: How Long Does It *Really* Take to Launch a Custom PET Bottle?

A custom PET bottle project realistically takes 10 to 17 weeks from the final design confirmation to stable, full-scale production. This timeline is a sum of critical phases: design and

Want to Find a Quality Chinese Blow Mold Factory Fast? Ask These 5 Questions.

The fastest way to find a quality Chinese blow mold factory is to ask five specific, challenging questions. These questions test their authenticity, technical knowledge, experience, problem-solving skills, and long-term

Persistent Bottle Defects? 5 Signs Your Blow Mold Supplier May Be the Root Cause?

Your blow mold supplier could be the hidden source of your persistent quality issues. A subpar mold design and lack of support create problems that no amount of machine adjustment

.png)

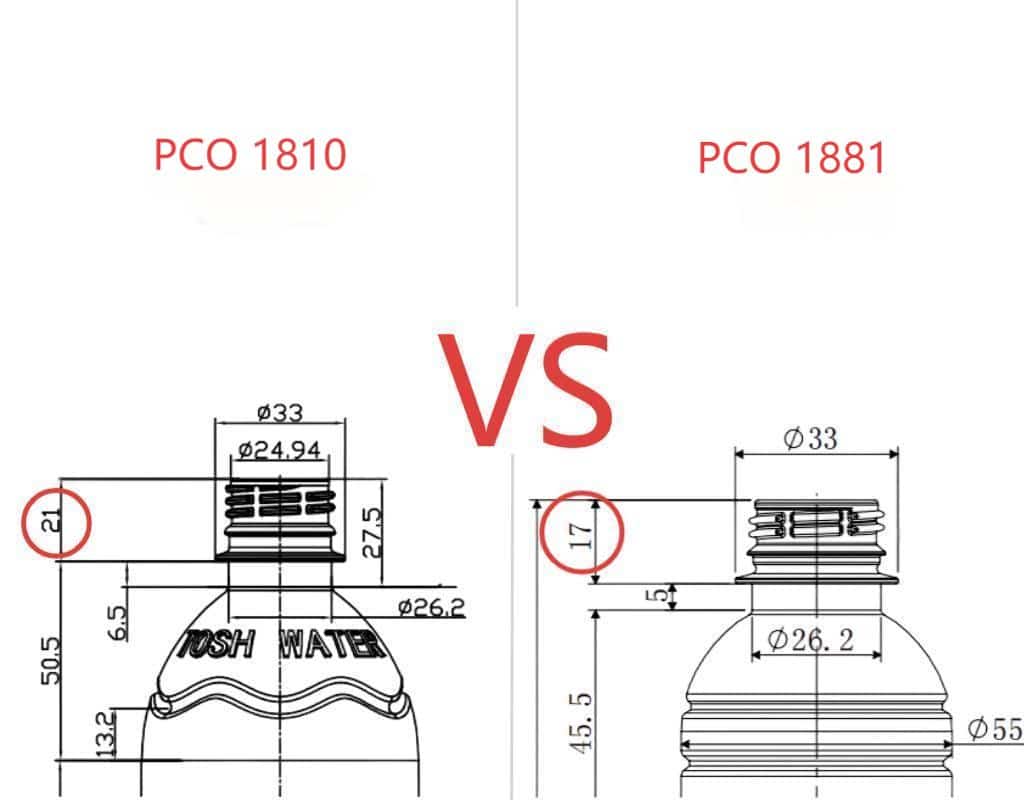

Decoding the Numbers: A Deep Dive into PET Neck Finishes (1881, 1810, 29/25, 30/25)

These numbers are standards for PET bottle openings. PCO1881 and PCO1810 are ISBT codes for shorter and taller carbonated drink necks. 29/25 and 30/25 are dimensional names (thread/inner diameter in

The Big Switch: Why are Premium Olive Oil Brands Moving from Glass to PET?

The primary reasons for this shift are significant cost savings in logistics, greater design freedom for branding, superior product protection with modern technology, and a surprisingly stronger case for sustainability

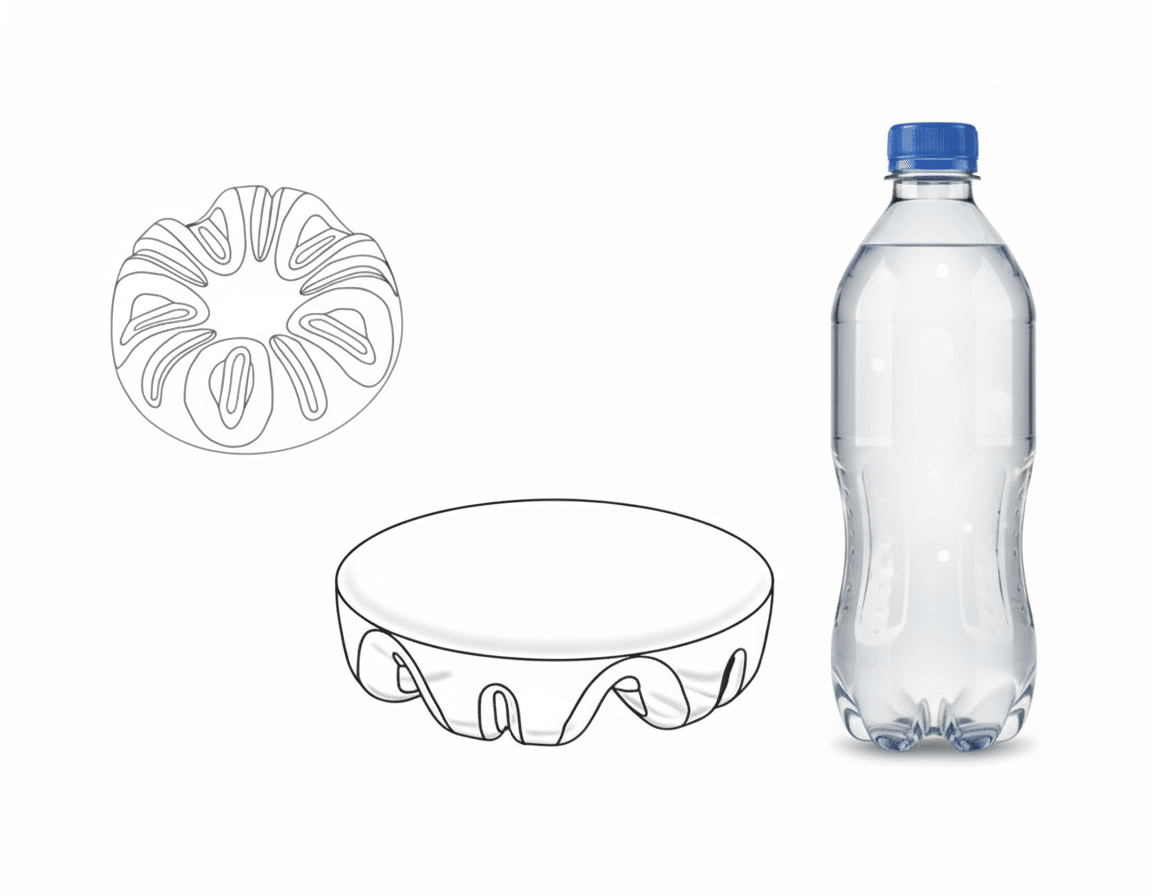

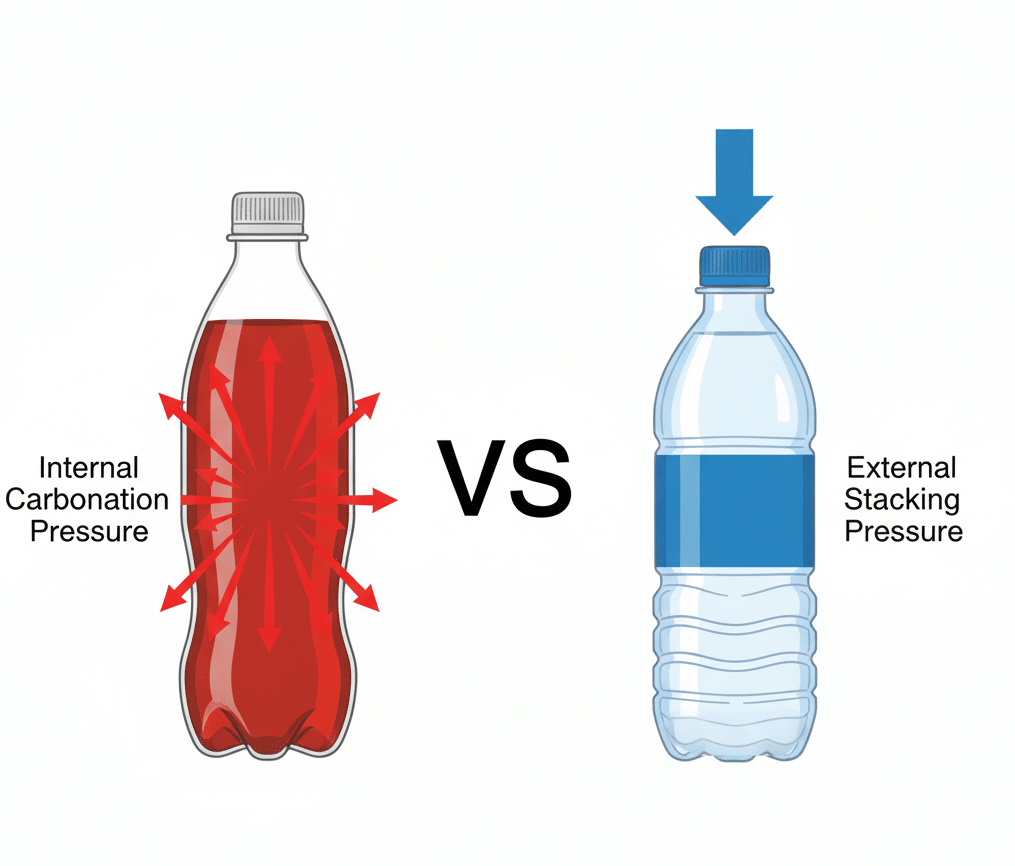

Why Do Soda Bottles Have That 5-Point Base? A Deep Dive into Petaloid Design

The 5-point base, known as a “petaloid base,” is an engineering solution to withstand the high internal pressure from carbonated drinks. This design uses arched shapes to distribute stress evenly,

The Most Common Mistake in Measuring Hot-Fill Bottle Volume (And How It Costs You Money)?

The biggest mistake is measuring your bottle’s volume by weighing it with water and assuming 1 gram equals 1 milliliter. This is only true for water. For sugary drinks like

Precision in Every Milliliter: The Simple Trick to Fine-Tuning Your CSD Bottle Volume?

The best way to fine-tune CSD bottle volume is by using a mechanical system of high-precision volume adjustment spacers, or shims. This allows operators to physically change the mold cavity

Need Molds for Your Sidel or Krones Machine? How Do You Vet Alternative Suppliers?

A reliable alternative supplier can be found by conducting a rigorous audit of their technical capabilities, material sourcing, performance design, and after-sales support. This vetting checklist gives you the critical

Beyond the Fizz: 5 Critical Design Secrets for Your Soft Drink Blowing Mould?

The critical design secrets for a successful soft drink blowing mould lie in five key areas: a specialized petaloid base for pressure distribution, reinforced body and shoulder geometry, the mandatory

Injection vs Blow Molding: The Two-Step Journey of a PET Bottle?

Injection molding and blow molding are two essential stages of a single journey. Injection molding creates the initial shape, called a preform, and blow molding then transforms that preform into

From Water Bottles to Jars: A Guide to Choosing the Right Blow Molding Machine?

The key is matching the machine type to your specific product. For clear PET bottles and jars, you need a stretch blow molding machine. For opaque HDPE/PP containers, you need

.png)

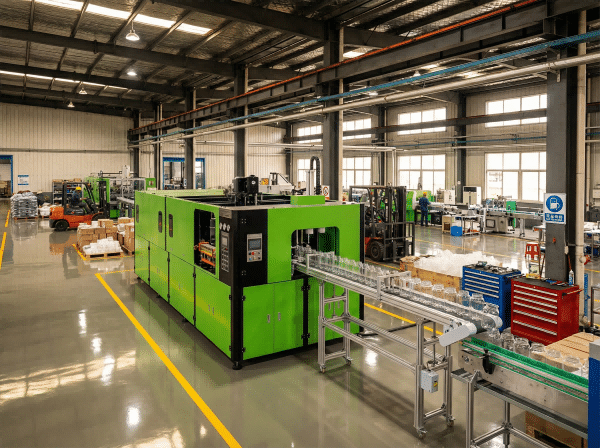

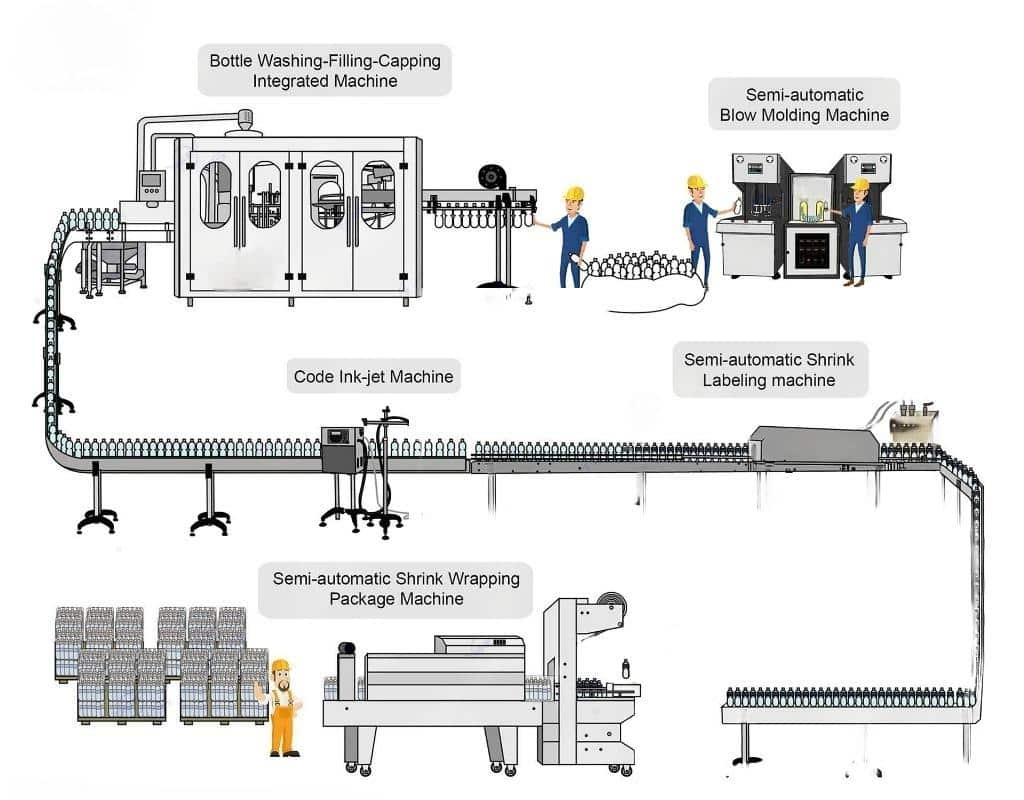

Setting Up a PET Bottle Production Line: The Ultimate Equipment Checklist?

This ultimate checklist provides a clear, step-by-step guide to every piece of equipment you need. We will cover everything from the main machine to essential utilities, ensuring you are fully

Sourcing Bottle Blowing Machines from China: 7 Critical Questions to Ask Your Supplier?

Finding a trustworthy partner is crucial. A great supplier provides a high-quality PET blow molding machine at a fair price, backed by solid engineering and transparent after-sales service. This ensures

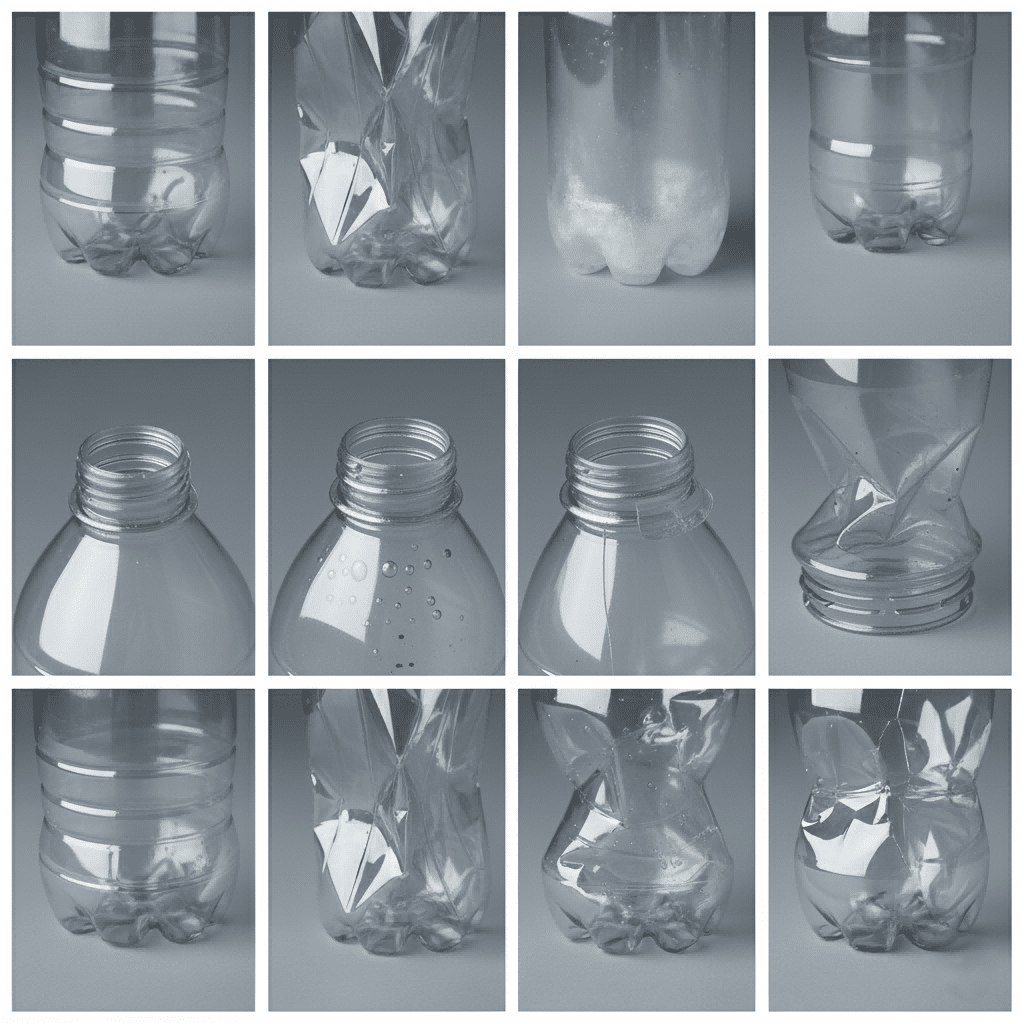

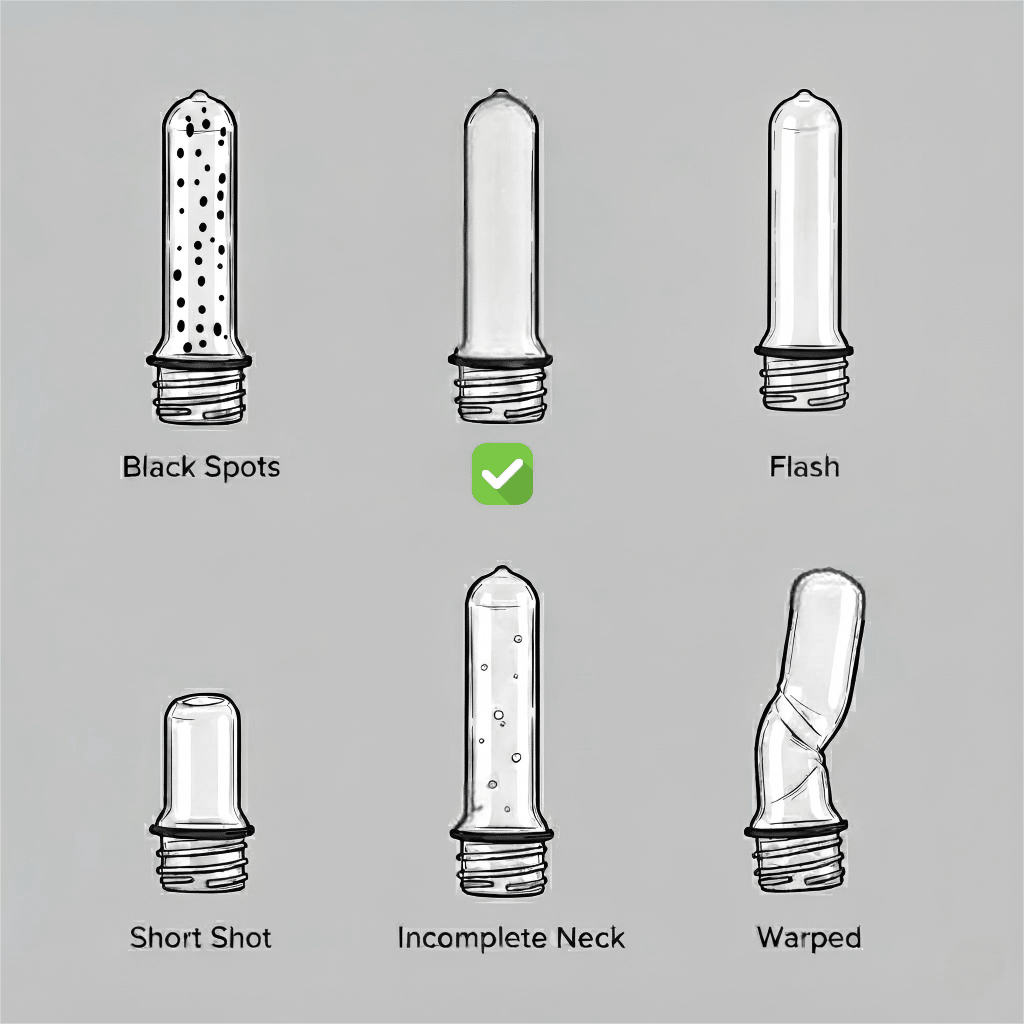

The 10 Most Common Defective PET Bottles (And How to Fix Them at the Source)?

The key to solving these issues is identifying the specific defect and knowing its root cause. This guide provides a visual map to the 10 most common PET bottle defects,

Blow Molding Machine for Sale: A Global Buyer’s Guide for 2025/2026?

The best blow molding machine for your business depends on your production scale, industry, and regional market. For startups, semi-automatic machines offer flexibility, while established businesses benefit from the high

Beyond the Price Tag: 5 Hallmarks of a Bottle Mold Manufacturer That Delivers True ROI?

High-quality bottle molds aren’t an expense; they’re a profit-generating asset. The right bottle mold manufacturer can provide the tools to increase production efficiency, reduce scrap, and ultimately boost your return

A Beginner’s Guide to the PET Bottle Blowing Process (Explained Simply)?

The PET bottle blowing process transforms a small, test-tube-shaped plastic piece called a “preform” into a full-sized bottle using heat and compressed air inside a mold. It is a straightforward

The Ultimate PET Preform Defect Chart: How Can It Solve Your Production Headaches

This guide provides a comprehensive PET preform defect chart, complete with pictures, to help you quickly identify the root causes of common problems. From material issues to injection parameters, you’ll

Sourcing from China? A Checklist for Vetting PET Blow Molding Machine Manufacturers?

Vetting a PET blow molding machine manufacturer is the most crucial step. It helps you verify their technical claims, confirm they are a real factory, understand their quality control processes,

PET Bottle Defect Troubleshooting: Before You Blame the Machine, Start with the Preform?

The preform dictates the final bottle’s potential. Its material properties, dimensions, and visual clarity set the upper limit for quality. A flawless blowing process simply cannot fix a flawed preform.

Troubleshooting Your “Powerhouse”: A Guide to Defects Caused by the Air Compressor & Chiller?

Your bottle defects might not originate from your mold or machine. Instead, the problem often lies with the auxiliary equipment. An unstable air compressor or a faulty water chiller can

Still Blaming the Mold? A Troubleshooting Guide for Bottle Defects Caused by the Blow Molding Machine Itself?

If you have already completely ruled out any mold issues, then it’s time to turn your attention to the next primary suspect: the blow molding machine. This guide will walk

The Blow Mold “Health Check”: A Complete Guide to Defects Caused by Mold Issues (Cooling, Venting, & Wear)?

A stable blow molding process with sudden bottle defects almost always points to a problem with the blow mold itself. Issues with the mold’s cooling channels, venting system, or mechanical

The Ultimate Guide to Starting a 10L Single-Use Water Bottle Business: An A-Z of Design, Preforms, and Caps

This guide provides a complete A-to-Z roadmap. We’ll dive deep into the design principles for 10L bottles, how to precisely select preforms (weight, neck, color) and caps, and the correct

The PET Preform & Cap Order Calculator: Your Best Inventory Guide for Small Factories?

This article provides a straightforward calculator and formula to determine your exact reorder point for PET preforms and caps. It helps you balance supplier lead times, daily consumption, and safety

PET Bottle Production from A to Z: Do You Really Understand Preforms, Blowers, Molds, and Auxiliaries?

The PET bottle manufacturing process starts with a “preform,” which looks like a test tube. This preform is heated in an oven and then placed into a bottle-shaped mold. High-pressure

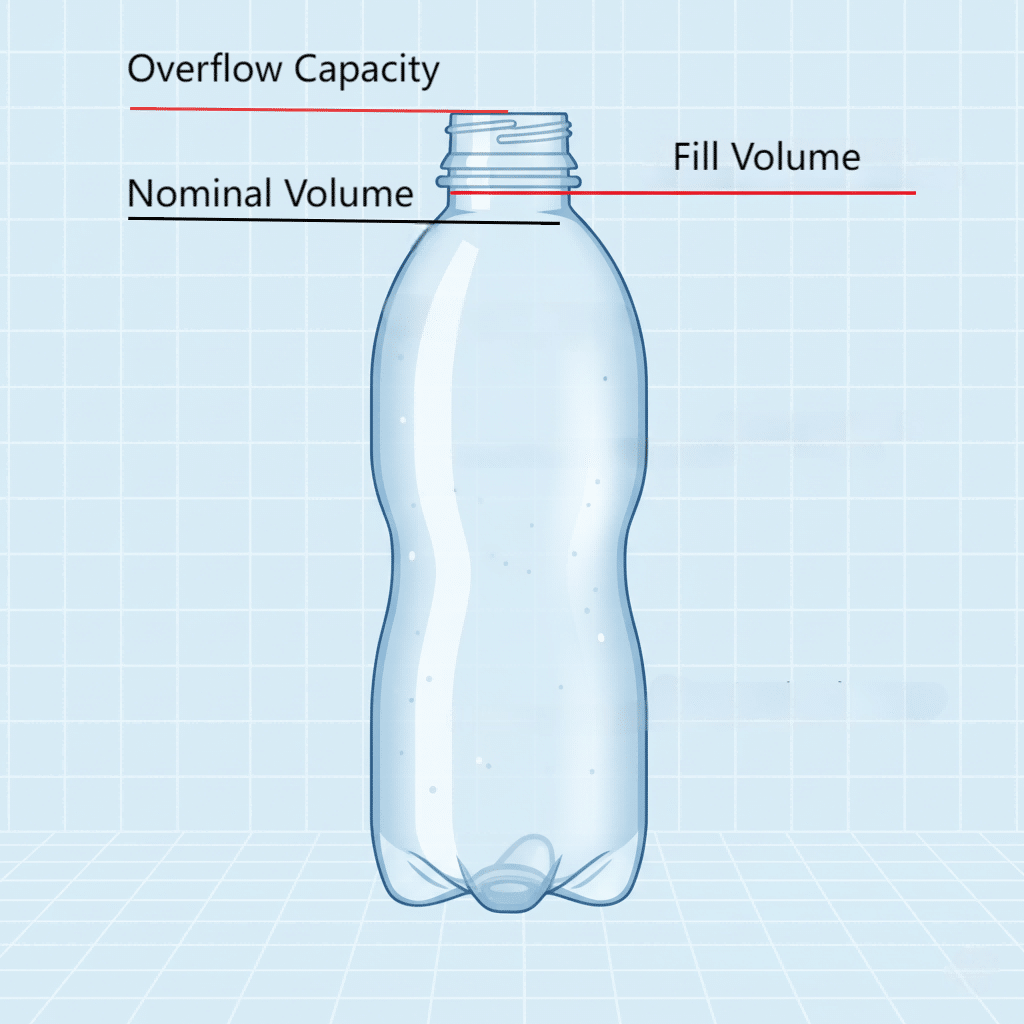

Overflow, Nominal, and Fill Volume: A Complete Guide to PET Bottle Capacity?

The key is understanding three distinct capacities: Nominal Volume (the label claim, e.g., 500ml), Fill Volume (the actual liquid amount set by your filler), and Overflow Capacity (the bottle’s absolute

Top 5 Common Defects in 1.5L CSD Bottles and How to Fix Them

The most common defects in 1.5L CSD bottles, like stress cracking and thin walls, come from an unbalanced blowing process. Fixing them requires adjusting the preform heating profile, pre-blow pressure

10 Questions Every PET Bottle Mold Manufacturer in China Should Answer

This guide provides 10 core evaluation questions for sourcing PET blow molds from China. It helps you look beyond the price to investigate a manufacturer’s true capabilities, including: factory verification,

.png)

Is Investing in a PET Preform Plant the Right Move for Your Startup?

A complete PET preform plant investment involves more than just an injection machine. You must budget for molds, auxiliary equipment, infrastructure, raw materials, and daily operational costs. A small line

How to Design a Head-Turning PET Bottle: 3 Key Inspirations for 2025?

A PET bottle is your most powerful salesperson. In 2025, its design will be defined by three key trends: visible sustainability, minimalist geometry, and functional art. These elements transform a

A Cost-Saving Guide to Water Bottle Design: Reduce Preform Weight Without Sacrificing Performance?

The key is not just using less plastic, but using plastic smarter. By optimizing the bottle’s geometry—its shape, ribs, and base—you can significantly reduce preform weight while actually improving strength

How to Create Your Next Hit Product: A Guide to Custom Flat Water Bottles for Innovative Brands?

A custom flat water bottle is your key to unlocking market differentiation. Its unique, slim profile is not just aesthetically pleasing but also highly practical, offering better portability and space

Beyond “The Bundled Mold”: Why Sourcing Your PET Blow Mold from a Specialist is a Smart Upgrade?

A specialized PET blow mold is a smart upgrade. It solves quality issues and boosts efficiency beyond what a standard bundled mold can offer. A dedicated factory provides superior engineering,

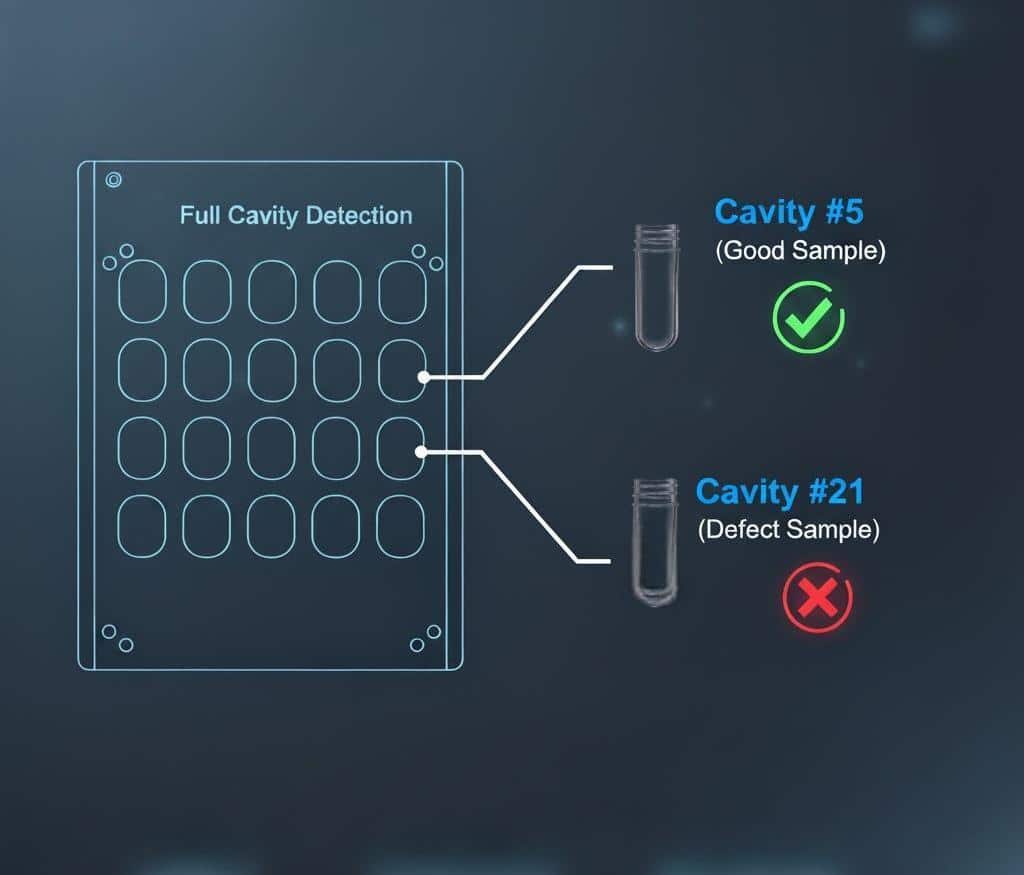

How to Properly Specify Base Markings for Your New Blow Mold?

Properly specifying base markings for your new blow mold involves two key elements: including the essential, legally required recycling codes and the highly recommended cavity numbers for traceability. This simple

A Guide to Tritan Bottle Production: How to Choose the Right Blowing Machine and Mold?

The best way for newcomers to start is with the two-step reheat and blow process. This method has a much lower initial investment. It also gives you more production flexibility

Rotary Blow Mold Design Guide: How to Ensure Stability Consistency in Every Cavity at High Speeds?

Achieving stability and consistency in high-speed rotary blow molding demands a holistic engineering approach. It requires precise material selection to withstand high forces, advanced cooling and balanced airflow for uniformity,

Used Blow Molding Machine: A Smart Investment or a Costly Mistake?

A used blow molding machine can be a smart investment if you find a well-maintained unit with available spare parts and have in-house technical expertise. However, it often becomes a

Why Are PP Bottles So Tricky to Blow? 5 Common Technical Hurdles and Their Solutions?

PP bottles are tricky due to low melt strength, a narrow heating window, uncontrolled stretching, slow crystallization, and the need for structural design. The solution lies in optimizing preform design,

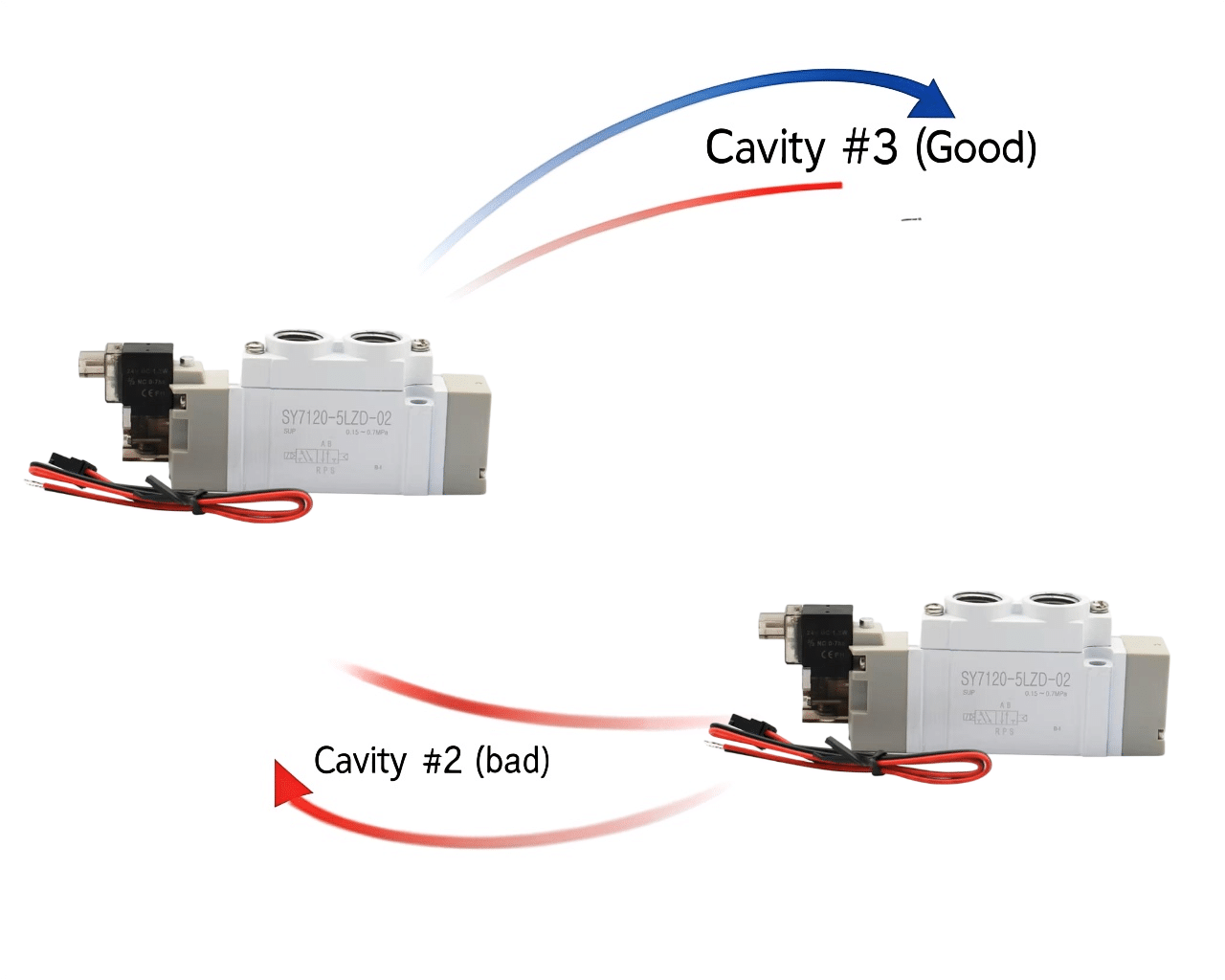

Why is Only One Cavity Failing in Your PET Multi-Cavity Mold?

The most common reason for a single cavity failure is an issue isolated to that specific cavity’s support systems. This includes the dedicated heating lane, valve block, sealing unit, or

Commissioning Guide: How to Set Safe and Effective Baseline Parameters on Your First Startup of a Semi-Automatic Blower?

To set initial parameters on a semi-automatic blower, first complete a full safety check of all connections. Then, power on auxiliary units before the main machine. Start with low heating

Beyond the Paper Promise: How to Ensure Your Blow Molding Machine Warranty Translates to Real Service?

The warranty is your production line’s insurance. A good supplier treats it as a partnership commitment, providing proactive remote support, a comprehensive knowledge base, and a rapid spare parts system

How Can You Train Your Operators for Maximum Safety and Efficiency on a Semi-Automatic Blower?

The most effective training for a semi-automatic blow molding machine operator combines foundational knowledge of PET material with strict safety protocols, a step-by-step operational workflow, hands-on practice for quality control,

Don’t Forget These 5 Hidden Costs When Calculating Bottle Cost (With 500ml PET Bottle Cost Formula)?

The true cost of a 500ml PET bottle goes far beyond the price of the plastic preform. It must include equipment depreciation, auxiliary power consumption, production scrap, maintenance, and downtime.

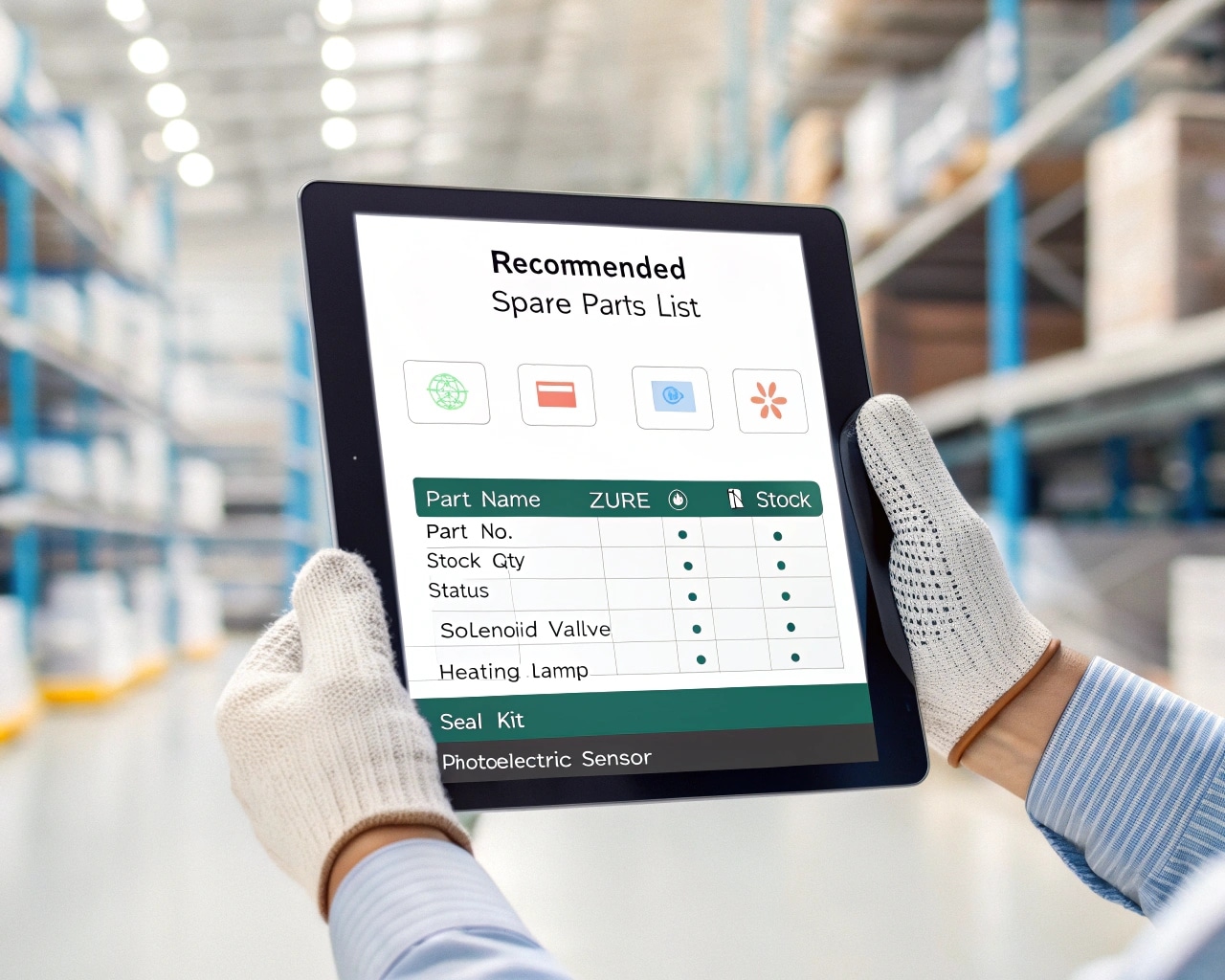

Avoid a Production Shutdown: The 10 Critical Blower Spare Parts You MUST Have on Hand?

Having a well-organized stock of critical PET blow molding machine spare parts is the single most effective strategy to prevent catastrophic downtime. This includes heating lamps, power supplies, sensors, high-pressure

From Water Bottles to Cosmetic Jars: A Complete Guide to Standard PET Preform Neck Sizes

The neck finish is the most critical interface of your bottle. It dictates the cap you can use, the performance of your product on the filling line, and your final

Found Out After Upgrading? Why the Same Preform Works on Semi-Auto But Jams Your Full-Auto Machine?

The critical difference lies in precision. A fully-automatic machine requires preforms with much tighter inner diameter (ID) tolerances than a semi-automatic machine. Human operators can subconsciously adjust for minor flaws,

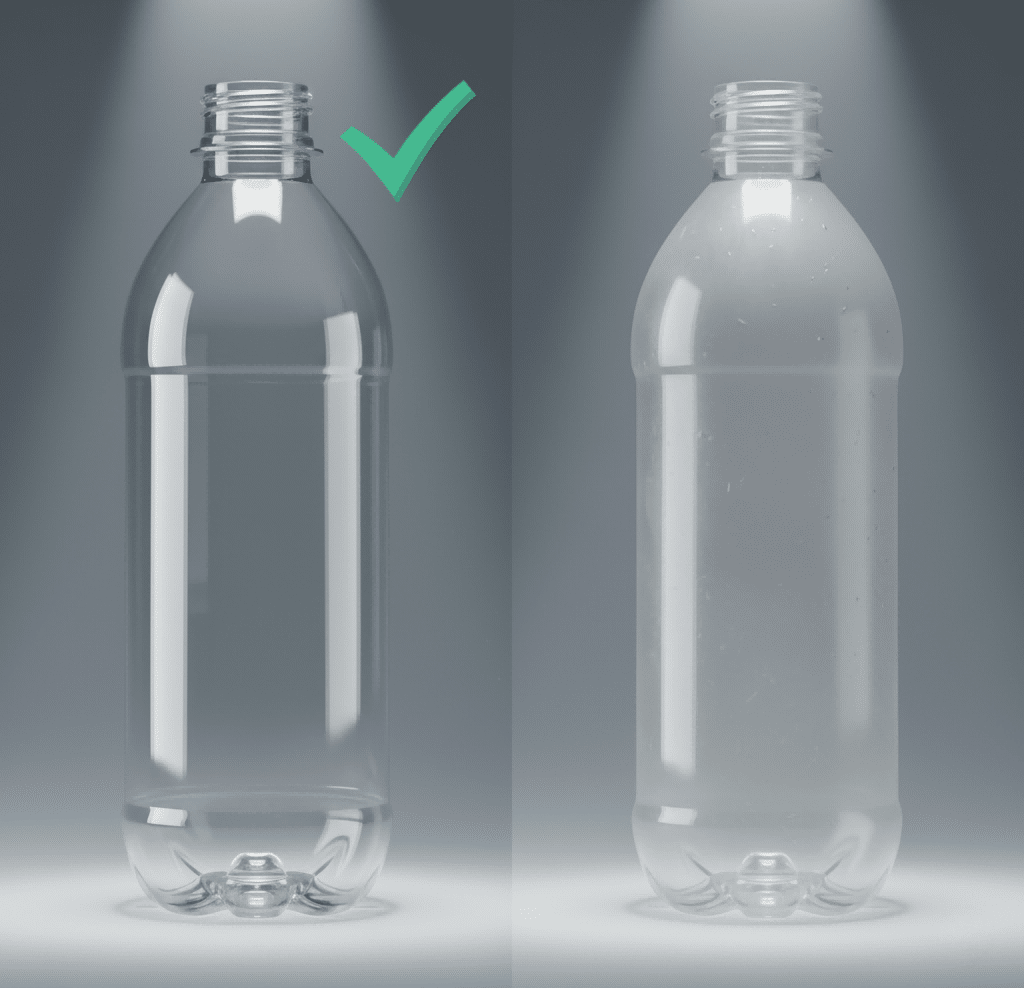

Why Do My PET Bottles Look Hazy / Not Clear? (A Comprehensive Haze Troubleshooting Guide)

Haze in PET bottles is typically caused by microscopic crystals that form when the material is processed incorrectly. The most common culprits are improperly dried raw material, overheating the preforms

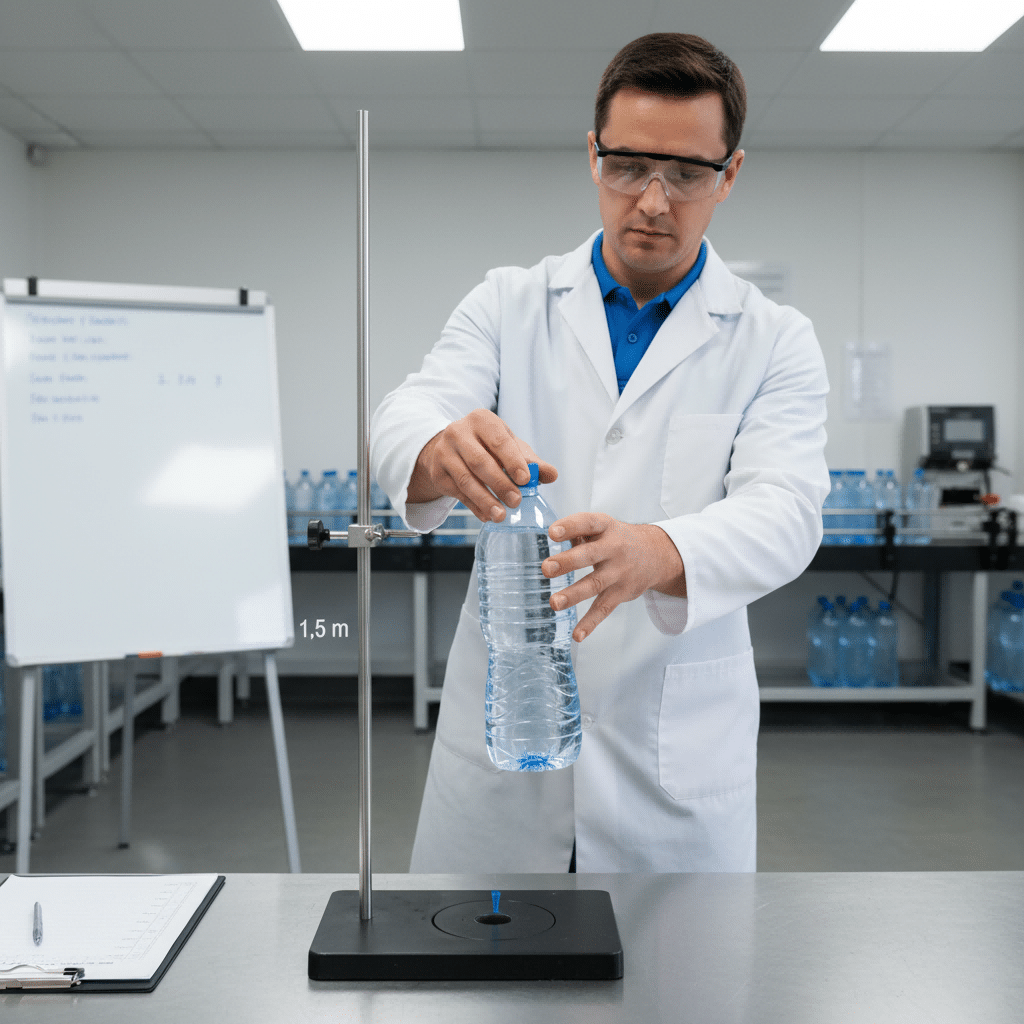

Your PET Bottle Cracking on Impact? 5 Blow Molding Tips to Improve Drop-Test Performance

Improving drop-test performance involves five key areas: optimizing the preform design, redesigning bottle corners for impact dispersion, mastering the stretch ratio, perfecting the heating profile for uniform wall thickness, and

The New Blue Ocean for PET Bottles: Why Milk Tea Shops Are Becoming the Next Big Customer for Bottle Makers?

A massive, high-profit market for PET bottles is quietly booming within the milk tea and new-style beverage industry. These shops have a soaring demand for custom, small-batch, high-value bottles, creating

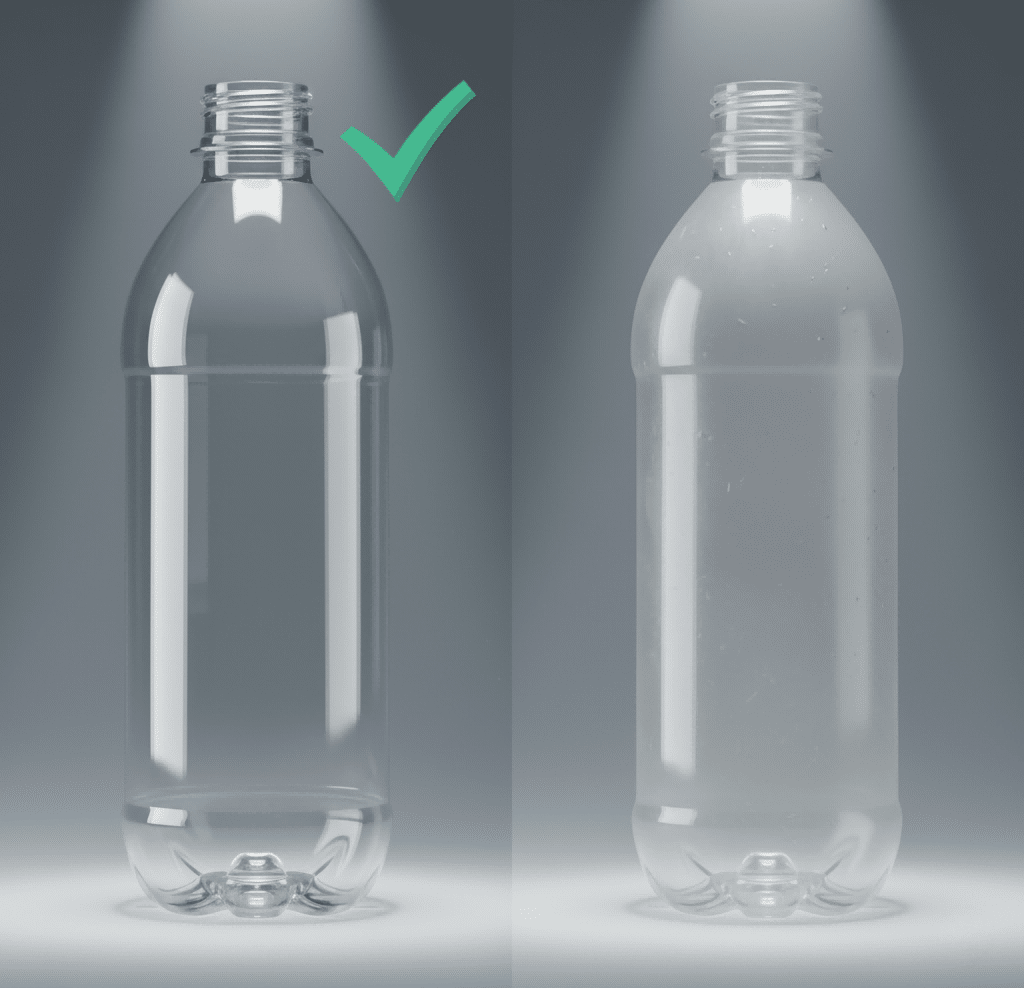

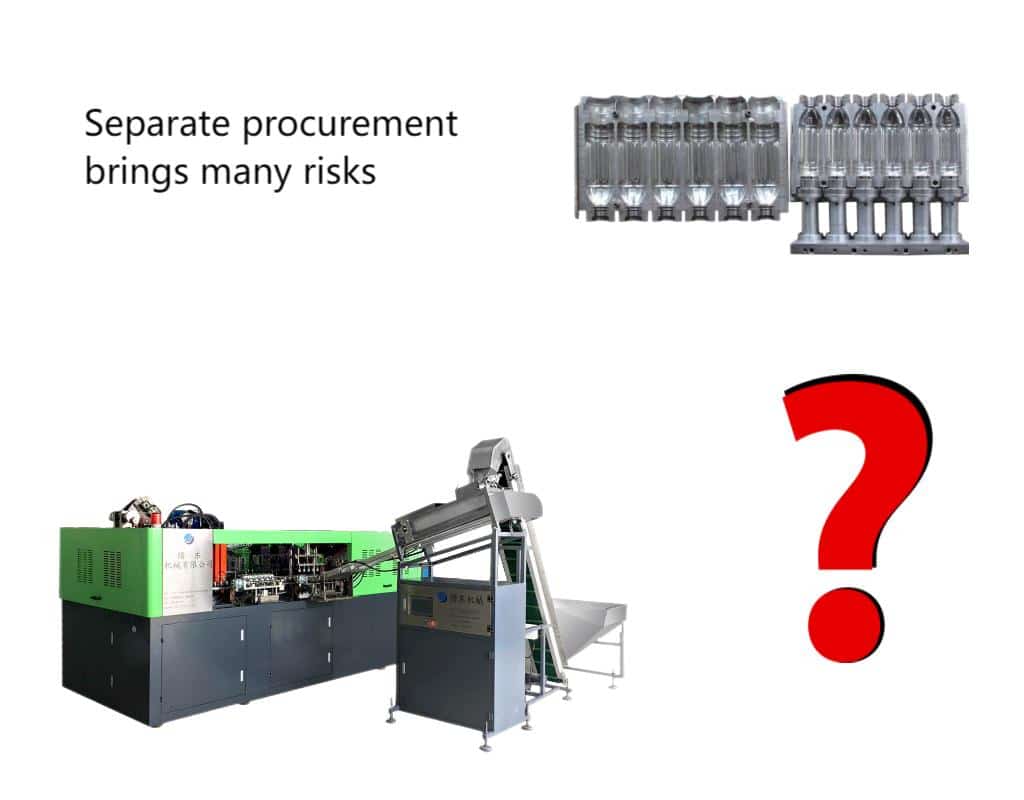

The #1 Mistake in Buying a Blow Molding Machine: Ordering the Mold Separately?

The single biggest mistake a first-time buyer makes is purchasing the blow molding machine and the first mold from separate suppliers. This decision often leads to a nightmare of technical

To 15L Water Bottle Startups: A Data-Driven Investment Decision Analysis for Semi vs. Fully-Automatic Lines?

The core decision for a 15L single-use bottle startup boils down to two paths: a semi-automatic line for around $22,000 or a fully-automatic line for about $85,000. The right choice

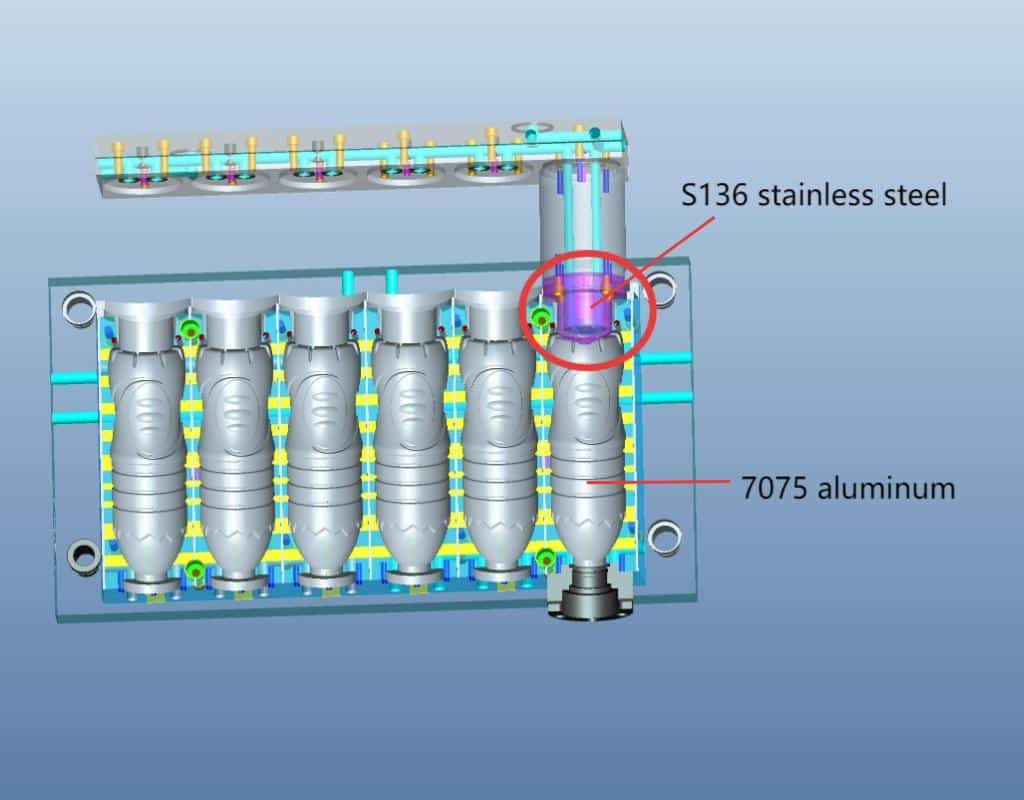

In-Depth Analysis: Why We Insist on Using a Stainless Steel Base in Aluminum Blow Molds?

The primary reason for premature blow mold failure is wear and tear on the mold base. We solve this by incorporating a high-hardness stainless steel insert into the aluminum mold

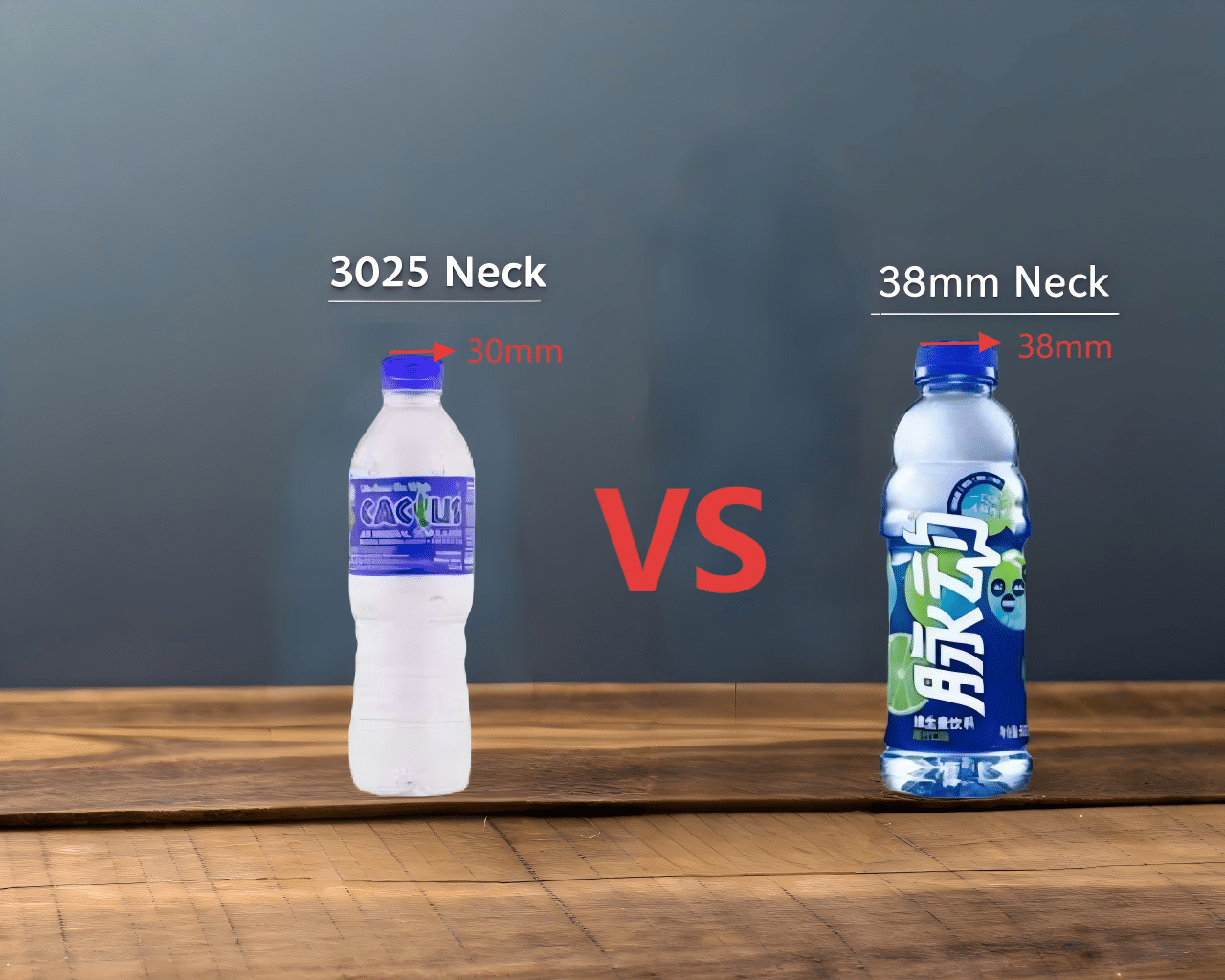

Technical Guide: How to Upgrade a 3025 Blow Molding Machine for 38mm Bottles?

The answer is yes, you can upgrade your existing 3025 machine to produce 38mm bottles. This technical conversion involves replacing key components like grippers, preform holders, and the sealing unit,

How Much “Hidden Cost” Are You Paying for Your Low-Cost Blow Mold?

The true cost of a blow mold isn’t its purchase price. It’s the total cost of ownership, including downtime, wasted preforms, and constant repairs. A cheaper mold often leads to

How can you get an accurate blow molding machine quote quickly by describing just 7 key needs?

To get a fast and accurate blow molding machine quote, clearly define your bottle specifications, plastic resin type, required production capacity, preform source, necessary auxiliary equipment, any special process needs,

Repair or Replace? A Cost-Benefit Analysis on How to Repair Blow Molds

Deciding whether to repair or replace a damaged blow mold is a critical financial and operational choice. A successful repair can quickly restore production at a low cost, while a

Hot-Fill vs Cold-Fill: Choosing the Right PET Bottle Design for Your Juice?

The primary difference is temperature. Hot-fill sterilizes juice with heat (85-95°C) inside a special, heat-resistant bottle. Cold-fill uses other sterilization methods before filling into lighter, more flexible bottle designs at

A Technical Teardown: Why a 90 Degree Shoulder Creates an Undercut in a Blow Mold?

A 90-degree bottle shoulder creates an “undercut.” This is a feature that physically blocks the bottle from being ejected cleanly after the mold opens. This blockage leads to damaged products,

Want to Increase Bottle Capacity? A Guide to Modifying Old Blow Molds (530ml → 550ml)

Yes, in many cases, modifying an old blow mold to increase bottle capacity is completely feasible. The key is to assess the mold’s existing design and material allowance. Through precise

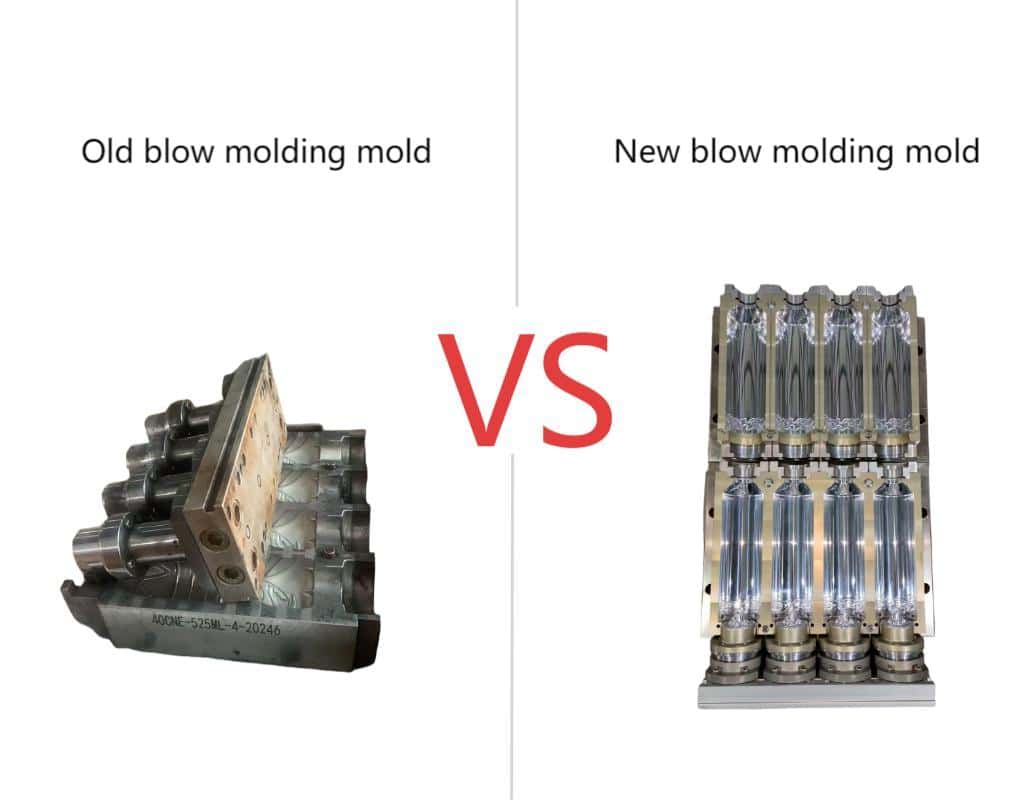

The Transition from PCO 1810 to 1881: Why is a Lighter, Shorter Neck Finish the Future of the Beverage Industry?

The PCO 1881 neck finish is the future because it significantly reduces PET resin usage, lowering production costs and carbon footprint without compromising performance. This lightweight standard, already adopted by

PET Bearbrick Bottle Technology Uncovered: From Mold Design and Production to Market Trends?

The solution is a PET Bearbrick bottle. This unique shape turns a simple product into a viral sensation. It combines high-quality PET material with a trendy, collectible design, ensuring your

The Core of the Blow Molding Process: Why is Temperature Control the First Step to Perfect Bottle Quality?

Proper temperature control is the first step to perfect bottles. It ensures PET plastic is soft enough to stretch but not so hot it crystallizes. This precise heat activation is

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

A 5-gallon (18.9L) bottle blow molding machine is specifically engineered for these large containers. It features a robust clamping unit, a larger mold area, and a specialized, powerful heating oven

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

These spots, known as pitting, are tiny cavities caused by corrosion on your mold’s surface, most often from moisture. This guide will show you how to identify the cause, properly

A complete PET preform acceptance checklist: 7 key inspection points for purchasing preforms, from size to IV value

The best way to guarantee bottle quality is to implement a strict incoming preform inspection process. This involves seven core checkpoints: preparation, visual checks, dimensional measurements, weight consistency, material property

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

A blow mold fee is a one-time engineering cost to create the unique, physical tool required to produce your custom PET bottle. This fee is separate from the per-bottle price

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

A new machine is a big investment, but it often provides far greater long-term value. It brings higher efficiency, better reliability, and prepares your business for the future. An upgrade

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

A 0.5% scrap rate isn’t a sign of success; it’s a symptom of hidden inefficiencies. Achieving a 0.1% rate is possible by focusing on details beyond visible defects, like preform

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Deciding between in-house production and outsourcing bottles is a critical strategic choice. In-house offers control and long-term cost savings once you achieve scale. Outsourcing provides a low-cost entry point but

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Yes, you can often replace only the broken parts of a blow mold. This is possible if your mold has a modular design with standardized, separable components like the base

Do You Always Need a New Preform When Changing Bottle Shape? 8 Key Factors You Might Overlook

The answer is: not always, but it depends heavily on the design changes. For minor tweaks, your current preform might work. However, significant changes in height, shape complexity, or capacity

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Your choice depends entirely on your priorities. An ad agency excels at creating a visually stunning bottle that tells a brand story, but they can miss critical production details. A

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

The design of a sports drink bottle is a critical factor in driving sales. Key elements like capacity, ergonomic grip, cap functionality, and visual appeal directly influence consumer choice, user

Troubleshooting Thin or Collapsing PET Bottle Bottoms in Blow Molding?

A collapsing bottom is often due to a combination of factors, not a single error. Key areas to check are the preform design, mold compatibility, heating profile, process parameters, and

Launching 750ml Bottled Water in Thailand? What You Must Know Before Ordering a Custom Mold?

The 750ml bottle is your answer. It perfectly meets the demand for all-day personal hydration, offering better profit margins and shelf presence. It’s the ideal size for consumers who want

Can One Blow Mold Fit Multiple Machines? The Truth About Compatibility and Modifications?

The short answer is no. A single blow mold generally cannot fit different machine models or brands without significant, and often risky, modifications. Key parameters like the clamping system, mold

PET Bottle Molds Manufacturing in China: What Do Global Buyers Need to Know?

Sourcing a PET bottle mold from a **China PET mold factory** offers significant cost benefits and high customization. The key to success is to properly vet suppliers based on their

Semi-automatic blow molding machine operation explanation: a step-by-step guide for beginners

A semi-automatic blow molding machine transforms heated PET preforms into finished bottles through a manually assisted process. The key is to perfectly heat the preform, place it in the mold,

Common Issues with Tech-Long Hot-Fill Blow Molds (and How We Solve Them)

The core issues are typically concentrated in areas like bottle bottom deformation, bottle eccentricity, poor venting, inconsistent wall thickness, and system mismatches. As your mold partner, our value lies not

Blow Mold Text and Logo Design: Depth, Placement, and Anti-Deformation Tips

Your logo and text can be perfectly clear on every bottle. The key is designing for the blow molding process itself, considering depth, placement, and how the plastic behaves. This

Is Your PET Preform Suitable for Your Bottle? Key Checks Before Customizing Blow Molds?

The key is to check if the preform’s weight, neck finish, wall thickness, and length are compatible with your bottle design. Verifying these aspects against your bottle’s final shape, volume,

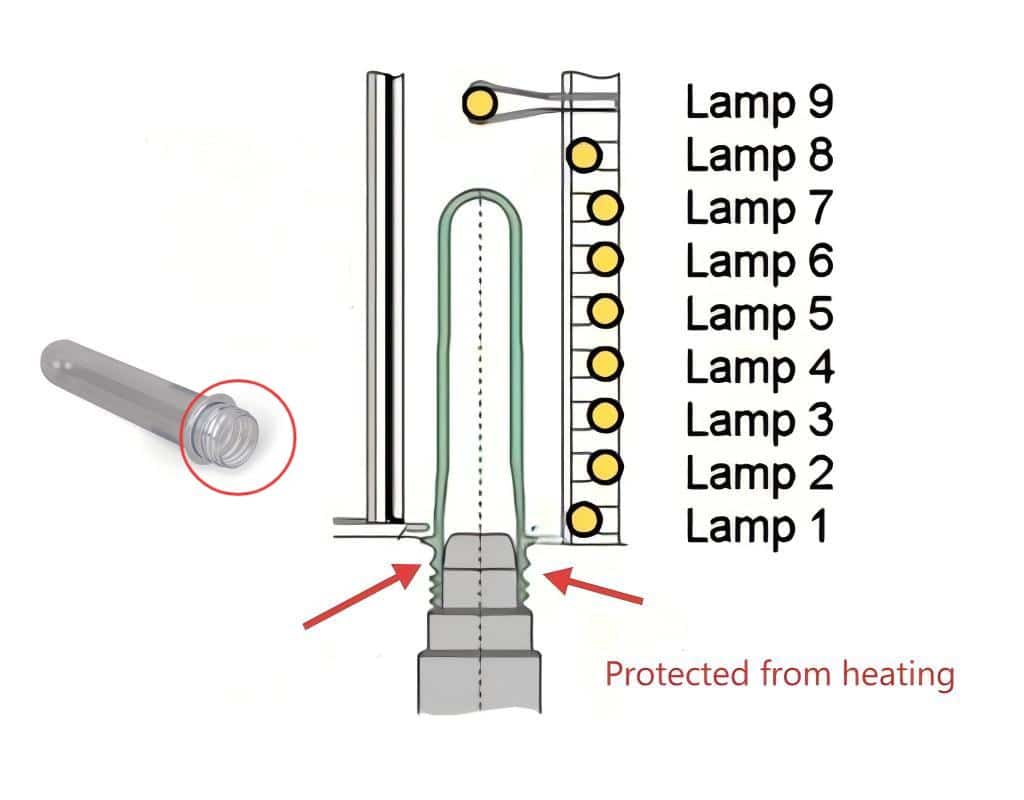

Why Should You Never Heat the Neck of a PET Preform During Blow Molding?

The preform neck must remain cool because its precise dimensions are critical for a proper seal. Heating softens the PET material, causing the neck to deform. This leads to capping

Mould vs Die: What Do They Mean in PET Blow Molding?

In PET production, a **”die”** is an injection mould that creates the bottle preform. A **”mould”** is a blow mould that inflates the preform into the final bottle shape. They

Why Is My Blow Mold Failing? Common Issues and How to Fix Them

A new blow mold fails because critical data was not confirmed before manufacturing. This often includes machine mounting specifications, bottle design details like capacity and shrinkage, or preform dimensions. Clear

Common Problems with Tall PET Bottles: Stability, Filling & Blow Molding Challenges?

A tall PET bottle’s main problems are instability, complex blow molding, and filling line difficulties. Its high center of gravity causes it to tip easily. The larger stretch ratio required

PET Blow Moulding Pros and Cons: Should You Choose It for Your Bottle Project?

PET blow moulding is a two-step manufacturing process ideal for producing lightweight, high-clarity, and strong bottles. It involves injecting molten PET into a preform shape, then reheating and inflating it

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Relax. We have the mounting dimensions for over 80% of blow molding machines globally. By matching your machine’s brand and model to our extensive database, we guarantee a perfect fit

When changing the preform diameter, which key parts of the fully automatic bottle blowing machine need to be replaced?

Successfully executing a neck size changeover is not about improvisation; it is about a rigorous, systematic process of hardware replacement and parameter recalibration, grounded in engineering principles and material science.

Can One Semi-Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

The answer is no. A single semi-automatic blow molding machine cannot efficiently produce all bottle sizes. The machine’s fixed design for stroke, heating, and clamping means using it outside its

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

The simple answer is that we provide a faster, more flexible, and cost-effective solution without sacrificing quality. Our deep understanding of Krones’ technical requirements ensures our custom molds are 100%

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

PET preform colors are not just for looks; they are crucial for function. Different colors affect heating speed, UV protection, and blow molding efficiency. The color choice depends on the

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

The key to producing perfect 600ml PET bottles on a semi-automatic machine is a precise balance of heating, stretching, and blowing. This involves setting the heating temperature between 100°C and

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

You can rapidly validate blow mold designs by using 3D printed bottle samples. This process allows you to hold a physical model of your bottle, checking its shape, size, and

How to Match PET Preform Neck Finish with the Right Cap: A Guide for Bottle Manufacturers?

A PET preform neck finish is the specific design of the bottle’s opening, defined by its diameter, thread style, and height. Matching it correctly to a cap is absolutely essential

Designing Complicated Shapes with Blow Molding: What’s Possible and What’s Not?

Struggling to know if your unique bottle design can actually be made? You have a brilliant idea for a complex bottle, but the fear that it’s technically impossible to produce

Key Spare Parts to Inspect and Replace on Ribo 6-Cavity PET Blow Molding Machines After Warranty

The best strategy is to shift from reactive repair to proactive maintenance. After the warranty, you must systematically inspect and replace key “wear and tear” components like SMC and Parker

PET Mouthwash Bottle Blow Molding Solutions: From Bottle Design to Machine Selection, What Do You Need to Know?

Choose PET for its clarity, safety, and cost-effectiveness. The right bottle design, combined with a suitable bottle blowing machine , ensures a premium look and efficient production. This guide covers

Why 15 L PET Water Bottles Are Replacing PC Gallons: Blow Molding Technology Explained

The primary reason 15L single-use PET bottles are replacing traditional PC gallons is due to significantly lower production costs, superior hygiene standards, and greater consumer convenience. This shift eliminates the

A Definitive Guide to PET Blow Molding Machine Delivery Times (Semi vs. Fully Automatic)?

The delivery time for a [PET blow molding machine](https://ibottler.com/bottle-blowing-machine/) is not a simple number; it’s a calculated range based on deep customization. Expect a 2-4 week lead time for simpler

How to Match Your PET Preform Mold with the Right Injection Molding Machine?

Choosing the right mold feels complex. A mismatch is a costly mistake that can halt your production. Let’s make sure your investment pays off by matching your equipment perfectly. To

Can You Replace Sidel Blow Molds with Third-Party Custom Molds?

you can absolutely replace Sidel blow molds with third-party custom molds. The key is ensuring the custom mold manufacturer can precisely match the technical specifications, interface dimensions, and system requirements

-8.jpg)

Why Do PET Bottles Have Curved or Petal-Shaped Bottoms Instead of Flat Bases?

The uniquely shaped bottom of a PET bottle, whether it’s a series of ‘petals’ or a simple dome, is crucial for withstanding the internal pressure from carbonated drinks. This design

Why Are PET Bottles for Juice and Sports Drinks Heavier Than Water Bottles?

The simple answer is that beverages like juice and sports drinks need stronger, thicker PET bottles. This is because they often undergo hot-filling, contain acidic or sugary liquids that create

Why Are Most PET Drink Bottles Round Instead of Square?

Most PET bottles are round because this shape offers the best structural integrity to withstand the internal pressure from carbonation and nitrogen dosing. It also ensures efficiency in high-speed manufacturing,

Why Do PET Blow Molds Need to Be Connected to a Chiller?

A chiller provides constant, low-temperature water (typically 8-12°C) to the blow bottle mold . This rapid and stable cooling is crucial for setting the bottle’s final shape, ensuring structural integrity,

Air Leakage in PET Blow Molding Machine: Causes, Detection Methods and Solutions

a hidden air leak is likely the source of your production woes. These leaks cause unstable air pressure, leading to deformed bottles, lower output, and surging energy costs as your

How to Replace Blow Molds on Semi-Automatic Blow Molding Machines

first, ensure all machine pressure is released for safety. Then, unbolt and carefully remove the old mold halves. Next, clean the platens and precisely position, align, and securely fasten the

Critical Maintenance Tips for Blow Molding Machines: 8 Issues You Shouldn’t Ignore

Ignoring routine maintenance on your bottle blowing machine leads to predictable failures that cost you dearly. Neglected stretch rods cause deformation, dirty heating zones waste energy, and clogged filters create

Designing PET Bottles for Hot-Fill Products: A Deep Dive into Structure, Materials, and Molds?

The key to successful hot-fill packaging lies in a professional and systematic design approach. You must have a bottle with specific structures like vacuum panels, select the correct heat-resistant PET

Blow Molding Machine Buyer Alert: Hidden Costs You Shouldn’t Ignore

The total cost of a blow molding machine goes far beyond the initial price tag. Hidden costs like unquoted auxiliary equipment, installation fees, mold rework, high defect rates, energy consumption,

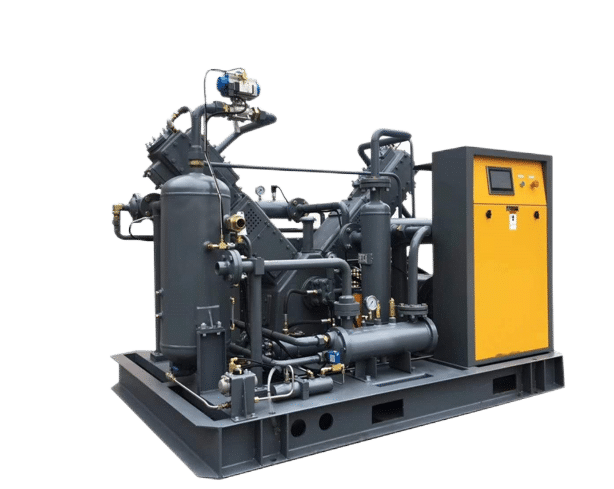

Cost-Efficient Air System: Can You Run a Whole Blow Molding Line with Just One High-Pressure Compressor?

A modern, integrated system using a single high-pressure compressor with an internal pressure regulator is a highly efficient and cost-effective solution for many PET bottle production lines, simplifying operations and

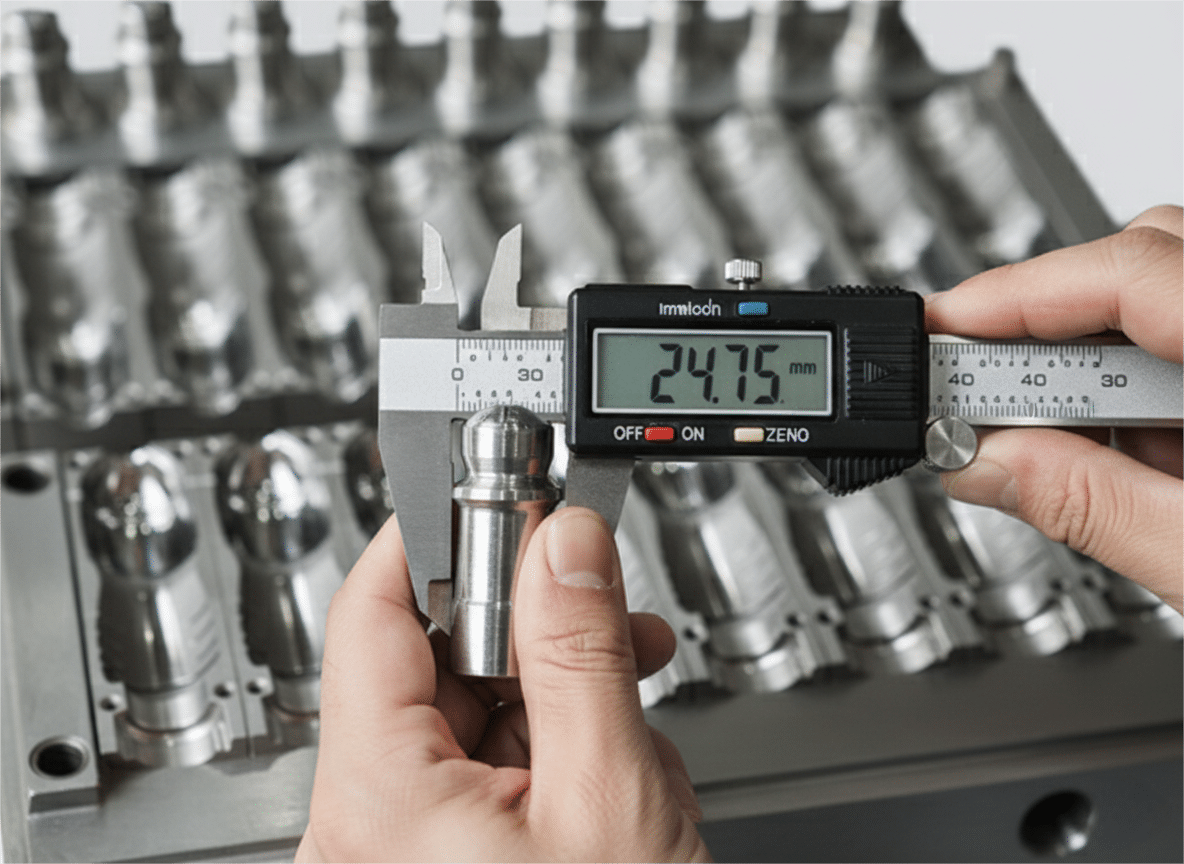

How can you be sure your blow mold’s precision is perfect before it ships?

The best way to check blow mold precision is to demand a comprehensive quality control process from your supplier. This includes CMM reports for critical dimensions, photos and videos of

Why PET Is the Preferred Material for Water Bottles over HDPE?

The clear choice for bottled water is PET (polyethylene terephthalate) due to its superior transparency, lightweight nature, and high production efficiency. Its glass-like appearance enhances brand appeal, while its suitability

How Do You Design PET Bottle Fill Lines for Accurate Net Content and Structural Integrity?

The fill line on a PET bottle indicates the target height for the liquid to reach the labeled net content. It is not the total volume of the container. Getting

Is In-House PET Wide-Mouth Jar Production Your Next Big Win?

Bringing your PET wide-mouth jar production in-house with an integrated injection and blow molding line is the definitive solution. This approach gives you complete control over the entire process, from

How Do You Adjust PET Blow Molding Machine Parameters for New Bottle Sizes?

The key is to methodically adjust heating, pre-blowing, stretching, and main blowing parameters based on the new bottle’s size, weight, and shape. Start with the heating profile, make one change

How Much Factory Space for a 2000 BPH vs12000 BPH Blow Molding Line?

A 2,000 bottles per hour (BPH) line needs approximately 400-600 square meters. In contrast, a 12,000 BPH line demands a much larger space, typically around 1,500-2,000 square meters, mainly due

How to Accurately Calculate the Investment Cost of Producing PET Bottles Based on Daily Output?

To accurately calculate the investment cost for PET bottle production, you must first determine your daily output. This key metric directly dictates whether you need a small-scale, semi-automatic solution or

Why is Custom Shampoo Bottle Production So Different From Standard Bottle Making?

The key is recognizing that shampoo bottles have unique needs. Their heavier weight, thicker walls, and often complex shapes require specialized bottle blowing machine and mold designs. Standard equipment designed

How to Prevent PET Bottle Blowing Problems Before They Happen?

The best way to prevent PET bottle blowing problems is to focus on proactive planning. This includes detailed bottle design analysis, pre-manufacturing simulations, and verifying that your blow bottle mold

How Do You Choose the Right Compressor and Support Equipment for Your Blow Molding Line?

Choosing the right support equipment means matching its specifications to your bottle blowing machine. The most important items are a correctly sized air compressor, a water chiller for mold temperature

Why Choosing a Reliable PET Bottle Mold Manufacturer Saves You Time and Money?

Choosing a reliable PET bottle mold manufacturer is the most important decision for your beverage business because it prevents catastrophic financial loss and brand damage. A top-tier partner guarantees precision,

PET Bottle Mold Design Guide: From Concept to Production?

A successful PET bottle design begins with a deep understanding of the market and the bottle’s function. This is followed by the precise definition of key parameters like the neck,

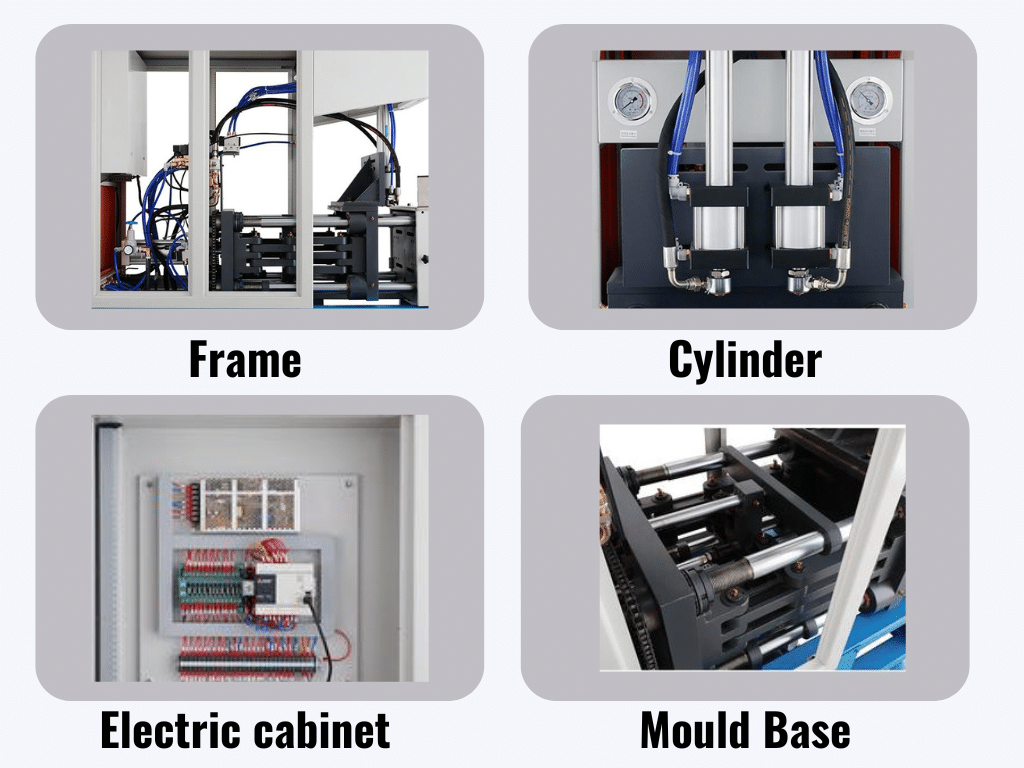

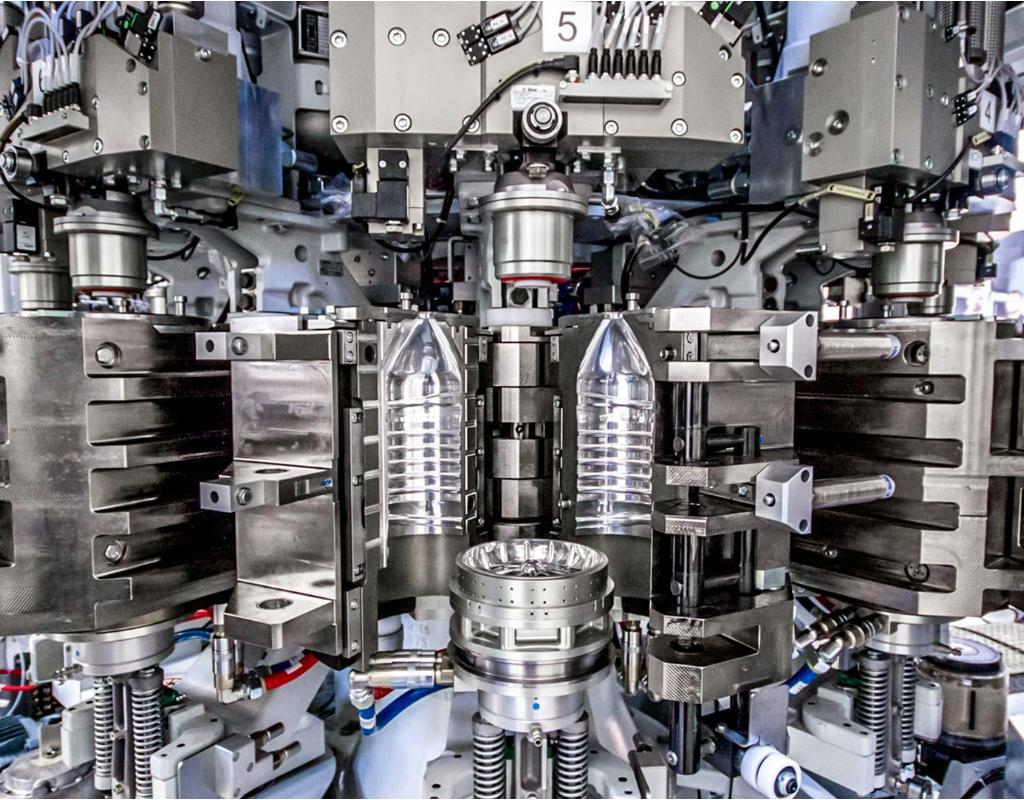

Unveiling the Core of a 6-Cavity Automatic Blow Molding Machine: What Key Structures Should You Know?

A 6-cavity automatic blow molding machine’s performance is defined by its key structures. These include the touchscreen control system (PLC), the servo-driven stretching and clamping units, the preform transmission and

Common PET Blow Molding Defects and How to Fix Them Quickly

Quickly fixing PET blow molding defects involves identifying the specific issue, like wrinkles or uneven thickness, and then systematically adjusting parameters such as heating, pre-blow pressure, or checking mold and

Blow Molding Types: How to Choose the Right Process for Your Bottles, Especially PET and PP?

Blow Molding, also known as hollow forming, is a key plastic processing manufacturing technique. Its core principle involves melting plastic raw materials (such as PET, PP, HDPE, etc.) into a

What Are Rotary Blow Moulds? What You Need to Know Before Ordering?

Rotary blow moulds are specialized moulds designed for high-speed rotary blow moulding machines. They enable continuous, rapid production of PET bottles, making them essential for large-scale operations demanding efficiency and

Which PET Blow Molding Machine is Right for Your Oil Bottle Project?

Choosing the right PET blow molding machine for oil bottles depends on your bottle sizes, production volume, automation level, and budget. This guide helps you make an informed decision for

Semi-Auto Blow Molding Machine: The Best Choice for Small PET Bottle Projects

A Semi-Auto Blow Molding Machine is often the perfect solution for small-scale PET bottle production. It offers a balance of affordability, ease of use, and flexibility, making it ideal for

How to Choose the Right Preform Neck Size for Your PET Bottle Project?

The right preform neck size ensures your PET bottles are sealed perfectly, work with your chosen caps, and are compatible with your filling equipment. Getting this detail correct is crucial

PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained?

This guide explains everything about starting PET wide-mouth jar production. You will learn about equipment, molds, processes, and costs to make an informed decision for your business.

PET Blow Mold Design: 8 Critical Details You Can’t Ignore?

Designing PET bottles seems simple on the surface, but it’s a complex process where small oversights can explode into major production headaches and escalating costs. If you want a smooth

How Much Does a PET Bottle Mold Cost in 2025? (With Price Breakdown)

A PET bottle mold’s price in 2025 varies significantly based on the machine type and materials: from around $300 per cavity for semi-automatic machines using 7075 aluminum (or ~$500/set for

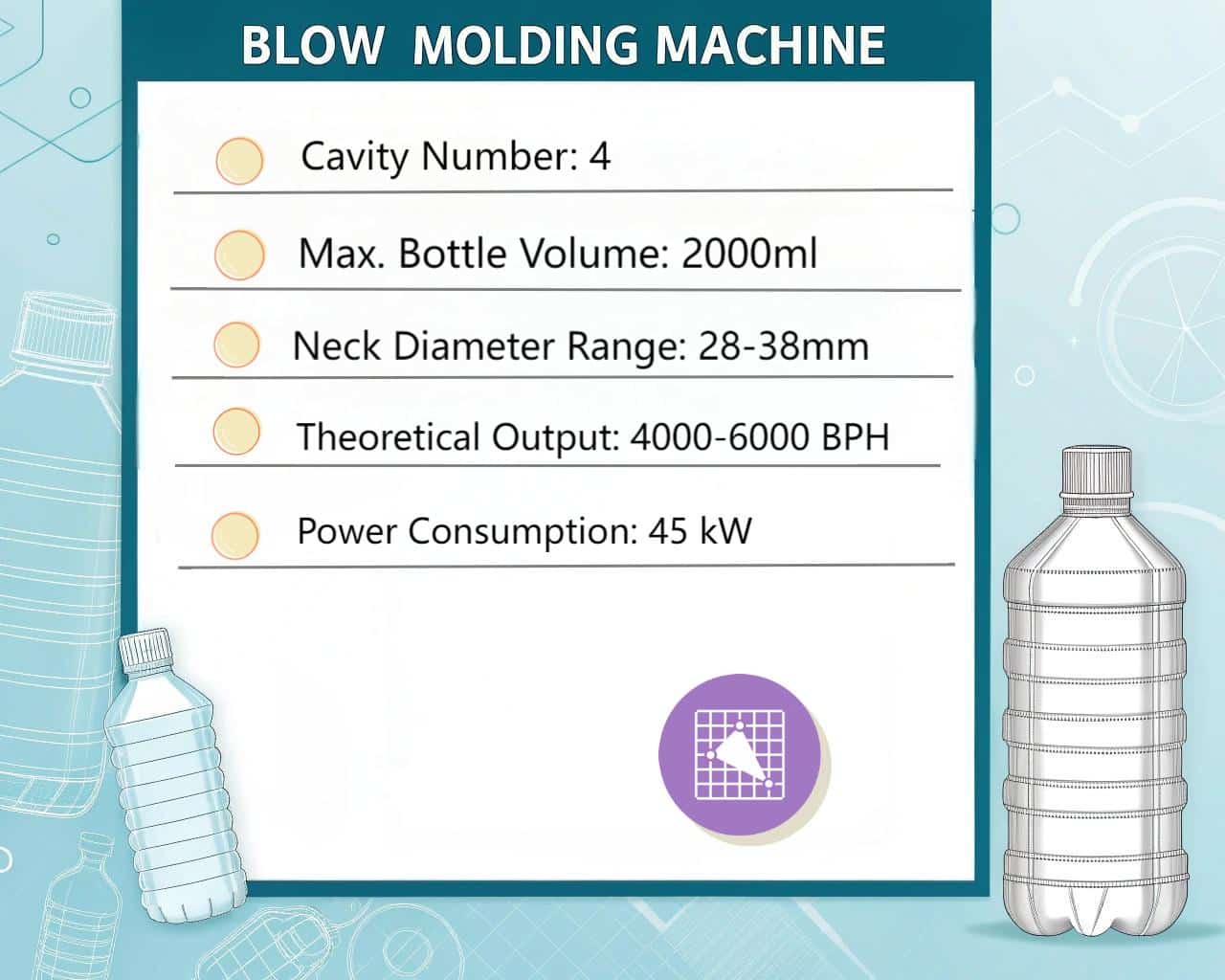

What Exactly is a 4-Cavity Blow Moulding Machine?

A 4-cavity blow moulding machine can offer a significant boost to your bottle production efficiency. The key is to deeply understand the differences between semi-automatic and fully automatic versions and

Ten Proven Ways to Reduce Cycle Time in PET Preform Injection Molding?

Are you finding PET preform production too slow? High cycle times hurt your profits. I’ll show you proven ways to increase your output. Reducing PET preform injection molding cycle time

Blowing Moulds for PET Containers: What Should Buyers Know Before Making a Purchase

The best blowing moulds for PET containers are those precisely engineered to match your specific blow moulding machine’s capabilities and are meticulously developed based on a thoroughly vetted and finalized

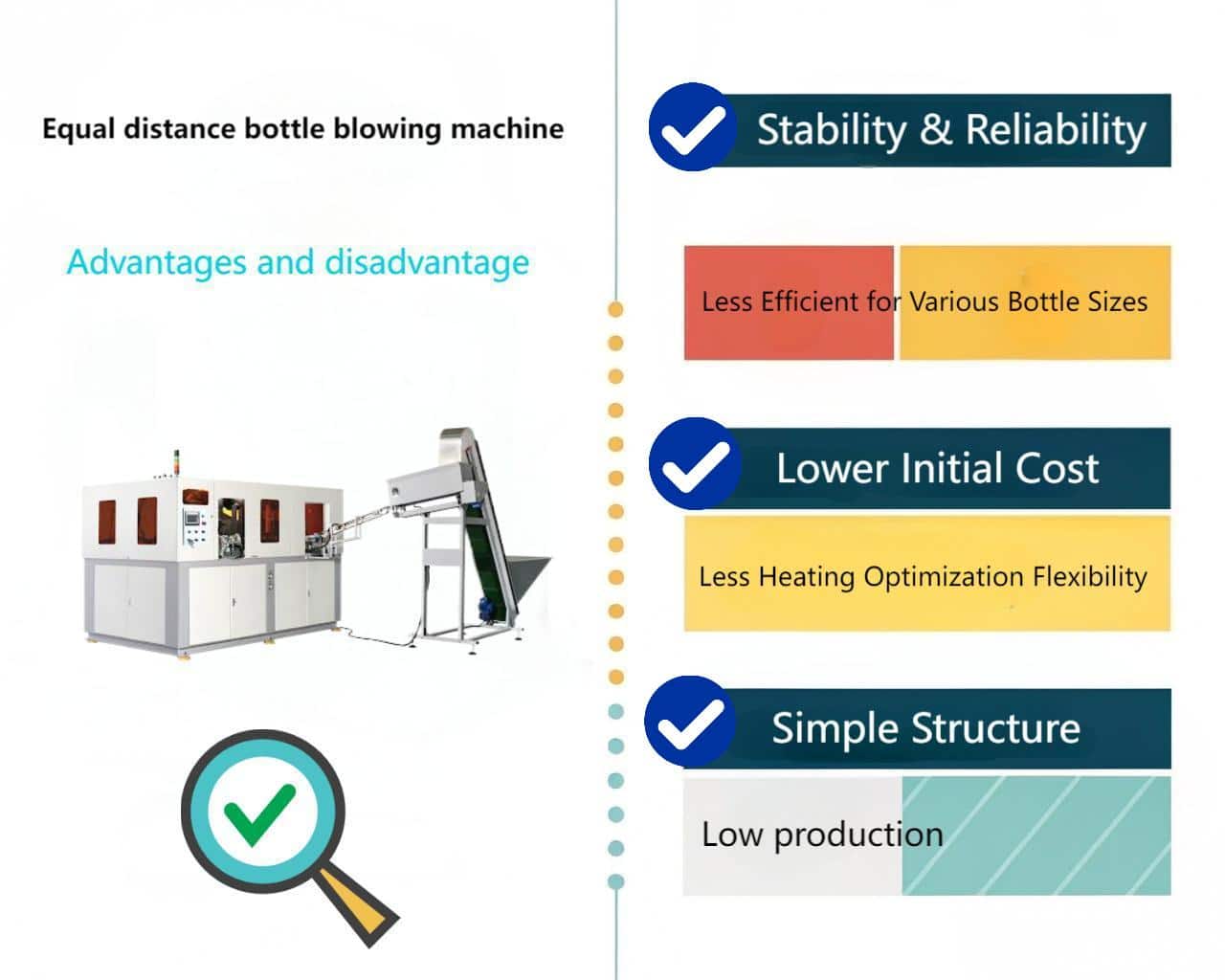

2L 4-Cavity Blow Molding Machine: Equal or Variable Distance, Which Is Better?

The best choice between equal and variable distance 2L 4-cavity blow molding machines depends on your specific needs. Variable distance often offers higher efficiency and flexibility for diverse bottle sizes,

What Are the Best PET Blow Molding Machine Solutions for Your Cosmetic Packaging Bottles?

The best PET blow molding machine solutions for cosmetic bottles offer precision, accommodate specific neck finishes, and handle materials like PET and PP effectively, ensuring high transparency and surface quality

Start Right: Choose the Blow Molding Machine Before Customizing Your PET Blow Mold

you absolutely should choose your blow molding machine *before* customizing your PET blow mold. This sequence ensures the mold is perfectly compatible with your machine’s specifications, preventing production issues and

Choosing the Right Bottle Blow Molding Machine: Save Costs & Avoid Common Pitfalls

Selecting the right bottle blow molding machine involves matching machine type to your bottle design and volume, understanding price factors, and considering auxiliary equipment. This ensures cost savings and avoids

Should You Buy Preforms or Invest in a Preform Mold?

Ultimately, the decision of whether to buy PET preforms or invest in your own [preform mold](https://ibottler.com/preform-mold/) and manufacturing capabilities is a pivotal one. It’s not merely an operational choice but

Which is better 4 cavity blow molding machine: semi or automatic?

Choosing your 4-cavity blow molder wisely by aligning its capabilities with your unique budget, labor, volume, and technical realities is paramount for sustainable and profitable business growth.

How to Fix Bottle Deformation in Blow Molding?

Bottle deformation in blow molding often stems from issues with preforms, heating, mold cooling, or blowing parameters. Identifying the specific type of deformation is the first step to finding a

How to Produce PET Wide-Mouth Jars? Machines & Process Explained

Producing PET wide-mouth jars effectively involves selecting the right blow molding machine, often a specialized automatic or semi-automatic unit. The process starts with PET preforms, which are heated, then stretched

What Should I Know Before Ordering a PET Bottle Mold?

Ordering PET bottle molds can feel overwhelming. You want the right mold, but a wrong move costs time and money. I’m here to guide you through the key things to

Efficient air compressor solutions for PET bottle blow molding

Optimizing your PET bottle blowing machine’s compressor involves matching capacity to output, selecting the right type (piston, screw, or oil-free), correctly configuring pressure systems, understanding CFM, and consistent maintenance. This

Can a blow molding machine make shampoo bottles?

blow molding machines are very commonly used to manufacture shampoo bottles, and they do an excellent job. The critical decision lies in selecting the *specific type* of blow molding process

What material makes the PET preform mould better?

Are you still struggling with inconsistent PET preform quality or moulds that wear out prematurely? The choice of mould material might be the crux of the problem. The right selection

How to find a high-quality PET bottle mold?

Finding a top-quality PET bottle mold means you’re actually looking for a skilled and trustworthy mold manufacturer. The mold’s precision, how long it lasts, and how well it works with

Is It The Same Blowing Machine That Blows PET And PP Bottles?

The answer isn’t a simple yes or no. While some blowing machines, particularly two-step systems, *can* theoretically process both PET and PP, it heavily depends on the machine’s specific type,

What is a PET blowing machine?

A PET blowing machine is specialized equipment designed to transform pre-made PET (Polyethylene Terephthalate) preforms into finished, hollow bottles. The machine operates on a two-step process that involves precisely heating

What exactly is a PET preform mould?

A PET preform mold is a specialized multi-cavity injection mold. It produces PET (Polyethylene Terephthalate) preforms, which are then blown into bottles. High-quality molds ensure precision, efficiency, and durable final

What are the Most Common Problems When Blow Molding PET Bottles?

Common defects in PET bottles include whitish bottoms, uneven wall thickness, surface haze, and incorrect neck finishes. These issues usually stem from problems with the PET preform quality, blow molding

What Are the Key Factors to Consider When Designing a Preform Mold?

Key preform mold design factors include: 1. **Quality (concentricity, gate design). 2. Efficiency (cooling, hot runner). 3. Longevity (S136 steel). 4. Maintenance. These factors directly control your final cost per

How can we find a reliable mold maker in China?

To find a reliable Chinese mold maker, you absolutely need to verify they are a real factory with a proven history. Ensure you can contact the owner for accountability, consider